Bearing Bronze C93600, Manufacturer of Custom Machined Parts

About us

Manufacturer of custom machined C93600 Bronze Alloy parts

Bearing Bronze C93600, also known as High-Lead Tin Bronze, is a bronze alloy with a high proportion of lead. This material is widely used for manufacturing sliding bearings due to its unique physical and mechanical properties.

Here are some key characteristics and applications of Bearing Bronze C93600:

High Lead Content: C93600 typically contains about 8-11% lead, which enhances its self-lubricating properties.

Excellent Wear Resistance: The presence of lead gives this bronze alloy superior wear resistance, making it suitable for high load and low speed conditions.

Good Thermal Conductivity: Bronze inherently possesses good thermal conductivity, helping bearings dissipate heat during operation.

Superior Castability: C93600 is easy to cast, allowing for the production of complex bearing shapes.

Mechanical Properties: It offers good mechanical properties, including high strength and good impact toughness.

Corrosion Resistance: Bronze alloys are generally resistant to a variety of chemicals.

High-Quality C93600 for marine and chemical industries

Applications: It is commonly used to manufacture sliding bearings, bushings, gears, shims, and other components that require self-lubricating properties.

Maintenance: Due to its self-lubricating features, bearings made of C93600 generally require less maintenance.

Environmental Adaptability: Suitable for various environments, including marine and chemical industries, where corrosive media might affect the performance of other materials.

Cost-Effectiveness: Due to its durability and long life, C93600 bearings can reduce long-term operational costs.

For more detailed technical specifications or specific questions about Bearing Bronze C93600, please contact us.

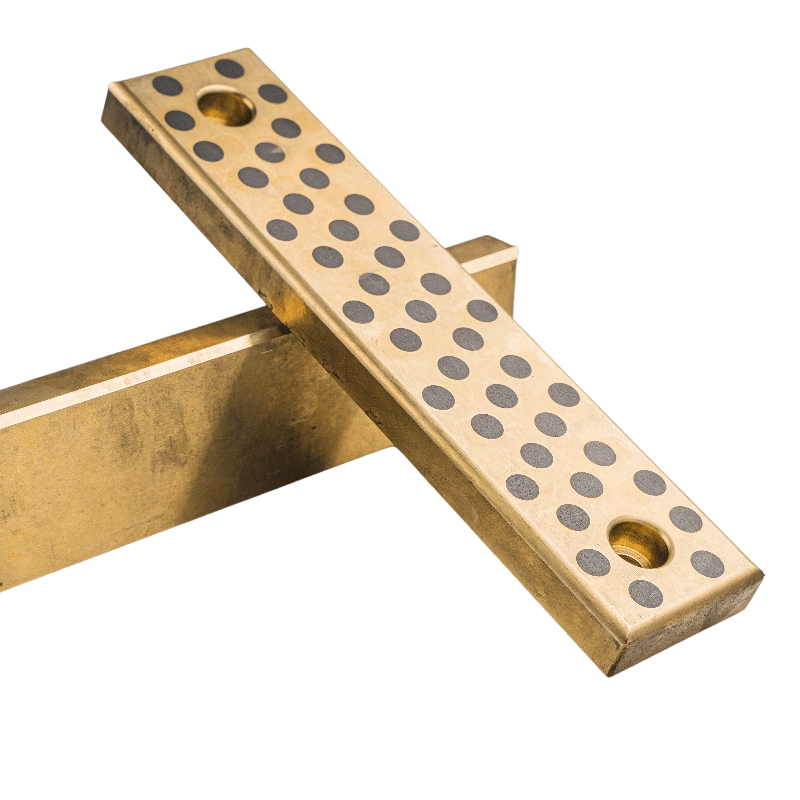

C93600 High Leaded Tin Bronze Slide Plate

Maintenance-Free: Due to their self-lubricating properties, these bearings require no maintenance, reducing upkeep costs and enhancing reliability.

Solid Lubricants: The contact surfaces of the bearings are embedded with solid lubricants made of graphite. These lubricants are patterned according to the “macroscopic distribution principle” to suit the types of motion the bearings will undergo.

Similar or Equivalent Specifications

| Specification | CDA | ASTM | SAE | AMS | Federal | Military | Other |

|---|---|---|---|---|---|---|---|

| C93600 | C93600 | B505 / B505M | – | – | – | – | – |

Chemical Composition The chemical composition of C93600 Bronze Bearing Alloy, according to ASTM B505/B505M-18, is as follows:

| Element | Cu% | Pb% | Sn% | Zn% | Fe% | P% | Ni%1 | Al% | S% | Sb% | Si% |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Range | 79.00-83.00 | 11.00-13.00 | 6.00-8.00 | – | 1.00 | 0.20 | 1.50 | 1.00 | 0.005 | 0.08 | 0.55 |

Note: The Ni value includes Co. Cu + sum of named elements must total a minimum of 99.3%. The values listed represent maximum limits.

