Leaded Bronzes Bearings Bshing

About us

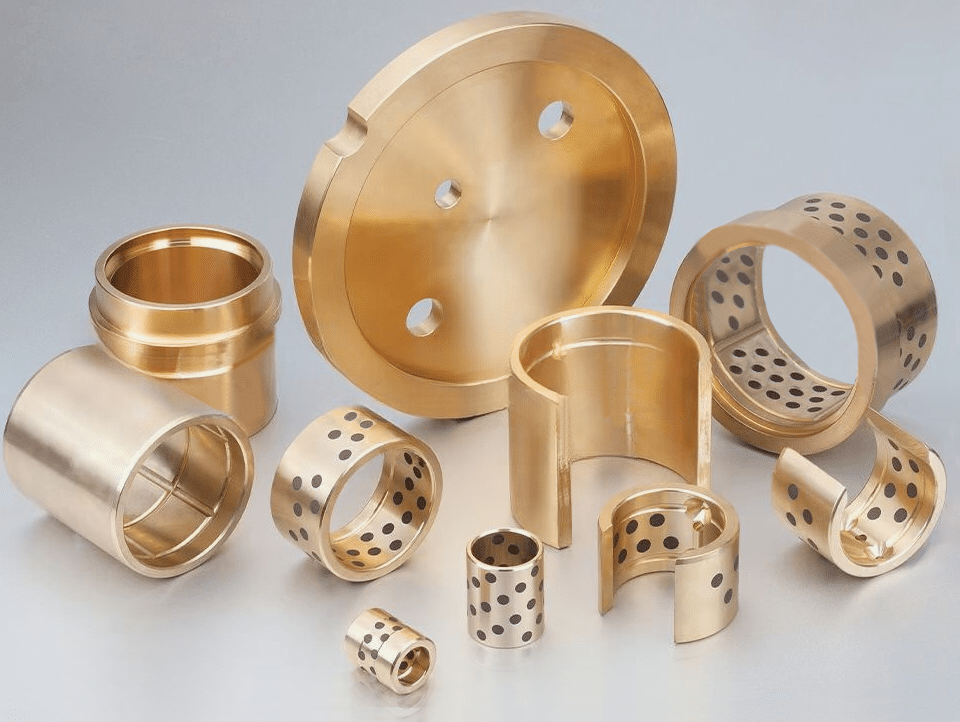

Custom-Made Leaded bronzes Bearings

Leaded bronzes are known for their excellent corrosion resistance and high operational performance. Our selection includes the most popular leaded bronzes, and we also offer custom alloys tailored to client specifications.

Type Of Bearing

Understanding CuSn10Pb10: The Benefits of Leaded Bronzes in Bearing Applications

When it comes to choosing materials for bearings, engineers and manufacturers often turn to leaded bronzes for their superior performance and reliability. Among the various leaded bronzes, CuSn10Pb10 stands out as a particularly effective alloy for bearing applications. In this post, we’ll explore the properties, benefits, and common uses of CuSn10Pb10 leaded bronze bearings.

What is CuSn10Pb10?

CuSn10Pb10 is a high-grade leaded bronze alloy, primarily composed of copper (Cu), tin (Sn), and lead (Pb). The designation “CuSn10Pb10” indicates that the alloy typically contains about 10% tin and 10% lead, with the remainder being mostly copper. This composition offers an excellent balance of durability, machinability, and resistance to wear and corrosion, making it a preferred material for various bearing applications.

Custom Plain Bearing, CuSn10Pb10 leaded bronze bearings

CuSn10Pb10 leaded bronze bearings offer a robust solution for demanding bearing applications. Their unique combination of load capacity, machinability, conformability, and corrosion resistance makes them a top choice for industries requiring high-performance bearings. As manufacturers continue to seek materials that provide longevity and reliability, CuSn10Pb10 remains a go-to alloy in the world of advanced engineering materials.

ASTM B505 93700: This is a standard specification for copper and copper alloy bearing materials. The ASTM B505 covers a range of materials, and 93700 refers to a specific grade within this standard.

BS 1400 LB2: This is a British Standard for bearing bronzes. LB2 is a designation for a particular grade of bearing bronze, which corresponds to a specific composition and set of properties.

Custom Parts Services and Prototyping!

leaded bronze bearings, Phosphor And Aluminium Bronze Bearing, Search Our Material Alloy

Lead Bronze, Cast Bronze Bushings Bearings- Alloy Selection

Lead bronze bearings are a type of bearing material made from an alloy primarily composed of copper, tin, and lead. This combination provides several advantageous properties that make lead bronze particularly suitable for various industrial applications. Lead bronze bearings are a robust choice for applications requiring durability, low friction, and corrosion resistance. Their unique properties make them a preferred option in demanding environments such as marine settings and heavy industrial machinery.

