C63000, Manufacturer of Custom Machined Parts

About us

Manufacturer of custom machined C63000 parts, Aluminium Bronze C63000, Copper Nickel-Aluminum-Bronze Alloy (UNS C63000)

C63000 aluminum bronze is a material known for its high strength and good wear resistance, often used to manufacture structural parts like brackets, gears, and bushings that require durability and resistance to wear. According to the search results provided, the corresponding grades for C63000 aluminum bronze are QAl10-4-4 in China, CA104 in the UK, and CuAl10Ni5Fe4 in Germany.

Experience unmatched performance with our C63000 CuAl10Ni bronze bearings. Tailored for high-load applications. Order now!

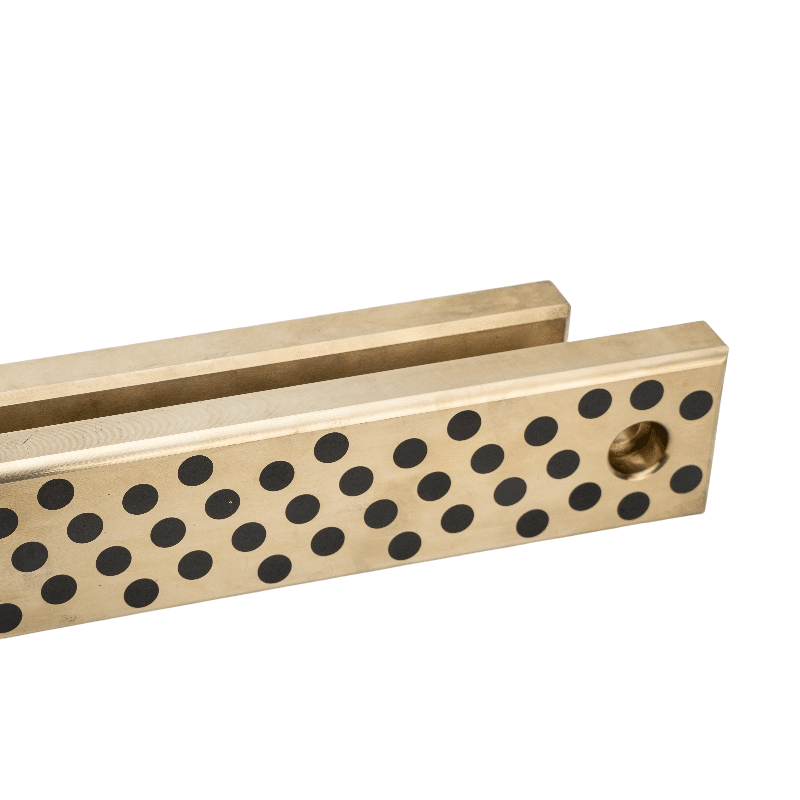

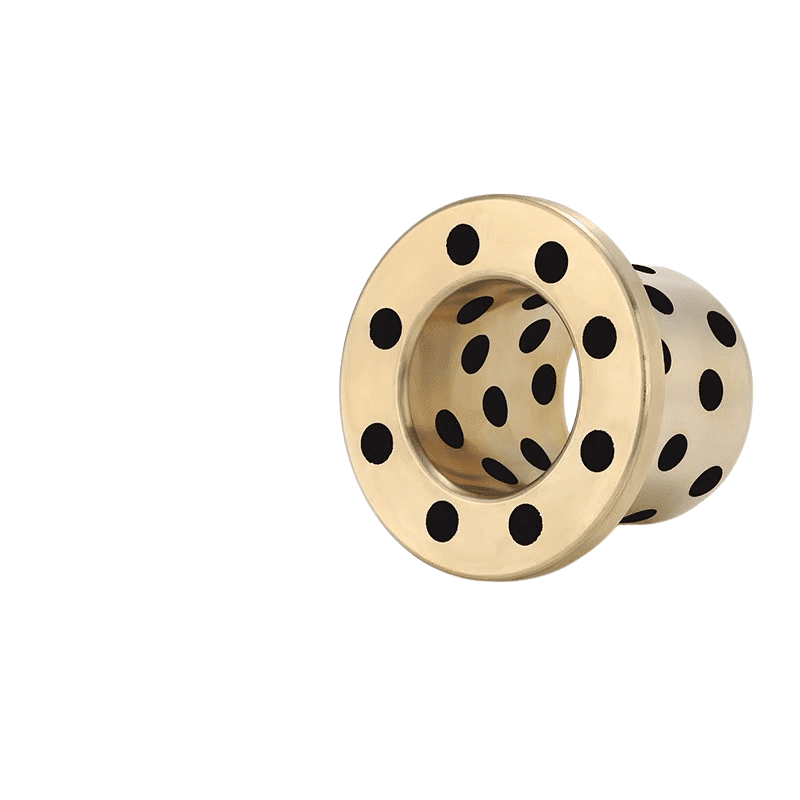

C63000 Bronze Bushings for Sale, aluminium bronze Bearing, c63000 bronze Plate

The chemical composition and mechanical properties of C63000 aluminum bronze make it very popular across various industrial applications, especially where corrosion resistance, ease of machining, and good weldability are required. It contains elements like iron and manganese, which enhance the alloy’s strength and wear resistance. With quenching and tempering treatments, the hardness of C63000 can be further increased, while maintaining excellent high-temperature corrosion resistance and oxidation resistance.

The C63000 (AMS 4640 – CDA 630) aluminum bronze alloy is an outstanding option for applications that require the handling of heavy loads and exceptional resistance to abrasion, friction, and wear.

Enhance your equipment with our high-strength C63000 bronze bushings. Ideal for marine & industrial use. Affordable prices!

High-Quality C63000 Bushings, Aluminium Bronze C63000 Bearing, Aluminium Bronze C63000, c63000 bronze

CuAl10Ni5Fe4 (CW307G) : Boost efficiency with our C63000 bronze bushings. Perfect for heavy-duty applications. Superior wear resistance. Shop now!

Additionally, the international designation for C63000 aluminum bronze is UNS C63000, and it is detailed in the ASTM B150 standard, which is a specification for aluminum bronze rod, bar, and shapes.

If you are considering manufacturing custom mechanical parts using C63000 aluminum bronze, you should seek out professional manufacturers who can produce customized parts according to specific application needs and design requirements. Manufacturers typically choose the appropriate material and manufacturing processes based on the mechanical properties of the material, the operating environment, and the expected service life.

Aluminium Bronze C63000, Durable Bronze Bearings Available, Cnc Machined Components

Need reliable bronze bearings? Our C63000 CuAl10Ni options offer superior corrosion resistance & longevity. Get a quote today!

