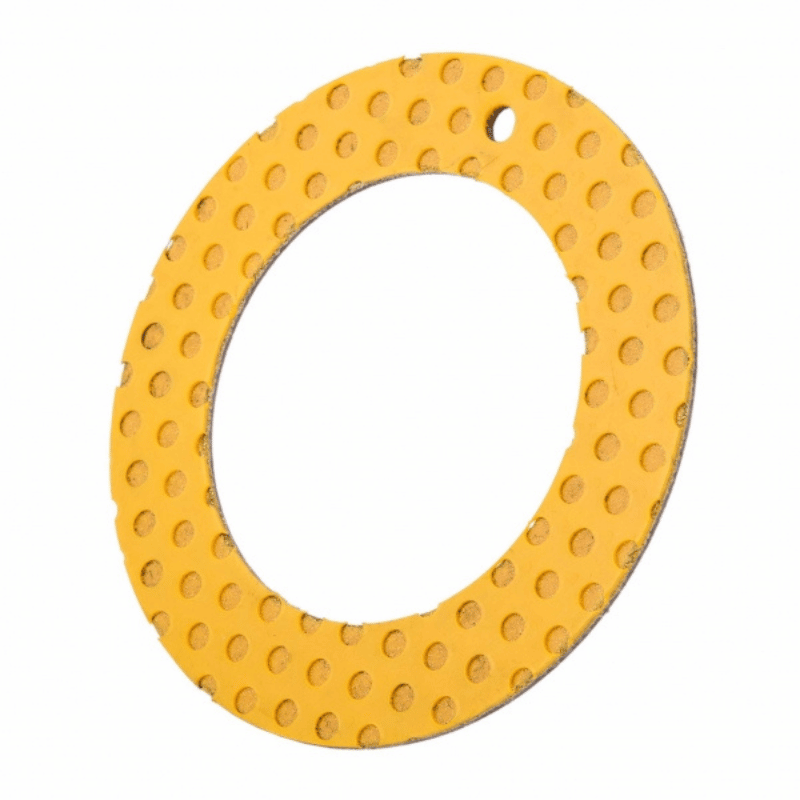

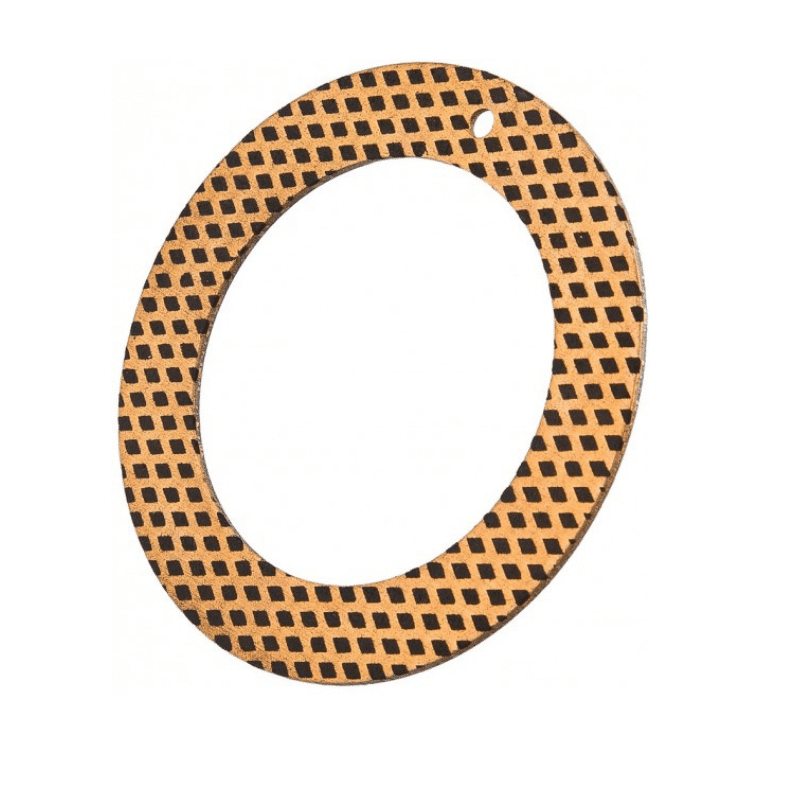

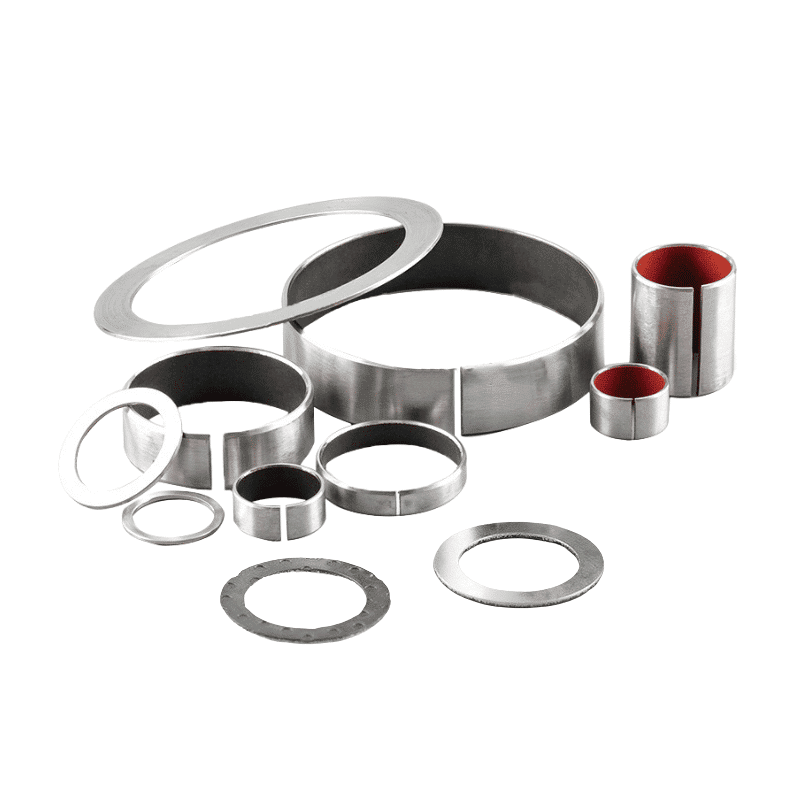

Gasket material type, washer

The typical materials utilized for these gaskets include Graphite, Bronze, PTFE (Polytetrafluoroethylene), and Oilless Bronze.

Our innovative line of gasket material products provides self-lubricating solutions to solve unique sealing challenges, improve plant productivity, reduce costs and help our customers comply with increasingly stringent environmental regulations. We process and sell self-lubricating bearing materials and provide the corresponding services. We process raw materials into advanced materials for use in our daily lives, while developing new materials for the future.

