Bushing vs Bearings ? | Easy Assembly | Save Costs!

sleeve bearing vs bushing

Sleeve bearing vs bushing

Sleeve bearings, also known as “Plain Bushes” or “Sleeve Bushings,” are designed for use in numerous applications and offer features and benefits unavailable with many rolling-element bearings. Bushings (plain bushes) are distinguished from rolling-element bearings primarily by the fact that they consist of only one part.

What are the differences between Sleeve bearings and bushing?

Sleeve bearings, also called plain bushings, are differentiated from roller bearings by the fact that they have no rolling elements. Discovery bronzelube.com to learn more.

Inspired By Excellence & Innovation

We offer a wide range of high quality of sliding bearings & bushing parts.

Welcome to bronzelube.com

Reliable & safe- producer and supplier bearings & bushings for of industry.

The promise of bearings & bushings quality.

Bushing vs Bearings ? | Easy Assembly | Save Costs!

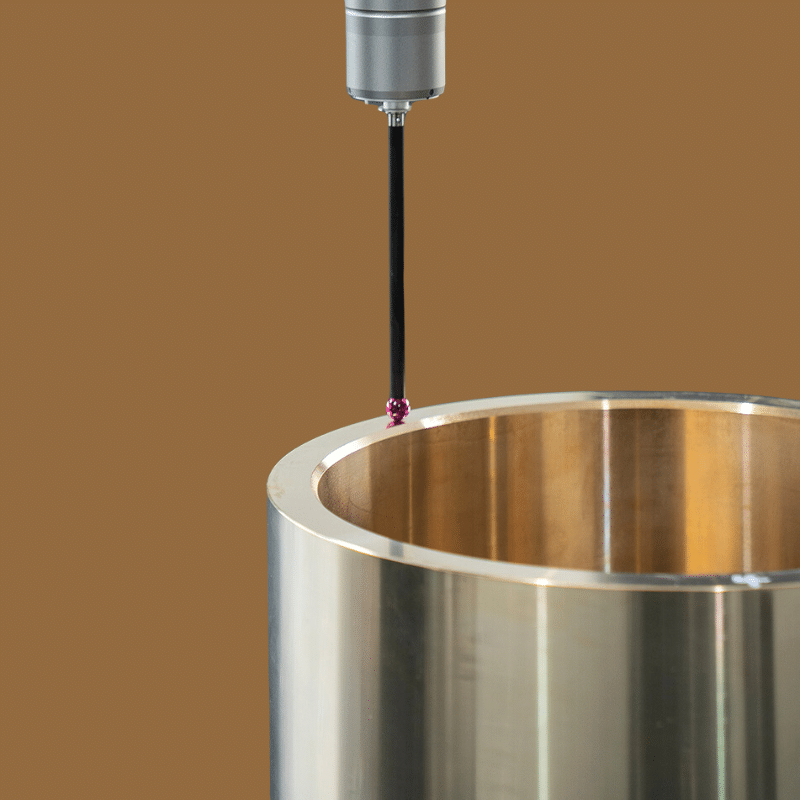

We have all kinds of professional testing equipment, strict quality assurance system, excellent QC department and professional testing personnel to ensure the quality of bushings!

Bushings Industries – design, types and advantages

Bushing VS Bearings

Bushing vs Bearing – Which Do You Choose ?

Bronzelube as an experience supplier from China.

Provide Custom Design, Cost-Effective & Reliable Bushings and Bearings Solutions.

- Bushing

A bushing might also be called a sleeve bearing. However, the term sleeve bushing would be redundant. Thus, a bushing is a bearing, but a bearing is not necessarily a bushing type. Bushings slide over smooth rods and provide an extremely low friction motion which minimizes power consumption, noise, and wear on parts. Bushings look like plain metal tubes, but they are actually fairly sophisticated parts.

The bushings are self-lubricating and therefore ideal for low-maintenance or maintenance-free operation. Self-lubrication is achieved by a uniform pattern of depressions on the surface of the bushing that serve as grease reservoirs. Some nylon bushings operate without the use of lubricants and are particularly useful in the food and textile industries where dry applications are preferred.

- Bearing

A bearing is the general term for something that allows relative motion between two components, surfaces, etc.

Bearings are tribological components that carry a load while in contact and moving relative to another part. The movement can be sliding or rotating. There are basically two different types of bearings: plain bearings and roller bearings. Other types include fluid bearings that support their loads on a thin layer of gas or liquid; magnetic bearings that use magnetic fields to carry their loads; hinged bending bearings in which the load is supported by a bending member; and jewel bearings used in watches and clocks.

- What is the difference between a bushing and a bearing?

