Guide Bearings and Bushings

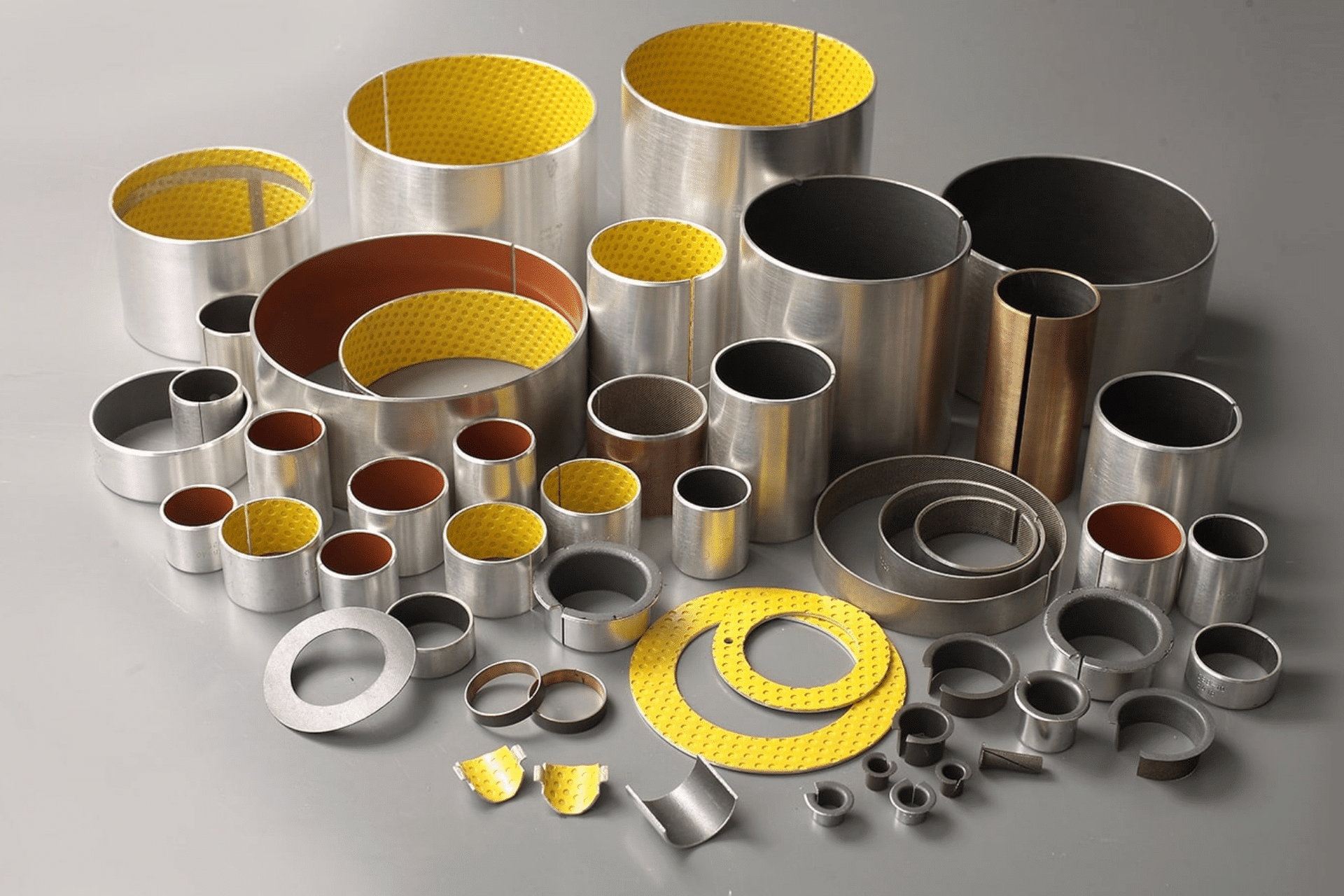

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Guide Bearings and Bushings

“Bushing or Bearing: Which One Is Right for Your Machine? Learn the Key Differences Now!”