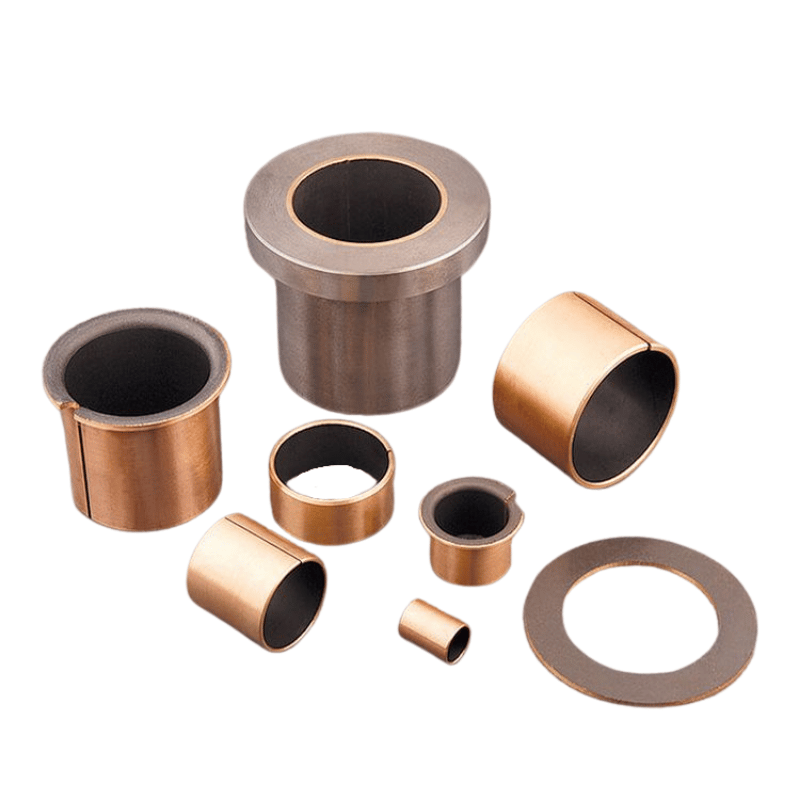

Thrust washers are used as a bearing surface for rotary applications. They are usually made of steel, bronze, bimetal, or other material with low friction washer...

High Performance

Thrust Washer Bearing For Pumps And Valves, the thrust washer material can be sized in place by boring, reaming, etc.

Self-lubricating Solutions

Self-lubricating Thrust Washer offer very good wear and low friction performance over a wide range of loads, speeds and temperatures.

Online Support

Steel-backed material from which bearings, gasket, thrust washers, and other shapes can be made.

Thrust Bearings, Self LubricatingThrust Washer.

Browse below to see our time-tested products that serve a variety of markets including chemical processing, food and beverage, marine, mining, nuclear, oil and gas, pharmaceutical, power generation, primary metals, pulp and paper, water and wastewater, and others.

Gaskets & Metallic Washer

Discover Top Gasket Materials! – Find the perfect Self-Lubricating Bearing Washers for your needs. Explore our range of Graphite, Bronze, PTFE, and Oilless Bronze. Enhance your machinery’s efficiency today! Low-maintenance and maintenance-free plain bearings and washer, Universal use, Low friction values, high wear resistance, Extremely good performance in dry runs as self-lubricating. The Standard Gaskets And Thrust Washer Material. Our Gasket Washer Materials, Metallic, And Non-Metallic Washer Are Made Using Unique, Proprietary Materials. Find of our portfolio of high-performance Gaskets & Washer solutions.

High-Performance Gasket Materials Awaiting You! – Need reliable gaskets? Check out our Self-Lubricating Bearing Washers in Graphite, Bronze, Polytetrafluoroethylene, and more. Perfect for any industrial application. Shop now for durability and precision!

Upgrade with Superior Gasket Materials! – Get the best in Self-Lubricating Bearing Washers. Choose from Graphite, Bronze, Polytetrafluoroethylene, PTFE, and Oilless Bronze. Ideal for high-temperature and high-pressure environments. Buy now for unbeatable performance!

Garlock gasket washer equivalents

Steel Washer, Gaskets Material, Your Solution for Tough Gasket Needs!

Self-lubricating Gaskets Material Provides longer life compared to competitor thrust washer products, even in the most abrasive applications.

Explore our selection of Gasket Materials, including Graphite, Bronze, and Polytetrafluoroethylene. Perfect for Self-Lubricating Bearing Washers in challenging industrial applications. Quality and reliability in one place!

thrust washer, embodies the product characteristic of permanently low-wear sliding. The use of solid lubricants in the plastic matrix makes it possible to use PTFE plain bearings from material group steel backed bronze with PTFE (maintenance-free materials) without oil or grease lubrication. It is not always possible to carry out plain bearing application tasks using products made from maintenance-free material. In these cases, low-maintenance steel backing bronze with POM materials are the perfect solution.

Industry-leading gaskets are trusted for superior sealing where it counts.

Garlock gasket equivalents catalog for wind turbine parts

Hydraulic Components Gaskets

The standard Hydraulic Gaskets and thrust washer material.

Find the garlock gasket equivalents supplier, Custom-made Gaskets and metal-polymer washers shaped in our proprietary custom self-lubricated thrust bearing design. in different Thickness, PTFE Material.

Gear pump special bearings are made of high quality low carbon steel plate as the substrate, sintered porous bronze layer in the middle and PTFE and Pb mixture rolled on the surface. It can provide good self-lubrication, wear resistance. Low friction and other properties, giving full play to the advantages of metal and multi-element polymer. The products are used in printing machines. Textile machinery, tobacco machinery, fitness equipment, etc.

Support & Delivery, New Thrust Washers Products

Mechanical Hydraulic Components Gaskets, Experience the Difference with Advanced Gasket Materials!

