How to determine the thickness of the thrust washer thrust bearing?

The thickness of a thrust washer or thrust bearing depends on several factors, including the nature of the load, the speed of operation, the material of the components, and the working conditions.

Durable and Versatile

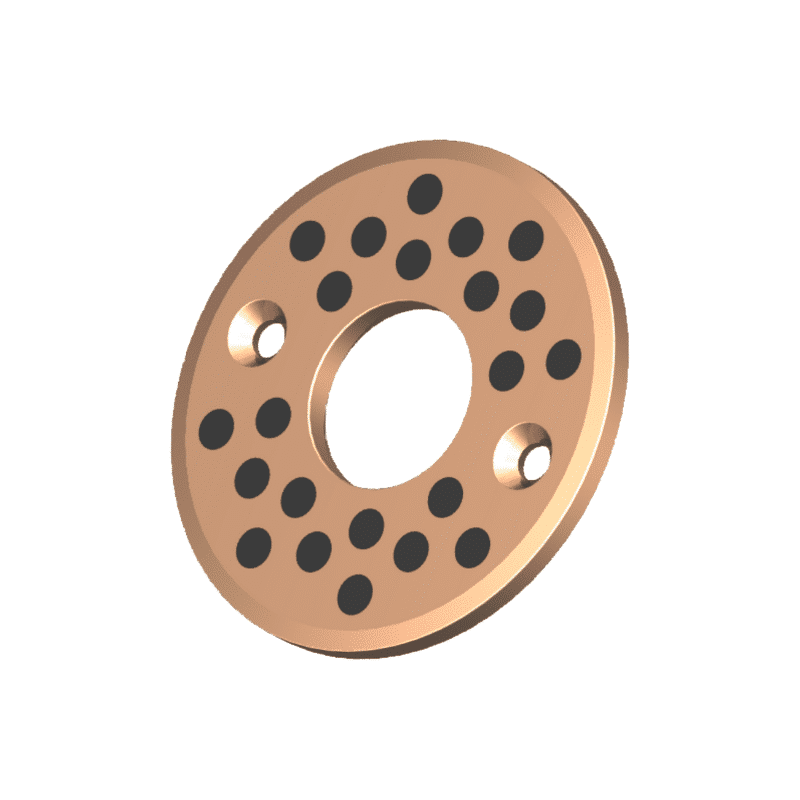

Self-lubricating thrust washers are a type of thrust bearing that includes a lubricating material, reducing friction and wear without the need for additional lubrication. The material used is often a type of plastic, bronze, or composite that can release lubricant under operation conditions.

Noise Reduction

The thickness of a self-lubricating thrust washer will largely depend on similar factors as outlined in the previous response: the load it will bear, the speed of operation, and the safety factors involved.

24/7 Support

Bearing Life: Estimate the bearing life. The thickness of the washer may need to account for the wear that will occur over its expected life. Consult with an Engineer: It’s crucial to involve an engineer in the process to ensure that the calculations are correct and the product will be safe and effective.