Guide Bearings and Bushings, Efficient Production & Fast Delivery! Bushing and bearing are often used interchangeably, but there is a difference, here we explain what they are. Need assistance with creating the perfect bearing bushing finish for your job? Get started today. Quality design and supply of Plain Bearings and Engineering self-lubricating bearing bushing materials!

Bushing or Bearing, what’s the difference? – Request a free quote

Self-lubricating Bearings –

A Guide to Bearings & Bushings

With no moving parts, plain bearings are simple. They are usually cylindrical, although exact designs depend on movement. Read on for more technical details Maintenance Savings. We’re customizing bearings.

Plain and Specialty Bearings

Maintenance Free Plain Bearings, Standard and Custom Bearing

Self-lubricating and maintenance-free bearings made from high-performance oilless bearing material offers a range of specialized properties for applications. The new self-lubricating steel bushing bearings are ideal for earth moving machinery, drilling machinery, industrial equipment and more. If your business depends on the slide bearings, bronzelube.com the right choice. Contact us today…

Product Quality Index

Energy Generation

Bushing Design and Bearing Prototype Build

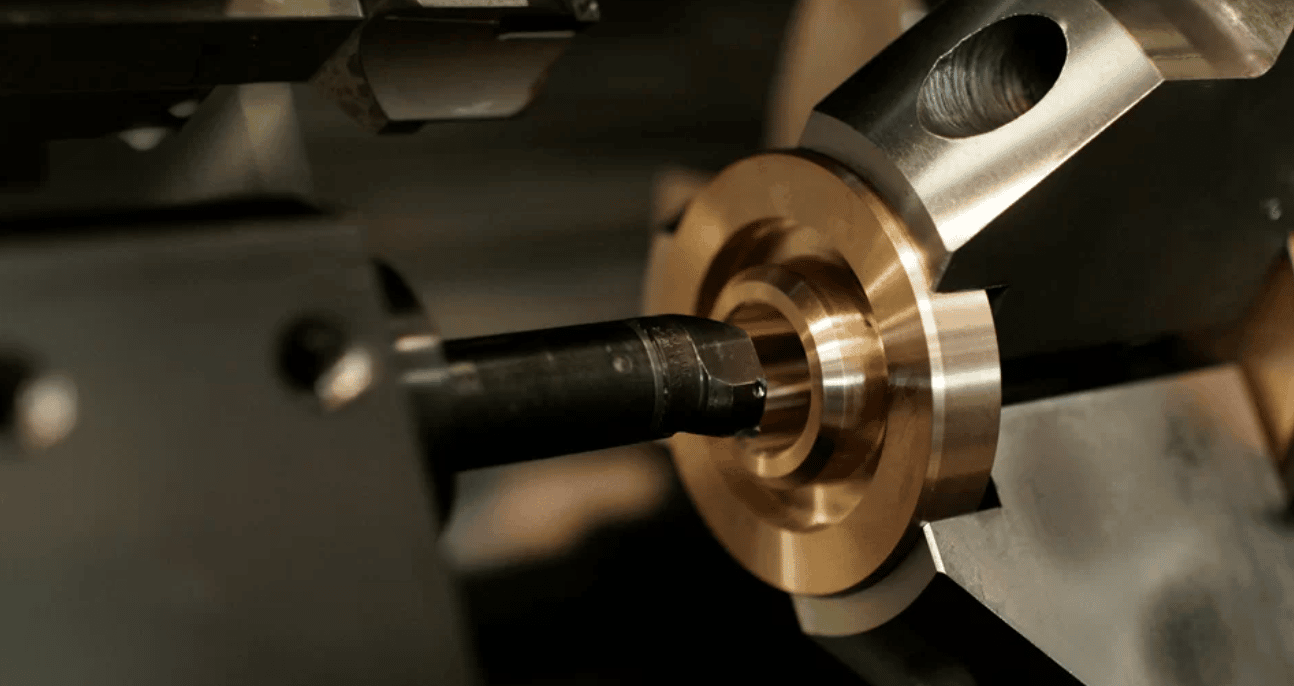

Mechanical bearing bushings come with their own set of advantages and disadvantages, and we are here to help you navigate to the most effective solution for your specific needs. Our approach to solving manufacturing challenges is genuine and thorough, starting from the core of the problem. We specialize in machining strategies tailored for materials commonly used by medical device OEMs, including copper alloys and stainless steel. Our expertise extends from deep hole drilling to oil groove machining, ensuring burr-free machining of copper alloy bearings. Additionally, we are at the forefront of innovation with self-lubricating bearing bushing coatings that transform component performance. Our expertise goes beyond just bearings – we enhance system performance with advanced polymer coatings, helping design engineers to refine and optimize their applications.

Self-lubricating Bronze Bushing For Long Life

Trusted & reliable bearing bushing supplier, All about Plain Bearings – Design World, Maintenance-free plain bearings considerably reduce lubricant and maintenance costs as they do not require any oil or grease, Plain and sleeve bearings use sliding motion instead of rolling elements to carry heavy loads. Plain bearing bushings supplier. At bronzelube,com we collaborate with customers to engineer hydrodynamic fluid film bearings for optimized performance in individual operating…

