Plain Bearing Custom Size

For applications where multi-directional, self-aligning motion exists

Explore plain bearings, rod ends and bushings/bushings that meet your application needs while providing high reliability, long life and minimal maintenance.

Sliding bearings are used in a wide variety of industries and applications that require a cost-effective and reliable way to meet the challenges posed by oscillation and possible misalignment. From mining and construction equipment, agricultural and forestry machinery all the way to forklifts and solar equipment.

80%

Sales Growth

90+

Projects Delivered

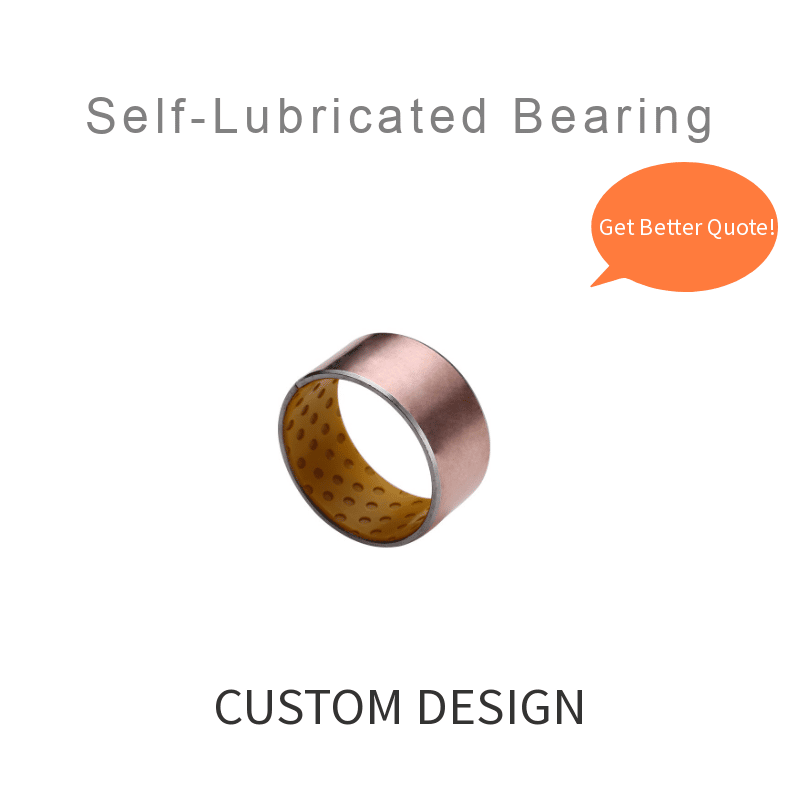

Plain Bearings

Tribology Design

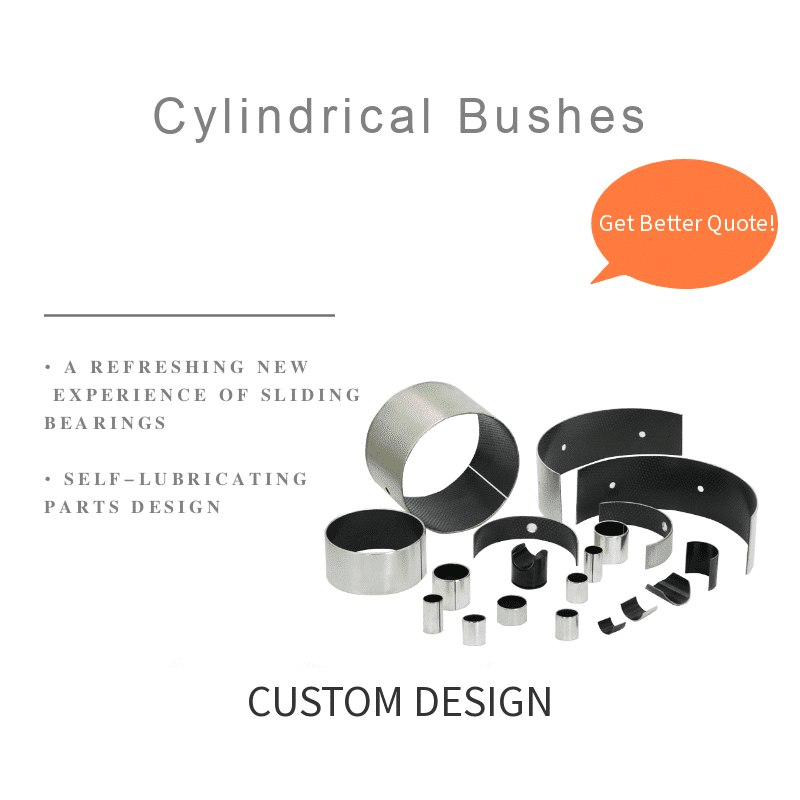

Bushing manufacturers – Oilless Self-lubricating Tech. Design Custom Plain Bearings Made From High-Strength Lubricating…

professional

Plain Bearing

Lubricating Metal Bushings – Metal Bearings, Special Dimension Plain Bearings and Custom Bearings.

SEM

Focus

Bronze Bushings Available – Made In China, development and supply of small and medium-sized enterprises.

Customized

Plain Bearing

Can Economically Make Custom Bushings. Custom Bearings and Components.

Bushings, thrust washers and bushings

Consideration of which sliding material and sleeve/bushing type to select and its different combinations of sliding contact surfaces and operating characteristics is critical to the performance of the plain bearing in a given application.

Low-maintenance plain bearings are usually lubricated with grease. The amount of grease used during mounting is usually sufficient to last the entire service life. If grease-lubricated plain bearings are used under difficult conditions, subsequent lubrication is recommended.