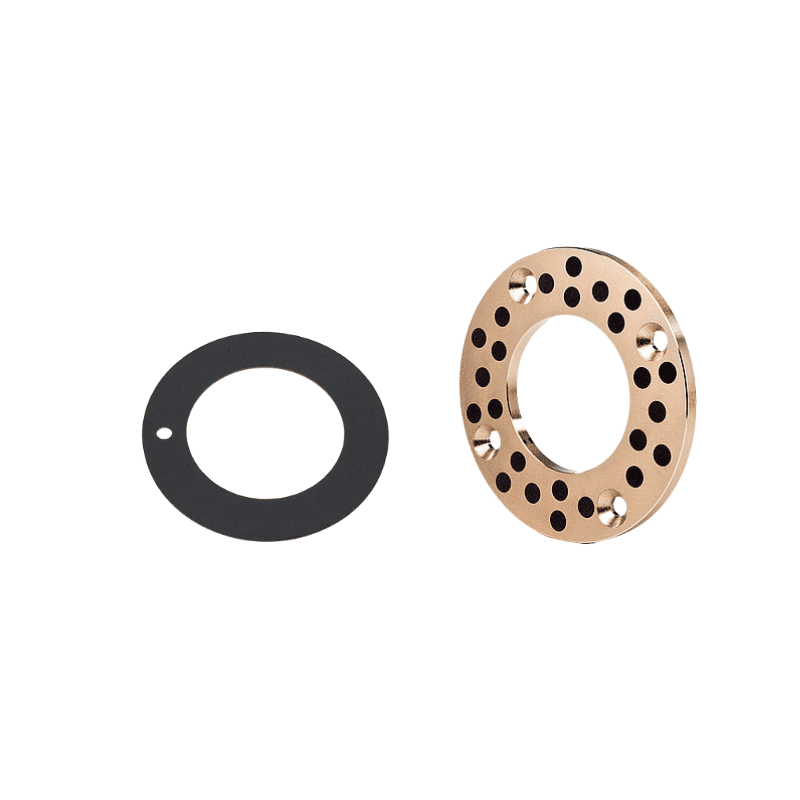

self-lubricating thrust washer

If you’re looking to manufacture custom size self-lubricating thrust washers, you’ll need to consider the same factors as previously mentioned (load, material properties, safety factor, and wear). You also need to know the inside and outside diameters for the custom size. Material Selection: Choose a material that can support the load and is suitable for your application. For self-lubricating washers, materials such as bronze embedded with graphite, PTFE Polytetrafluoroethylene , or other suitable composite materials are commonly used.