Applications: Lead bronze bearings are widely used in various industries due to their beneficial properties:

Marine Applications: Their corrosion resistance makes them suitable for components exposed to seawater 23.

Heavy Machinery: Commonly found in earthmoving equipment and mining machinery due to their strength and wear resistance 23.

Automotive and Aerospace: Used in bushings and bearings where lightweight materials with high performance are required

CuSn5Pb20

| Chemical Composition mass/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Al | Fe | Mn | Ni | Pb | Si | P | Zn |

| 70.0-78.0 | 4.0-6.0 | – | 0.25 | 0.2 | 0.5-2.5 | 18.0-23.0 | 0.01 | 0.1 | 2 |

|

Mechanical properties |

|||

|---|---|---|---|

| Tensile strength Mpa(Min) | Yield strength MPa(Min) | Elongation % | Brinell hardness(HB) |

| 180 | 90 | 7 | 50 |

C94300, HIGH.LFAD.TIN BRONZEUNS..C94300

C94300 high-leaded tin bronze alloys are perfectly suited for bearing applications that may experience a breakdown of the lubrication boundary.

| Chemical Composition mass/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Al | Fe | Mn | Ni | Pb | Si | P | Zn |

| 67.0-72.0 | 4.5-6.5 | 0.01 | 0.15 | – | 1 | 23.0-27.0 | 0.01 | 1.5 | 0.8 |

| Mechanical properties | |||

|---|---|---|---|

| Tensile strength Mpa(Min) | Yield strength MPa(Min) | Elongation % | Brinell hardness(HB) |

| 145 | 103 | 7 | 48 |

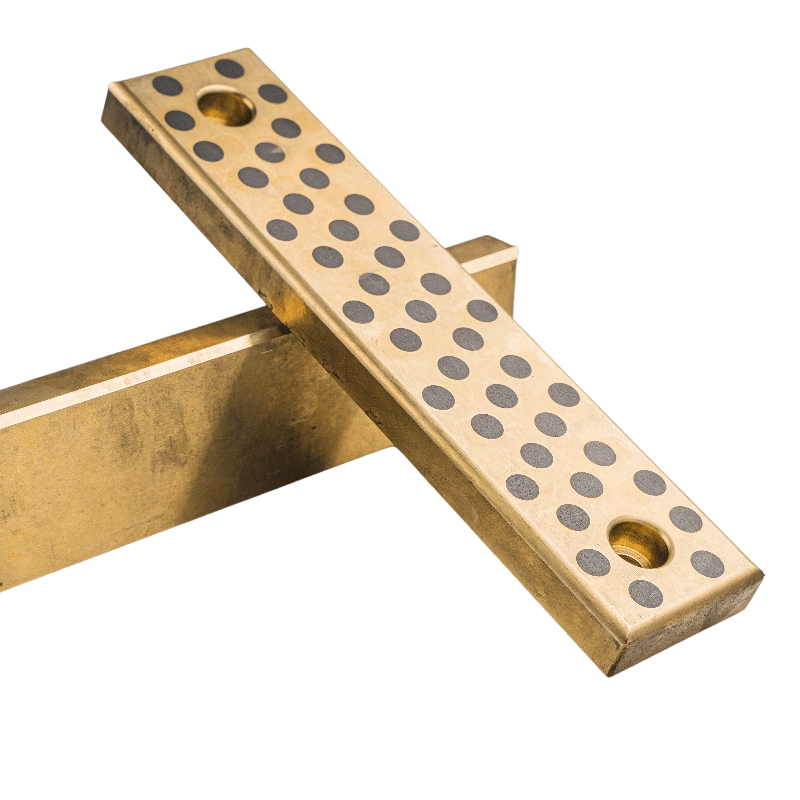

Design Custom Parts & CuSn10Pb10 bronze Bearing and bimetallic Bearing

CuSn10Pb10 bronze, also known as leaded tin bronze, is a type of copper alloy that includes 10% tin (Sn) and 10% lead (Pb) by weight. This specific composition provides the alloy with a range of beneficial properties that make it suitable for certain applications, particularly in the manufacturing of bearings.

C94300 Alloy, C943 High leaded tin bronze bushing bearings

C94300 is a high-leaded tin bronze alloy, commonly known as high leaded tin bronze. It is primarily utilized in applications that demand excellent wear resistance and superior machinability, especially in bearings and bushings.

Composition and Properties: C94300’s chemical composition typically includes:

- Copper (Cu): 67.00% – 72.00%

- Lead (Pb): 23.00% – 27.00%

- Tin (Sn): 4.50% – 6.00%

- Zinc (Zn): up to 0.80%

- Iron (Fe): up to 0.15%

- Phosphorus (P): up to 1.50%

- Nickel (Ni): up to 1.00% The high lead content of the alloy enhances its machinability and lubricity, making it ideal for applications susceptible to boundary lubrication failure due to contaminants such as dirt.

