Technology of Sliding Bearings, Bushing Online Sourcing

Custom Bushing – Prompt Delivery, Global Supply

Sliding Bearing Super Technology Aftermarket parts and maintenance: We provides a range of maintenance bushing required for the sliding bearing aftermarket and repair, such as aftermarket metal bushing self-lubricating bearings for machinery and equipment, as well as auto parts (automotive repair parts). We also provides technical bearing material data services, and custom bearings maintenance and replacement bushing. * Also see the “Aftermarket Business” for sales of aftermarket products and various technical services. Sliding bearings support all rotating parts of automobiles and industrial machinery and contribute to saving energy. By utilizing our core technology of plain bushing bearings in a wide range of fields, where people can easily lead a secure and fulfilling life in harmony with nature.

Self lubricating Bush Market

Focus on the most challenging bushing applications

Self-lubricating Bearing Applications: On-Highway, Vocational, Off-Highway, Crane & Cargo. Partnered with our customers to ensure their needs are met throughout every step – from product planning and development through order fulfillment. We pride ourselves on going the extra mile to meet our customers’ expectations and assure their satisfaction. Our pledge is superior service and support; outstanding product quality; and consistent, on-time delivery. “We see a lot of markets where bushing product development schedules are very tight, but maintaining high quality is still a big priority.” The market is expected to be driven by increased demand for specialized self-lubricating bearing solutions that meet specific requirements and challenges in different industries. VIIPLUS engineers bring their expertise and love of tribology to the automotive, aerospace and industrial manufacturing sectors.

Self lubricating bush Design

Self-lubricating Bushes Market Size, Trends Analysis

Suppliers of plain and self lubricating bearings, and bushings. The market is expected to be driven by increased demand for specialized Self lubricating bush solutions that meet specific requirements and challenges in different industries.

- Metal-Polymer bearing: low friction coefficient, high wear resistance

- Engineering plastic bearings: self-lubricating, low friction

- Reinforced fiber bearings: wear resistance, corrosion resistance

- Metal and bimetal bearings: high load capacity

However, there are many applications where a more suitable Self lubricating bush can improve efficiency, accuracy, service intervals, reliability, speed of operation, size, …

Widely Application

The Self lubricating bushes are widely used in different area.

Self lubricating bush Service

Small minimum order value & quantity, fast delivery.

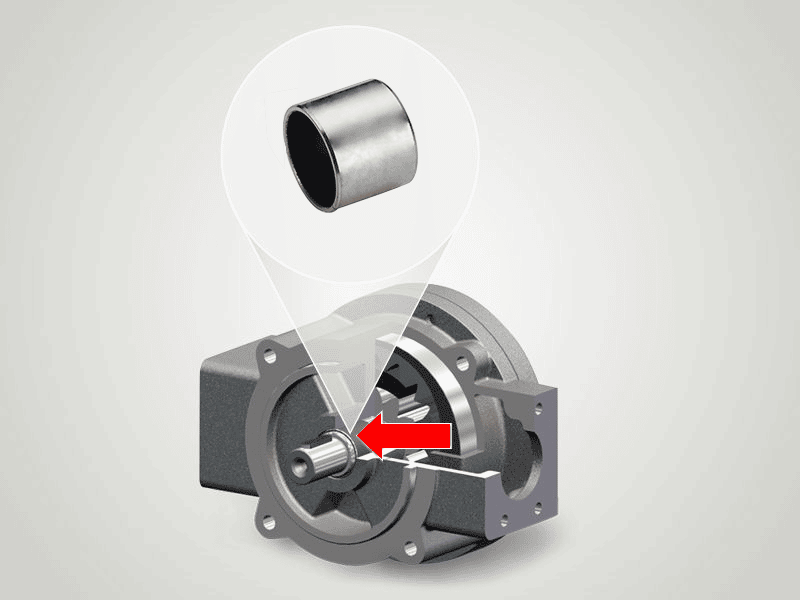

Principles of bushings & bearing selection and application

Bearing Type

Bearings Market Size, Share & Outlook. Always tested. Always proven. Global website www.bronzelube.com

Custom Design

Bushing & Bearing Application Design Examples. Choose your proper bushings & bearings types online. To meet the related application.