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

Why choose plain bearings

- For static and dynamic heavy loads

- Multi-directional motion

- Allowing misalignment

Basic elimination of marginal stresses and excessive stresses in adjacent components. Allows for deformation of peripheral components during operation. Allows for large manufacturing tolerances, enabling the use of low-cost welded components.

Lubricating Plain Bearings – Wide Range of Applications.

Why Choose Sliding Bearings

Wide selection of products for different application conditions. Lifetime lubrication option available to reduce grease usage. Highly corrosion resistant versions available. Available in a variety of sizes. Range includes spherical and plain bearings as well as rod ends, bushings, thrust washers, strips and pivot joints. Plain bearings for the railway segment

Discover our solutions for the railway industry.

Choose from Lubricating Plain Bearing Types, Sizes and Materials. Contact Our Friendly Team Today for Info! We Take Pride in Providing You with High Quality Slide Bearings for Your Use.

Plain Bearing Bushing

Custom Designed plain Bearings – Custom Engineered Bushing

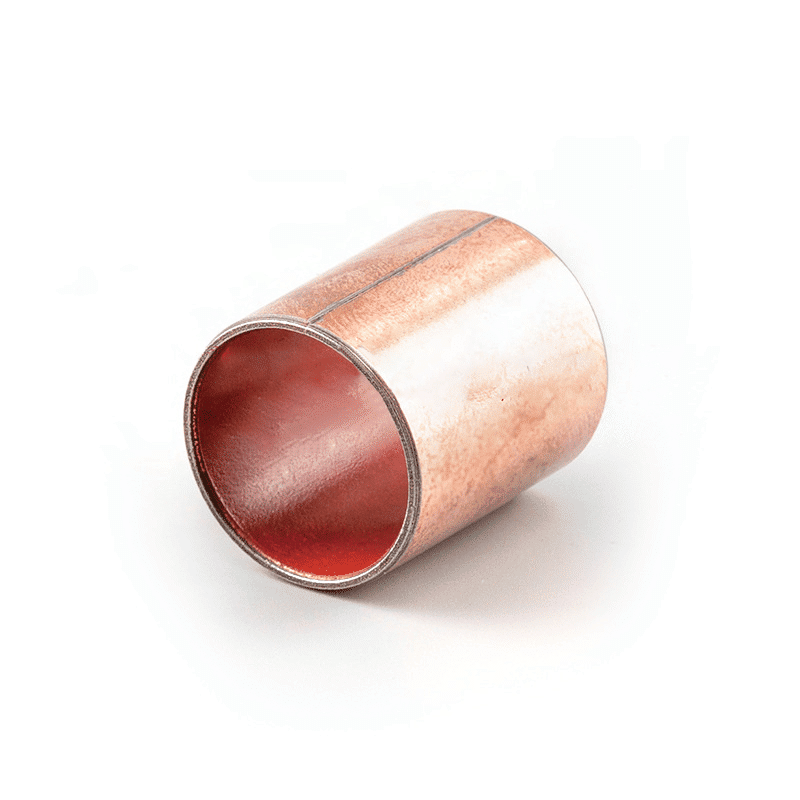

Manufactured in a variety of designs and materials, available from stock, each combination of design and material creates unique characteristics that make it suitable for specific applications. CuSn7Zn4Pb7 bronze bushing. or CuSn8 solid bronze wrapped bushing.

