CuSn5Zn5Pb5 Machined Bronze Bearings & Custom Parts

About us

CuSn5Zn5Pb5, leaded tin bronze alloy Bushing and bearing.

CuSn5Zn5Pb5 is a type of bronze material containing copper (Cu), tin (Sn), zinc (Zn), and lead (Pb), commonly used in manufacturing machine bearings. This material is widely favored for its excellent mechanical properties and wear resistance. Here are some details about machining bronze bearings made from CuSn5Zn5Pb5:

Leaded, Phosphor And Aluminium Bronzes Bearing,

Search Our Material Alloy

Perfect For Any Application. Order Today!

Tin bronze alloy, also referred to as red bronze or leaded gunmetal, corresponds closely to several international standards. These include BS 1400 LG2, ASTM B505 C83600, and CuSn5ZnPb (Rg5).

Applications: CuSn5Zn5Pb5-C is a multi-component bronze ideal for casting. It can be soft soldered and, to some extent, brazed, making it suitable for marine environments.

CuSn5Zn5Pb5 Standards: It complies with standards such as PN-EN 1982, Applications: This alloy is commonly used in various applications such as bearings, bushings, and other parts requiring good wear resistance, low friction, and excellent machinability, It offers a good machinability and offers good resistance to corrosion.

CuSn5Zn5Pb5, also known as lead-tin bronze alloy, is a copper alloy containing tin, zinc and lead. It is widely used in the manufacture of bronze bushing, bearing, flange and groove components due to its good mechanical properties, wear resistance and corrosion resistance

Maximize Productivity With Our Advanced Bronze Bearings.

Machinability: The LG2 alloy offers excellent machinability, medium strength, and good sealability without de-zincification.

Product Range: Our company provides custom bronze bearing products with diameters ranging from Φ10mm to Φ1500mm. This includes cylindrical bronze bearings, flanged bronze bearings, and bronze thrust washers.

Versatility: CuSn5Pb5Zn5 (ASTM B 505 C83600) is a leaded red brass produced by continuous casting in the USA, considered a versatile non-ferrous bearing material.

Innovative Bearing Solutions, Solid Lubricated CuSn5Zn5Pb5 Bronze Bearings

Solid Lubricants: we supplies bronze bearing materials embedded with solid lubricants containing CuSn5Zn5Pb5, suitable for oil-free die-casting mold parts.

These details highlight CuSn5Zn5Pb5 as a versatile bronze material, particularly suited for manufacturing bearings that require good wear resistance and mechanical strength. For more detailed technical specifications or to purchase related products, visit the provided links for more information.

Closest International Standards for Tin Bronze Alloy

- Europe

- BS 1400 LG2: In force

- DIN 1705 CuSn5ZnPb (Rg5): Annulled

- NFA 53707: Annulled

- EN 1982: 1998 CuSn5Zn5Pb5-C (CC491K): In force

- USA

- ASTM B505 C83600 (SAE 40): In force

- ASTM B271 C83600 (SAE 40): In force

- Australia

- AS 1565 C83600A: In force

- AS 1565: 1996 C83600A (85/ 5/ 5/ 5 Leaded gunmetal): In force

- Japan

- JIS H5121 CAC406C (BC6): In force

- JIS H5120 CAC406: In force

- JIS H 5111: 1988 BC 6 (Class 6): In force

- ISO

- ISO 1338 CuPb5Sn5Zn5: Annulled

- ISO 1338: 1977 CuPb5Sn5Zn5: Annulled

- Germany

- DIN 1705: 1981 CuSn5ZnPb (2.1096, Rg5): In force

- China

- GB 1176: 1987 CuSn5Pb5Zn5 (5-5-5): In force

- Denmark

- DS 3001: 1978 Rodgods 5204 (Rg 5): In force

- Spain

- UNE 37-103-2: 1981 CuSn5Zn5Pb5 (C-3520): In force

- Finland

- SFS 2209: 1977 CuPb5Sn5Zn5: In force

- France

- NF A 53-707: 1987 CuSn5Pb5Zn5: In force

- Hungary

- MSZ 8579: 1984 CuSn5Zn5Pb5 (Vöt 5): In force

- Italy

- UNI 7013-8: 1972 CuSn5Zn5Pb5 (BS ZN 5, Bronzo allo zinco): In force

- Norway

- NS 16530: 1977 CuSn5Pb5Zn5 (Rodmetall Stopelegering): In force

- Poland

- PN/H-87026: 1991 CuSn5Zn5Pb5 (B555): In force

Note: Optional thermal treatments available on client’s request.

