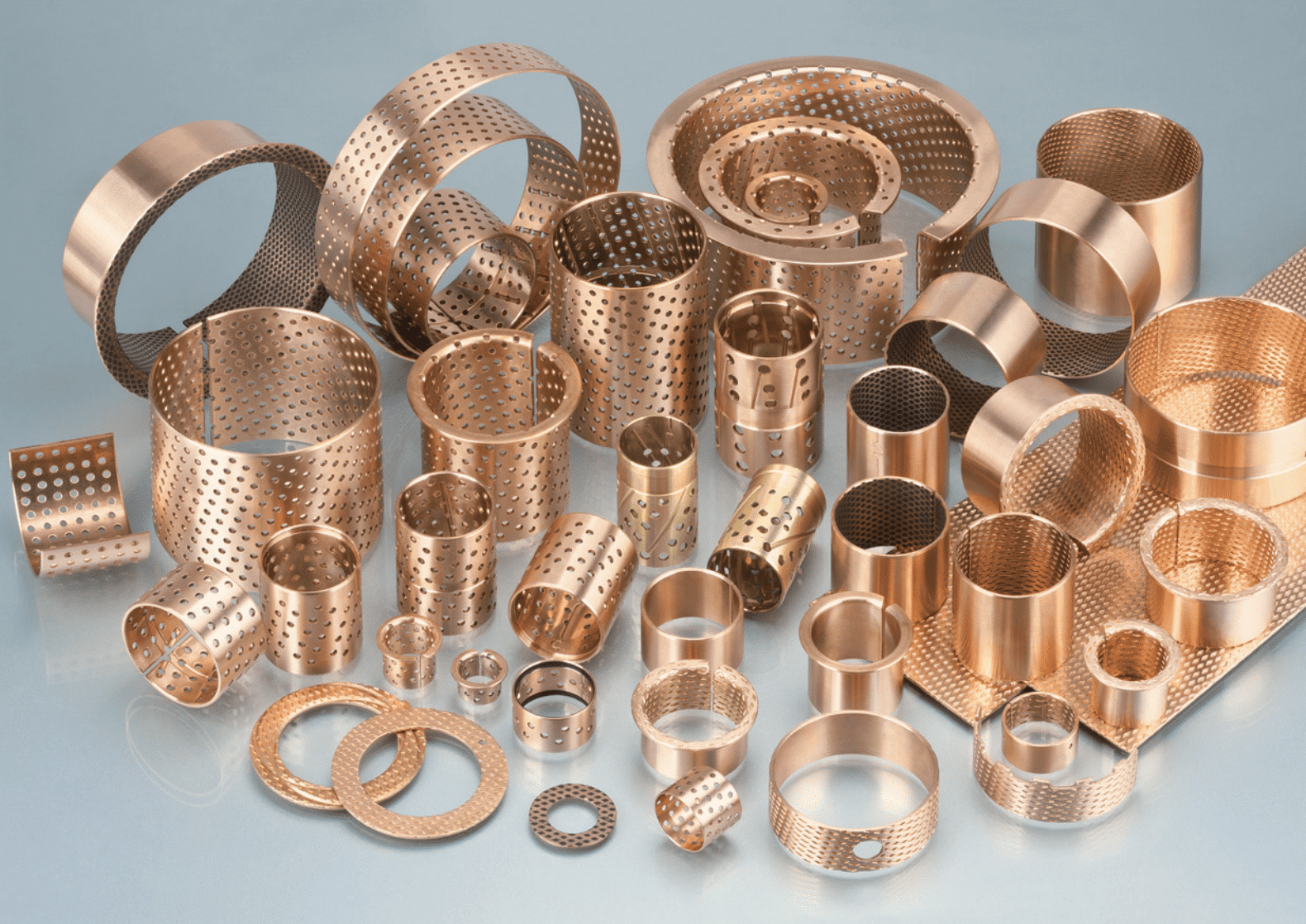

Bronze Bushes

Bronze Bushes

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Bronze Bushes

Bronze bushes are self-lubricating, which means you never need grease. Perforated wrapped bronze bushes, also known as perforated collar bushes, are bearings made from a durable and wear-resistant bronze alloy, typically CuSn8P (Phosphor Bronze). These bushes feature small holes or perforations filled with lubricant to reduce friction and wear during operation. The phosphorus in the bronze alloy enhances wear resistance and stiffness, making it suitable for demanding applications like construction, mining, agriculture, and automotive industries

Product list

090 bronze bushing

090 flange bronze bearings

FB-092 Bronze Bushes, Bronze Rolled Bushing, Bronze Rolled Bushing

Perforated wrapped bronze bushes are widely used in industrial applications due to their high load capacity, self-lubrication properties, low friction characteristics, and corrosion resistance. They are ideal for applications requiring long bearing life without continuous maintenance and are commonly found in various industries such as construction, mining, agriculture, and automotive sectors.