Product Quality Index

Energy Generation

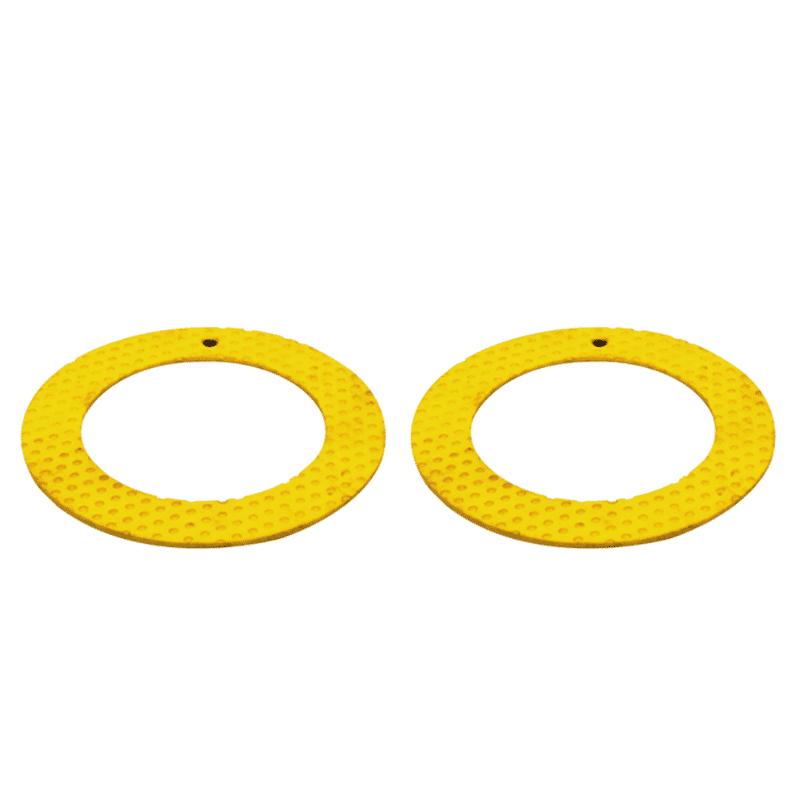

Thrust washers, PTFE Composite Bushings/bushings

Beautifully crafted leather products.