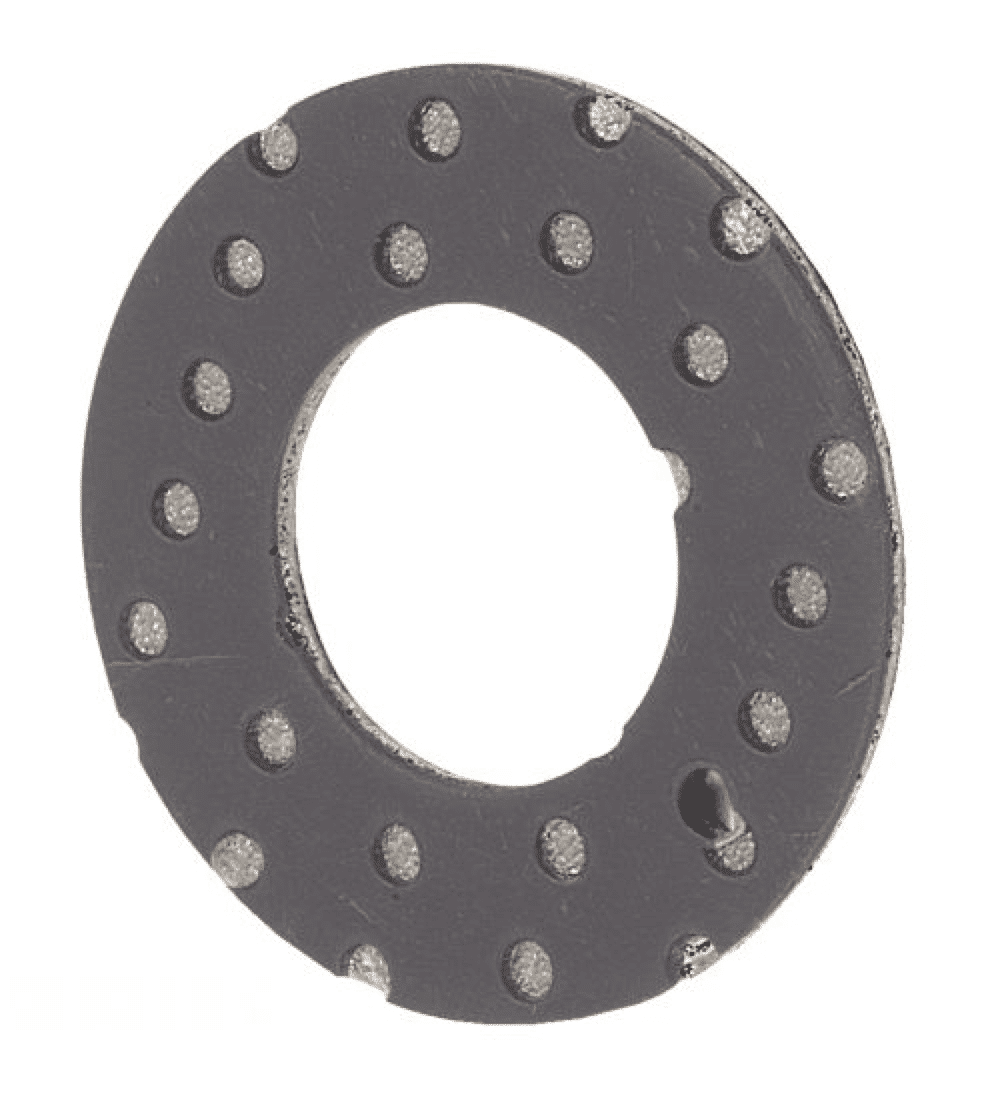

Solid bronze graphite thrust washers

Solid bronze graphite thrust washers are a type of self-lubricating washer. They incorporate graphite plugs into a bronze matrix, which provide lubrication as the washer is used.

Guidance on gasket thickness, and how to select the proper gasket thickness for a given application is a question that often arises and is difficult to answer simply. Therefore, we encourage users to talk to their application engineers when they are unable to determine how to select a thickness.

As gasket application engineers, we recommend the use of thinner thrust washer bearing whenever possible. However, there are certain situations where thicker shims are required and recommended, which we will first explain. Metal self-lubricating graphite thrust washer bearing of 3.0mm, 5.00mm, 7.00mm, 8.00mm and 10.00mm thickness are recommended for some common applications.

One of the reasons thicker thrust washer bearing are used for low pressure large diameter flanges is that these flanges do not have enough bolts, mainly because the internal pressure is not high, so the design does not require a large number of bolts. Limited bolts means limited compression of the gasket, and thin flanges mean that the flange will deform when the bolts are tightened, and the gap between the bolts will compress very little or not at all. A thin gasket does not have enough compression to compensate for these insufficiently flat flanges.

Bearring Bushing

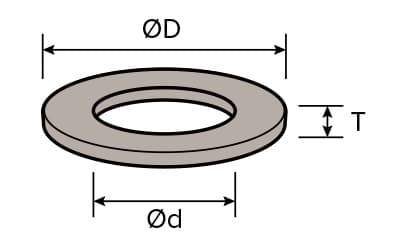

Thrust Washer Size and Design

Apply a Safety Factor: Incorporate a safety factor into the calculation. This ensures the thrust washer can handle higher than expected loads, providing a safety buffer. The safety factor typically ranges from 1.5 to 3, depending on the criticality of the application and the potential consequences of failure.

If you look at our recommended installation stresses, we require more stress (load) as the gasket thickness increases. But where the load is very low, such as in flanges, it is rarely possible to provide the adequate flange thickness needed to keep the flange flat and seal the thin gasket. In most cases, these flanges have low internal pressures, so there is no high risk of blowout for thicker thrust washer bearing.

First, such a large bolt spacing would result in a very small compression load between the two bolts. A thin gasket does not fit well in a bent flange.

Second, in the absence of internal pressure, there is no disadvantage or drawback to using a thicker gasket because the gasket will not be blown out.

