Exploring the Marvels of c93700 bronze Bushing: A Comprehensive Guide

Experience the Strength of Self-lubricating Bearings

Exploring the C93700 Bronze Bushing and Wear Plate

The self-lubricating properties of C93700 alloy are primarily attributed to the presence of lead and tin. During mechanical movement, they can form a lubricating film, reducing direct contact between metals and enhancing the wear resistance and lifespan of parts.

In addition to lead, tin, and copper, C93700 alloy may also contain small amounts of other elements such as zinc, iron, nickel, etc., to further improve its performance.

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

self-lubricating properties of C93700 alloy

The self-lubricating properties of C93700 alloy are primarily attributed to the presence of lead and tin. During mechanical movement, they can form a lubricating film, reducing direct contact between metals and enhancing the wear resistance and lifespan of parts.

In addition to lead, tin, and copper, C93700 alloy may also contain small amounts of other elements such as zinc, iron, nickel, etc., to further improve its performance.

High-Quality C93200 Bronze Bearings, Superior Durability & Performance: Discover our range of C93200 bronze bearings. Perfect for heavy-duty applications with excellent wear resistance. Shop now for unbeatable prices and reliability!

Durable C93200 Bronze Plates, C93700 alloy application

C93700 alloy finds extensive applications, including but not limited to:

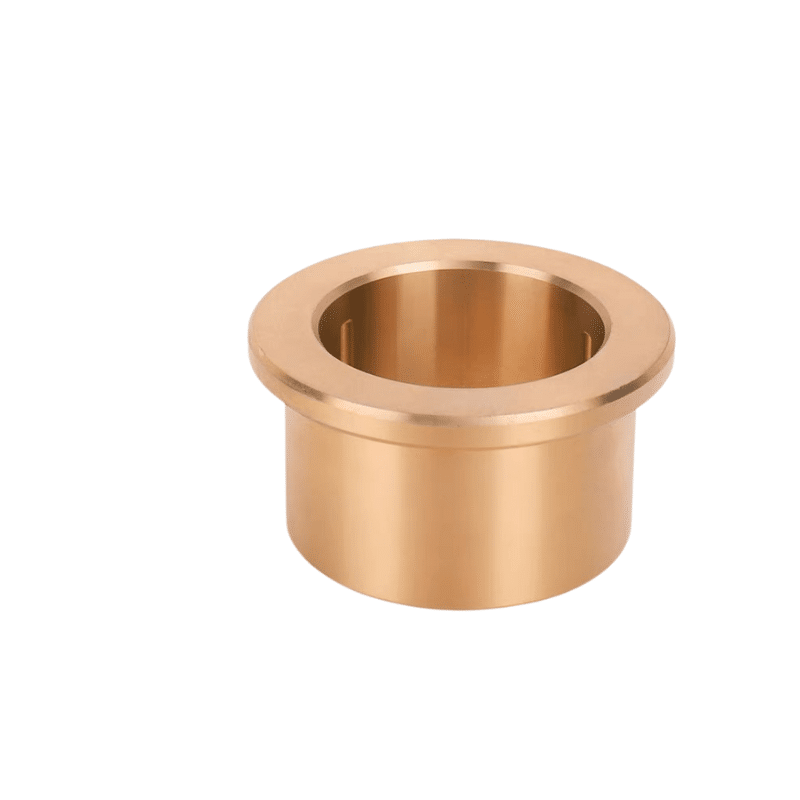

Bearings: Used in sliding bearings for various machinery, especially in low-speed, high-load, or challenging-to-lubricate environments.

Bushings: Utilized as bushings in mechanical components where reducing friction and wear is necessary.

Self-lubricating components: Various self-lubricating parts in industries like automotive, including components in engines, transmissions, and suspension systems.

Marine applications: Due to its excellent corrosion resistance, C93700 alloy is also suitable for mechanical components in marine environments.

Customized parts: With its excellent casting performance, C93700 can be customized into various shapes and sizes to meet specific application requirements.

If you need more detailed information or want to understand the performance of C93700 alloy in specific applications, please provide more context or specific questions, and we will be happy to assist you.

Exploring the Excellence of High Leaded Tin Bronze Bushing Bearings

In the realm of machinery and equipment, the quest for superior performance, durability, and reliability is unending. Among the myriad of materials used in engineering applications, High Leaded Tin Bronze stands tall as a versatile and highly effective option. In this comprehensive guide, we delve into the world of High Leaded Tin Bronze bushing bearings, exploring its applications, benefits, and variations, including C93200 (SAE 660), C93400, C93500, C93600, C93700 (SAE 64), and C93800 Bronze.