A bearing is designed to “bear” or carry stress or loads in various design applications, but to add a layer of confusion, bushings are often referred to as plain bearings or sleeve bearings. Generally speaking, the difference between bushings and rolling element bearings in that bushings are designed as a single part, while bearings can have multiple parts.

A bushing is a round shaped cylindrical component. It is either equipped with rolling elements (ball, roller) or not and mainly used as a support component in an assembly to reduce machine wear out and for smooth operation. Its primary use is static (support) or dynamic (motion). On the other hand, a bearing is a machine element used for moving parts specifically for dynamic (motion) such as radial bearings and linear bearings.

- The common point both bushings vs bearings

Both bearings and bushings can be composed of metal or plastic composites, or a combination of the two. Plastic bearings provide the advantages of a self-lubricating design(never needs grease), plus corrosion and chemical resistance, and superior longevity and wear.

- Types of bushings vs bearings

There are several bushing types on the market with different material compositions. Some can withstand corrosion, whereas others are suitable for controlling high pressure and impact. Select the best bushing type based on the application and operating environment.

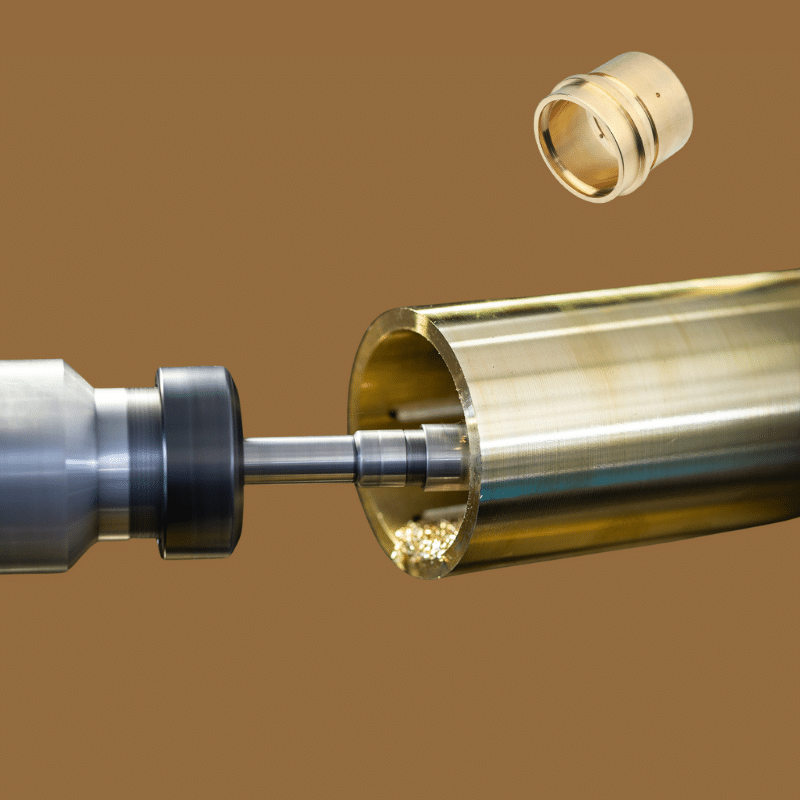

- Bronze bushings

Bronze bushings are typically made from a continuous casting of bronze material to ensure a uniform bronze structure throughout the bushing. These are general purpose bushings that provide excellent load-carrying capacity and wear protection. They can handle high levels of heat and withstand temperatures up to 450 ° F. They can be easily modified by adding oil and grease grooves and self-lubricating graphite plugs. Bronze bushings can also be flanged to withstand combined loads.

- Plastic bushings

Solid plastic bushings are increasingly popular due to their lightweight and corrosion resistant properties. They require little or no maintenance, or additional lubrication. Modern plastics were designed to overcome previous concerns, such as heat sensitivity, softening, wear, or reduced life at high temperatures. Bronzelube bushings are one of the most common types of plastic bushings offering exceptional machinability and durability. They work well in damp or damp conditions, such as on dryer cart wheels in lumber drying facilities, where the water acts as a lubricant for the socket.

- Bushing vs Bearing Maintenance

Proper maintenance and inspection are essential. Periodic maintenance should include monitoring the operating conditions for any abnormalities. Any changes in noise, vibration and temperature should be inspected. Bearing and ring failures such as chipping, scratches, cracks, corrosion and abnormal wear should be addressed immediately. The supply or replacement of lubricants should also be checked regularly for continued optimum performance.

- Bushing vs Bearing Application

Bushings are precision parts for specific requirements in very different sectors of the industry, such as the automotive, electrical, machine building and so on. Wherever parts need to be seated, reinforced or centered bushings will be the best solution. All bushings are made of tube. It is the most economical form of production. Using standard dimensions avoids extra tooling costs. We manufacture bushings in aluminum, steel, brass, copper and stainless steel.

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com