Bimetal Bush

Bimetal Bush

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Bimetal Bush

Structure Characteristics and Applications Bimetal Bushing

Bimetal-bearing bushes satisfy the various types of applications and lubrication conditions in which the bushes may be used. A bimetal bush is a type of bushing that is composed of two different metals bonded together. These bushings are designed to provide specific properties and advantages for various applications.

Bimetal Bush, China Bimetal Bearing – High-Quality Price Ratio

Bimetallic composite rolling bearings, Providing you the best range of bi- metal bushes and graphite filled bronze bushes with effective & timely delivery.

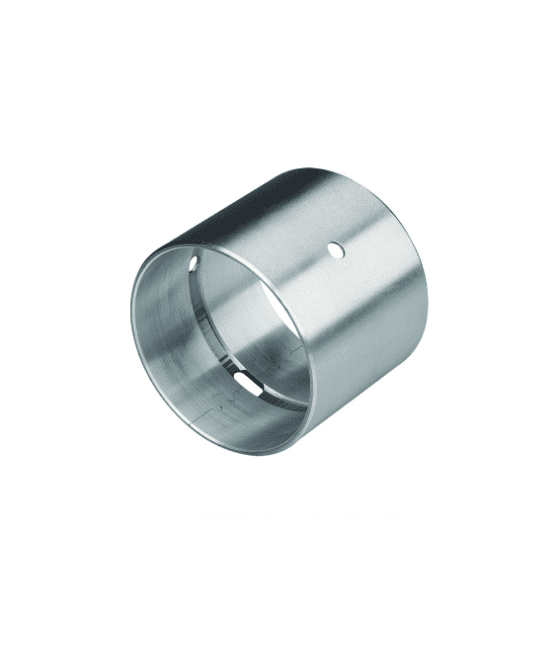

Durable bimetallic bushings, also known as bimetal bushes, consist of two metal strips, each made from distinct materials. The first strip is typically composed of steel, while the second strip is typically an alloy containing copper. When combined with the steel strip, the copper alloy serves as an inner layer. Additionally, some sizes come equipped with an external relubrication hole.

ADVANTAGES These bimetal bushes boast a unique design that grants them excellent wear resistance, particularly when operating at medium speeds with moderate loads or at low speeds with heavy loads.

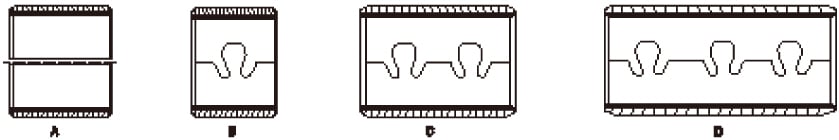

SPECIAL TECHNICAL FEATURES The internal surface of Bimetal bush can feature various types of channels, catering to diverse applications and lubrication requirements in which these bushings might be utilized.

Bimetal bush and bearings are specialized components integral to a wide range of industrial and mechanical applications. They are meticulously engineered to establish a low-friction interface between moving parts, effectively mitigating wear and prolonging the operational life of machinery.

These bearings are fashioned by combining two distinct metals, typically featuring a steel backing complemented by a lead bronze layer.

The alloy compositions mentioned (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) pertain to various lead bronze alloys employed in crafting these bearings. Each alloy exhibits unique properties that render it suitable for specific applications:

- CuPb10Sn10: Widely used in bearings operating under moderate loads and moderate-to-high speeds, such as those found in electric motors and appliances. It excels in emergency running situations and boasts high wear resistance.

- CuPb6Sn6Zn3: Although specific details about this alloy were not found, it is likely employed in similar applications to the other alloys.

- CuPb24Sn4: Designed for oil-lubricated applications, this alloy offers exceptional load-bearing capacity and fatigue resistance.

- CuPb30: Though specific information is not readily available, it likely serves analogous purposes to the other alloys.

- AlSn20Cu: Utilized in the bimetal bush for its unique properties, although detailed application specifics were not uncovered in the search results.

- CuSn8Ni: While specific information remains elusive, it is probable that this alloy is used in applications akin to the other alloys.