Wrapped bronze bushes are constructed by sintering bronze material with fine pores filled with oil or grease under vacuum or pressure. They are then wrapped with a layer of PTFE for self-lubrication and wear resistance. These bushes operate on the principles of hydrodynamic lubrication, offering corrosion resistance, cost-effectiveness, and high load capacity. They find applications in shock absorbers, electric motors, industrial machinery, pumps, compressors, and gearboxes. These bushes are designed to reduce installation space, protect against contamination, and extend service life after greasing. They are suitable for various applications such as hoisting machines, construction equipment, automobiles, tractors, trucks, machine tools, and mineral engines. Wrapped bronze bushes are cost-effective compared to other bearing types and offer advantages like self-lubrication, low friction, high wear resistance, and corrosion protection

Specific types of bronze bushings, namely BRO-MET, FB090, BRM10, and WB800. These are specialized bushings often used in various machinery due to their durability and superior wear resistance.

Bronze bushings are made from bronze and feature built-in lubricant reservoirs. This design significantly reduces the likelihood of the component being deprived of lubrication and becoming defective. Such a configuration ensures a long service life for the bushing and thus helps protect friction mechanisms of the equipment from overheating and failure. Bronze bushings are resistant to aggressive environments. They are suitable for use in machinery and industrial equipment and are characterized by low operational noise.

The inner diameter of the bushings available in the “PromBering” catalogue ranges from 10 mm, with the outer diameter starting from 12 mm. They come in a cylindrical design. The production uses a bronze alloy that meets international standards DIN 17662.

In summary, bronze bushings are renowned for their durability, ability to work in harsh environments, and their capacity to maintain lubrication, which reduces maintenance and extends the lifespan of the equipment in which they are used.

Bronze bushings, in general, are preferred in industrial applications because of their excellent load-bearing capabilities and resistance to wear and tear. They’re especially useful in high-load, high-temperature situations where other materials might fail or degrade more rapidly.

- Bronze: This is a range of self-lubricating, sintered bronze bushings. The bronze base offers excellent load-bearing capacity, and the bushings have a porous structure that can be impregnated with oil or another lubricant to reduce friction.

- FB090: Also known as wrapped bronze bushings, these are made from bronze strips with oil-filled holes or pockets. The oil provides self-lubrication, reducing friction and wear. They are widely used in construction machinery, agricultural machinery, and other high-load applications.

- BRM10: These bushings are made of high-strength brass with embedded solid lubricants, typically graphite. They are designed for high-load, slow-moving applications, and the solid lubricant allows them to operate without additional lubrication.

- WB800: These are self-lubricating bushings made from bronze with an embedded solid lubricant. They’re well suited to situations involving heavy loads and low speeds and perform well in environments where traditional lubrication is difficult or impossible.

In summary, these bushings provide a reliable and maintenance-free solution for a variety of demanding applications. Their self-lubricating features reduce maintenance requirements, extend equipment lifespan, and help improve the overall efficiency of the machinery in which they are installed.

The range and variety of our Bronze Rolled Bushing are not afraid of the competitors: we offer itself as a unique interlocutor for its customers, with a complete range of products ready in stock that can satisfy any request and design need.

Sliding bushings

Sliding bushings (bimetal sliding bearings), or dry sliding bushings, are sleeves or inserts designed to be installed between the housing socket and the shaft. Their main function is to separate rotating parts of a moving structure to prevent them from coming into contact with each other. Such products are made from anti-friction materials with a low friction coefficient. By type, dry sliding bushings are classified as radial sliding bearings. They are capable of withstanding medium radial loads. The advantages of using such bushings include:

- Maximum reduction of resistance in moving parts of the structure.

