Brass Wear Strips

Brass Wear Strips

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Brass Wear Strips

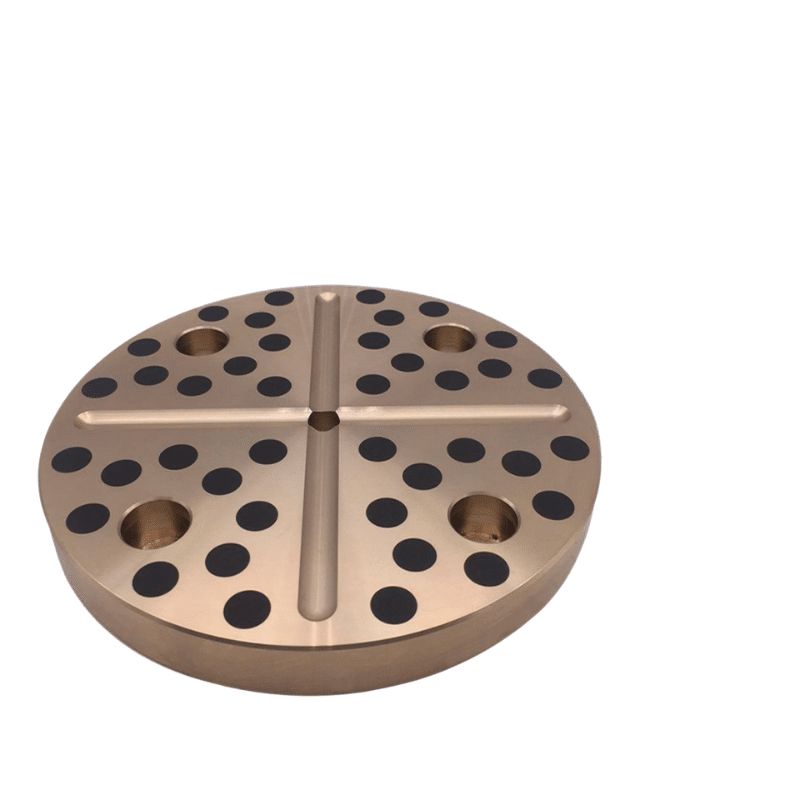

Bronzelube in the field of high-precision standard Bronze Wear Strips parts. Self-lubricating Bronze Plates flat guiding stock, with screw holes, Aluminum Bronze Wear Strips and Gibs, crafted from ASTM-C95400 continuous cast aluminum bronze, are embedded with self-lubricating graphite plugs for enhanced performance.

Navigating the World of Bronze Wear Strips: Enhancing Precision in Metal Stamping Dies, Molds, and Machines, Bronze Precision Wear Plates

Standard Components, Placas de Bronce Autolubricadas,Oilless Wear Plate

Slide Components. Outline of Oilless Wear Plate. Wear Plate -Thickness 10mm- Bronze Type, Wear Plate

Flanged Bronze Plate – Metric. Materials: C954 Aluminum Bronze w/graphite, Wear strips

Shop Oil-Free Slide Plates and Press Die Components needs. We offer free CAD download, short lead times, competitive pricing, …

We offer wear strips in metric and imperial sizing, including NAAMS sizes. Made of aluminum bronze and can be ordered with or without self-lubricating graphite, the reliable global partner for making molds, and dies.

“Aluminum Bronze Bushings Meximold: We produce a wide array of durable bronze bushings for the mold industry. This includes both metric and inch sizes, solid bronze bushings, and bushings embedded with graphite.

We provide an extensive selection of enhancements for our hassle-free flat guiding stocks, available both with and without screw holes. Introducing our Bronze Flat Guiding Stock, now infused with a solid lubricant – a self-lubricating flat guiding stock that also comes equipped with screw holes for added convenience.

Our selection encompasses a broad range of upgrades for our low-maintenance, flat guiding stocks, which are offered in versions that either include or exclude screw holes. Featuring our premium Bronze Flat Guiding Stock, uniquely designed with an integrated solid lubricant. This self-lubricating flat guiding stock is also thoughtfully designed to incorporate screw holes, ensuring greater versatility and ease of use.