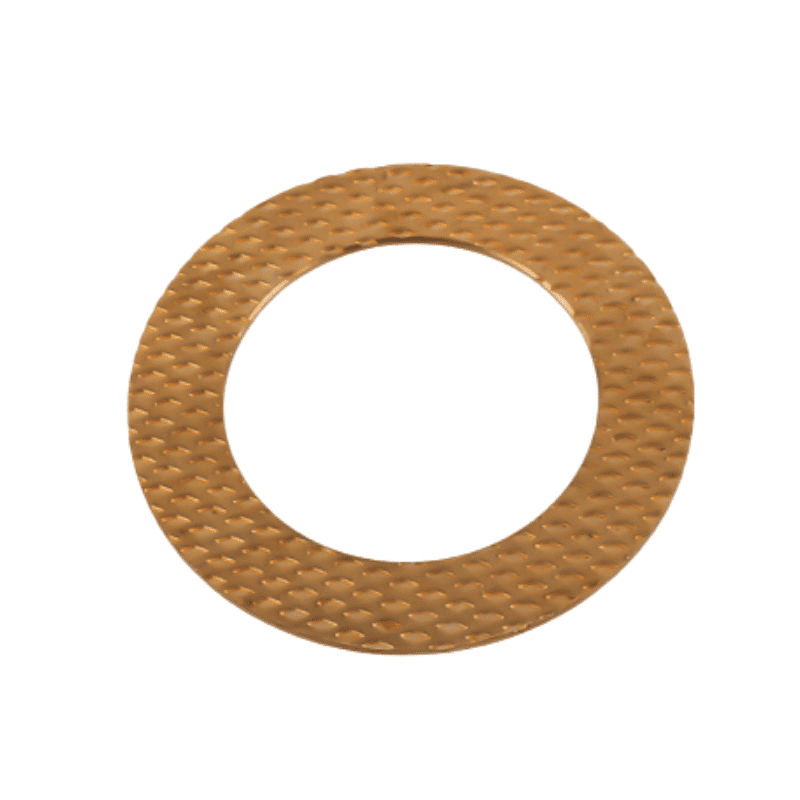

Cast Bronze Washer

Bronze graphite washers

Additional Thickness for Wear: Bronze graphite washers will wear away over time as they release their lubricating graphite. You may need to add extra thickness to account for this wear over the expected lifetime of the washer.

However, for flanges designed for higher pressures, the situation is quite different. These flanges are much thicker, which means that when the bolts are tightened, they can usually remain flat to 0.1 mm, in which case the recommendation “the thinner the better” is appropriate. The advantages of thin self-lubricating composite shims are many:

