The C83600 Custom Machined Parts, C836 / C83600 Leaded Red Brass Alloy

About us

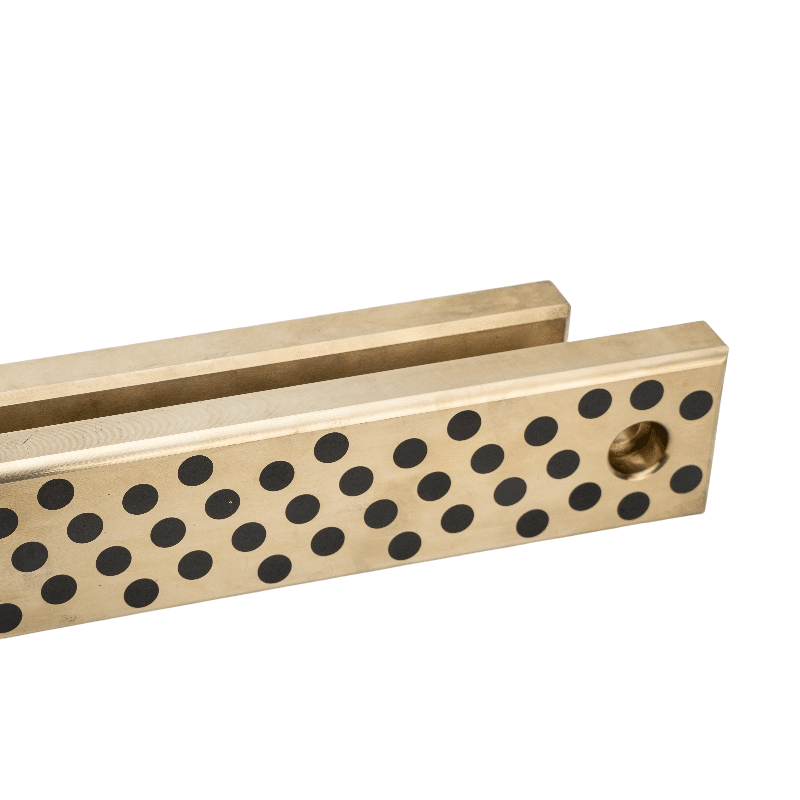

Cost-Effective C83600 Bronze Bushings for Low-Load Bearings

C83600 Red Brass is a copper alloy known for its excellent corrosion resistance, good mechanical properties, and appealing appearance. It primarily consists of copper with zinc and sometimes small amounts of lead to enhance machinability. This red copper alloy is widely used for bearings and components needing wear resistance. Though called bronze, it is more often referred to as brass and is commonly used for bearing bushings in various industrial applications due to its outstanding performance and durability.fe.

key points about C83600 Red Brass, C83600 Alloy, C836 Leaded red brass Bearing

Brass composition: red brass composition, C83600 Leaded Red Brass, commonly referred to as 85 metal or 85-5-5-5, is the most prevalent type of red brass bar. It is composed of 85% copper, with each of tin, lead, and zinc making up 5%.

Corrosion Resistance: The high copper content in C83600 Red Brass makes it resistant to many forms of corrosion, which is beneficial for components that may be exposed to various environmental conditions.

Mechanical Properties: This alloy has good mechanical properties, including strength and hardness, which are important for bearing applications where the material needs to withstand loads and maintain its shape.

Non-Ferrous: Being a non-ferrous metal, C83600 Red Brass does not have magnetic properties, which can be an advantage in applications where magnetic interference is undesirable.

Low-Load Bearings: For low-load bearing applications, the combination of strength, corrosion resistance, and non-magnetic properties makes C83600 Red Brass a suitable and economical choice. It can handle the low to moderate loads typically found in such applications without the need for more expensive materials.

C836 / C83600 Leaded Red Brass Alloy, Benefits Of c836 Bronze Bushing For Such Applications:

Cost-Effectiveness: Compared to other materials like stainless steel or more complex alloys, C83600 Red Brass can be a more cost-effective option for certain applications, particularly where the loads are not too high.

Machinability: The addition of lead can enhance the machinability of the alloy, making it easier to manufacture components with tight tolerances and complex geometries.

Aesthetics: Red Brass has a distinctive reddish color that can be appealing in applications where appearance is also a consideration.

Non-Toxic: Red Brass is often used in applications where contact with food or beverages is possible, as it is considered non-toxic.