Understanding the different grades and standards across countries is very useful when selecting materials and manufacturers, helping ensure that the material you choose meets the performance requirements for your specific application. For instance, if you are looking for materials in the UK, you should look for aluminum bronze marked as CA104; in Germany, the grade to look for would be CuAl10Ni5Fe4.

Please note, this information is based on the search results provided, and actual chemical compositions and performances may vary depending on specific manufacturing processes and heat treatment conditions. It is advisable to consult material suppliers or manufacturers for the most accurate information when selecting materials and designing parts. C63000 aluminum bronze is a copper-based alloy primarily alloyed with aluminum, typically containing 5.00% to 11.00% aluminum. Additional elements like iron, nickel, manganese, and silicon may be added to enhance the material’s properties. This alloy is widely used in industry due to its high strength and excellent corrosion resistance.

Leaded, Phosphor And Aluminium Bronzes Plates and Bearing,

Wear Plates – Mold and Die Products, Search Our Material Alloy

Similar or Equivalent Specifications:

| Material | ASTM | SAE | AMS | Federal | Military | Other |

|---|---|---|---|---|---|---|

| C63000 | B150, B150M | J461, J463 | 4640 | QQ-C-465B AMD1 |

Chemical Composition (According to AMS 4640):

| Element | Copper (Cu)% | Tin (Sn)% | Zinc (Zn)% | Iron (Fe)% | Nickel (Ni)% | Aluminum (Al)% | Manganese (Mn)% | Silicon (Si)% |

|---|---|---|---|---|---|---|---|---|

| Range | Remainder | 0.20 | 0.30 | 2.00-4.00 | 4.00-5.50 | 9.00-11.00 | Up to 1.50 | Not specified |

Notes:

- The copper value includes silver (Ag).

- The sum of Cu plus named elements must be at least 99.5% minimum.

- The values listed represent the maximum allowable percentages for each element except copper, which is given as the remainder after accounting for all other elements.

aluminium bronze C63000, an American grade of nickel aluminium bronze, is composed of approximately 10% aluminium, 5% nickel, and 3% iron. This alloy is notable for its inherent high strength and hardness, exceptional toughness, and superior resistance to wear, shock, and abrasion.

It provides excellent corrosion, erosion, and cavitation resistance in seawater and non-oxidizing acids. Notably, Aluminium Bronze C63000 also displays outstanding galling resistance and maintains its mechanical properties at elevated temperatures, making it well-suited for aerospace applications. This alloy is commonly used in environments such as the oil and gas industry and marine settings.