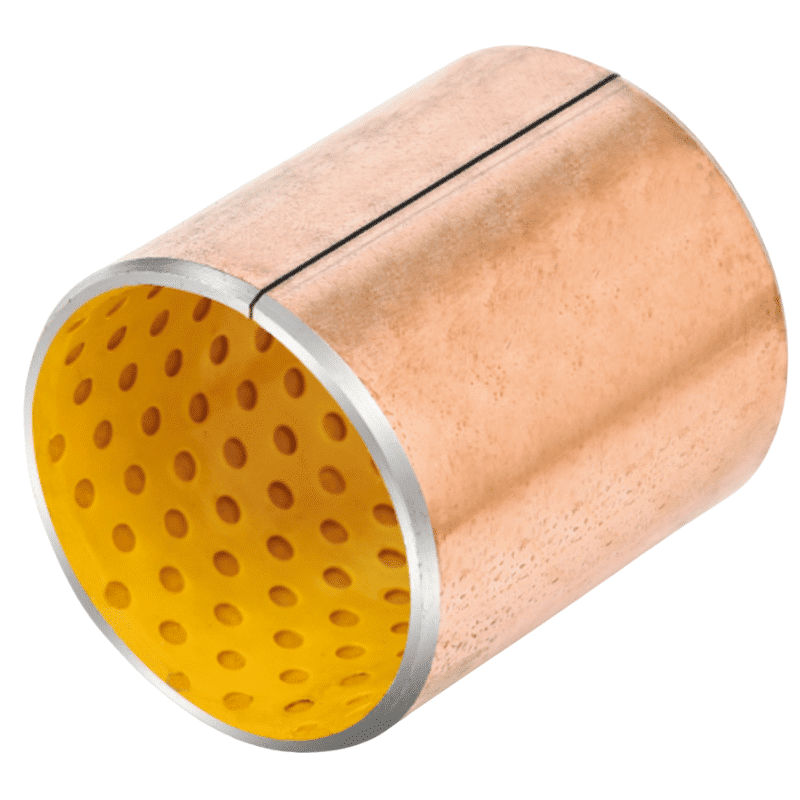

Made of PTFE and POM composites for applications where axial space is limited, reciprocating or rotating motion is present, maintenance is not possible, lubrication is inadequate, and pins/screws inserted into the gasket holes prevent rotation. The chemical resistance of composite plain bearings depends primarily on the chemical resistance of the steel backing and the sintered tin bronze layer, as the sliding (overlay) layer is chemically resistant to many substances. Although, at elevated temperatures, the overlay is subject to attack by molten alkali metals and free fluorine, it is virtually chemically resistant because it contains PTFE. Metric straight bushings: ISO 3547-1

Inch straight and metric flange bushings: not standardized. At room temperature, the sintered tin bronze structure is highly resistant to seawater, steam, atmospheric influences, salt solutions and sulfuric acid, but not to oxidizing acids or ammonia media. The steel backing is electrolytically tinned on all exposed surfaces, but in most applications provides only limited resistance to corrosion. If the bearing washer needs to be exposed to corrosive media, or if there is a corrosion hazard on the contact surface between the steel backing and the housing material, the backing can be protected by electroless nickel, chromium or zinc plating. For more information, please contact Plain Bearing Application Engineering Services.

POM Bearing Bushing Thrust washers

Beautifully crafted leather products.

The steel backing has a layer of sintered/bronze and the micro-perforations are filled and covered with a layer of paraformaldehyde composite. The chemical resistance of composite plain bearings depends largely on the chemical resistance of the steel backing and the sintered tin bronze layer, as the sliding (cover) layer is chemically resistant to many substances. The paraformaldehyde resin coverings are largely resistant to organic substances.

Composite dry sliding strips are designed for applications where axial space is limited, where maintenance is not possible, or where lubricants may be inadequate. Strips can be bent, extruded or reproduced to form flat linear guides, such as L- or V-sections, or other types of dry sliding assemblies and are suitable for practical applications.

Standard strips are manufactured from PTFE and POM composites for composite bushings and thrust washers.

At room temperature, the sintered tin bronze structure is very resistant to seawater, steam, atmospheric influences, salt solutions and sulfuric acid, but not to oxidizing acids or ammonia media.

The steel backing is electrolytically tinned on all exposed surfaces, but in most applications provides only limited resistance to corrosion. If the bearing washer needs to be exposed to corrosive media or if there is a corrosion hazard on the contact surface between the steel backing and the housing material, the backing can be protected by electroless nickel, chromium or zinc plating. For more information, please contact Application Engineering Services.

Electrical properties The paraformaldehyde resin coverings are insulating when used new. To avoid static buildup, parts with a risk of static buildup should be grounded. For more information, please contact Application Engineering Services.

lubricating Slide Plates and Strips

Various types of bushings are manufactured using different materials. Therefore, a wide range of bushings are available from stock.