C83600 Red Brass, cusn5zn5pb5 material, C836 / C83600 Custom Parts

It’s important to note that while C83600 Red Brass can be a good choice for low-load bearing applications, it may not be suitable for high-load or high-wear applications where more robust materials would be required. Additionally, the specific properties and suitability of C83600 Red Brass can vary depending on the exact formulation and any heat treatment or processing it has undergone.

The Chinese equivalent of C83600 is ZCuSn5Pb5Zn5. C83600 is an American standard bronze alloy, primarily composed of tin as the main alloying element in the copper base. It is widely used in industries such as shipbuilding, chemicals, machinery, and instrumentation.

83600 ASTM Casting Copper Alloy Tin Bronze

| Chemical Composition mass/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Al | Fe | Mn | Ni | Pb | Si | P | Zn |

| 84.0-86.0 | 4.0-6.0 | 0.005 | 0.3 | – | 1 | 4.0-6.0 | 0.005 | 0.05 | 4.0-6.0 |

| Mechanical properties | |||

|---|---|---|---|

| Tensile strength Mpa(Min) | Yield strength MPa(Min) | Elongation % | Brinell hardness(HB) |

| 248 | 131 | 15 | 60 |

Note:

1、In Chemical Composition, Single values represent maximums.

2、Mechanical performance of hardness value is only for reference

In industrial applications, these materials are primarily used to manufacture components such as bearings, bushings, and turbine bearings. Here is a brief description of these materials:

Flanged Graphite Copper Bushing: This material usually refers to a composite material where graphite is added to a copper alloy. The inclusion of graphite significantly enhances the self-lubrication of the material, reducing friction and wear, especially under dry friction conditions. Graphite copper bushings are suitable for applications requiring low friction coefficients and high wear resistance.

ZCuPb20Sn5: This is a type of leaded tin bronze, with a relatively high lead content, typically around 20%. The addition of lead improves the material’s self-lubricating properties and load-bearing capacity, making it suitable for heavy-load and low-speed applications.

ZCuSn5Pb5Zn5: This material is a variant of the QCuSn5-5-5 tin bronze you previously mentioned, containing tin, lead, and zinc. This alloy offers good overall performance, including high strength, good wear resistance, and corrosion resistance, making it suitable for manufacturing parts that operate under higher loads.

Bearing Bronze Bushing: Typically refers to a copper alloy bushing used in bearings. They can be made from any of the materials mentioned above or other copper alloys that offer good wear resistance and load-bearing capacity.

Rolling Mill ZCuSn5Zn5Pb5 Copper Bushing: This material is a copper alloy specifically designed for rolling mill applications, combining the properties of tin, zinc, and lead to provide excellent wear resistance, load-bearing capacity, and corrosion resistance.

Turbine Bearing Series: Turbine bearings are critical components in turbines that must withstand high temperatures, high speeds, and high loads. Copper alloys are commonly used to manufacture these parts due to their good thermal conductivity, wear resistance, and strength.

Copper Alloy Bushing -Tin Bronze, C83600 Tin Bronze

Experience the Strength of Self-lubricating Bearings

Bronze Material: Red brass alloys, like C836, C836 / C83600 Leaded Red Brass Alloy Bearing Bushing

C83600 Leaded Red Brass, or 85 metal, is a widely used alloy containing 85% copper and 5% each of tin, lead, and zinc. It is frequently employed in plumbing applications. The most common in this group is C84400 semi-leaded red brass, valued for its cost-effectiveness and excellent machining and casting properties, with lead enhancing pressure tightness. Red brass is also a budget-friendly choice for low-load bearings.

We offer machining, design, and engineering services characterized by integrity, quality, and commitment. Our products include affordable, high-quality, precision CNC machined parts. Our gallery highlights capabilities in CNC milling and turning, 5-axis CNC machining, and complex parts and assemblies production.

C89835 Lead-free replacement for C932, C836, C844

C89835 is a lead-free alternative to traditional bronze alloys such as C932, C836, and C844. It is used in the CNC machining of bronze parts, customized using the lead-free or low-lead C89835 and C932, C935 alloys.

C89835 is a lead-free replacement alloy for C932, C836, and C844, and is available as a standard-stocked product. This alloy meets the market demand for materials that comply with lead-free regulations.

C89833 Lead-free Replacement for C836, Copper Casting Alloy – Leaded Red Brass UNS C83600

C89833, a lead-free replacement for C836, is manufactured meet market demand for regulation-compliant, lead-free materials.