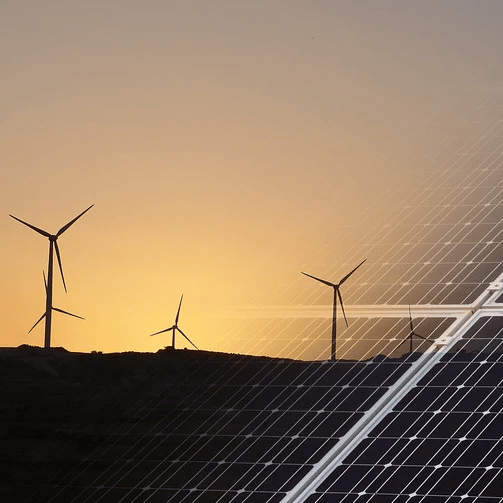

Energy facilities

Wind power generation

We serve the technical partner for wind turbine manufacturers worldwide. For example, because of advances in artificial intelligence, automation, and new energy, farm machinery can be produced faster and last longer than it did 50 years ago. But, in the meantime, both manufacturers and customers want the machine to be free of any performance problems. The same is true for the wind industry, where replacing the main shaft bearings of offshore turbines can cost hundreds of thousands of dollars. So these bearings have to be used for up to 25 years in some of the harshest conditions imaginable. We manufacture self-lubricating bushings apply to new energy support swing area to meet long-term use without maintenance requirements for environment-friendly new energy such as wind power, solar power, hydroelectric power, etc.

Logistics, port machinery

Bearing Characteristics

Our self lubricating bush bearings widely used in such as van, stacker, lift platform cars, port machinery and other outdoor logistics machinery.

Application filed: Maintenance-free, Low cost, Corrosion resistance. Slide bearings & Self lubricating bush are widely used in hydraulic industry, forging machine tool industry, plastics machinery industry port machinery, office, fitness machinery, textile machinery, food package, filling machinery, chemical machinery, automobile, shipbuilding industry, construction machinery and so on. For example, in the food and beverage industry, bushing bearings are replaced regularly every six months, but plant managers still require high quality sleeve bushing & bearings. For them, bearing failures mean risks such as tainted food and damaged brand reputations, or at the very least lost revenue as factory operations grind to a halt. Oil-free bushing quality and reliability are critical in industry applications.

* Our enterprise, is one of the undisputed supplier of the highly competitive order bushings & self lubricating bush bearings industry in china.

Railway

Transportation

Advancements in railway transportation now demand meticulous attention to bearing design, noise reduction, and cost considerations. Numerous manufacturers still depend on outdated bearing technology, posing significant risks to passenger and cargo safety, given the escalated stress, speed, and load on railway components.

