Understanding 500SP CSC304 Oilless Bearings in Vacuum Disk Plates: A Deep Dive into Sizing and Lifespan Estimation

The advent of oilless bearings, particularly the 500SP CSC304, has been a game-changer in the realm of vacuum disk plates. These components, known for their high-load capacity and self-lubricating features, have become a staple in this industry. However, there are circumstances where these bearings may not perform up to their potential due to incorrect sizing, leading to issues such as over torque alarms. So, how can you ensure that the 500SP CSC304 bearing is correctly sized, designed, and its lifespan adequately estimated? Let’s delve deeper.

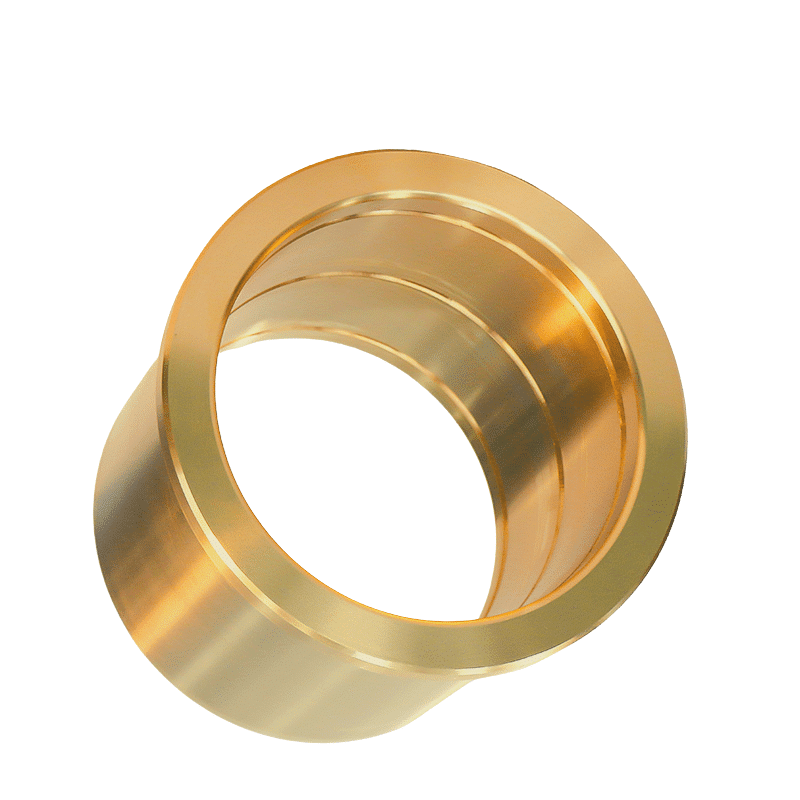

A Closer Look at the 500SP CSC304 Oilless Bearing

specializing in oilless bearing Plate

Before we dive into the nitty-gritty, let’s understand the product in question. The 500SP CSC304 Oilless Bearing is a self-lubricating bearing made from bronze and impregnated with graphite plugs. This composition allows it to function in oilless conditions, while the graphite plugs provide self-lubricating properties, reducing friction and ensuring smooth operations. The 500SP MoS2 graphite-plugged oilless bearing plates are a cutting-edge solution, offering superior performance, durability, and cost-effectiveness. Whether you’re replacing old components or designing new machinery, considering these advanced oilless bearing plates could prove to be a beneficial decision. If you’re unsure about the sizing or installation process, don’t hesitate to consult with a bearing specialist to ensure you get the most out of these remarkable components.

The Importance of Correct Sizing

In any application, correct sizing is paramount. For 500SP CSC304 bearings, this is no exception. A bearing that’s undersized will struggle under loads for which it isn’t designed. This could lead to performance issues like constant over torque alarms, premature wear, and reduced lifespan. Conversely, an oversized bearing may seem like a safe bet but could lead to unnecessary expenses without any added benefits.

To determine if the existing bearing is undersized, you should conduct a thorough examination of your application’s specific needs, including load, speed, and operational conditions. Comparing these factors with the bearing’s specifications should provide you with the answer.

