ASTM b505 C95400

ASTM b505 C95400

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

ASTM b505 C95400

C95400 Aluminum Bronze (C954) – per ASTM B505 Bushing

Aluminum Bronze C954 (ASTM B505 C95400) is a versatile and robust material offering a blend of strength, corrosion resistance, and wear resistance. Its wide range of applications across industries underscores its reliability and effectiveness in demanding conditions. The alloy stands as a testament to the advancements in material science, providing practical solutions to modern engineering challenges.

- Applications: C954 bronze bushings are commonly used in various industries such as automotive product lines, water engineering, plastic industries, steel rollers in the metallurgy industry, ships, turbo generators, hydraulic turbines, and injection molding machinery.

- Manufacturing Processes: The production of C954 bronze bushings involves turning, boring, grooving, drilling, and tapping. These bushings can be designed with features like ID spiral grooves for lubrication dispersion and tapped holes for fittings.

- Custom Solutions: Suppliers offer custom solutions tailored to exact specifications to ensure unparalleled performance and reliability. These custom solutions enhance efficiency and longevity of machinery by providing durable and resilient components

Aluminum bronze alloys are a recommended option for bearings in automotive pump applications, particularly when bearings face considerable axial loads and high velocities while being immersed in coolant. The subsequent aluminum-bronze materials are suggested based on their attributes:

C95500 Aluminum Bronze:

Properties: Known for its robustness and superior corrosion resistance, this alloy boasts a yield strength of up to 68,000 psi and a tensile strength of up to 120,000 psi. This enables it to endure unit loads 50% greater than the leaded tin bronze Alloy C93200.

Applications: Frequently utilized for oilless bushings, pump parts, and bearings, it stands out as an excellent choice for the stated application.

Manufacturing: Custom parts can be precision-engineered to meet exact requirements, ensuring exceptional precision and quality.

C95400 Aluminum Bronze:

Properties: C95400 aluminum bronze is recognized for its robustness, improved grain structure, and absence of lead, offering a potent alternative to brass with enhanced mechanical properties.

Applications: It finds use in worm gears, shaft sleeves, pump components, and bearings, aligning well with automotive pump application needs.

Nickel Aluminum Bronze:

Properties: This alloy is celebrated for its outstanding wear and galling resistance, robustness, and corrosion resistance. It’s particularly resistant to cavitation and biofouling, advantageous in a coolant environment.

Applications: Employed in various settings, like seawater pumps and valves, indicating its appropriateness for immersion in coolant.

General Guidelines for Aluminum Bronze Bearings:

Design: A meticulously engineered aluminum bronze bearing can surpass the lifespan of the equipment it serves. It demands careful consideration of lubricant purity and dependability, as these alloys lack the anti-seizing qualities found in leaded and tin bronze bearings.

Maintenance: Consistent maintenance is essential for optimal performance and durability.

Machinability: Although more challenging to machine, aluminum bronze is manageable with appropriate tools and techniques, such as employing a plain carbide end-mill and coolant during CNC milling.

In conclusion, aluminum bronze bearings, particularly C95500 and C95400, are strong contenders due to their high strength, corrosion resistance, and compatibility with high-load, high-speed scenarios. It’s crucial to verify that the chosen material aligns with the specific demands of the automotive pump application, including coolant compatibility.

Understanding C95400 ASTM B505: An Insight into Double Spiral Grooved Bronze Bushings and Self-Lubrication

The world’s trusted partner in metal alloy solutions

C95400 Aluminum Bronze, commonly referenced by its ASTM B505 standard, is a popular material choice in the production of various mechanical components. Among these, double spiral grooved bronze bushings and self-lubricated bushings stand out for their unique properties and applications in various industries. This article delves into the specifics of C95400 ASTM B505 material, highlighting its composition, characteristics, and the advantages it brings to double spiral grooved and self-lubricated bushings.

BUSHING, SLEEVE W/ FLANGE, GROOVED, C954 BRONZE, CUSTOM SIZE BUSHING DIMENSIONS

Material Characteristics: C954 Aluminum Bronze is known for its high yield and tensile strength, good ductility, weldability, exceptional resistance to wear, fatigue, and deformation under shock or overload. when seeking custom size bushing dimensions in C954 bronze, it is crucial to consider the material properties, specific applications, manufacturing processes involved, and the availability of custom solutions from trusted suppliers to meet your unique requirements effectively.

Custom Size Bushing Dimensions in C954 Bronze

Composition and Properties

C95400 Aluminum Bronze is a high-strength, corrosion-resistant alloy composed primarily of copper and aluminum, with additional elements like iron and nickel. This composition imbues the alloy with remarkable traits such as high wear and corrosion resistance, making it suitable for demanding environments. It’s also notable for its ability to withstand high temperatures and pressures.