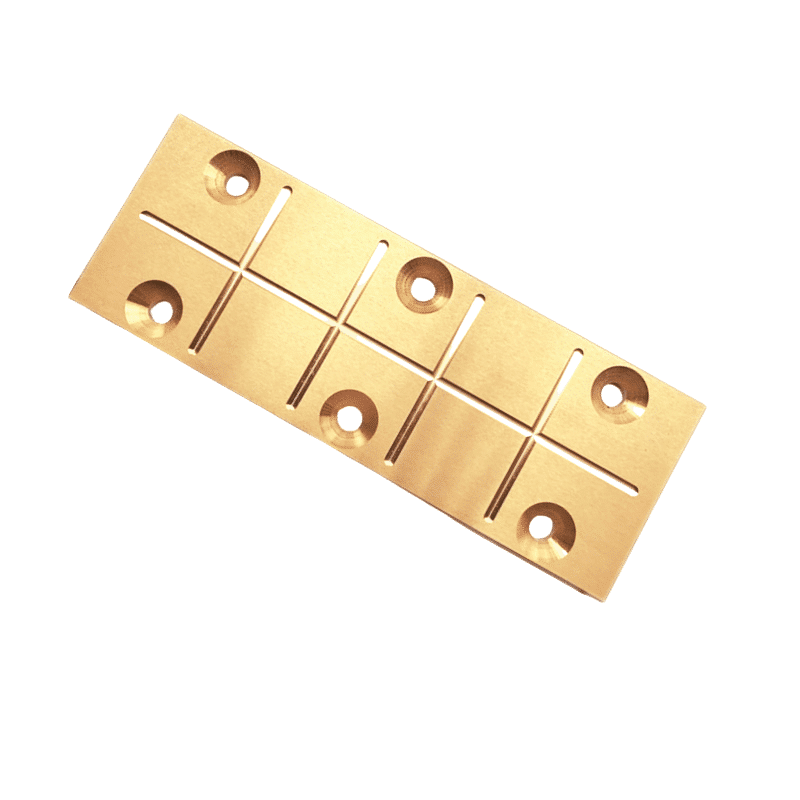

Available Bearing Forms in Standard Dimensions

- Cylindrical Bushes

- Flanged Bushes

- Sliding Plates

- Thrust Washers

- Flanged Washers

Main Base Alloy

| Phy. Performance. & Chemical Compositions |

CuZn25Al6FeMn3

Bronze Bushing |

CuZn25Al6FeMn3

Bronze Bushing |

CuSn5Pb5Zn5

Bronze Bushing |

CuAl10Ni Bronze Bushing | CuSn12 Bronze Bushing | Cast Iron HT250 |

| Cu% | 65 | 65 | 85 | 80 | 88 | |

| Sn% | 5 | 12 | ||||

| Pb% | 5 | |||||

| Zn% | 25 | 25 | 5 | |||

| Ni% | 5 | |||||

| Al% | 6 | 6 | 10 | |||

| Fe% | 5 | |||||

| Mn% | 4 | 4 | ||||

| Dengity g/cm 3 |

8.0 | 8.0 | 8.8 | 8.3 | 8.8 | 7.3 |

| Hardness | >210 | >180 | >70 | >150 | >80 | >160 |

| Tensile Strength | >750 | >550 | >200 | >500 | >360 | >250 |

| Elongation | >12 | >12 | 15 | >10 | >8 | |

| Coefficient of linear expansion |

1.9·10 -5 /℃ | 1.9·10 -5 /℃ | 1.8·10 -5 /℃ | 1.6·10 -5 /℃ | 1.8·10 -5 /℃ | 1.0·10 -5 /℃ |