Understanding High Leaded Tin Bronze:

High Leaded Tin Bronze is an alloy renowned for its exceptional wear resistance, self-lubricating properties, and corrosion resistance. Comprising primarily of copper, tin, and a high proportion of lead, this alloy is meticulously engineered to meet the demanding requirements of various industrial applications.

Applications:

High Leaded Tin Bronze bushing bearings find extensive use across a diverse range of industries, including:

- High-Speed Bearings: The remarkable wear resistance and self-lubricating properties of High Leaded Tin Bronze make it ideal for high-speed bearing applications, where friction and heat generation need to be minimized.

- Pump Parts: In pump assemblies, where continuous movement and high pressures are commonplace, High Leaded Tin Bronze bushing bearings excel due to their durability and corrosion resistance.

- General Utility Bearings: From automotive components to industrial machinery, High Leaded Tin Bronze bearings serve as reliable utility bearings, providing essential support and reducing friction in various mechanical systems.

- Bushings and Wear Plates: In applications requiring precise alignment, reduced friction, and resistance to wear, such as in construction equipment and hydraulic systems, High Leaded Tin Bronze bushings and wear plates offer unmatched performance and longevity.

Variations of High Leaded Tin Bronze:

- C93200 (SAE 660) Bronze: Known for its excellent machinability and wear resistance, SAE 660 Bronze is commonly used in applications requiring high load-bearing capabilities.

- C93400 Bronze: This variation of High Leaded Tin Bronze offers superior corrosion resistance, making it suitable for marine and saltwater environments.

- C93500 Bronze: With enhanced tensile strength and hardness, C93500 Bronze is favored for heavy-duty applications subjected to extreme pressures and loads.

- C93600 Bronze: Renowned for its high machinability and thermal conductivity, C93600 Bronze is often chosen for applications requiring intricate machining and thermal management.

- C93700 (SAE 64) Bronze: This alloy is celebrated for its self-lubricating properties, making it ideal for bearings and bushings in low-speed, high-load applications.

- C93800 Bronze: Known for its exceptional resistance to fatigue and deformation, C93800 Bronze is utilized in applications where durability and long-term performance are paramount.

Conclusion:

High Leaded Tin Bronze bushing bearings represent a pinnacle of engineering excellence, offering unmatched durability, reliability, and performance in various industrial applications. Whether in high-speed bearings, pump parts, general utility bearings, or bushings and wear plates, the versatility and effectiveness of High Leaded Tin Bronze ensure optimal performance and longevity in machinery and equipment. With variations such as C93200 (SAE 660), C93400, C93500, C93600, C93700 (SAE 64), and C93800 Bronze, engineers and manufacturers have a wide array of options to choose from, tailored to meet specific requirements and challenges.

C93700 alloy, also known as SAE 64 or high leaded tin bronze, is a copper-based alloy with a high proportion of lead and tin. This material is widely used in the manufacturing of bearings, bushings, and other self-lubricating custom parts due to its excellent self-lubricating properties, good wear resistance, and corrosion resistance. Here are some detailed insights into the C93700 alloy:

Chemical Composition: The chemical composition of the C93700 alloy typically includes:

- Copper (Cu): Approximately 80-85%

- Lead (Pb): Approximately 10-15%

- Tin (Sn): Approximately 1-3%

- Zinc (Zn): May contain small amounts, depending on the production process.

Performance Characteristics:

- Self-Lubrication: The addition of lead and tin enables the formation of a lubricating film during friction, providing excellent self-lubricating properties to the C93700 alloy.

- Wear Resistance: The inclusion of lead and tin enhances the alloy’s wear resistance, making it suitable for high-load and low-speed applications.

- Corrosion Resistance: Copper-based alloys typically exhibit good corrosion resistance, and C93700 is no exception.

Standards and Specifications: The C93700 alloy adheres to various industrial standards and specifications, including:

- CDA 937: Standard number from the Copper Development Association.

- SAE 64: Standard number from the Society of Automotive Engineers.

- 80-10-10: Commonly used to describe the approximate proportions of copper, lead, and tin in the C93700 alloy.

- AMS 4842: Number from the Aerospace Material Specification.

- ASTM B505, ASTM B271, ASTM B22: Standard numbers from the American Society for Testing and Materials, covering casting and processing of copper and copper alloys.

Applications: The applications of the C93700 alloy are widespread and include:

- Bearings: Used in sliding bearings for various machinery, especially in environments where lubrication is challenging.

- Bushings: Utilized as bushings in mechanical components to reduce friction and wear.

- Marine Applications: Suitable for mechanical components in marine environments due to its excellent corrosion resistance.

- Automotive Industry: Used in engines, transmissions, and other systems requiring self-lubricating components.

- Custom Parts: Can be customized into various shapes and sizes to meet specific application requirements.