Looking for gaskets that last? Our Self-Lubricating Bearing Washers in Graphite, Bronze, Polytetrafluoroethylene, and PTFE are your answer. Exceptional durability and resistance for all your machinery needs. Shop today!

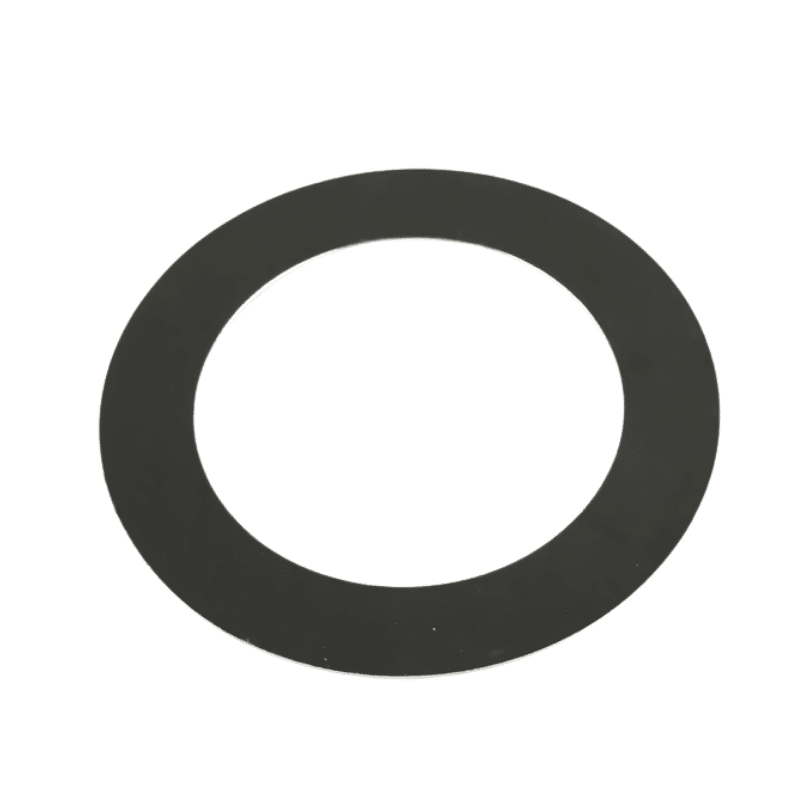

Maintenance-free and robust washer. PTFE Washer Technology, Oilless Bearing & Washer. Thrust washer, robust sliding material with maximum tribological performance. … Thrust washers. Strips. Sliding elements Bushes Washer

