Bushing Feature

Self-lubricating Bushing & BearingMade To Order

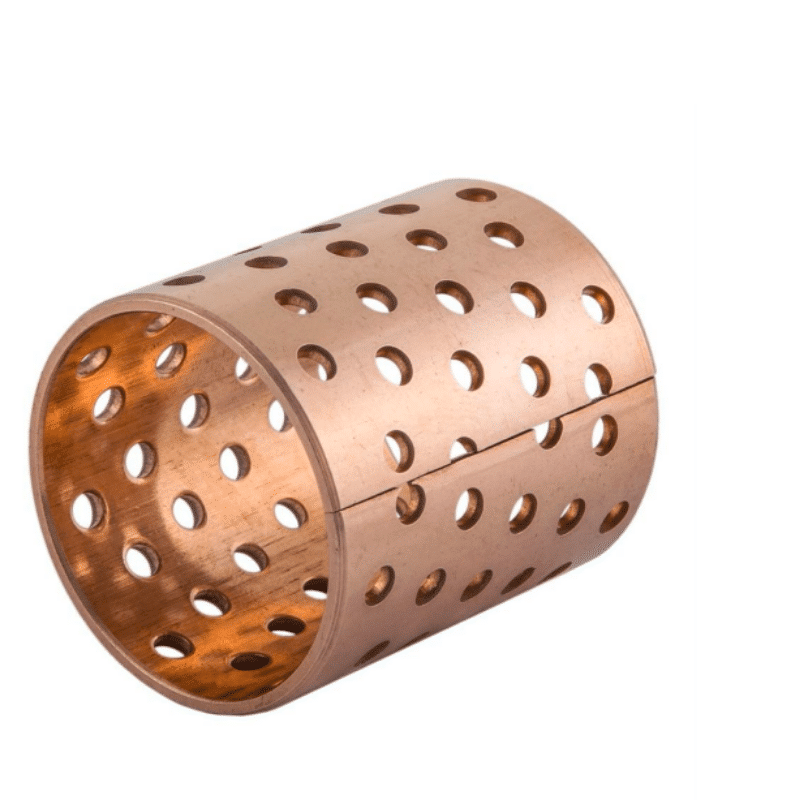

Bimetal bushing, bearing bush and thrust washer are made of high quality low carbon steel and sintered bronze powder on the surface.

They are suitable for rotating and swinging motion under high load and low speed.With the characteristics of low friction coefficient, good wear resistance, long service life and good anti-bite performance, copper alloy layer can be processed according to the requirements of various types of oil holes and grooves.

The bimetal bushings Products are widely used in mining machinery, steel rolling machinery and so on.

Cylindrical bushing / custom bearing bushing

Bushing Services, Self-lubricating Bearing Supplier

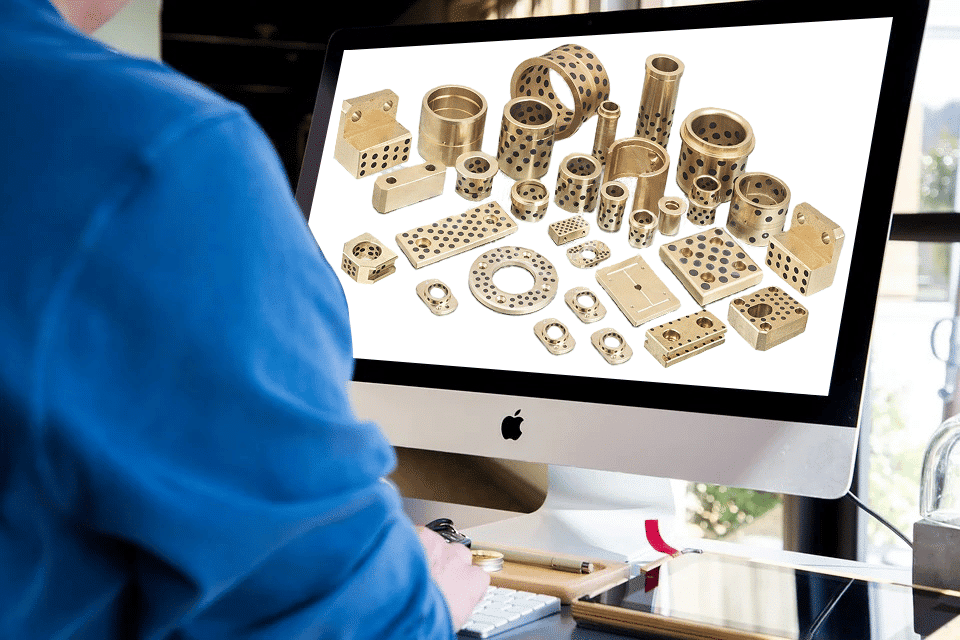

Industrial and Oilless Bearing Supplies, We have a wide range of plain bushing bearings to meet virtually all the needs of the steel industry. Extreme temperature variations, high contamination levels, high forces during slow rotations and grid shocks. Self-lubricating plain bearings address all the toughest conditions with specially engineered and custom designed bearing materials. Graphite self-lubricating bearings have at least 6 times longer service life compared to ordinary copper bushings and are highly sought after for the following advantages:

