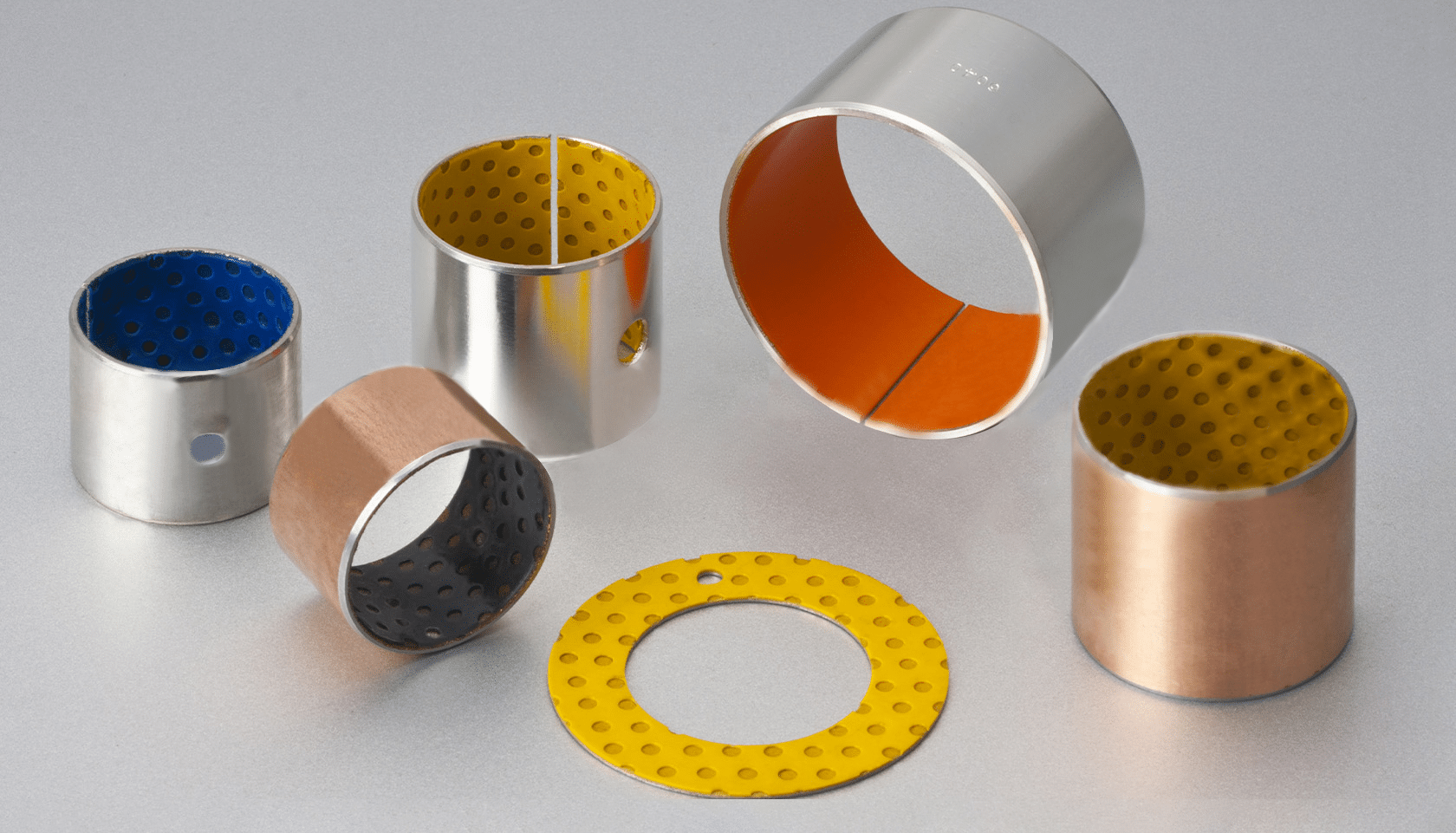

High-Quality Phosphor Bronze Bushings & Graphite Phosphor Bronze Liner Plate with Drill Holes, machined slide plate bronze – Durable & Reliable!

Experience the Strength of Self-lubricating Bearings

Discover alloy Grade Phosphor Bronze Bushings – Shop Now!