- Significant reduction in heating and premature failure of friction mechanisms.

Sliding bushings are often used in the assembly of rotating and pivot points of industrial machinery and production equipment.

The online store “PromBering” offers you to buy bushings wholesale or retail. Here, you will find Bronze (steel/PTFE) products of various sizes. They are cylindrical in shape, and there are also models in the form of a cylinder with a flange. Maintenance-free products (with the ability to function without lubrication) are easy to install and maintain.

Sliding bushings are ideal for applications requiring minimal friction and maintenance. They are versatile, and durable, and offer a variety of benefits that can significantly enhance the operational efficiency and lifespan of industrial machinery and production equipment.

(bronze with through-holes) For very dirty environments and an extra of lubrication.

It can also substitute for a copper liner that sharply reduces the cost. It is applicable to the situation of medium load and low velocity. For instance, conveyors, lifts, winding engines, smoothing machines, and so on.

It may supply the products: straight bush, flange bush, plate, shaft tile, slide, and steel liner combination.

various types of wrapped bronze bearings, such as FB090, FB092, and WB800. These are specific types of bronze bushings designed for various industrial applications.

- FB090 Wrapped Bronze Bearing: These bearings are made from bronze strips with built-in oil-filled pockets. The oil-filled pockets provide self-lubrication, which reduces friction and increases the lifespan of the bearing. They are suitable for a variety of applications, including in construction machinery and agricultural equipment, where they must withstand high loads.

- FB092 Wrapped Bronze Bearings: Similar to the FB090, the FB092 also has built-in lubrication pockets. However, the design or the placement of these pockets can differ depending on the specific requirements of the application.

- WB800 Slide Bearing: This type of bearing is made from bronze and contains a solid lubricant. They are designed for applications where heavy loads and low speeds are involved. They perform well in environments where traditional lubrication is difficult or impossible.

- WF-WB800 Wrapped Flange Bushing: These bearings come with a flange and are made for more specific applications where the flange can provide additional support or serve as a stop. The WF-WB800 also has the same solid lubricant feature as the WB800, allowing for reliable operation even under heavy loads or in challenging environments.

- WB800-Washers or Blanks: These are additional components that can be used with the WB800 bearing. They may serve various purposes depending on the specific design of the machinery or equipment.

