Phosphor Bronze PB1 Bushing, Cnc Machined Components

About us

Phosphor Bronze PB1, Cnc Machined Components

Phosphor Bronze PB1 is a high-strength, corrosion-resistant material that is well-suited for manufacturing bushings and other components that require precision and durability. Grade Recognition: Phosphor Bronze PB1 is an ideal material for manufacturing bushings and other CNC machined components that require high strength, good corrosion resistance, and precision. Its properties make it suitable for a variety of applications, particularly in harsh or demanding environments. Increased tin content minimizes the risk of corrosion.

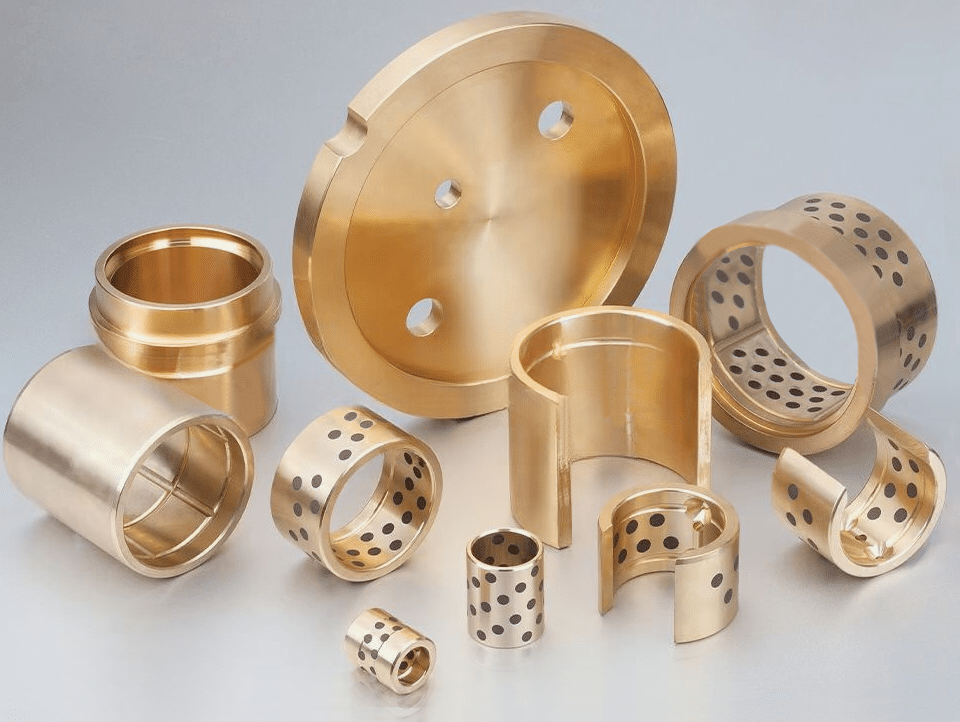

Leaded, Phosphor And Aluminium Bronzes Bearing,

Search Our Material Alloy

Phosphor Bronze PB1 Material, Phosphorus enhances wear resistance.

PB1 is a continuously cast phosphor bronze alloy, composed of 10-12% tin and trace amounts of phosphorus. It offers high mechanical strength along with good conductivity and wear resistance, though wrought materials may offer superior performance in these areas. Additionally, PB1 exhibits excellent corrosion and fatigue resistance and can be effectively soldered and brazed.

Material Properties: Phosphor Bronze PB1 is a phosphor bronze alloy that conforms to the requirements of B.S. 1400 – 1985 alloy PB1. It is known for its good machining properties, high strength, and excellent corrosion resistance, particularly to seawater and brine. This makes it suitable for pump and valve components, as well as bearings with medium to high loads and speeds. Adequate lubrication and good alignment are necessary for PB1 bearings. It is also suitable for heavy-duty gears and wormwheels with high working loads and speeds, provided they have proper lubrication and alignment. The composition of PB1 is strictly controlled, and the casting conditions are carefully managed to ensure quality and consistency. Products made from PB1 are manufactured using the latest continuous and centrifugal casting technology.

Grade Recognition: The PB1 grade bronze is recognized by various standards such as BS1400, ASTM B505, and SAE 65, indicating its widespread acceptance and use in the industry.