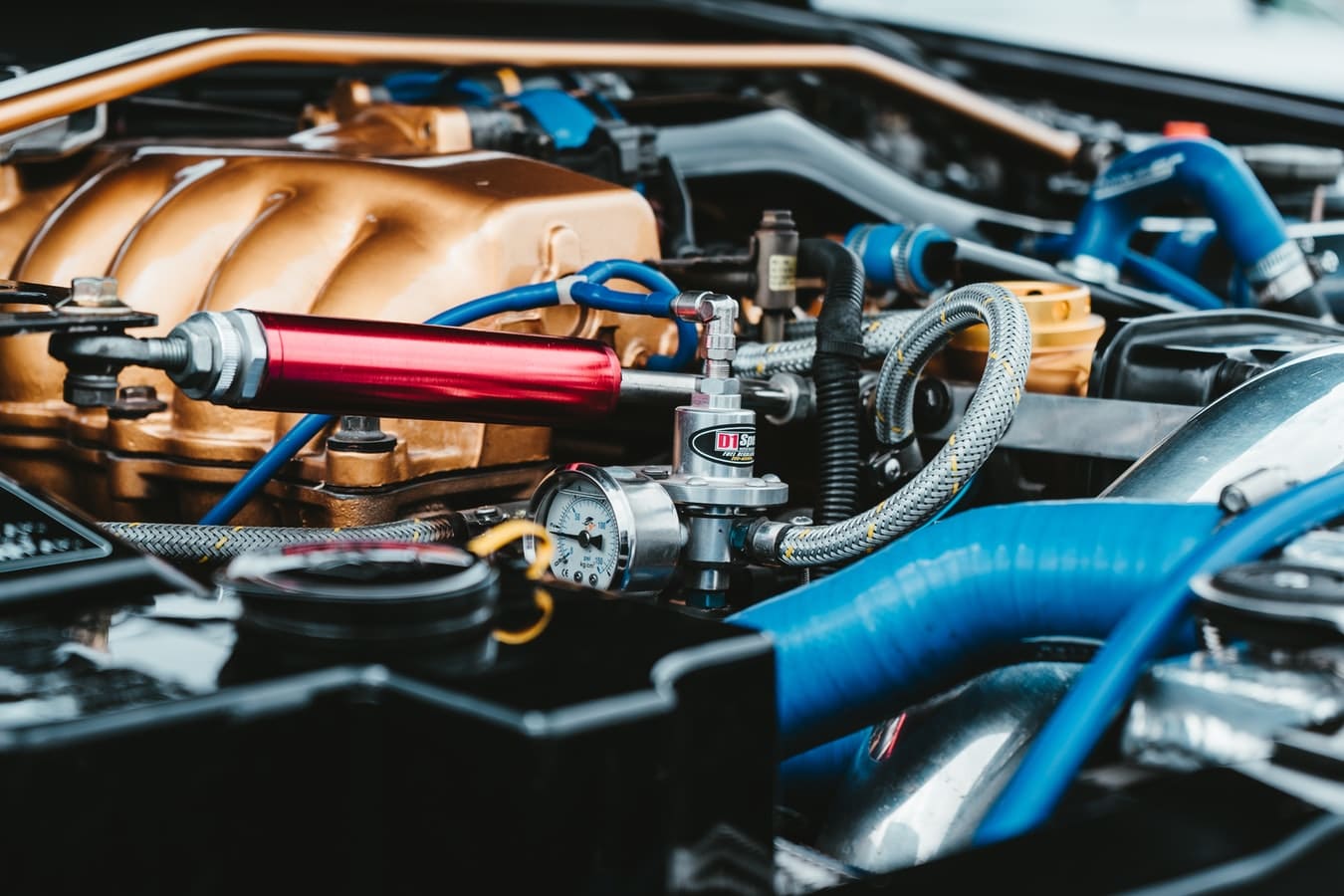

Automotive

Customized Bushing & Self-lubricating Bush

Customized Bushing & Self-lubricating Bush Solutions From China. “The quality and volume standards for bushings are very high in our industry, necessitating well-designed, reliable, high-quality solutions.” Discover Automotive Bushings, Self-lubricating Bush manufacturers, suppliers & exporters in China.

Our enterprise is one of the leading suppliers in China’s highly competitive order bushings and self-lubricating bush bearings industry.