Machinability and Density

- UNS No.: C93600

- Machinability Rating: 80

- Density: 0.325 lb/in³ at 68 °F

G-CuPb10Sn is a leaded tin bronze alloy designated under the German Industrial Standard (DIN). This material is notable for its high proportions of lead and tin, which typically confer good mechanical properties, reduced friction, and corrosion resistance. It is also known for its ease of machining, as well as excellent brazing and welding characteristics.

Based on research, the G-CuPb10Sn alloy is equivalent to the Japanese Industrial Standard (JIS) designation LBC3, and the American Standard (ASTM) designation C93700. This material is often used in applications that require self-lubricating properties and durability against wear, such as in bearings, bushings, and gears.

For more detailed information on G-CuPb10Sn, such as its chemical composition, physical properties, or specific use cases, please provide more context or specify your particular needs so I can offer more precise information. This material is well-suited for a range of industrial applications where its specific attributes—like its ease of fabrication and reliable performance under pressure and wear—are particularly valuable.

Aluminum bronze alloys form a family of copper-based alloys where aluminum is the primary alloying element, alongside other elements like iron, nickel, and manganese. These alloys are renowned for their high strength, corrosion resistance, and wear resistance, making them suitable for a wide range of industrial applications.

ZCuAl10Fe3: This aluminum bronze alloy contains approximately 10% aluminum and 3% iron. It is celebrated for its exceptional wear resistance and is commonly used in applications requiring high strength and durability, such as bushings, bearings, and other components.

ZCuAl8Mn13Fe3: Another variant of aluminum bronze, this alloy comprises about 8% aluminum, 13% manganese, and 3% iron. It is noted for its high strength and corrosion resistance, often used in marine and offshore applications.

AL10-3-1.5, AL10-4-4, AL10-5-5, and QAL11-6-6: These appear to be proprietary or non-standard names for aluminum bronze alloys. Without additional information on their composition and properties, it is difficult to provide specific details.

Standard Aluminum Bronze Alloys:

- C61400, C62300, C63000, C63200, C95200, C95300, C95400, C95420, C95500, and C95800: These are standard names for aluminum bronze alloys defined by the Copper Development Association (CDA) and other standard organizations. The aluminum content varies across these alloys, as do the contents of other alloying elements such as iron, nickel, and manganese. They are widely used in various industrial applications due to their ideal performance characteristics.

In summary, the provided information covers a range of aluminum bronze alloys, each with unique compositions and properties, typically used in industrial applications that require high strength, corrosion resistance, and wear resistance.

C93600 Alloy, C936 High-Leaded Tin Bronze Bearing Bushing, graphite inserts, bearing bushes, Bronze rings

Experience the Strength of Self-lubricating Bearings

Graphite Bronze Bearings, Industrial Graphite Bearings, ASTM Standards

Graphite bronze bearings are self-lubricating bearings that integrate graphite within a bronze matrix to improve performance under specific operating conditions. These bearings excel in environments where traditional lubrication might be impractical, such as at high temperatures, or in situations where maintaining lubrication can be challenging.

Industrial graphite bearings, on the other hand, are generally made from materials high in graphite content. They are deployed in scenarios requiring low friction, high wear resistance, and the capability to function without constant lubrication.

ASTM International is a globally recognized authority in developing and issuing international voluntary consensus standards. For graphite bronze and industrial graphite bearings, ASTM provides specific standards to guide manufacturers and users in ensuring quality and performance. Key standards include:

Adhering to these ASTM standards is crucial for ensuring that bearings meet essential performance and safety standards. They also facilitate the interchangeability of replacement parts and reliability across various industrial applications.

It’s important to reference the appropriate ASTM standards when specifying or using graphite bronze or industrial graphite bearings to ensure they are fit for purpose and manufactured to a recognized quality standard.

C936 is a high lead tin bronze alloy material

C936 is a high lead tin bronze alloy material, with excellent mechanical properties and wear resistance, widely used in the manufacture of various bearings and bushings and other parts.

Self-lubricating bearings are designed to operate without the need for external lubricants. These bearings typically incorporate solid lubricants, such as graphite, into their contact surfaces. Based on the information you provided, these bearings are made from bronze alloys. Specifically, bearings with an inner diameter greater than 180 millimeters are made from the ASTM B271 C86300 alloy, while those with an inner diameter less than 180 millimeters use the ASTM B505 C86300 alloy.

plain bearings – Design Guide, Search Our Material Alloy

Continuous cast, Bronze C93600 bearing and Bushing, Bearing Bronze Supplier

C93600 is a high-lead tin bronze alloy, recognized under different standards and designations across various countries. In the German Industrial Standard (DIN), C93600 is equivalent to the grade G-CuPb10Sn. This material is known for its high lead content, which provides excellent self-lubricating properties and good wear resistance, making it commonly used for manufacturing bearings and bushings.

Please note that DIN stands for German Industrial Standard. China has its own national standards system, known as GB/T. There is no direct equivalent of C93600 under the Chinese national standard designations readily available in search results. To find the corresponding Chinese standard for C93600, it is typically necessary to consult relevant Chinese national standard documents or databases, or to contact material suppliers for more detailed information.