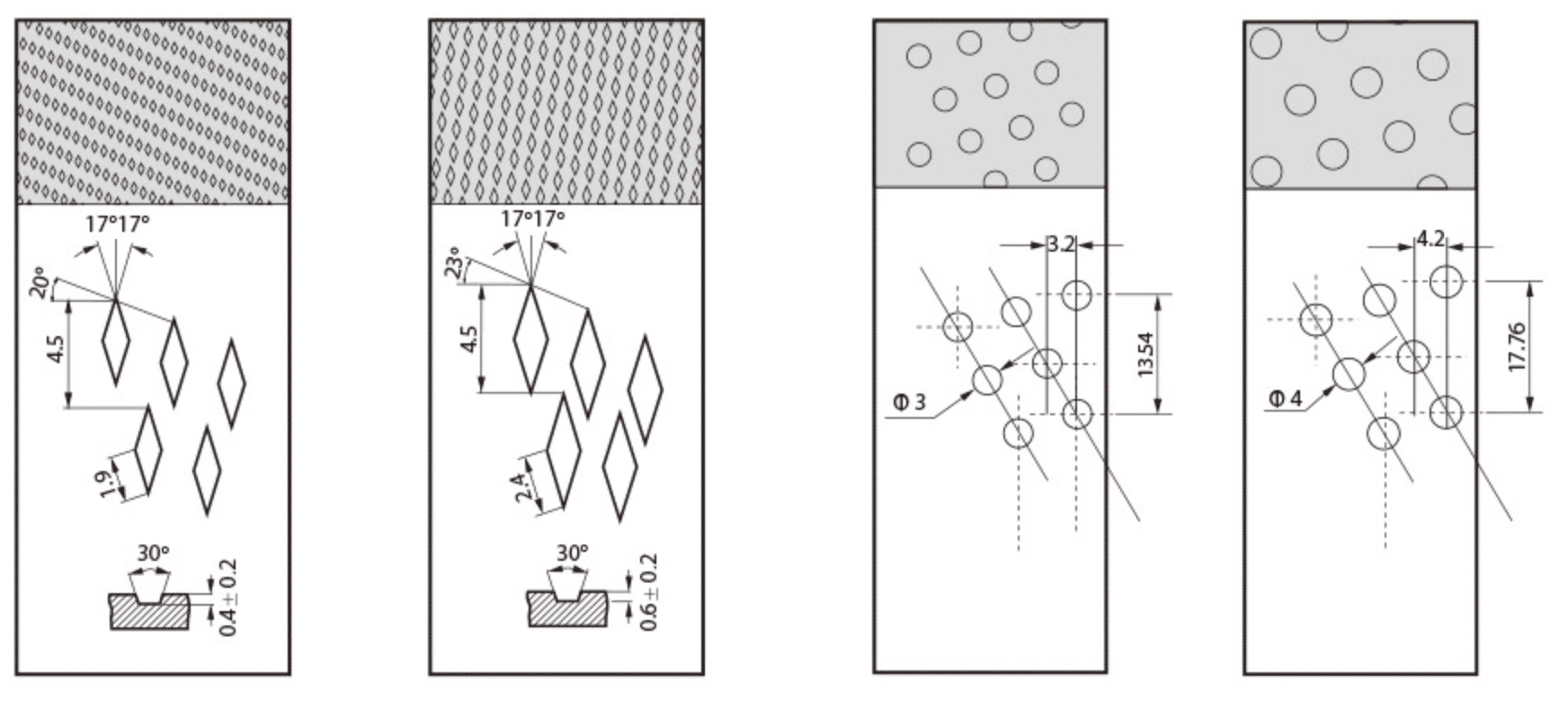

- Wrapped bushes with grease pockets, FLANGE SLIDE BUSHING PTFE (FB090) circular pockets or diamond groove: These are bushings with specially designed pockets for holding grease or other lubricants. The shape and arrangement of the pockets can be circular or in a diamond pattern, depending on the application’s needs.

These wrapped bronze bearings are all designed to provide superior performance in high-load applications and challenging environments. They offer the advantage of self-lubrication, reducing the need for maintenance and increasing the lifespan of the machinery or equipment.