We manufacturing bearing bushing tailored to your individual needs.

Bushing & Bearing. Factory Price, Quick Response, Reliable Service.

PTFE (polytetrafluoroethylene) is a low friction self-lubricating plastic. PTFE is a popular engineering polymer in that it has a low coefficient of friction, maintains constant torque across a range of tolerances, and (a big plus for the automotive industry where rattles are deadly) has noise-damping properties. With its resistance to high temperatures, corrosive chemicals, and water, PTFE can be used in a huge range of applications. It’s an excellent bushing material for high-performance bearings – but, unlike other plastic bearings, it’s not always a low-cost option. It can also be difficult to join and isn’t suitable for environments with high radiation levels.

Fabric-woven PTFE Plain Bearings, PTFE composite bushing

3 layer Bearings are made from PTFE, which is reinforced with metal to manage heavy-duty applications and to ensure long and reliable service life. We recommend specifying ptfe frbric for sleeve bearings for its superior load-bearing properties. If you like the noise-dampening and self-lubricating properties of plastic, but require a heavy-duty component, this is the perfect solution.

To find out more, take a look at our range of fabric-woven PTFE Plain Bearings.

It is an innovative enterprise specializing in the research, manufacture, sales and service of self-lubricating copper sleeves and products. The products are now widely used in new energy such as machinery, instrumentation, electricity, petroleum, chemical industry, automobiles, aviation, environmental protection, ships and photovoltaics. field.

The company’s business scope includes mechanical copper straight sleeves, flange graphite copper sleeves; thrust washers, sliders, graphite guide sleeves for molds; and other special self-lubricating sliding bearing materials.The business philosophy of creating value for customers, innovating with the development of science and technology, creating high-quality products with strength, and serving customers with integrity” has won the trust and support of the majority of users. We sincerely welcome enterprises and experts at home and abroad to visit the company, guide, and carry out technical cooperation. And exchange, work together to create a brilliant future.

Bushing or Bearing, what’s the difference?

Extensive experience in their engineering department allows slide bearings to work closely with end-users and OEMs in order to offer the high quality bearing bushing.