Garlock gasket material. Gasket Supplier, Flat Metal Washer Products

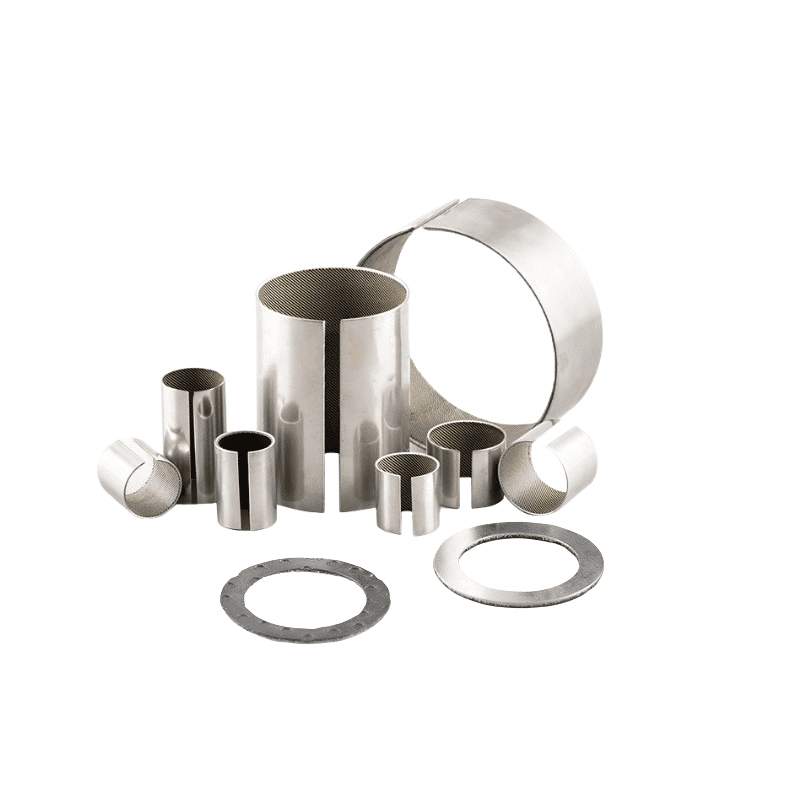

Self-lubricating bearings products including sleeves, flange bushes products, and thrust washer.

Plain bearing production

Standard designs are thrust washers, stainless steel back, maintenance-free, with steel backing.

Cylindrical bushes

Collar bushes

Thrust washers

Strips

Wide range of material sections with self-lubricating material. Custom-designed Washer Material Design and Manufacturing service.

Shipping in some Days? Material, Internal diameter (mm), Outer diameter (mm), Thickness (mm), Weight (g),

Characteristics of Steel Washer

- Very low stick-slip tendency

- Low wear

- Good chemical resistance

- Low friction value

- No tendency to weld to metal

- Extremely swell-resistant

- Does not absorb water

Preferred areas of application

- Maintenance-free operation under dry-running conditions

- Rotating or oscillating movements

- Up to a velocity of 2 m/s

- Linear movements

- Temperature range -200 °C to 280 °C

Thrust washers, Model range with steel-backed, maintenance-free washers

Please take a look at our application examples with PTFE thrust washer plain bearings

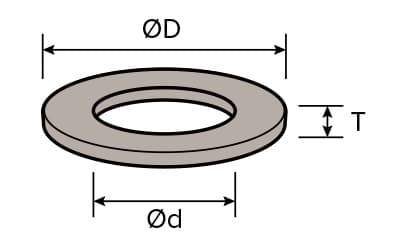

Thrust Washer Size

| Description | d | D | T |

|---|---|---|---|

| PAW 12 P10 | 12 | 24 | 1,5 |

| PAW 42 P10 | 42 | 66 | 2,0 |

| PAW 48 P10 | 48 | 74 | 1,5 |

| PAW 14 P10 | 14 | 26 | 1,5 |

| PAW 28 P10 | 28 | 48 | 1,5 |

| PAW 26 P10 | 26 | 44 | 1,5 |

| PAW 20 P10 | 20 | 36 | 1,5 |

| PAW 22 P10 | 22 | 38 | 1,5 |

| PAW 38 P10 | 38 | 62 | 1,5 |

| PAW 18 P10 | 18 | 32 | 1,5 |

| PAW 32 P10 | 32 | 54 | 1,5 |

| PAW 52 P10 | 52 | 78 | 2,0 |

| PAW 16 P10 | 16 | 30 | 1,5 |

| PAW 10 P10 | 10 | 20 | 1,5 |

| PAW 62 P10 | 62 | 90 | 2,0 |

Plain bearing bushes / composite material

This high-quality wear part washer

Material thrust washers. PAS strips. PAP P10. PAF P10. PAW P10. PAP P11.

Oil Free Washers products

Oil Free Washers products

Oil Free Washers for industrial applications. We offers free CAD downloads, prompt lead times, competitive pricing, and no minimum order quantity. Manufacturer of products such as plain bearings, bearing sleeves and thrust washers. Oilless washer SOBW/SOBWN size model is available. Oilless High Strength Bronze Graphite Plug Lubricant Metallic …Offering ZCuZn25AI6Fe3Mn3 Oilless Washers, ZCuZn25AI6Fe3Mn3 Oilless Bronze Graphite Washers, Size: 5 mm to 250mm, Bushings & Plain Bearings

Product Quality Index

Energy Generation

Online Catalogue of Washer Parts, Get the Gasket Materials for Maximum Efficiency!

Ensure strong seals with our superior Gasket Materials. Explore options like Polytetrafluoroethylene, Graphite, and Bronze. Ideal for any application. Click here for durable, long-lasting results!