As a supplier of Brass Wear Strips, our company specializes in manufacturing robust bronze bushings tailored for the molding industry. We utilize aluminum bronze, recognized as one of the best bearing materials for wear plates due to its high load capacity and exceptional durability against wear and tear.

Our Brass Wear Strips bushings are available in two varieties: plain aluminum bronze and aluminum bronze with integrated graphite plugs. These graphite plugs serve as a solid lubricant, offering several benefits over traditional liquid lubricants like grease or oil. Notably, they are permanent, eliminating the need for regular lubrication.

Graphite is especially advantageous in environments where cleanliness is paramount. Being solid, it eliminates the risk of drips or spills. Additionally, Brass Wear Strips highlight the effectiveness of graphite in extremely dirty environments. The absence of liquid lubricants, which can attract grit and contaminants, significantly extends the service life of components responsible for guiding and controlling motion.

Our expertise extends to understanding the fundamental operations, including the interaction between air and plastic, to produce high-quality brass wear strips parts.

Brass Strip – Bronze Wear Plate, Huge Selection & Great Prices

We Offer an Extensive Selection Of Everything Else stores at bronzelube.com Order Today! Read Customer Reviews & Find Best Sellers. Fast Free Delivery.

In the intricate field of metalworking and machinery, wear strips play an indispensable role. These components, integral to the functionality of metal stamping dies, molds, and specialized machines, are pivotal in ensuring precision and longevity. This article delves into the diverse types of wear strips, including Bronze Wear Strips with Holes and Graphite, Metric Wear Strips, and Custom Wear Strips, highlighting their functions, materials, and the convenience of accessing product information through a comprehensive description sheet.

Understanding Bronze Wear Strips and Their Functions

Wear Strips

The Role of Bronze Wear Strips and Bronze Wear Plate

Wear strips serve as linear bearings, crucial in guiding and controlling the movement within metal stamping dies, molds, and special machines. They are designed to withstand high friction and stress, ensuring smooth operation and extending the life of the equipment by reducing wear.

Oilless Wear Plate Material and Design Varieties

Bronze Wear Strips, often embedded with holes and graphite, are popular for their durability and self-lubricating properties. The incorporation of graphite provides continuous lubrication, reducing friction and wear even under high loads and slow speeds. Similarly, Metric Wear Strips are typically crafted from solid aluminum bronze, prized for its strength and resistance to corrosion.

Delving into Metric Wear Strips

Metric Wear Strips are specifically designed to meet global metric standards, ensuring compatibility with a wide range of international machinery and equipment. The use of aluminum bronze in these strips provides a robust and reliable solution for linear motion in mechanical setups.

Accessing Information with Ease: Product Description Sheets

For those seeking detailed information about wear strips, product description sheets offer a treasure trove of data. These sheets layout essential details, including sizes, materials, and specifications of various wear strips. This information is invaluable for selecting the right component for specific industrial needs.

Custom Bronze Wear Strips: Tailored Solutions

Understanding that one size does not fit all, the industry offers custom wear strips. These are tailored to meet unique specifications and requirements of different machines and applications. Customization allows for greater flexibility and precision, ensuring that the wear strips perfectly align with the specific needs of a machine or mold.

The Significance of Wear Strips in Various Industries

Wear strips are vital across various sectors, including automotive, aerospace, and manufacturing. In metal stamping dies, they ensure the accurate and smooth operation of the stamping process. In molds, they play a critical role in maintaining the integrity of the mold design. Specialized machinery also relies on wear strips for precise movement and longevity.

Custom Bronze Wear Strips and Bronze Wear Plate

Wear strips, be it Bronze Wear Strips with Holes and Graphite, Metric Wear Strips, or Custom Wear Strips, are fundamental components in the world of metalworking and machinery. Their primary function as linear bearings significantly enhances the precision and durability of metal stamping dies, molds, and specialized machines. The availability of detailed product description sheets and the option for customization further add to their versatility and applicability in various industrial settings. As technology advances, the role of wear strips in maintaining the efficiency and longevity of machinery continues to be of paramount importance.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.