Choosing the right bushing bearing – Buying Guides: Offering an unparalleled range of bearings and sliding rolled parts for all applications in all industries. Whether you are working on a large, complex project requiring many different sizes of bearings or a small project requiring standard size bearings, we have the right solution for you. We are able to provide quotations for both metric and inch sizes and have the ability to produce special, one-off sizes specifically for your particular project. The main types of bearing! “There is a difference between a bearing and a bushing. The bushing is actually just a type of sliding bearing. The main function of the bearing is to support the mechanical rotating body, reduce the friction coefficient during its movement, and ensure its rotation accuracy. The bushing is sleeved on the rotating shaft. The cylindrical mechanical part is an integral part of the sliding bearing. The shaft sleeve is sleeved on the shaft, which can protect the shaft. After the wear and tear, the shaft sleeve can be replaced to avoid the direct wear of the shaft and reduce the maintenance cost; the bearing is to support the rotation of the shaft body, which can reduce friction. The same thing between the shaft sleeve and the bearing is that they both bear the load of the shaft, the difference is that the shaft sleeve is an integral structure, and the relative movement between the shaft and the shaft sleeve when rotating; The body type, the relative movement of the inner and outer rings of the bearing itself when it rotates.”

Difference between bushing and bearing

A bushing and a bearing are both mechanical components that are used to support and guide rotating and sliding parts. However, there are some key differences between the two.

Bushing:

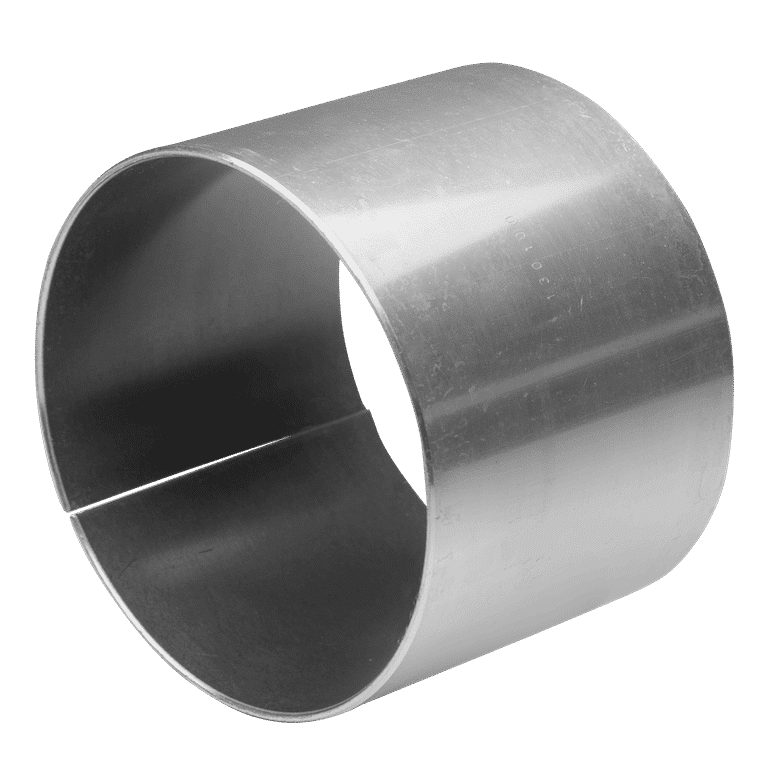

A bushing is a cylindrical liner that is placed between two parts to reduce friction and wear.

It is typically made of materials such as bronze, plastic, or rubber and is used to support rotating parts that have low load-bearing capacity.

Bushings are often used in applications where low-speed and low-load operations are required, such as in automotive suspension systems and electrical equipment.

Bearing:

A bearing is a component that allows for smooth, low-friction motion between moving parts.

It is typically made of materials such as steel or ceramic and is used to support rotating or sliding parts that have high load-bearing capacity.

Bearings are used in a wide range of applications, from industrial machinery to consumer products, and can be found in anything from electric motors to bicycles.

In conclusion, the main difference between bushings and bearings is the type of load they are designed to support and their construction materials. Bushings are used for low-speed and low-load applications, while bearings are used for high-speed and high-load applications. When selecting between a bushing and a bearing, it is important to consider the specific requirements of your application and choose the component that is best suited to your needs.