Double Spiral Grooved Bronze Bushings

Double spiral grooved bushings made from C95400 are designed for applications where reliable lubrication is crucial yet challenging to maintain. The double spiral grooves on the inner diameter of these bushings act as channels for lubricant distribution, ensuring consistent lubrication and reducing the risk of wear and tear. This design is particularly beneficial in applications involving oscillating or rotating movements where lubricant dispersal can be uneven.

Self-Lubricated Bushings

Self-lubricated bushings crafted from C95400 ASTM B505 take the alloy’s natural properties a step further. They are engineered to reduce the need for external lubrication. This is achieved either by incorporating lubricant materials into the bushing or by the bushing’s ability to form a thin layer of lubricating film between its surface and the counterpart. These bushings are ideal for environments where regular maintenance is difficult or where contamination from lubricants must be avoided.

Applications

The robustness and versatility of C95400 make it an ideal material for bushings in various sectors, including aerospace, marine, industrial machinery, and automotive industries. Its ability to function under high loads and in abrasive environments makes it particularly suited for heavy-duty applications.

Advantages

- Durability: C95400 bushings exhibit excellent wear resistance, prolonging their service life.

- Corrosion Resistance: Ideal for use in corrosive environments, reducing maintenance and replacement costs.

- Self-Lubrication: Minimizes the need for regular maintenance, especially in hard-to-access areas.

- Temperature and Pressure Resistance: Suitable for high-stress applications without compromising performance.

Conclusion

C95400 ASTM B505 Aluminum Bronze is a material that combines strength, durability, and versatility. Its application in double spiral grooved and self-lubricated bushings offers a reliable solution in various industrial applications, ensuring efficient operation even under challenging conditions. As industries continue to evolve, the importance of materials like C95400 in reducing maintenance needs and increasing operational efficiency cannot be overstated.

References

- ASTM B505 Standard

- Industry Journals on C95400 Applications

- Case Studies on the use of C95400 in Various Industries

Aluminum Bronze (C954) – ASTM B505 C95400: Composition, Properties, and Applications

Introduction

Aluminum Bronze C954, designated as C95400 in the ASTM B505 standard, is a high-strength, corrosion-resistant copper alloy prominently used in various industrial applications. Its unique composition of aluminum, copper, and other elements makes it an ideal material for components requiring durability and resistance to wear and corrosion.

Composition

C95400 Aluminum Bronze primarily consists of copper (approx. 83%), aluminum (approx. 11%), with additional elements like iron and nickel. This combination creates a dense, hard material that excels in strength and resistance to corrosion and wear. The presence of aluminum in the alloy imparts higher strength and hardness compared to standard bronze.

Properties

- High Strength and Hardness: The aluminum content enhances the strength and hardness, making it suitable for heavy-duty applications.

- Corrosion Resistance: It effectively resists corrosion in seawater and other harsh environments, thanks to its protective aluminum oxide layer.

- Wear Resistance: Exhibits excellent wear resistance, which is crucial in applications involving friction and abrasion.

- Heat Resistance: Maintains its properties even at elevated temperatures, making it suitable for high-temperature environments.

Applications

C95400 Aluminum Bronze is widely used in various sectors due to its robust properties:

- Marine Applications: Ideal for propellers, pump parts, and ship components due to its seawater corrosion resistance.

- Industrial Machinery: Used in gears, bearings, and valve components where high strength and wear resistance are necessary.

- Aerospace and Defense: Components requiring high strength-to-weight ratio, such as landing gear parts.

- Automotive: Suitable for heavy-duty bearings and bushings in vehicles.

Advantages

- Longevity: The durability of C95400 reduces the need for frequent replacements, offering long-term cost savings.

- Reduced Maintenance: Its resistance to wear and corrosion minimizes the need for regular maintenance.

- Versatility: Suitable for a wide range of applications across different industries.

- Environmental Resistance: Performs reliably in various environmental conditions, including underwater and high-temperature settings.

-

- Adequate lubricant levels.

- Absence of debris in grooves.

- Overall bushing integrity.

Grooved Type for Bronze Bushings: Enhancing Lubrication and Performance

Grooved bronze bushings represent a specialized category in the realm of mechanical components, designed to enhance lubrication efficiency and longevity in various applications. These bushings, often made from durable materials like bronze, are engineered with grooves that facilitate the distribution of lubrication, significantly impacting their performance and durability.