Enhance Your Machinery with Our Phosphor Bronze Bushings! Phosphor bronze graphite bushings are a composite material that combines the excellent mechanical properties of phosphor bronze with the self-lubricating characteristics of graphite. Phosphor bronze itself is a copper alloy containing tin and phosphorus, known for its good conductivity, fatigue resistance, and wear resistance. It is commonly used to manufacture wear-resistant parts and flexible components, such as computer connectors, mobile phone connectors, and springs for electronics and electrical applications.

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

Precision Phosphor Bronze Bushings for Any Application, Graphite Phosphor Bronze Slide Plate with Drilled Holes

Graphite, serving as a lubricant, has self-lubricating properties that can reduce friction and wear, thereby enhancing the efficiency of mechanical operations. By embedding graphite within the phosphor bronze matrix, bushings that are both wear-resistant and self-lubricating can be produced. These products are widely used in applications that require reduced maintenance and enhanced reliability.

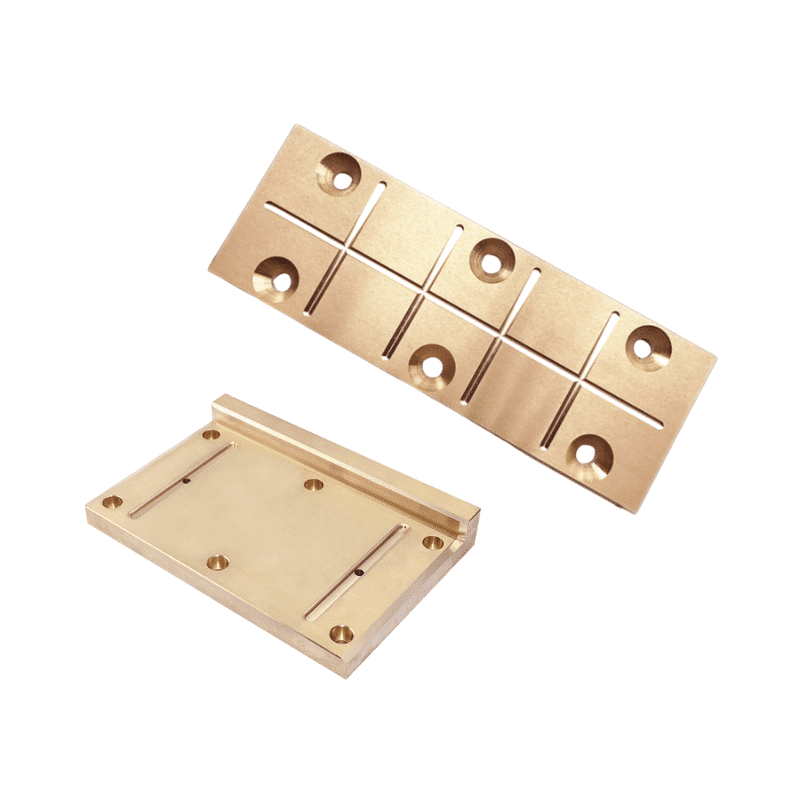

This slide plate is crafted from phosphor bronze, an alloy mainly composed of copper, tin, and phosphorus, and is enhanced with graphite for superior self-lubrication. The addition of drilled holes within the bronze matrix improves the distribution of graphite, enabling continuous lubrication and reducing wear during operation. The precise machining of this slide plate allows it to meet specific dimensional tolerances and performance criteria, making it ideal for a variety of industrial applications where durability and low maintenance are paramount.

Features of phosphor bronze graphite bushings include

High Load Capacity: Due to the high strength and hardness of phosphor bronze, these bushings can withstand substantial loads.

Self-Lubrication: The addition of graphite provides self-lubricating properties, reducing dependency on external lubricants.

Wear Resistance: The combination of phosphor bronze and graphite offers excellent wear resistance.

Corrosion Resistance: Phosphor bronze has good corrosion resistance, making it suitable for various environments.

Thermal Stability: Phosphor bronze maintains stable performance within a certain temperature range.