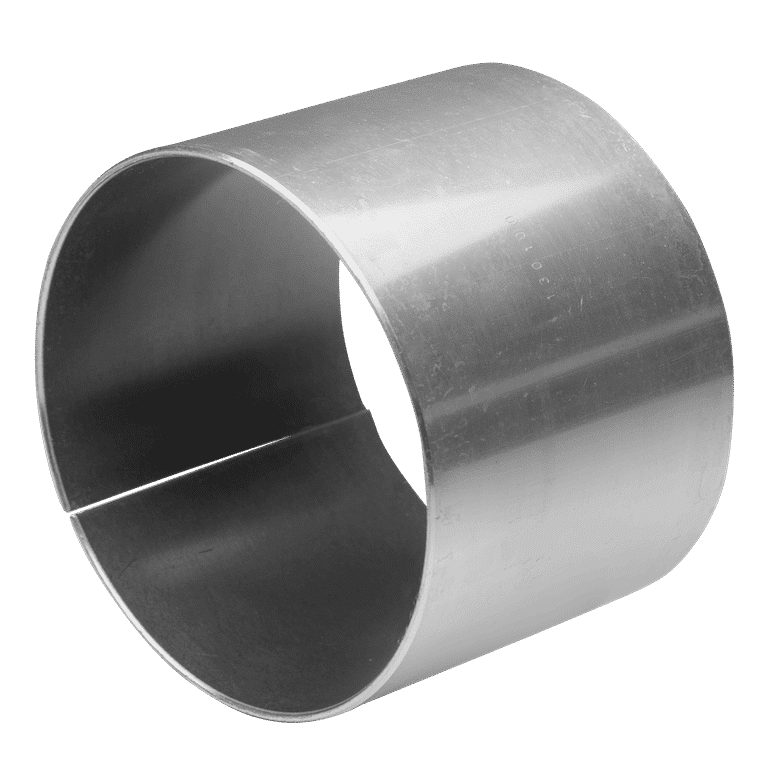

While straight (cylindrical) bushings can only carry radial loads, flanged bushings are capable of carrying radial and axial loads in one direction.

Each design and combination of bushings has unique properties that make them individually suitable for certain applications.

Made of the same composite material and designed to be used in the same type of applications as the thrust washers, dry sliding strips can be bent, extruded or cast to form flat linear guides, such as L or V sections.

Steel backing with a layer of sintered/bronze, micro-perforations filled and covered with a layer of paraformaldehyde composite strips.

Steel backed with a layer of sintered/bronze, micro-perforations filled and covered with a layer of ground PTFE with molybdenum disulfide additive, standard sizes.

- Widths B = 100 mm and 200 mm

- Length L = 500 mm

- Other sizes available on request

The chemical resistance of composite plain bearings depends primarily on the chemical resistance of the steel backing and the sintered tin bronze layer, as the sliding (cover) layer is chemically resistant to many substances. Although, at elevated temperatures, the cover layer is subject to attack by molten alkali metals and free fluorine, it is virtually chemically resistant because it contains PTFE. At room temperature, the sintered tin bronze structure is highly resistant to seawater, steam, atmospheric influences, salt solutions and sulfuric acid, but not to oxidizing acids or ammonia media. The steel backing is electrolytically tinned on all exposed surfaces, but provides only limited resistance to corrosion in most applications. If the strip needs to be exposed to corrosive media, or if there is a corrosion hazard at the contact surface between the steel backing and the bearing housing material, the backing can be protected by electroless nickel, chromium or zinc plating. For more information, please contact Application Engineering Services.

Sliding bearing (sliding bearing), a bearing that works under sliding friction. Sliding bearing works smoothly, reliably and without noise. Under the condition of liquid lubrication, the sliding surface is separated by lubricating oil without direct contact, which can also greatly reduce the friction loss and surface wear, and the oil film also has certain vibration absorption ability. But the starting friction resistance is large. The part of the shaft supported by the bearing is called the journal, and the parts matched with the journal are called the shaft tile. In order to improve the frictional properties of the surface of the shaft tile and cast in its inner surface of the friction reducing material layer called bearing lining. The material of the shaft and bearing liner is collectively called sliding bearing material. Plain bearing applications are generally in the low-speed heavy load conditions, or maintenance and lubrication difficulties in the operating parts

Plain Bearing Lubrication Designs and Variants

Bushing configuration design

The most important factors to consider when selecting the material and surface finish of the mating surface (the surface on which the sleeve slides) are the load conditions (load, swing angle, type of movement, etc.) and environmental influences.

In situations where there is a risk of corrosion, the mating surface must be sufficiently resistant. Corrosion scars on the mating surface, for example, corrosion as a side effect of wear particle contaminants increase the surface roughness and accelerate wear. In such cases, stainless steel should be considered, with surface treatments such as hard chrome plating, nickel plating or electrolytic oxidation.