1. Higher resistance to blow-out due to smaller surface area in contact with the internal pressure.

2. The leakage rate is also lower due to the smaller surface area in contact with the internal pressure.

3. Better torque retention of the fastener due to the lower creep relaxation characteristics of the thinner shim.

4. The shims themselves are also less costly.

solid bronze thrust washer bearing

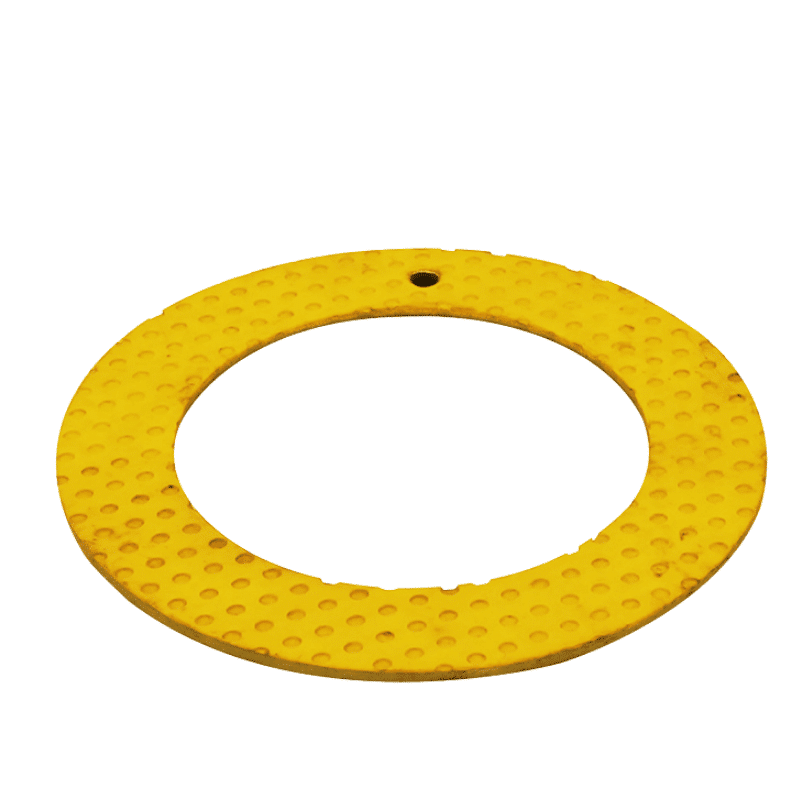

Thicker thrust washer bearing

Thicker thrust washer bearing will be more suitable for severely damaged or warped flanges. This is because the ability of a gasket to fill an uneven flange is based on the amount of gasket compression at a given load, and the compression at a given load is expressed as a percentage of the gasket’s original thickness. Thicker thrust washer bearing gaskets have a larger original thickness and actually have more compression.

The advantages of using thicker thrust washer bearing gaskets can be misleading, and in any case, may lead to more problems in the future when thicker thrust washer bearing are used to seal more defective flanges. Thicker thrust washer bearing result in higher creep relaxation, and higher creep relaxation means that the user may need to re-tighten the bolts to maintain sufficient compression load on the gasket throughout the life of the flange connection. Thicker thrust washer bearing create greater blow-out forces, which are exacerbated by the increased surface area of the part of the gasket in contact with the internal pressure, which actually creates a greater total force trying to push the gasket out of the flange, i.e. blow-out force. (The unit of internal pressure is Mpa, and a thicker gasket is “taller” in the direction of the internal pressure, which means more surface area. Multiplying the internal pressure in Mpa by the larger area gives a larger force.)

Finally, since all gasket materials are permeable to some degree, the medium can penetrate the gasket body. Thicker thrust washer bearing create larger permeation channels and therefore higher leakage rates. It is important to note here that the reverse of this can occur as well. If the gasket is too thin to compensate for the flaws in the flange, the media will leak instead of through the gasket body, and the leak rate may be higher than with thicker thrust washer bearing.

Expert Bushings and Support:

Thrust Washer Manufacturer

Flanges that require thicker thrust washer bearing gaskets can create problems beyond the gasket manufacturer’s control. The best solution is to use or design flanges that can provide higher compression loads, keep the flange surface in good condition, and use gaskets thrust washer bearing that are 1.5mm or even 1.00mm thick.

The type of gasket material and allowable compression load also affects the gasket thickness for sealing a specific flange connection. Under ASTM F36 standard testing, a gasket with a higher compression rate would not require the same gasket degree thickness compared to a gasket with a lower compression rate because a more easily compressed gasket would not need to be as thick to accommodate the flange’s defects.

We are always asked to seal defective flanges. This can usually be accomplished by carefully considering all variables of the application when selecting the type and thickness of gasket material. However, sometimes a flange or bolt defect is not completely compensated by a gasket. Likewise, proper installation of the flange connection system is critical.

Here is a general way to determine thickness:

- Load Calculation: Determine the axial load the bearing will need to support.

- Washer Material Properties: Consider the properties of the washer material. Different self-lubricating materials will have different strength and wear characteristics.

- Safety Factor: Incorporate a safety factor to ensure the washer can handle unexpected loads or stresses.

- Manufacturer’s Specifications: Consult with the manufacturer’s specifications for recommended thickness for a particular load and speed of operation.

- Additional Thickness for Wear: Self-lubricating washers wear away as they release their lubricating material. You may need to add extra thickness to account for this wear over the lifetime of the washer.

- Calculations: Use the determined parameters (load, material properties, safety factor, speed of operation) to perform a stress analysis. This analysis will help you determine an appropriate thickness.

Again, for the most accurate and safe bearing thickness for your specific application, it is strongly recommended to consult with an engineer or washer manufacturer.