Plain bushing and bearing

Bushings and bearings are two different types of mechanical components that serve the same purpose of reducing friction and allowing rotary or linear motion between two objects. However, they are designed and manufactured differently, each with its own unique features and applications.

Bushings, also known as plain bearings, are simple and cost-effective components that are made of a cylindrical material, such as bronze or plastic, with a low friction surface. They are used in a variety of applications, including machinery, vehicles, and electronics, and are typically inserted into a housing to provide a smooth surface for an object to rotate or move around. Bushings are known for their low cost and ease of installation, as well as their low maintenance requirements and long lifespan.

Bearings, on the other hand, are more complex components that use small balls or rollers to reduce friction and support rotary motion. They are available in a wide range of materials, including steel, ceramic, and plastic, and can be manufactured in various shapes and sizes to meet the specific needs of different applications. Bearings are commonly used in high-load, high-speed applications, such as in motors, pumps, and conveyors, and are known for their durability and resistance to wear and tear.

One of the key differences between bushings and bearings is their load capacity. Bearings are designed to handle much higher loads than bushings, and can support heavy loads for long periods of time without wearing out or breaking down. Bushings, on the other hand, are designed for lighter loads and are typically used in applications where the load is spread out over a large area.

Another difference between bushings and bearings is the type of motion they support. Bushings are designed for linear or rotary motion, while bearings are designed specifically for rotary motion. Bearings can also handle high speeds, making them ideal for high-speed applications, while bushings are typically limited to slower speeds.

In terms of maintenance, bearings require more attention and maintenance than bushings. Bearings need to be lubricated regularly to maintain their performance, and they may also need to be replaced more frequently than bushings. Bushings, on the other hand, are known for their low maintenance requirements and long lifespan, making them a popular choice for applications where maintenance is difficult or costly.

In conclusion, bushings and bearings are both important components in a variety of applications, and the choice between them will depend on the specific needs of each application. Bushings are low-cost, easy to install, and low maintenance, making them ideal for lighter loads and slow speeds. Bearings, on the other hand, are designed for high loads and high speeds, and are known for their durability and resistance to wear and tear. When choosing between bushings and bearings, it is important to consider the load capacity, type of motion, speed, and maintenance requirements of the application to determine the best solution.

Bushing Bearing Types & Sizes:

The Main Types of Bearing, Bushings • Plain (sleeve) Bearings. Designs manufacture and distribute materials and solutions that are key to the well-being of each of us and the future of all. They can be found everywhere in our living spaces and in our daily lives: In buildings, in transportation, in infrastructure, and in many industrial applications. Different types of bearings have the same basic structure and the same purpose: they have two surfaces that move over each other, allowing the mating parts to move easily and without friction. The main difference is whether they work with a rotational or linear motion. Here is our at-a-glance guide to the main types of bearings:

- Ball Bearings

- Deep Groove Ball Bearing

- Roller Bearing

- Bronze Bearings

- Steel BackedPTFE Lined Bearings

- POM Acetal Lined Bearings

- Oilless Bearings

- CuSn8 Bronze Bearings

- Bronze Backed Bushing

- Thrust Washer Bearings

- Acetal Washers

- Sintered Components

Crossfit workout

Plain Bearings Made From Self-Lubricating Metallic

Plain & Self-Lubricating Bearings

Always self-lubricating & grease-free.

Maintenance-free plain bearings

Plain bearings. Providing superior reliability, durability, and quality.

Self-lubricating Steel Bearings Supplier

Switch from Bearing – Bushing Solutions

Steel bushings & bearings are ideally suited for your grease & oil lubricated applications. Available with plain or grooved sliding layer. Self-lubricating bushing. Short Periods Of Delivery. Small Minimum Quantities. Cost-Effective Prices. Highlights: Brochures Available, Offering Cost-Effective Prices.

Plain Bearing Bushing Services

Quote request / design help

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.