Wrapped Bronze Bushing Size Chart d×D×L

| Designation | d×D×L | Designation | d×D×L |

| FB090/FB092 1010 | 10×12×10 | FB090/FB0922515 | 25×28×15 |

| FB090/FB092 1015 | 10×12×15 | FB090/FB0922520 | 25×28×20 |

| FB090/FB0922525 | 25×28×25 | ||

| FB090/FB0921210 | 12×14×10 | FB090/FB092 2530 | 25×28×30 |

| FB090/FB0921215 | 12×14×15 | ||

| FB090/FB092 1220 | 12×14×20 | FB090/FB0922815 | 28×32×15 |

| FB090/FB0922820 | 28×32×20 | ||

| FB090/FB0921410 | 14×16×10 | FB090/FB0922825 | 28×32×25 |

| FB090/FB0921415 | 14×16×15 | FB090/FB0922830 | 28×32×30 |

| FB090/FB0921420 | 14×16×20 | ||

| FB090/FB092 1425 | 14×16×25 | FB090/FB0923015 | 30×34×15 |

| FB090/FB0923020 | 30×34×20 | ||

| FB090/FB0921510 | 15×17×10 | FB090/FB0923025 | 30×34×25 |

| FB090/FB0921515 | 15×17×15 | FB090/FB0923030 | 30×34×30 |

| FB090/FB0921520 | 15×17×20 | FB090/FB0923040 | 30×34×40 |

| FB090/FB0921525 | 15×17×25 | ||

| FB090/FB0923215 | 32×36×15 | ||

| FB090/FB0921610 | 16×18×10 | FB090/FB0923220 | 32×36×20 |

| FB090/FB0921615 | 16×18×15 | FB090/FB0923225 | 32×36×25 |

| FB090/FB0921620 | 16×18×20 | FB090/FB0923230 | 32×36×30 |

| FB090/FB092 1625 | 16×18×25 | FB090/FB0923240 | 32×36×40 |

| FB090/FB092 1810 | 18×20×10 | FB090/FB0923515 | 35×39×15 |

| FB090/FB092 1815 | 18×20×15 | FB090/FB0923520 | 35×39×20 |

| FB090/FB0921820 | 18×20×20 | FB090/FB0923525 | 35×39×25 |

| FB090/FB092 1825 | 18×20×25 | FB090/FB0923530 | 35×39×30 |

| FB090/FB0923540 | 35×39×40 | ||

| FB090/FB0922010 | 20×23×10 | FB090/FB0923550 | 35×39×50 |

| FB090/FB0922015 | 20×23×15 | ||

| FB090/FB0922020 | 20×23×20 | FB090/FB0924020 | 40×4×20 |

| FB090/FB0922025 | 20×23×25 | FB090/FB0924025 | 40×4×25 |

| FB090/FB0922030 | 20×23×30 | FB090/FB0924030 | 40×44×30 |

| FB090/FB0924040 | 40×44×40 | ||

| FB090/FB0922215 | 2×25×15 | FB090/FB0924050 | 40×44×50 |

| FB090/FB0922220 | 2×25×20 | FB090/FB092 4060 | 40×44×60 |

| FB090/FB0922225 | 22×25X25 | ||

| FB090/FB0922230 | 22×25×30 | ||

| FB090/FB0922240 | 22×25×40 | ||

| FB090/FB0922430 | 24×27×30 |

| Designation | d×D×L | Designation | d×D×L |

| FB090/FB0924520 | 45×50×20 | FB090/FB092 12060FB090/FB092 120100 | 120×125×100 |

| FB090/FB0924525 | 45×50×25 | ||

| FB090/FB0924530 | 45×50×30 | ||

| FB090/FB0924540 | 45×50×40 | FB090/FB092 12560 | 125×130×60 |

| FB090/FB0924550 | 45×50×50 | FB090/FB092 125100 | 125×130×100 |

| FB090/FB092 4560 | 45×50×60 | ||

| FB090/FB09213060 | 130×135×60 | ||

| FB090/FB092 5025 | 50×55×25 | FB090/FB092 130100 | 130×135×100 |

| FB090/FB0925030 | 50×55×30 | ||

| FB090/FB0925040 | 50×55×40 | FB090/FB092 13560 | 135×140×60 |

| FB090/FB0925050 | 50×55×50 | FB090/FB02135100 | 135×140×100 |

| FB090/FB092 5060 | 50×55×60 | ||

| FB090/FB092 14060 | 140×145×60 | ||

| FB090/FB092 5520 | 55×60×20 | FB090/FB092 140100 | 140×145×100 |

| FB090/FB0925525 | 55×60X25 | ||

| FB090/FB0925530 | 55×60×30 | FB090/FB092 14560 | 145×150×60 |

| FB090/FB0925540 | 55×60×40 | FB090/FB092 145100 | 145×150×100 |

| FB090/FB0925550 | 55×60×50 | ||

| FB090/FB092 5560 | 55×60×60 | FB090/FB09215060 | 150×155×60 |

| FB090/FB092 150100 | 150×155×100 | ||

| FB090/FB092 6025 | 60×65×25 | ||

| FB090/FB0926030 | 60×65×30 | FB090/FB092 15560 | 155×160×60 |

| FB090/FB092 6035 | 60×65×35 | FB090/FB092 155100 | 155×160×100 |

| FB090/FB0926040 | 60×65×40 | ||

| FB090/FB092 6050 | 60×65×50 | FB090/FB092 16060 | 160×165×60 |