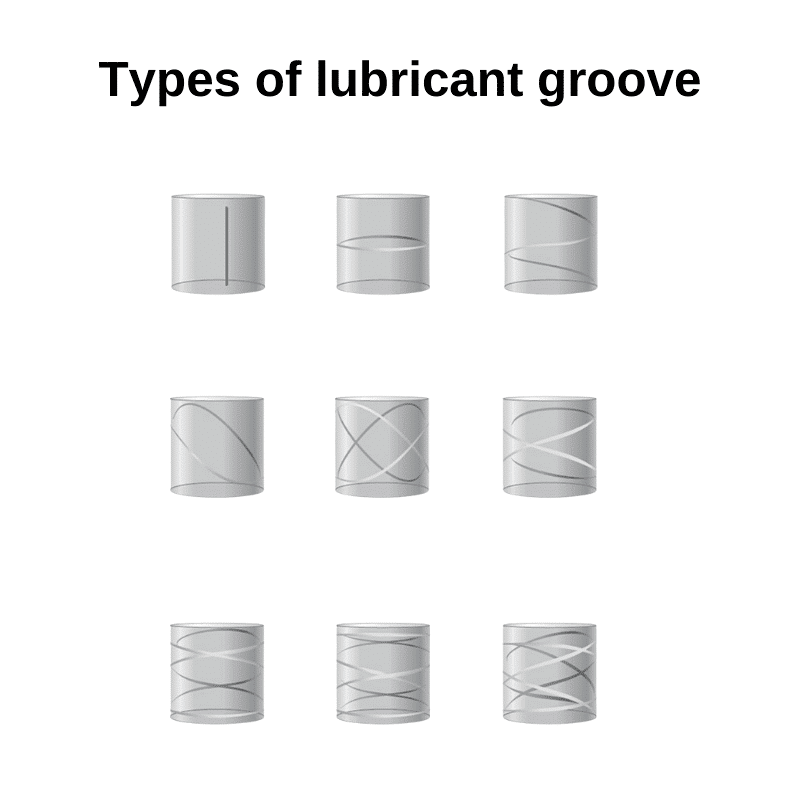

Types of Grooves

- Straight Grooves: Linear grooves that run parallel to the axis of the bushing. Ideal for linear movements.

- Spiral Grooves: These grooves wind around the bushing, suitable for rotational and oscillating motions.

- Double Spiral Grooves: A more complex pattern that ensures even lubrication in highly dynamic applications.

- Circular or Dot Grooves: Common in applications with intermittent movements, these grooves provide pockets for lubricant retention.

Advantages of Grooved Bronze Bushings

- Enhanced Lubrication: Grooves serve as channels for lubricants, ensuring consistent coverage and reducing friction.

- Reduced Wear and Tear: Consistent lubrication minimizes wear, extending the bushing’s life.

- Improved Performance: Enhanced lubrication leads to smoother operation and higher efficiency.

- Versatility: Grooves can be designed to suit specific applications, making these bushings adaptable to various requirements.

Applications

Grooved bronze bushings are used in industries where reliable and continuous lubrication is crucial, such as:

- Automotive: In suspension joints, steering systems, and other moving parts.

- Industrial Machinery: In conveyors, gears, and rotating shafts.

- Aerospace: For components requiring precision and reliability under high loads.

- Marine: In propeller shafts and rudder assemblies where constant lubrication is necessary.

Material Choice: Bronze

Bronze, especially alloys like C95400 Aluminum Bronze, is often the material of choice for grooved bushings due to its inherent properties:

- Corrosion Resistance: Especially beneficial in harsh or marine environments.

- Wear Resistance: Essential for applications with high friction.

- Strength: Capable of handling heavy loads and stresses.

Maintenance and Care

While grooved bronze bushings are designed for reduced maintenance, regular checks are vital to ensure:

Grooved bronze bushings stand out for their ability to provide consistent lubrication, reduce maintenance needs, and extend the life of mechanical components. Their application in various industries underscores their importance in ensuring smooth, efficient, and long-lasting operation of machinery and mechanical systems. The choice of bronze, particularly alloys like C95400, further enhances their performance, making them a reliable and effective solution in engineering and industrial applications.

- C95400 Aluminum Bronze, commonly referred to as C954, is a highly adaptable aluminum bronze alloy known for its superior yield and tensile strengths, excellent ductility, weldability, and outstanding resistance to wear and fatigue. Below are key insights about C95400 Aluminum Bronze:Applications:

- Bearings

- Gears

- Valve components

- Wear plates and strips

Standards:

- ASTM B-148, ASTM B-271, ASTM B-505, ASTM B-763

- SAE J461, SAE J462, SAE J463, SAE 68A

- AMS 4870, AMS 4871, AMS 4635

Physical and Mechanical Properties:

- Density: 8.2 g/cm³

Shapes Available:

- Solid Bar: Available in diameters ranging from 1/2″ to 16″

- Hollow Bar (Continuous Cast): Available with inner diameters from 1/2″ to outer diameters of 1″, and inner diameters from 9″ to outer diameters of 10″

- Hollow Bar (Centrifugal): Stock sizes up to 20″ outer diameter, with special orders up to 50″ outer diameter

These alloys are prized for their blend of strength, durability, and resistance to a variety of conditions, making them indispensable across numerous industrial applications.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.