Phosphor Bronze Liners, phosphor bronze Plate material, Phosphorous Bronze Plates Thickness 10-15mm, 15-20mm

Phosphor bronze liners plates are metal plates made from an alloy of copper, tin, and phosphorus. Phosphor bronze is valued for its excellent properties such as high corrosion resistance, durability, and wear resistance. Liner plates made from phosphor bronze are commonly used in various industrial applications, including machinery components, bearings, bushings, and electrical connectors. They provide reliable performance in environments where high strength and resistance to fatigue are essential. These plates are often used to line surfaces where friction and wear are a concern, helping to extend the lifespan of machinery and equipment.

Get Your Phosphor Bronze Bushings – Fast Shipping Available!

About us

Supplier of Phosphor Bronze Bushings – Order Today!

Phosphor bronze graphite bushings can be customized according to specific application requirements to meet different dimensions, shapes, and performance needs. For example, they can be used to manufacture self-lubricating liners and sliding bearings.

Custom Parts Services and Prototyping!

Leaded, Phosphor And Aluminium Bronze Bearing, Search Our Material Alloy

Phosphor bronze Bushing Bearing Material – Custom size

Phosphor bronze, as a type of copper alloy, may have different designations in various countries and regions according to international standards.

Properties of Graphite Phosphor Bronze

Phosphor bronze is an alloy primarily composed of copper, tin, and phosphorus. The addition of graphite enhances its self-lubricating properties, making it ideal for applications where friction reduction is essential.

Key Features:

- Excellent Machinability: Phosphor bronze is known for its good machinability, allowing for precise drilling and shaping without significant tool wear. This is particularly important for producing components with specific dimensions and tolerances.

- Self-Lubrication: The incorporation of graphite allows these liners and plates to maintain lubrication during operation, reducing the need for additional lubricants and minimizing maintenance efforts.

- Corrosion Resistance: Phosphor bronze exhibits good resistance to corrosion, making it suitable for use in harsh environments.

Applications

Graphite phosphor bronze liners and plates are commonly used in:

- Bushings and Bearings: These components are often utilized in machinery where they serve as bushings, providing low-friction surfaces for rotating shafts.

- Industrial Machinery: The self-lubricating properties make them ideal for sliding applications in various types of industrial equipment.

- Automotive Components: They are also found in automotive applications where durability and low maintenance are critical.

Availability and Customization

Manufacturers often provide these components with specific drilling patterns to enhance lubrication distribution. Custom sizes and shapes can be produced to meet particular engineering requirements, ensuring that they fit seamlessly into existing machinery designs.In summary, graphite phosphor bronze liners and plates with drilled holes are valuable components in many industrial applications, offering a combination of durability, machinability, and self-lubrication that enhances performance and reduces maintenance needs.

| MATERIAL LIST | ||||||||||

| Material description | Analysis | Physical properties | Application | |||||||

| DIN Alloy No. |

ASTM Alloy No. |

Scandinavian Alloy No. |

British Alloy No. |

Chemical Composition |

Yield Strength |

Tensile Strength |

Elongation | Emodule | Hardness | |

| % | N/mm² | N/mm² | % | x 103 | HB | |||||

|

CuSn7ZnPb1 CuSn7ZnPb2 CuSn7ZnPb3 |

C93200 | JM1 | 1400 LG2 |

Cu 81-85 Sn 5-6 Zn 3-5 Pb 5-7 Ni 2 max Sb 3,3 max |

120 130 120 |

240 270 270 |

15 13 16 |

106 106 106 |

65 75 70 |

Medium-hard bearing alloy Good anti-friction properties Seawater resistant Applicable for light edge loads |

|

CuSn12Pb1 CuSn12Pb₂ |

C92500 | JM3 | 1400 PB2 |

Cu 84-88 Sn 11-13 Pb 1-2 Ni 2 max Sb 0,2 max P 0,2 max |

140 150 140 |

260 280 280 |

10 5 7 |

112 112 112 |

80 90 85 |

Material for high loads Seawater resistant |

|

CuAl10Ni₁ CuAl10Ni2 |

C95500 | JM7 | 1400 AB2 |

Cu 75 min Al 8,5-11 Ni 2-8,5 Fe 3,5-5,5 Mn 3,3 max |

270 300 300 |

600 700 800 |

12 13 13 |

122 122 122 |

140 160 160 |

Hard Ni-Al bronze Very high strength Excellent wear resistance Corrosion-resistant Seawater resistant High-temperature strength |