Oils and fluids: parts catalogue from China. Washer. Oils and fluids parts ; Wiper and thrust washer … Thrust washer, also known as thrust bearings or thrust plates, are They are flat disc-shaped bearings made of metallic polymers or reinforced fiber materials. Thrust washer and thrust bearings: This means that they have many of the same properties as straight bearings, such as excellent wear resistance and a low coefficient of friction. Thrust washer are designed to support heavy axial loads and are used in applications where axial loads are required. The thrust washers are carbon steel based and it consists of PTFE and reinforced fiber material. The thrust bearing has a proprietary filled PTFE tape liner on both surfaces that provides excellent impact resistance and high load capacity, making it well suited for applications such as pulley washer, gear gasket, main pins, crane and valve actuator linkages. We also manufacture red metallic polymer thrust washer for hydraulic gasket. The low friction and wear resistance of the red composite bearing thrust washer bearing ensures the reliability and safety of the braking system for the life of the vehicle. In addition, the light weight of the thrust bearing gaskets helps to reduce weight. Oil-free bearing features: maintenance-free and long life brand: click to learn. Thrust bearing washer self-lubricating fiber washer, product maintenance-free, reduce production costs, professional R & D production line, purchase sales, quality service, welcome your inquiry, long service life, purchase quality thrust thrust washer.

We manufacturer plain bearing and thrust washer tailored to your individual needs.

What is a plain bearing

Upgrade your equipment with our range of Gasket Materials. From high-temperature resistant Graphite to versatile PTFE, we have it all. Shop now for optimal sealing solutions!

A plain bearing is a bearing that works under sliding friction. Sliding bearings work smoothly, reliably and without noise. Under the condition of liquid lubrication, the sliding surface is separated by lubricating oil without direct contact, which can also greatly reduce the friction loss and surface wear, and the oil film also has certain vibration absorption ability. But the starting friction resistance is large. The part of the shaft supported by the bearing is called the journal, and the parts matched with the journal are called the shaft tile. In order to improve the frictional properties of the surface of the shaft tile and cast in its inner surface of the friction reducing material layer called bearing lining. The material of the shaft and bearing liner is collectively called sliding bearing material. Sliding bearing applications are generally in the low speed and heavy load conditions, or maintenance and filling lubrication difficult operating parts.

China is one of the countries that invented rolling bearings earlier in the world, and the structure of axle bearings has been recorded in Chinese ancient books. From the archaeological relics and information, the oldest Chinese bearing with the prototype of modern rolling bearing structure appeared in the village of Xuejiya, Yongji County, Shanxi Province in 221~207 BC (Qin Dynasty). After the founding of New China, especially since the 1970s, bearing industry has entered a new period of rapid development of high quality. At the end of the seventeenth century, the British C. Varro design and manufacture of ball bearings, and installed in the mail carriage trial as well as the British P. Worth to obtain the patent for ball bearings. At the end of the eighteenth century, H.R. Hertz of Germany published a paper on the contact stress of ball bearings. On the basis of Hertz’s achievement, Germany’s R. Streibeck, Sweden’s A. Palmgren and others conducted a large number of experiments, and contributed to the development of rolling bearing design theory and fatigue life calculation. Subsequently, N.P. Petrov of Russia applied Newton’s law of viscosity to calculate bearing friction. Britain’s O. Reynolds of Thor’s discovery of mathematical analysis, derived the Reynolds equation, from then on laid the foundation of hydrodynamic pressure lubrication theory. The early form of linear motion bearing is a row of wooden rods placed under a sled. This technology may date back to the construction of the Great Pyramid of Giza, although there is no clear evidence. Modern linear motion bearings use the same operating principle, except that balls are sometimes used instead of rollers. The earliest sliding and rolling element bearings were made of wood. Ceramics, sapphire or glass were also used, and steel, copper, other metals, and plastics (such as plastic, metal ptfe, Polytetrafluoroethylene, and pom) were commonly used.

The difference between self-lubricating graphite washer and bronze washer, Your One-Stop Shop for All Gasket Material Needs!

Find the perfect seal with our extensive selection of Gasket Materials. Graphite, Bronze, Polytetrafluoroethylene, and more await you. Click here for top quality and reliability in every seal!