Composite Dry Sliding Plain Bearing Lubrication Thrust Washers (Cost-effective and space-saving solution for axial positioning. PTFE and POM composite thrust washers are suitable for reciprocating and rotary motion applications. These washers are stamped from composite materials and come standard with a hole for a locating pin or bolt to prevent the washer from rotating on its base.

Composite Thrust Washers

PTFE composite thrust washers (self-lubricating and maintenance-free) offer long service life due to their low friction. Despite their compact design, they can withstand heavy axial loads and are suitable for relatively slow rotational or reciprocating movements. They also provide good dimensional stability and thermal conductivity.

PTFE composite washers consist of a steel plate backing with a 0,2 to 0,4 mm thick porous layer of tin/copper sintered on top. In addition, a mixture of PTFE (polytetrafluoroethylene) and molybdenum disulfide additives is filled into the fine holes of the sintered layer by means of a rolling technique. This additional wear layer of 5 to 30 μm thick achieves an optimal combination of the mechanical properties of the sintered tin/copper with the excellent Plain Bearing Lubrication and lubricating properties of the PTFE mixture.

Break-in phase

During a short break-in period, trace amounts of PTFE material from the wear layer are transferred to the mating surface. Once the transfer has occurred, the washer acquires low friction and wear resistance properties.

POM composite thrust washers

POM composite thrust washers have recessed holes in the sliding Plain Bearing Lubrication contact surface (which are used as grease holes and are filled prior to installation). The sliding contact surface grooves make these washers suitable for applications with low maintenance requirements in complex operating conditions, such as applications where lubricant cannot be provided continuously or frequently in contaminated environments. Despite their compact design, POM composite washers can withstand heavy axial loads and are much less sensitive to centering errors. These bushings are suitable for slow rotation or reciprocating motion.

POM composite thrust washers consist of a steel plate backing with a sintered 0,2 to 0,4 mm thick tin/copper hole layer. The main characteristic of these washers is that they have a relatively thick (0,3 mm) cover layer of polyoxymethylene resin (POM – polyoxymethylene) with additives. This cover has a grease groove to retain the grease and is firmly attached to the sintered tin/bronze layer.

The thickness of the cover makes the gasket less susceptible to misalignment and the edge stresses associated with misalignment, even if there is some degree of misalignment.

Plain bearing thrust washer configuration design

Even in cases where the axial load is small and the surface is not sufficient to carry the thrust, the use of a thrust collar can be very beneficial, especially if the material or its finish is not suitable for use as a suitable surface to carry the thrust. For shafts that require both radial support and axial positioning, a combination of a sleeve (sleeve arrangement design) and a thrust bearing collar can be used, depending on the axial load. The thrust collar is usually positioned radially in the recess in the bearing housing, shown, and secured with a locating pin or flat head screw to prevent it from rotating. The head of the locating pin or flat head screw must be recessed at least 0.3 mm below the sliding contact surface, and the entire surface of the thrust collar must be supported. The mating surface should completely cover the sliding contact surface of the composite thrust collar. If for some reason it is not possible to machine a recess in the housing, the thrust collar can be attached to the housing with two locating pins or screws or fixed by means of gluing.

Lubrication Plain Bearing Type

- Solid bronze bushings/bushings

- Wrapped Bronze Bushings

- Oilless Bushing

- Graphite Bearing

- Rolled bronze bushings

- PTFE composite bushings

- POM composite bushings

- PTFE self-lubricating bushings

- Stainless steel braided composite bushings

- PTFE composite thrust washer

- POM composite thrust washers

- PTFE composite sheet and tape

- POM composite strip

Custom-Made Sliding Bearings

Custom-Made Bearings – Leave your details or chat us, We will consult you and deliver the best quality of sliding bearings. Download the PDF now. Our team will consult you for the best sliding bearing solution. Bushings, Plain Bearings.

Safe Stainless Bushing Lubricating. High Quality Stainless Bushing with Competitive Price. Quality China Products. We manufactures bushings in various designs and from different materials. Therefore, we offers a wide assortment of bushings available from stock. Stainless Plain Bearing Bushing Self-lubricating- Trusted Bushing Supplier. PTFE bushing manufacturers/supplier, China bushing manufacturer & factory list, find best price in Chinese bushing manufacturers, suppliers, factories!