The choice for customers in the steel industry. The most popular self-lubricating bearing bushings

Self-lubricating Bearing Bushing, Not finding the bearing bushing product or spare part you are looking for, please contact us.

Product Quality Index

Energy Generation

Steel Industry Customers’ Choice: Most popular Oilless Graphite Bearings

Beautifully crafted leather products.

Whether in a smelter with dolomite particles, a smelter with slag and furnace cement, or a smelter with many types of iron ore and quartz in an extremely dusty environment; whether in a ladle with extremely high temperatures or in a copper bushing that tends to liquefy at high temperatures, the typical methods of grease lubrication cannot be used. Whether you are looking for bearings for arch furnace lift mechanisms, scrap hinges, hydraulic cylinders, or hot or cold rolling mills, we can provide OEM quality, custom designed bearings, and trouble-free installation in a short lead time. Solid sliding bearing. DIN 1850 / ISO 4379, maintenance-free, Different bronze alloys available on request Water-resistant solid lubrication available on request. Sliding surface: Bronze + Solid Lubricant Plugs! Solid bronze sliding bearing with solid lubricant inserts. … graphite bearings is a maintenance free sliding bearing, but initial lubrication is necessary! We produce all special designs at short notice! Cylindrical bushing. Flanged bushing. Graphite Thrust washer. Solid sliding bearing CuZn25Al5! pockets in which a specially formulated solid lubricant is embedded. … that each bearing is specially made to meet all load!

A complete line of slide bearings developed for all relevant conditions encountered in the steel industry.

What sets us apart in the industry is our expertise in providing you with a one-stop shop for custom-designed turnkey solutions based on your requirements. Our engineers will work with your team to develop the most appropriate bearing, from the initial design phase all the way through to meeting your application requirements.

We offer a large selection of graphite copper sleeve and flange bushing.

MAINTENANCE Self-lubricating flange bushing, highly durable, and reliable bushing supplier with or without graphite plugged. Learn more!

CUSTOM-MADE STANDARD PRODUCTS

Learn More

Choose your bushings for steel rolling industry

Bimetal-bearing is a bimetal bushing, wrapped of steel-backed with a layer of lead bronze CuPb10Sn10.

- High load capacity

- Works well even in difficult conditions

- Good lubrication properties because of lubrication indents

- Wide range of temperature

Enhancing Steel Mill Efficiency with Self-Lubricating Bronze Bearings and Plates

Steel mills represent some of the most challenging industrial environments due to the extreme conditions of high temperatures and significant mechanical stress. These conditions demand materials that not only withstand the harsh environment but also contribute to the efficiency and longevity of the machinery used. One such material that stands out for its exemplary performance in steel mills is wear-resistant bronze, particularly in the form of self-lubricating bearings and plates.

Key Properties of Bronze in Steel Mills

Bronze is favored for its robustness in industrial applications, owing to several key properties:

- High Wear Resistance: Bronze’s remarkable resistance to wear makes it ideal for components that are in constant friction contact. Its durability is essential for the continuous operation of machinery without frequent replacements or downtime.

- Corrosion Resistance: The ability of bronze to resist various forms of corrosion is crucial in steel mills, where exposure to corrosive substances is common. This ensures longevity and reliability of the components even in adverse conditions.

- Heat Resistance: The capability to maintain integrity at high temperatures is vital in a setting like a steel mill, where ambient temperatures can be extremely high.

- Conductivity: Possessing good electrical and thermal conductivity, bronze is advantageous in applications that require efficient heat dissipation or electrical conduction.

- Strength and Rigidity: Bronze alloys are not only strong but also maintain their mechanical properties under substantial loads, making them suitable for structural applications within the mill.

Applications of Wear-Resistant Bronze in Steel Mills

Bronze plates and bearings find multiple applications in a steel mill, enhancing both the performance and durability of various components:

- Rolling Mill Rolls: Rolls that process the steel are subject to immense pressures and friction. Coating these rolls with wear-resistant bronze can significantly extend their service life.