Processing and Manufacturing: The C93700 alloy exhibits excellent casting properties and can be processed into the desired parts through methods such as casting, forging, and machining.

If you have specific application requirements for the C93700 alloy or want to learn more about this material, feel free to provide further details for more specific assistance.

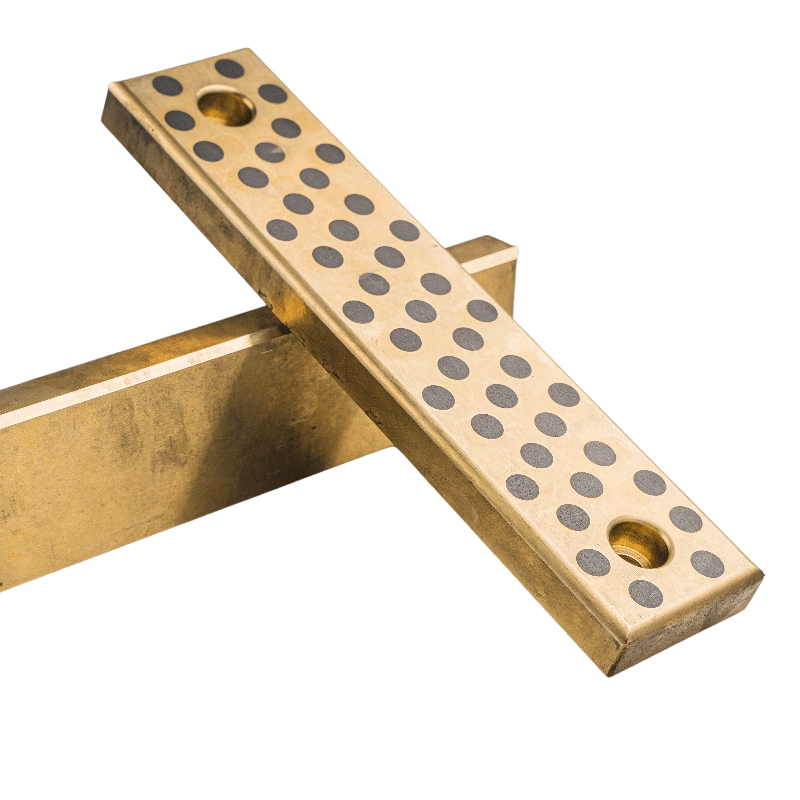

Introducing the Ultimate Solution: C93700 Bronze Wear Plate with Graphite Plugs

In the realm of machinery and industrial equipment, durability and reliability are paramount. That’s where the C93700 Bronze Wear Plate with Graphite Plugs steps in as the ultimate solution. This innovative component combines the robustness of C93700 bronze with the self-lubricating properties of graphite plugs, offering unmatched performance in high-wear environments.

Exceptional Durability:

Crafted from C93700 bronze, known for its exceptional wear resistance and longevity, the wear plate ensures prolonged service life even under the most demanding conditions. Whether facing heavy loads or abrasive materials, this wear plate stands the test of time, minimizing downtime and maintenance costs.

Self-Lubricating Design:

What sets the C93700 Bronze Wear Plate apart is its incorporation of graphite plugs. These self-lubricating inserts reduce friction and heat buildup, providing smooth operation and preventing premature wear. As the machinery operates, the graphite plugs release lubricating particles, ensuring continuous protection against friction-induced damage.

Optimized Performance:

The synergy between C93700 bronze and graphite plugs results in optimized performance across various applications. From high-speed machinery to heavy-duty equipment, this wear plate enhances operational efficiency and reliability, delivering consistent results even in challenging environments.

Versatile Applications:

The versatility of the C93700 Bronze Wear Plate with Graphite Plugs makes it suitable for a wide range of applications, including:

- Heavy Machinery: Ideal for use in heavy machinery subjected to constant wear and friction.

- Industrial Equipment: Perfect for industrial equipment requiring reliable wear protection and smooth operation.

- Mining Operations: Well-suited for use in mining equipment exposed to abrasive materials and harsh conditions.

- Construction Machinery: Essential for construction machinery operating in rugged environments and high-load scenarios.

Conclusion:

In summary, the C93700 Bronze Wear Plate with Graphite Plugs represents a breakthrough in wear protection technology. Combining the durability of C93700 bronze with the self-lubricating properties of graphite plugs, this innovative component offers unmatched performance and reliability in high-wear environments. Whether in heavy machinery, industrial equipment, mining operations, or construction machinery, this wear plate ensures optimal performance and longevity, making it a valuable asset for any application requiring superior wear protection.

Explore Other Alloys

Suggested Searches: C86200, C86300, C93200, C95400