High Precision CuSn10P Bronze Bearing, Bronze Bearings Sleeve and Plain Bearing

About us

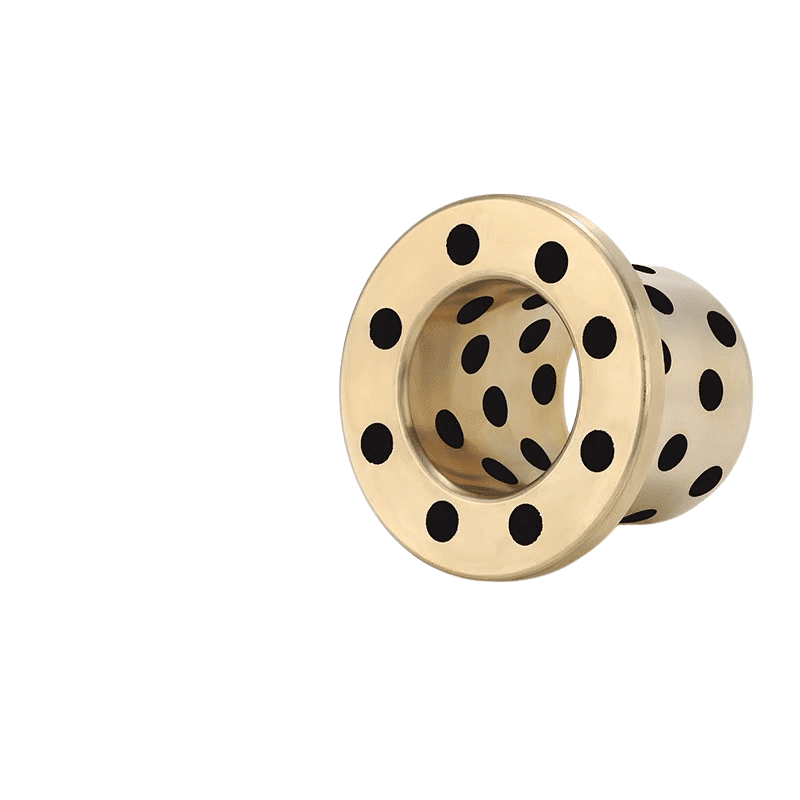

CuSn10P Bronze Bushings, Solid Bronze Bearings, Bronze Bearings Sleeve and Plain Bearings

CuSn10P bronze bushings are self-lubricating and crafted from a specialized bronze alloy ideal for bearings and mechanical parts. Our engineering team excels in producing large centrifugal bushes, rings, and sleeves. CuSn10P, known for its strength and machinability, is commonly used for wear-resistant parts. Centrifugal casting ensures high-precision copper-aluminum bearing sleeves. Depending on standards, CuSn10P is also known as ZCuSn10Pb1, PB1, among other names.

Solid bronze bearings are constructed from CuSn10P, a type of continuously cast bronze. Each surface of these plain bearings is precisely machined. In addition to the standard material, a variety of other alloys are also available. Among the most frequently used are CuSn7Zn4Pb7, CuAl10Ni, CuSn10, and CuSn12.

Durable CuSn10P Bearings, High Load Capacity, Seawater Resistant, Tin Bronze Bushing – CuSn10

CuSn10P bronze alloy bushings benefit from self-lubricating properties that reduce friction and extend lifespan. They are designed for high load capacity and can handle demanding applications with prolonged static loading. Additionally, their excellent corrosion resistance makes them ideal for harsh environments.The alloy composition of CuSn10P includes 10% tin and a small percentage of phosphorus, which enhances wear resistance and contributes to the self-lubricating characteristic of the bushings. This unique combination minimizes the need for regular maintenance and lubrication schedules, allowing for more consistent performance over time. As a result, these bushings are perfectly suited for use in industrial machinery, marine applications, and other environments where exposure to moisture and chemicals is common. Furthermore, their capacity to withstand thermal fluctuations and maintain structural integrity under varying temperatures ensures reliability in diverse operating conditions. When selecting bushings for equipment subject to high stress and challenging environments, the CuSn10P bronze alloy presents a dependable solution that balances durability, performance, and longevity.

Tin Bronze Bearings, CuSn10P Material, Custom Parts Available

CuSn10P bronze bearings are made from tin bronze material known for its good machinability. These are typically produced through centrifugal or sand casting for applications needing strong wear resistance and load capacity. They adhere to ISO CuSn10P and German DIN G-CuSn10 standards. When choosing materials and processes, users should carefully consider application-specific information.

CuSn10P bearings have low maintenance costs due to their self-lubricating property.

These bushings meet international standards, including American C90700, British PB4, and Japanese PBC2B.

CuSn10P contains approximately 10% tin and small amounts of phosphorus, enhancing hardness and wear resistance. PB1 might be an alternative designation for CuSn10P in certain regions.

cUSN10P Bronze Alloys with Solid Lubricants, Cylindrical bushing and flange Bushing, Thrust washer

Manufacturing Process: CuSn10P bronze bushings known for its strength and wear resistance.