- Guide Plates: These plates guide the steel through the mill and are subjected to continuous wear. Bronze guide plates can withstand this constant abrasion, ensuring smoother operations.

- Bearing Components: Bearings in steel mills operate under high-load and high-speed conditions. Self-lubricating bronze bearings are particularly valuable here, reducing the need for frequent lubrication and maintenance.

- Gear Components: Gears endure heavy loads and high friction; manufacturing these components from durable bronze alloys can prevent premature wear and failure.

Choosing the Right Bronze Alloy

The selection of the appropriate bronze alloy for specific applications within a steel mill is critical. Different alloys have varying properties tailored to distinct conditions, such as the expected type of wear (abrasive, corrosive), temperature range, and potential chemical exposure. It is important to analyze these factors meticulously to choose an alloy that not only meets but exceeds the requirements of the steel mill environment.

Conclusion

The use of self-lubricating bronze bearings and wear-resistant bronze plates in steel mills is a testament to the material’s superior properties and its ability to improve operational efficiencies. By choosing the right bronze alloy, steel mills can achieve higher productivity, reduced maintenance costs, and prolonged equipment life, making bronze an invaluable component in the harsh environments of steel processing.

Steel mills represent some of the most challenging industrial environments due to the extreme conditions of high temperatures and significant mechanical stress. These conditions demand materials that not only withstand the harsh environment but also contribute to the efficiency and longevity of the machinery used. One such material that stands out for its exemplary performance in steel mills is wear-resistant bronze, particularly in the form of self-lubricating bearings and plates.

Key Properties of Bronze in Steel Mills

Bronze is favored for its robustness in industrial applications, owing to several key properties:

- High Wear Resistance: Bronze’s remarkable resistance to wear makes it ideal for components that are in constant friction contact. Its durability is essential for the continuous operation of machinery without frequent replacements or downtime.

- Corrosion Resistance: The ability of bronze to resist various forms of corrosion is crucial in steel mills, where exposure to corrosive substances is common. This ensures longevity and reliability of the components even in adverse conditions.

- Heat Resistance: The capability to maintain integrity at high temperatures is vital in a setting like a steel mill, where ambient temperatures can be extremely high.

- Conductivity: Possessing good electrical and thermal conductivity, bronze is advantageous in applications that require efficient heat dissipation or electrical conduction.

- Strength and Rigidity: Bronze alloys are not only strong but also maintain their mechanical properties under substantial loads, making them suitable for structural applications within the mill.

Applications of Wear-Resistant Bronze in Steel Mills

Bronze plates and bearings find multiple applications in a steel mill, enhancing both the performance and durability of various components:

- Rolling Mill Rolls: Rolls that process the steel are subject to immense pressures and friction. Coating these rolls with wear-resistant bronze can significantly extend their service life.

- Guide Plates: These plates guide the steel through the mill and are subjected to continuous wear. Bronze guide plates can withstand this constant abrasion, ensuring smoother operations.

- Bearing Components: Bearings in steel mills operate under high-load and high-speed conditions. Self-lubricating bronze bearings are particularly valuable here, reducing the need for frequent lubrication and maintenance.

- Gear Components: Gears endure heavy loads and high friction; manufacturing these components from durable bronze alloys can prevent premature wear and failure.

Choosing the Right Bronze Alloy

The selection of the appropriate bronze alloy for specific applications within a steel mill is critical. Different alloys have varying properties tailored to distinct conditions, such as the expected type of wear (abrasive, corrosive), temperature range, and potential chemical exposure. It is important to analyze these factors meticulously to choose an alloy that not only meets but exceeds the requirements of the steel mill environment.

Conclusion

The use of self-lubricating bronze bearings and wear-resistant bronze plates in steel mills is a testament to the material’s superior properties and its ability to improve operational efficiencies. By choosing the right bronze alloy, steel mills can achieve higher productivity, reduced maintenance costs, and prolonged equipment life, making bronze an invaluable component in the harsh environments of steel processing.

Steel Fabrication: Building Metal Structures and Leading Industry Solutions

“Create Market-Leading Solutions, We Help the Steel Industry Stay in Front”

Stepping forward together with our customers, Technologies for top performance! Always tested. Always proven. Always Bronzelube.com, Explore more bushings & bearings for steel rolling industry online. Bimetal Bushings Solutions. Metallic, self-lubricating bushings are made up of one of four basic compositions: Strong Cast Bronze, Bronze Wrapped Bushings, Cast Bronze Bushing.