These alloys are fused onto the steel backing of the bearing through sintering, resulting in a robust, wear-resistant, and low-friction surface. The precise performance characteristics of a bimetal bush are contingent on the exact alloy composition employed. Consequently, collaborating with a reputable manufacturer or supplier is imperative to access essential information and receive guidance for selecting the most suitable product tailored to specific applications.

JF-800 Bimetallic composite bearings to the high-quality low-carbon steel substrate, the surface of the sintered copper alloy having a low friction characteristic (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as bearing wear layer, copper alloy surface may need to use conditions processing various types of sump hole, oil hole, so as to not be suitable for continuous refueling or difficult situations.

Bi-metal bushes are a type of bearing that consist of two different metal alloys bonded together. The two metals are chosen for their unique properties, with one typically being a harder and more wear-resistant material, while the other is chosen for its ability to withstand shock loads and vibration. The resulting combination creates a bearing that can withstand high loads and is ideal for use in applications where the bearing is subject to heavy wear and tear.

One of the key advantages of bi-metal bushes is their durability. The use of two different metals means that the bearing can withstand higher loads and last longer than traditional bearings made from a single material. The bearing’s ability to withstand heavy loads also makes it ideal for use in heavy machinery and equipment where high levels of wear and tear are commonplace.

Another benefit of bi-metal bushes is their versatility. They can be used in a variety of applications, including automotive, industrial, and marine applications. They are often used in engines, transmissions, and other parts of machinery where they can withstand the high forces and temperatures generated during operation.

One popular type of bi-metal bush is the graphite-filled bronze bush. This type of bush is made by bonding a layer of bronze to a layer of graphite. The bronze provides a strong base for the bearing, while the graphite helps to reduce friction and improve lubrication. This type of bush is commonly used in automotive applications, as well as in industrial machinery and equipment.

In terms of maintenance, bi-metal bushes require periodic lubrication to ensure smooth operation and to prevent premature wear. The exact lubrication requirements will depend on the specific application, but in general, regular maintenance is necessary to keep the bearing in good working order.

In conclusion, bi-metal bushes are a durable and versatile type of bearing that are ideal for use in applications where heavy loads and wear and tear are common. Their unique construction allows them to withstand high forces and temperatures, making them a popular choice in a variety of industries. With proper maintenance, bi-metal bushes can provide reliable and long-lasting service for many years to come.

Material Characteristics

| Data | Bimetal Bush Bearing | Bimetal Bushes |

| HSB-800 Structure |

|

|

| Steel + CuPb10Sn10 | Steel + AlSn20Cu | |

| Corresponding Code | SAE-792(SAE797). JIS-LBC3. |

SAE-783. JIS-AJL. |

| Max Load Capacity P | 150N/mm2 | 100N/mm2 |

| Greaes Lubrication | ||

| Max Speed V | 2.5m/s | |

| Maximum PV Value | 2.8N/mm2 · m/s | |

| Coefficient of friction u | 0.05~0.15 | |

| (Oil)Lubrication | ||

| Max Speed V | 10m/s | 25m/s |

| Maximum PV Value | 10N/mm2 · m/s | 6N/mm2 · m/s |

| 0.05~0.12 | 0.06~0.17 | |

| Max Working Temperature | ||

| Greaes Lubrication | 150℃ | 150℃ |

| Lubrication | 250℃ | 250℃ |

| Alloy Hardness | 60~100HB | 30~40HB |

Bimetal Bush Bearing Application

Construction Equipment: Track chassis running gear wheelset, towing wheelset, the tension wheelset;

Automotive industry: balance shaft bush, steel pin bushing, the kingpin Shaw bushings, rod bushings, valve rocker bushings, camshaft bushings, bushings differential, gearbox bushings, engine main bearing, thrust washers; And piston side panels, side panels, and another gear pump.

Hole machining and non-machining thickness tolerance

| Nominal Thickness | Tolerances of Series B (non-machinable) | Tolerances of Series C (non-machinable) |

|---|---|---|

| 1.0 | -0.025 | +0.25,+0.15 |

| 1.5 | -0.030 | +0.25,+0.15 |

| 2.0 | -0.035 | +0.25,+0.15 |

| 2.5 | -0.040 | +0.30,+0.15 |

| 3.0 | -0.045 | +0.30,+0.15 |

| 3.5 | -0.050 | +0.30,+0.15 |

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.