Determining the Lifespan of Oilless Bearings: Factors and Calculations

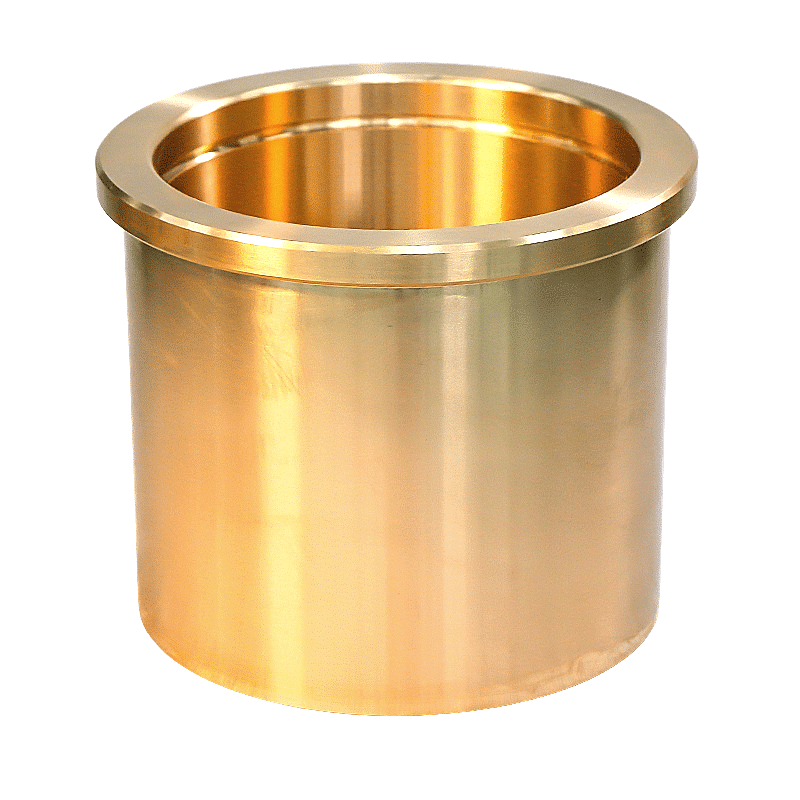

Oilless bearing materials

The lifespan of an oilless bearing, like any mechanical component, depends on several factors. These include the bearing’s material composition, the operational conditions, the load it bears, the speed of operation, and the maintenance routine, among others. Understanding these elements can help you more accurately predict an oilless bearing’s lifespan and ensure it functions optimally for as long as possible.

Key Factors Impacting Oilless Bearing Life

Material Composition: The material from which the oilless bearing is made plays a significant role in its durability. For example, bronze-based oilless bearings impregnated with graphite, like the 500SP MoS2, are known for their high load-bearing capacity and self-lubricating properties, which can significantly enhance their lifespan.

Operational Conditions: The environment in which the bearing operates can greatly impact its lifespan. Factors such as temperature, humidity, dust, and vibration levels can affect bearing wear and tear.

Load and Speed: The amount of load and speed at which the bearing operates also significantly influence its life. A bearing under heavy load or operating at high speeds may experience more rapid wear, reducing its overall lifespan.

Maintenance: Even though oilless bearings are largely maintenance-free due to their self-lubricating nature, they still require some level of inspection and care. Regular checks can help identify any early signs of wear or damage, prolonging the bearing’s life.

Calculating Oilless Bearing Life

The life of an oilless bearing can be estimated using calculations that consider load, speed, and operating conditions. A common method used is the L10 life calculation. The L10 life is the expected life that 90% of a group of identical bearings will achieve or exceed under the same operating conditions. This calculation provides a statistical reliability measure for the bearing life.

However, it’s important to note that this is only an estimate. The actual life of a bearing can vary due to real-world operating conditions and maintenance practices.

Increasing the Life of Oilless Bearings

There are several ways to extend the life of your oilless bearings. Selecting the right bearing for your specific application needs is crucial. Regular inspections and cleaning can also help prevent premature wear. Furthermore, ensuring that the bearing is installed correctly and operates within its specified load and speed limits is vital.

In conclusion, while predicting the exact lifespan of an oilless bearing is complex, understanding the factors that affect it can help you optimize its service life. As always, it’s best to consult with a bearing specialist when selecting and maintaining your bearings to ensure they perform optimally and last as long as possible.

The Role of Graphite-Plugged Oilless Thrust Washer Plates in Modern Machinery

Thrust washer plates play a crucial role in many types of machinery, reducing friction between rotating elements and increasing the efficiency and lifespan of the overall system. Among these, graphite-plugged oilless thrust washer plates stand out due to their exceptional properties and wide-ranging applications.