| Limit Temp. | 300~400 | 300~400 | 400 | 400 | 400 | 400 |

| Max. Load N/mm 2 | 100 | 80 | 60 | 50 | 70 | 10 |

| Max. Speed m/min | 15 | 15 | 10 | 20 | 10 | 15 |

| Max. PV N/mm2·m/min | 200 | 200 | 200 | 200 | 200 | 40 |

| 400N/mm2 | <0.01 | <0.01 | <0.05 | <0.04 | <0.05 | <0.015 |

Product Features of Self-Lubricated Bronze Bushing Bearings

1. No Oil Supply System Needed

These bearings eliminate the need for oil supply devices, oil holes, and grooves. This simplification reduces the costs associated with the fuel supply system, including processing and assembly, ultimately lowering manufacturing expenses.

2. Reduced Operating Costs

The use of self-lubricating bearings substantially cuts down on the need for lubricating oil and equipment maintenance, while also eliminating the risks associated with oil shortages.

3. Streamlined Design Process

The absence of oil simplifies the design and structure, reducing costs and saving design time. Additionally, using self-lubricating bearings can enhance mechanical properties, extend service life, and improve reliability.

4. Environmental Benefits

With no need for waste oil recycling, these bearings are environmentally friendly, promoting cleaner production practices.

5. Versatile Mechanical Applications

As essential parts of the mechanical industry, these bearings are crucial for normal machine operation. They are designed to withstand high loads and adverse conditions such as foreign body intrusion, extreme temperatures, and imperfect maintenance, which would typically cause galling in general sliding bearings.

Usage Notes

- Where possible, design using standard specifications.

- Ensure there are no foreign bodies in the assembly.

- After use, a solid lubricant may form a black or gray-black film on the sliding surface. Do not scrub this off; it is usual.

- Applying lubricating oil to the grinding parts before assembly can shorten the running-in period, facilitating smoother machinery operation.

- When assembling, press in slowly; avoid hammering to prevent bearing damage and deformation.

- Select appropriate materials for different parts to improve mechanical performance and extend the bearing’s service life.

- For high-load, reciprocating movements, consider using screw fixation.

- In environments like fresh water, seawater, or maritime settings, use stainless steel or surface plating.

Enhance Your Machinery, EN 1982 CC491K

CuSn5ZnPb5-C Machined Bearings

Experience the Strength of Self-lubricating Bearings

CuSn5Zn5Pb5 Bronze Bearings – Solid Lubricated! ASTM B505 C83600 and the CuSn5ZnPb (Rg5).

Experience top-notch performance and durability. Perfect for demanding applications. Click to explore our range!

CuSn5Zn5Pb5 machined bearings are high-quality bronze bearings crafted from a specific alloy composition that includes copper (Cu), tin (Sn), zinc (Zn), and lead (Pb). These bearings are noted for their excellent wear resistance and mechanical strength, making them suitable for a variety of demanding industrial applications. CuSn5Zn5Pb5 bearings are particularly effective in environments where durability and reliability are critical, and they are commonly used in machinery that requires high precision and robust performance.

Need Bearings That Last? Solid Lubricated Bronze Bearings – CuSn5Zn5Pb5

Reduce maintenance costs with our self-lubricated bearings. Ideal for high-wear environments. Learn more now!

CuSn5Zn5Pb5 bronze sheet is an alloy material containing copper (Cu), tin (Sn), zinc (Zn), and lead (Pb), commonly used in casting. This alloy is widely used due to its excellent castability, mechanical properties, and wear resistance.

Material Standards and Nomenclature: The CuSn5Zn5Pb5 bronze sheet is known by different names in various standards. For instance, it is referred to as CC491K or CB491K under the EN 1982 standard, as LG2 in the BS 1400 standard, and as C83600 in the ASTM B 505 standard.

Superior Bronze Bearings Here! CuSn5Zn5Pb5 with Built-in Solid Lubricant

Discover the ultimate solution for your CuSn5Zn5Pb5 bronze bearing needs for Medium load, medium-speed. Applications: This material is often used to manufacture parts that operate under high load and moderate sliding speeds, such as bearing caps, and is also suitable for other heavy industrial uses.