Surface Treatment: All surfaces undergo mechanical processing to ensure precision and performance.

Applications: These bushings and bearings are extensively used in industries like machinery, automotive, marine, and aerospace. Other Self-Lubricating Bronze Materials: Besides CuSn10P, alloys such as CuSn8 also offer self-lubricating properties.

- Germany: CuSn10P

- England: PB1

- European Union: CC481K, CuSn11P-C

- Poland: CuSn10P

- Czech Republic: 423120

Solid bronze bearings offer a range of advantages that make them a popular choice for various industrial and mechanical applications. Here’s a closer look at the benefits you’ve mentioned, along with some additional advantages:

- Not Affected by Impurities: Bronze alloys are known for their ability to embed and accommodate foreign particles, which means they can operate effectively even in environments where there might be contamination. This self-lubricating property allows the bearing to continue functioning smoothly even if the lubricant becomes contaminated.

- Suitable for Corrosive Environments: The copper in bronze provides inherent corrosion resistance, making these bearings suitable for use in environments where exposure to moisture, chemicals, or other corrosive agents might be a concern.

- Suitable for Impact Loads and Vibrations at Low Speeds: The high resilience of bronze alloys allows them to absorb shock loads and withstand vibrations, which is particularly useful in applications where there are intermittent or variable loads, such as in machinery that experiences vibration or has to handle sudden impacts.

- Has a Groove to Retain the Lubricant: The presence of lubrication grooves in solid bronze bearings helps to retain the lubricant, ensuring a consistent supply to the contact surfaces. This feature is crucial for maintaining the performance and longevity of the bearing.

Additional advantages of solid bronze bearings include:

- Long Life: Due to their material properties and the ability to maintain a lubricating film, solid bronze bearings typically have a long service life, reducing the need for frequent replacements.

- Good Load-Carrying Capacity: The combination of copper’s strength and the added elements in the bronze alloy (like tin and lead) results in a material that can handle high loads effectively.

- Compatibility with Various Lubricants: Solid bronze bearings can work with a variety of lubricants, including grease and oil, providing flexibility in terms of lubrication options.

- Low Maintenance: The self-lubricating nature of bronze means that these bearings require less frequent maintenance compared to bearings made from other materials.

- Resistant to Galling: Bronze alloys have a low tendency to gall or cold weld, which is important in applications where the bearing might experience start-stop cycles or sliding motion without sufficient lubrication.

- Recastability: Over time, the bearing surface can be reconditioned or “recast” by the lead content in the bronze, which can help to maintain a smooth running surface even as the bearing wears.

- Wide Temperature Range: Solid bronze bearings can operate effectively over a wide temperature range, making them suitable for applications with varying thermal conditions.

- Non-Magnetic: Bronze is a non-magnetic material, which is an advantage in applications where magnetic interference could be a problem.

These advantages make solid bronze bearings a reliable and versatile choice for a wide range of applications, from general machinery and automotive components to marine and aerospace equipment.

Graphite CuSn10P Bronze Bushing: Self-Lubricating Bearings

Experience the Strength of Self-lubricating Bearings

CuSn10P bronze bushings and self-lubricating bronze bearings

CuSn10P bronze bushings and self-lubricating bronze bearings are widely used in industrial applications for their self-lubrication, high load capacity, and corrosion resistance. Selecting the right bronze material and specifications enhances equipment reliability and lifespan while reducing maintenance costs. When choosing CuSn10P bronze bushings, consider the operating environment, load conditions, and speed. These components are designed to endure harsh conditions, making them ideal for mining, automotive, and marine applications. Phosphorus in the alloy improves wear resistance, making it suitable for high-stress uses.

Self-lubricating bronze bearings feature embedded solid lubricants that release lubricant during operation, minimizing maintenance and downtime, which is beneficial in environments where regular lubrication is impractical.

Consulting with specialists to select the appropriate bronze solution ensures optimal performance and longevity. Investing in high-quality CuSn10P bronze components reduces operational interruptions and extends service intervals, enhancing productivity and cost-efficiency in industrial operations.

CuSn10P Phosphor Bronze Self-Lubricating Bearings

Phosphor Bronze Bearing C54400 CuSn10P, primarily copper with about 10% tin and added phosphorus, offers excellent corrosion and wear resistance. Its superior anti-friction properties make it ideal for high-load, low-speed bearing applications. Phosphorus enhances hardness, tensile strength, and machinability by refining the grain structure. Widely used in electrical sockets, springs, and marine propellers, C54400 is versatile across industries and essential for precision engineering, maintaining structural integrity under mechanical stress.

CuSn10P Phosphor Bronze Bearings, C54400 Bronze Bearing

C54400 phosphor bronze bearings are widely used in machinery, automotive, maritime, and aerospace industries due to their high load and wear resistance. They meet American ASTM standards and are recognized globally for their superior performance.