Discovering the Advantages of Oilless Bushes: The Future of Friction Management

Experience the Strength of Self-lubricating Bearings

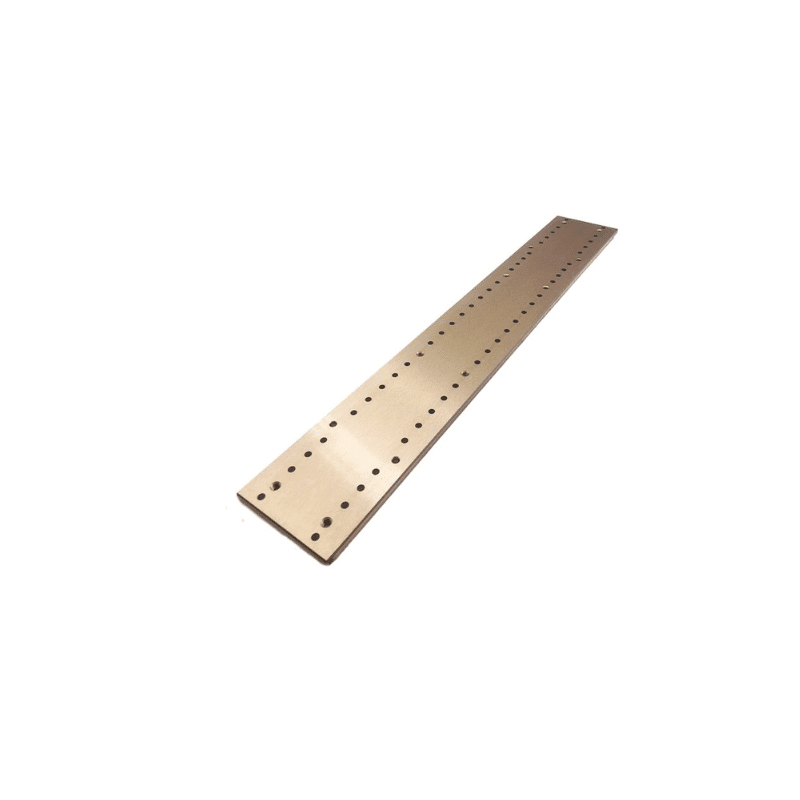

Oilless Bushes, Maintenance free bearing and guide bushes, thin walled, bronze with solid lubricant, Custom Bushings

In the realm of industrial machinery and automotive applications, the quest for reliable, efficient, and maintenance-free components is unending. One significant breakthrough in this pursuit is the development of oilless bushes, especially those made from leaded tin bronze alloys such as Alloy C93200. These components are not just an advancement in material science but a revolution in reducing operational downtimes and maintenance costs.

What Are Oilless Bushes? Leaded tin bronze alloys!

Oilless bushes are high-performance bearings designed to operate without the need for additional lubrication. These components are embedded with solid lubricants within their structure, which consistently release small amounts of lubricant during operation. This unique feature makes them maintenance-free, offering a substantial advantage over traditional bearings that require regular lubrication.

Leaded Tin Bronze Alloys: The Backbone of Oilless Bushes

Our oilless bushes are crafted from special brass, specifically SO#50SP2, which is known for its durability and corrosion resistance. The bushes are thin-walled and incorporate solid lubricants, eliminating the need for periodic greasing. This design innovation ensures that the bushes are both lightweight and robust, ideal for high-load applications where reducing downtime is essential.

These bushings provide substantial advantages, such as lower maintenance costs and simpler machinery design by removing the need for lubrication systems.

Applications of Alloy C93200 Bronze Bearings, lead and tin Alloy Material Bushing

These bearings are used in a wide range of applications. From heavy machinery in construction and mining industries to critical components in automotive assemblies, C93200 bearings provide reliable performance under challenging conditions. Their ability to function optimally without manual lubrication or regular maintenance makes them particularly valuable in hard-to-access locations or in applications where maintenance would be disruptive.

lead and tin Alloy, Self-Lubricating and Maintenance-Free Features

The self-lubricating feature of these oilless bushes is achieved by incorporating solid lubricants such as graphite or molybdenum disulfide within the cast bronze matrix. These solid lubricants are thermally stable and have a low coefficient of friction, which significantly reduces wear and tear. As the bearing operates, the lubricant is released slowly, forming a lubricating film between the bearing and the shaft, which minimizes direct metal-to-metal contact.

Oilless bushes made from leaded tin bronze alloys like Alloy C93200 represents a significant leap forward in bearing technology. With their exceptional durability, self-lubricating properties, and maintenance-free operation, these bearings are setting new standards in numerous industrial and automotive applications. As industries continue to seek more reliable and efficient solutions, the role of these advanced materials becomes increasingly crucial. Whether you’re involved in manufacturing, automotive, or any field requiring dependable mechanical components, considering oilless bushes could be a game-changing decision.

Environmental and Economic Benefits

The maintenance-free nature of oilless bushes not only reduces the need for lubricant disposal but also cuts down on the environmental impact associated with regular maintenance activities. This aspect is particularly important in industries looking to enhance their sustainability practices. Moreover, the reduction in downtime and the extension of component lifespans translate into significant cost savings over the lifetime of the machinery.

Custom Online CNC Machining Services

Get instant quotes for custom metal and self-lubricating bronze machined parts with our Online CNC Machining Service. Quickly produce prototypes and production parts in just a few days!