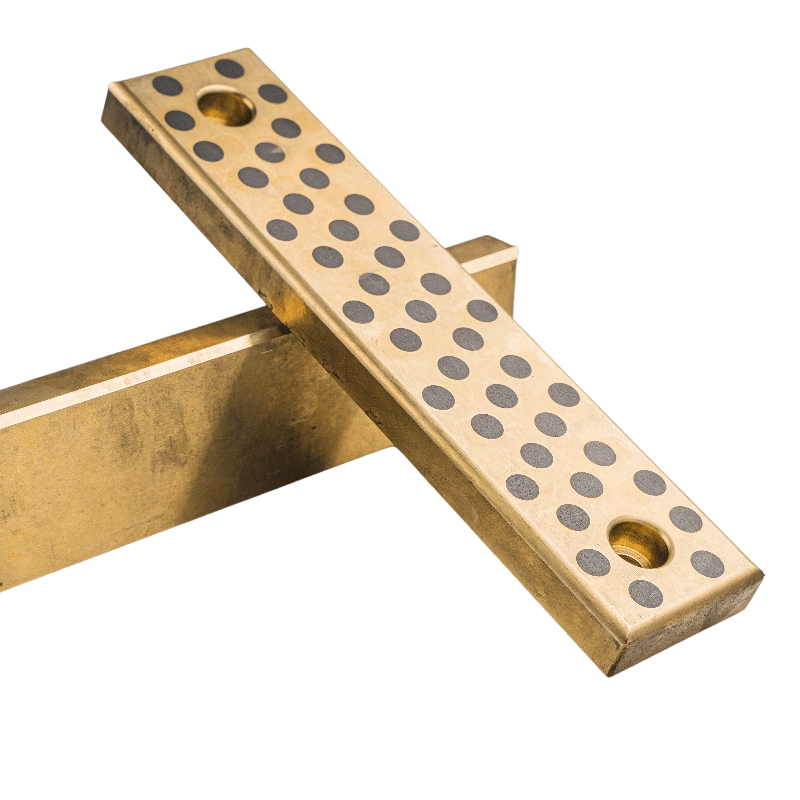

Commonly utilized in the production of bearings, sleeves, thrust washers, and gears.

Phosphor Bronze PB1 Chemical Composition and Mechanical Properties:

Phosphor Bronze PB1: PB1 is a cast phosphor bronze material, consisting of 10-11.5% tin and small amounts of phosphorus. This alloy is known for its high mechanical strength, good conductivity, and wear resistance, along with exceptional corrosion and fatigue resistance. Phosphor Bronze PB1 can also be soldered and brazed effectively.

Chemical Composition: The chemical composition of Phosphor Bronze PB1 typically includes Tin (10.0 – 11.0%), Lead (up to 0.25%), Zinc (up to 0.05%), Nickel (up to 0.10%), Iron (up to 0.10%), Aluminium (up to 0.01%), Phosphorus (0.50 – 1.0%), and Copper making up the balance.

Mechanical Properties: The mechanical properties of PB1 include a yield strength of 170 MPa, an ultimate tensile strength ranging from 340 to 360 MPa, and an elongation of about 10%. The typical hardness is between 100 – 150 BHN.

- MACHINED COMPONENTS

- MATERIALS

- FACTORED PRODUCTS

Applications: Phosphor Bronze PB1

Applications: PB1 is used extensively in the marine industry due to its excellent corrosion resistance in marine atmospheres and high mechanical strength. It is also used for worms and gears under high working loads, pump and valve components, bushes and bearings, flanges, hydraulics, and marine ultrasonics!

Enquire now and we will respond to your requirements!

CNC Machining, Phosphor Bronze PB1

CNC Machining: CNC machining of Phosphor Bronze PB1 allows for the production of high-precision components that meet exact design specifications and tight tolerances. This process is cost-effective and enables efficient production of parts, reducing material waste. The unique properties of bronze make it suitable for a wide range of applications across various industries.

Stock Availability: Phosphor Bronze PB1 is available in various forms such as flats, round bar, plate, sheet, round tube, hollow bar, square bar, and hexagon bar, making it versatile for different applications and manufacturing processes.