First of all, it is generally used as graphite thrust washer bearing is carbon graphite instead of graphite. Because the strength of pure graphite is too low, small hardness, not wear-resistant, not suitable for graphite inlay bearing to do graphite thrust washer bearing. The characteristics of graphite self-lubricating washer:

- Good self-lubrication. This is the other materials can not be compared. Can bimetal bushings to withstand a short period of dry wear.

- Good corrosion resistance. Carbon graphite has good corrosion resistance in the medium of acid and alkali salt except strong oxidizing acid.

- Good chemical stability and temperature resistance. It remains stable in the range of -200~1000℃. However, due to different impregnating resins, the actual use temperature varies depending on the resin. For example, the use temperature of graphite bearing gasket impregnated with furan resin is 200℃, that of epoxy resin is 150℃, and the use temperature of carbon graphite impregnated with metal is higher.

- Good thermal conductivity.

- Good wear resistance.

- Brittle, poor impact resistance.

- Good resistance to galling.

- processability is okay, but be careful because of brittleness.

- Cheap price.

Characteristics of bronze washer gasket:

- Self-lubricating property is okay, but not as good as carbon graphite.

- Limited corrosion resistance. Commonly used in clear water and seawater medium.

- Limited use temperature.

- General wear resistance. Can’t catch up with carbon graphite.

- Good toughness. Good impact resistance. This is its biggest advantage.

- General anti-seize performance.

- Good processability.

- The price is higher than carbon graphite. Especially now that the price of copper has gone up again.

What are the characteristics and scope of application of oil-free bearing washer?

Looking for reliable gasket solutions? Check out our selection of Graphite, Bronze, PTFE, and more. Perfect for any sealing challenge. Shop now for unmatched performance!

It has high bearing capacity, impact resistance, high temperature resistance, self-lubricating ability and other characteristics, especially for heavy load, low speed, reciprocating or oscillating and other difficult to lubricate and form oil film occasions, also not afraid of water and other acid corrosion and erosion. Users generally reflect that inlaid bearing washer not only save oil and energy, but also have a longer working life than ordinary sliding thrust bearing gaskets. At present, the products have been widely used in metallurgical continuous casting machine, rolling equipment, mining machinery, ships, steam turbines, hydraulic turbines, injection molding machines and equipment production lines.

Basic introduction of industrial bearings?

Discover our wide range of Gasket Materials for all industrial needs. From Graphite to Polytetrafluoroethylene, we have the perfect fit for your machinery. Click now for high-quality, durable solutions!

Basic structure of rolling bearings: Rolling bearings developed on the basis of sliding bearings are based on rolling friction rather than sliding friction. Usually, two rings, a set of rolling elements and a cage are highly common, standardized and serialized. Highly mechanical basic components. Due to the different operating conditions of various machines, various requirements are placed on rolling bearings in terms of load carrying capacity, structure and performance. Therefore, rolling bearings require a variety of structures. However, the most basic structure consists of an inner ring, an outer ring, a rolling element and a cage.

In the case of radial bearings, the inner ring is usually mounted tightly on the shaft and operates with the shaft. The outer ring is usually transition fit to the bearing housing or machinery housing bore to provide support. However, in some cases, there is also an outer ring running with the inner ring fixed to the support or the inner and outer rings operating simultaneously. For thrust bearings, there are collars that fit closely to the shaft and move together, and seat rings that transition fit to the bearing housing or machinery housing bore and are used as supports. The rolling elements (balls, rollers or needles) are usually arranged in the bearing between the two rings by means of a cage for rolling motion. The shape, size and number of bearings directly influence the load carrying capacity and performance of the bearing. In addition to the uniform separation of the rolling elements, the cage can be used to guide the rotation of the rolling elements and to improve the lubrication properties inside the bearing.

Steps for selecting bearings?

1. select the basic type of bearing, tolerance grade and clearance according to the working conditions of the bearing, including the direction and type of load, rotational speed, lubrication method, coaxiality requirement, positioning or non-location, installation and maintenance environment, ambient temperature, etc.

2. according to the working conditions, force and life requirements of the bearing, determine the bearing type by calculation, or according to the use requirements, select the bearing type, and then verify the life.

3. verify the rated load and limit speed of the selected bearing.

The main consideration in selecting the bearing is the ultimate speed and load capacity, while other factors help to determine the bearing type, structure, size and tolerance level and clearance requirements.