| CuZn25Al51 CuZn25Al52 CuZn25Al53 |

C86300 | JM18 | Cu 60-67 Al 3-7 Fe 1,5-4 Mn 2,5-5 Zn balance Ni 3 max |

450 480 480 |

750 750 750 |

88 |

115 115 115 |

200 220 220 |

Water resistant High-strength bearing alloy High fatigue resistance Not applicable for seawater applications |

|

| BEARING PROPERTIES* | ||||||||||

| Bronze Material |

Solid Lubricant |

p statc (N/mm² |

p dynamic (N/mm |

Friction dry |

Friction wet |

v[m/s]max. | max P. value N/mm²x m/s |

Temp.℃ max. |

Shaft Hardness HB[min] |

Shaft Finish R。(pm) |

| CuSn⁷ 7nPh | SL 4 SL 1 |

80

80 |

40 30 |

0.11-0.13

0.12-0.14 |

0.07 -0.12

Not available |

0.4

0.5 |

1.2

1.0 |

80 250 |

180 | 0.2-0.8 |

| CuSn12PB | SL 4 SL 1 |

100

100 |

70 25 |

0.11-0.13

0.12-0.14 |

0.07 -0.12

Not available |

0.4 0.15 |

2.0

1.6 |

80 250 |

180 | 0.2 -0.8 |

| CuAl10Ni | SL 4

SL 1 |

150

150 |

90 80 |

0.13-0.15

0.14-0.16 |

0.07 -0.12

Not available |

0.4

0.4 |

1.5

1.5 |

80 350 |

300 | 0.2-08 |

| CuZn25Al5 | SL 4

SL 1 |

150

150 |

100

90 |

0.13-0.15

0.14-0.16 |

0.07 -0.12

Not available |

0.4

0.15 |

1.5

1.0 |

80 300 |

300 | 0.2-0.8 |

Phosphor Bronze Enhanced with Graphite Lubricant

Phosphor bronze, a copper-based alloy, is distinguished by its superior mechanical properties, such as robust strength, excellent wear resistance, and notable fatigue resistance. Integrating graphite as a lubricant enriches this alloy with distinct qualities that render it highly effective for diverse industrial uses.

Key Features:

- High Load Capacity: The inherent strength and hardness of phosphor bronze enable it to support substantial loads effectively.

- Self-Lubrication: Infused with graphite, known for its natural lubricating features, the alloy ensures ongoing lubrication, thereby minimizing operational wear.

- Excellent Machinability: Phosphor bronze can be accurately machined, drilled, and shaped with minimal tool wear, facilitating the creation of components with precise dimensions and tolerances.

- Corrosion Resistance: The alloy is resilient against corrosion, making it apt for environments prone to harsh conditions.

Applications:

- Bushings and Bearings: Utilized in machinery as bushings, phosphor bronze with graphite lubricant provides low-friction surfaces essential for rotating shafts.

- Industrial Machinery: Its self-lubricating properties are ideal for sliding applications across various industrial equipment.

- Automotive Components: It finds applications in the automotive sector where durability and low maintenance are crucial.

- Rubber Machines and Light Industry: The alloy is well-suited for rubber machines and light industrial applications.

Advantages over Oil-Impregnated Bronze Bushings:

- Higher Density: Compared to oil-impregnated bronze bushings, phosphor bronze with graphite lubricant boasts a denser matrix, which translates to enhanced strength and extended service life.

- Suitability for Difficult Lubrication Conditions: This alloy is particularly advantageous in heavy load, low speed, reciprocating or oscillating conditions, and other scenarios where forming an oil film is challenging.

- Resistance to Water and Acid Corrosion: Unlike oil-impregnated bushings, phosphor bronze with graphite lubricant withstands water and acid corrosion effectively.

In essence, phosphor bronze with graphite lubricant is a multifaceted material that combines the resilience and wear resistance of phosphor bronze with the self-lubricating capabilities of graphite. This composition makes it ideal for numerous industrial applications where durability, minimal maintenance, and corrosion resistance are paramount.

Premium Phosphor Bronze Bushings – Excellent Wear Resistance!

Customizable Phosphor Bronze Bushings – Tailored to Your Needs! When purchasing phosphor bronze graphite bushings, factors such as nominal length, the intended working environment, required load capacity, and expected lifespan should be considered. It is also important to pay attention to the manufacturing quality and the reputation of the supplier to ensure reliable performance of the product.