What is a Graphite-Plugged Oilless Thrust Washer Plate?

A graphite-plugged oilless thrust washer plate is a specialized type of thrust bearing that uses the unique properties of graphite to offer superior performance in a variety of applications. These plates are usually made from bronze or a similar metal and feature plugs or pockets of graphite distributed across the bearing surface. This design allows the bearing to self-lubricate during operation, reducing friction and wear without the need for additional oil or grease.

Benefits of Graphite-Plugged Oilless Thrust Washer Plates

Self-Lubricating: The graphite plugs provide constant, reliable lubrication, reducing friction and wear. This self-lubricating property eliminates the need for additional lubrication, making these washer plates maintenance-free.

High Load Capacity: Due to their robust metallic composition, these washer plates can handle high loads and perform well under harsh operating conditions.

Extended Service Life: The combination of self-lubrication and high load capacity leads to an extended service life, making these washer plates a cost-effective solution in the long run.

Wide Range of Applications: Due to their superior performance and durability, graphite-plugged oilless thrust washer plates are used in a wide variety of industries, including automotive, aerospace, agriculture, and industrial machinery.

Ensuring Proper Use and Installation

As with any component, correct sizing and installation are key to maximizing the performance and lifespan of graphite-plugged oilless thrust washer plates. It’s crucial to understand the operational conditions and load requirements of your specific application when selecting a washer plate.

Proper installation is equally important. Incorrectly installed washer plates may lead to uneven wear, overheating, or other operational issues, reducing the component’s effectiveness and lifespan. Therefore, it’s always a good idea to consult with a bearing specialist or refer to the manufacturer’s guidelines when installing these components.

In summary, graphite-plugged oilless thrust washer plates represent a significant advancement in bearing technology, offering high performance, durability, and cost-effectiveness. Whether you’re looking to upgrade existing machinery or design new equipment, these components should be at the top of your consideration list.

Unraveling the Materials Behind Oilless Thrust Washer Bearings: A Detailed Overview

Thrust washer bearings are critical components in many types of machinery, reducing friction between rotating parts and enhancing overall system efficiency. Among them, oilless thrust washer bearings stand out for their unique self-lubricating property and reduced maintenance requirements. The selection of materials used in the manufacturing of these oilless bearings is crucial to their performance. Let’s delve into the different types of materials used in the production of oilless thrust washer bearings.

Bronze

Bronze, an alloy primarily composed of copper and tin, is one of the most common materials used in the manufacturing of oilless thrust washer bearings. This material is highly appreciated for its durability, strength, and resistance to wear and corrosion. Bronze-based oilless thrust washer bearings are especially suitable for applications requiring high load-bearing capacity.

Graphite

Graphite is a solid lubricant that is commonly incorporated into oilless thrust washer bearings. When embedded in the base material (typically bronze or another metal), graphite offers excellent self-lubrication properties. This self-lubricating feature reduces friction and wear, even under high-load conditions, extending the bearing’s lifespan and eliminating the need for additional lubrication.

Molybdenum Disulfide (MoS2)

MoS2 is another solid lubricant often used in oilless thrust washer bearings. It shares similar properties to graphite, including a low friction coefficient and excellent self-lubricating characteristics. Sometimes, MoS2 is used alongside graphite to further enhance the bearing’s performance.

Steel

In some cases, steel may be used as the base material for oilless thrust washer bearings, particularly in applications where higher strength or hardness is required. When used, the steel is typically combined with a solid lubricant like graphite or MoS2 to ensure self-lubrication.

PTFE (Polytetrafluoroethylene)

PTFE, or Polytetrafluoroethylene, is a type of polymer that’s used in some oilless thrust washer bearings. It offers excellent friction-reducing properties and chemical resistance. PTFE-based bearings are commonly used in applications where low friction is crucial, or where the operating environment involves exposure to corrosive substances.

Composite Materials

Composite materials combining two or more of the materials mentioned above are also frequently used in oilless thrust washer bearings. These composites aim to leverage the beneficial properties of each material, creating a product that offers excellent strength, durability, and self-lubricating characteristics.

In summary, the choice of materials plays a vital role in the performance and longevity of oilless thrust washer bearings. By understanding the properties and benefits of each material, you can make an informed decision when selecting the right bearing for your specific application. Always consider the operational conditions, load requirements, and maintenance expectations when choosing a bearing material.