| FB090/FB0926060 | 60×65×60 | FB090/FB092 160100 | 160×165×100 |

| FB090/FB092 6080 | 60×65×80 | ||

| FB090/FB092 16560 | 165×170×60 | ||

| FB090/FB092 6530 | 65×70×30 | FB090/FB092 165100 | 165×170×100 |

| FB090/FB0926540 | 65×70×40 | ||

| FB090/FB0926550 | 65×70×50 | FB090/FB092 17060 | 170×175×60 |

| FB090/FB092 6560 | 65×70×60 | FB090/FB092170100 | 170×175×100 |

| FB090/FB092 6580 | 65×70×80 | ||

| FB090/FB092 17560 | 175×180×60 | ||

| FB090/FB092 7040 | 70×75×40 | FB090/FB092 175100 | 175×180×100 |

| FB090/FB0927050 | 70×75×50 | ||

| FB090/FB0927060 | 70×75×60 | FB090/FB09218060 | 180×185×60 |

| FB090/FB0927070 | 70×75×70 | B090/FB092 180100 | 180×185×100 |

| FB090/FB0927080 | 70×75×80 | ||

| FB090/FB092 7090 | 70×75×90 | FB090/FB092 18560 | 185×190×60 |

| FB090/FB092 185100 | 185×190×100 | ||

| FB090/FB092 7530 | 75×80×30 | ||

| FB090/FB0927540 | 75×80×40 | FB090/FB092 19060 | 190×195×60 |

| FB090/FB0927560 | 75×80×60 | FB090/FB092 190100 | 190×195×100 |

| FB090/FB0927580 | 75×80×80 | ||

| FB090/FB092 19560 | 195×200×60 | ||

| FB090/FB092 8030 | 80×85×30 | FB090/FB092 195100 | 195×200×100 |

| FB090/FB0928040 | 80×85×40 | ||

| FB090/FB092 8060 | 80×85×60 | FB090/FB092 20060 | 200×205×60 |

| FB090/FB0928080 | 80×85×80 | B090/FB092 200100 | 200×205×100 |

| FB090/FB0928530 | 85×90×30 | FB090/FB09221560 | 215×220×60 |

| FB090/FB0928540 | 85×90×40 | FB090/FB092215100 | 215×220×100 |

| FB090/FB0928560 | 85×90×60 | ||

| FB090/FB0928580 | 85×90×80 | FB090/FB09222560 | 225×230×60 |

| FB090/FB092225100 | 225×230×100 | ||

| FB090/FB092 9040 | 90×95×40 | ||

| FB090/FB092 9060 | 90×95×60 | FB090/FB09223560 | 235×240×60 |

| FB090/FB092 9080 | 90×95×80 | FB090/FB092235100 | 235×240×100 |

| FB090/FB092 9090 | 90×95×90 | ||

| FB090/FB09224560 | 245×250×60 | ||

| FB090/FB092 10050 | 100×105×50 | FB090/FB092245100 | 245×250×100 |

| FB090/FB09210060 | 100×105×60 | ||

| FB090/FB092 10095 | 100×105×95 | FB090/FB09227560 | 275×280×60 |

| FB090/FB092275100 | 275×280×100 | ||

| FB090/FB09210560 | 105×110×60 | ||

| FB090/FB092105100 | 105×110×100 | FB090/FB09228560 | 285×290×60 |

| FB090/FB092285100 | 285×290×100 | ||

| FB090/FB09211060 | 110×115×60 | ||

| FB090/FB092110100 | 110×115×100 | FB090/FB09230060 | 300×305×60 |

| FB090/FB092300100 | 300×305×100 | ||

| FB090/FB09211560 | 115×120×60 | ||

| FB090/FB092115100 | 115×120×100 |

BRONZE BUSHING APPLICATIONS

090 and 092 bronze bushes can be used in different applications, for example:

* lifting equipment and platform lifts;

* machine tools;

* automobiles;

* tractors;

* trucks;

* etc.

Chemical Composition

| Part No | Material | Cu | Sn | P | Pb | Zn |

| BRONZE BUSHING-090 | CuSn8 | 91.3% | 8.5% | 0.2% | / | / |

| BRONZE BUSHING-092 | CuSn8 | 91.3% | 8.5% | 0.2% | / | / |

Material Characteristics

| Max. Load Capacity P | ||

| Static Load | N/mm2 | 120 |

| Dynamic Load | N/mm2 | 40 |

| Max. Speed V | ||

| HSB-090 | m/s | 2.0 |

| E92 | m/s | >2.5 |

| Max. PV Value | N/mm2·m/s | 2.8 |

| Tensile Strength | N/mm2·m/s | 450 |

| Yield Point | N/mm2·m/s | 250 |

| Hardness | HB | 90-120 |

| Elongation | 40% | |

| Coefficient of Friction | μ | 0.08~0.25 |

| Operation Temperature Range | ℃ | -100~200 |

| Thermal Conductivity | W/(m · k) | 60 |

| Coefficient of Thermal HSB-2pansion | k-1 | 15×10-6 |

Download complete catalog

Oil Indentations/Holes

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.