Key Characteristics:

- Aluminium is the primary alloying element added to copper, unlike standard bronze, which is primarily copper and tin.

- Offers higher strength and corrosion resistance compared to other bronze alloys.

- Exhibits corrosion resistance in seawater environments.

- The material forms a durable layer of aluminium oxide when exposed to atmospheric oxygen, enhancing its robustness.

- Frequently employed in the marine sector and oil and petrochemical industries, particularly in non-sparking environments.

- Typically used in the manufacturing of valves and fasteners.

Aluminum bronze is an alloy primarily composed of copper and aluminum, with the primary alloying element being aluminum. The typical composition of aluminum bronze can vary slightly depending on the specific requirements and applications, but a common formulation includes:

- Copper (Cu): Approximately 88% to 90%

- Aluminum (Al): Approximately 9% to 11%

- Other elements: May include small amounts of iron, nickel, manganese, and silicon to enhance specific properties such as strength, corrosion resistance, and machinability.

Here are some common additional elements and their purposes:

- Iron (Fe): Often included in the range of 2% to 5%, iron enhances the mechanical properties of the alloy by increasing its strength and toughness.

- Nickel (Ni): Added in amounts of up to 5%, nickel can improve corrosion resistance, especially in harsh environments.

- Manganese (Mn): Typically found in less than 1.5%, manganese can improve the alloy’s strength and resistance to impact.

- Silicon (Si): Usually less than 0.25%, silicon can be added to improve castability and reduce oxidation during melting.

Aluminum bronze is known for its excellent corrosion resistance, especially in marine environments, its high strength, and its resistance to wear. These properties make it suitable for various applications including bearings, gears, valve components, and undercarriage parts in aerospace and marine engineering.

Premium C63000 Bronze Bearings, Corrosion Resistance: It has excellent resistance to corrosion, making it suitable for use in harsh environments.

Experience the Strength of Self-lubricating Bearings

Key characteristics of C63000 aluminum bronze include:

C63000, also referred to as C630, is a nickel-aluminum bronze alloy. It offers a range of desirable properties thanks to its blend of aluminum and copper. The alloy is recognized by the UNS number C63000.

High strength: Aluminum bronze has higher strength than common copper alloys, making it suitable for high-load applications.

Good wear resistance: Due to its aluminum content, C63000 aluminum bronze exhibits good wear resistance, suitable for manufacturing bearings, bushings, and other wear-resistant parts.

Excellent corrosion resistance: Aluminum bronze is highly resistant to seawater and other corrosive environments, making it common in marine and chemical equipment.

Good machinability: C63000 aluminum bronze can be further improved in mechanical properties through heat treatment and cold working.

Heat treatment strengthening: The hardness and strength of C63000 aluminum bronze can be significantly enhanced through quenching and tempering.

Good weldability: C63000 aluminum bronze has good weldability and can be joined to other metals through various welding methods.

C63000 High Strength: The alloy has a high tensile strength, which allows it to support heavy loads.

Due to these properties, C63000 aluminum bronze is highly suitable for manufacturing a variety of mechanical parts, such as:

Bronze parts: Including high-strength structural components.

Bushings: Used to reduce friction and wear.

Bearings: Suitable for bearing rolling or sliding loads due to their wear resistance.

Rings: Serve as connectors or locators in various mechanical systems.

Plates: Used to manufacture various shaped parts, such as heat sinks, pipes, and decorative plates.

Worm Gear: Worm gears are used in power transmission applications where a high reduction ratio is needed. The worm gear set consists of a worm (screw) and a worm wheel. CuAl10Ni bronze is suitable for worm gears because it can withstand the sliding motion and high contact pressures typical of worm gear sets. Its wear resistance helps to extend the life of the gears.

These characteristics make C63000 aluminum bronze a preferred material for many industrial applications, especially in environments where high strength, wear resistance, and corrosion resistance are required.

Continuous cast, Bronze C63000 bearing and Bushing, Aluminium Bronze C63000 Bearing Bronze Supplier, Engineering Excellence

Elevate machine performance with top-tier C63000 CuAl10Ni bronze bearings. Exceptional strength & durability. Wear Resistance: The high aluminum content in the alloy contributes to its excellent wear resistance. Good Machinability: It can be easily machined into complex shapes and sizes.

Heat Treatment: The alloy can be heat-treated to improve its mechanical properties further. Click to explore! When specifying CuAl10Ni bronze for these components, it’s important to work with a reputable supplier who can provide material that meets the required specifications and standards, such as ASTM B150 for C63000 aluminum bronze. Additionally, the manufacturing process should be carefully controlled to ensure the components meet the necessary quality and performance standards.