Mechanical Properties:

- Tensile Strength: Minimum of 21 ksi (145 MPa)

- Yield Strength: Minimum of 15 ksi (103 MPa)

- Elongation: Minimum of 7%

- Brinell Hardness: Typically around 45 BHN These properties render it suitable for environments with high loads and wear, including bearings and bushings in light to medium pressure applications.

Applications: C94300 is extensively used in various industrial applications due to its beneficial characteristics:

- High-speed bearings

- Bushings

- Gears

- Centrifuge bushings

- Hydraulic components

- Pump and valve parts

- Steam fittings Its resilience in harsh conditions while maintaining structural integrity makes it a preferred choice in many engineering sectors.

Fabrication and Machinability: The alloy boasts a machinability rating of 80, indicating ease of machining using standard practices. However, welding methods like oxyacetylene or gas shielded arc welding are not recommended due to its composition, which can yield suboptimal results.

In conclusion, C94300 high-leaded tin bronze is a valuable material for bearing and bushing applications, noted for its exceptional wear resistance and machinability, making it a favored material across various industrial sectors.

Properties and Characteristics

1. High Load Capacity: CuSn10Pb10 leaded bronze bearings are renowned for their ability to withstand high loads. The presence of tin enhances the strength and hardness of the alloy, while lead acts as a lubricant, reducing friction and wear under heavy loads.

2. Excellent Machinability: The machinability of CuSn10Pb10 is exceptional due to the softness imparted by the lead content. This characteristic makes it easy to shape and machine the bearings into precise dimensions required for specific applications.

3. Good Conformability: CuSn10Pb10 bearings can adjust to minor misalignments in the assembly process, a trait that is crucial for maintaining performance in dynamic load environments.

4. Corrosion Resistance: The copper in the alloy provides significant resistance to corrosion, particularly against water and brine, extending the life of bearings in harsh environments.

5. Compatibility with Lubricants: This alloy works well with various lubricants, enhancing its performance and durability. Proper lubrication further reduces the coefficient of friction and wear rate.

Applications of CuSn10Pb10 Bearings

CuSn10Pb10 leaded bronze bearings are used in a variety of applications, reflecting their versatile properties:

- Marine Industry: Due to its excellent corrosion resistance, CuSn10Pb10 is ideal for marine applications, including ship propeller shafts and pump bearings.

- Heavy Machinery: The high load capacity makes it suitable for construction and mining equipment where bearings are subjected to extreme pressures.

- Automotive Industry: Components like connecting rod bearings and bushings benefit from the durability and wear resistance of CuSn10Pb10.

- General Engineering: This alloy is also used in general engineering applications, including electric motors and turbines, where high performance and reliability are required.

Here are some key characteristics and uses of CuSn10Pb10 bronze:

-

Machinability: The alloy is known for its excellent machinability, which means it can be easily shaped and machined into various components, including intricate designs.

-

Self-Lubricating Properties: The lead in the alloy helps to improve its self-lubricating properties. This characteristic is particularly useful in applications where bearings are required to operate with minimal or no external lubrication.

-

Wear Resistance: The combination of copper, tin, and lead provides the alloy with good wear resistance, which is crucial for components that are subject to friction and need to maintain their shape and function over time.

-

Corrosion Resistance: While not as corrosion-resistant as some other bronze alloys, CuSn10Pb10 still offers a reasonable level of resistance to corrosion, making it suitable for use in various environments.

-

Applications: Due to its properties, CuSn10Pb10 bronze is often used in the production of bearings, bushings, gears, and other mechanical components that require good wear resistance and low friction.

Cast Copper Alloy CuSn10Pb10-C: A Leaded Tin Bronze Overview

Main Components of CuSn10Pb10:

- Tin (Sn): 9.0% to 11.0%

- Lead (Pb): 8.0% to 11.0%

- Copper (Cu): Remainder

Performance Characteristics of CuSn10Pb10-C Alloy:

CuSn10Pb10-C is a cast copper alloy renowned for its excellent lubricity, wear resistance, and corrosion resistance. It is ideally suited for use as a bimetallic casting material. This alloy is particularly effective in applications where there are high surface pressures and lateral forces, such as in sliding bearings used in rolling, vehicle bearings, and parts subject to impact with peak loads of 60 MPa, as well as bimetallic bearings for internal combustion engines with peak stress levels up to 100 MPa. Additionally, it is used in piston pin bushings, friction plates, and other components.

Physical Properties of CuSn10Pb10-C Alloy:

CuSn10Pb10-C, a widely used leaded brass alloy, is characterized by its excellent machinability and good mechanical properties. It can withstand both cold and hot pressure processing, is easy to weld, and has good brazing capabilities. The alloy also demonstrates good stability against corrosion, although it is prone to corrosion cracking. Main applications include air conditioning valves and hardware machinery.