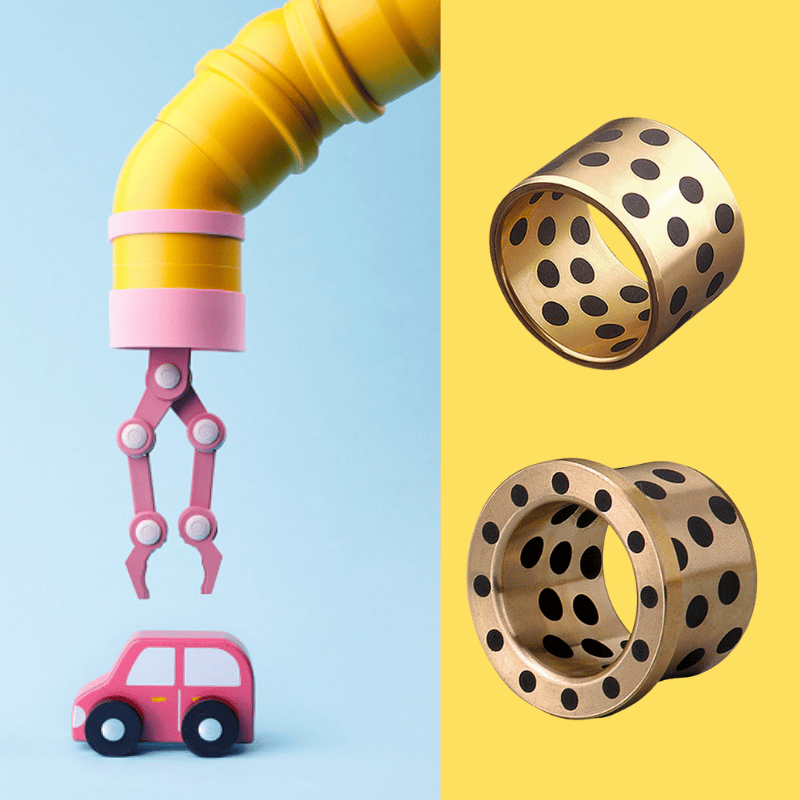

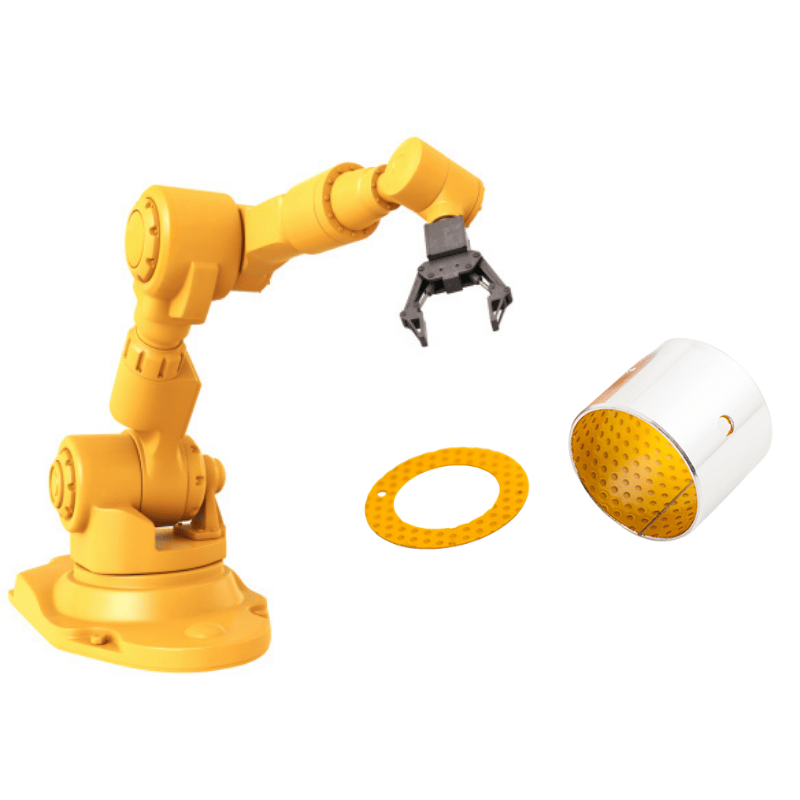

Focusing on robotics and packaging industry

Innovative self-lubricating bearing products cater to the robotics and packaging sectors, particularly focusing on robotics. These products, designed for collaborative robots’ joints, boast extended service life, tripling their longevity, thus enhancing performance and broadening applications. Capable of supporting loads up to approximately 20 kg, they serve as efficient solutions for multi-joint robots.

The food and packaging industries confront sustainability issues, cost constraints, and stringent hygiene standards. Our latest self-lubricating bearing product line for food, beverage, and packaging processing equipment exemplifies how automation can address these challenges. By offering sustainable and innovative solutions, we aim to curtail energy and raw material usage while providing significant advantages to customers.

Robotics & Automation, Robot Arm Bearings

High Performance Self-lubricating Bearings, Global Network

A solid lubricant bronze bearing can be a suitable choice for industrial robots as it offers low friction, high wear resistance, and can function in a wide temperature range. Additionally, the self-lubricating properties of bronze can reduce maintenance needs and prolong bearing lifespan. Robot arms often use bronze bearing bushings. Advanced Robotics Arm Bushings for Industrial Automation provide solutions such as self-lubricating bearings design and integration of solutions with programmable controllers, motion control, information systems, and various robotic systems. Our main bearing applications span industrial sectors including food manufacturing and pharmaceuticals. Robotics Bearings – Quickly find the bushing product application you need. Self-Lubricating Thrust Washers – maintenance-free, Anti-Friction, between 2 parts! Robotic Bearings – Bearings in Automation! Thin-section self-lubricating bearings are commonly used in robot arm joints due to their low mass, space-saving design, and high-speed capability. Rolling bearings consist of rolling elements (balls or rollers) between the inner and outer rings, functioning through rolling friction. They are broadly classified as deep groove ball bearings or roller bearings depending on the rolling element type and are available in radial bearings for radial loads and thrust bearings for axial loads. Self-lubricating bronze bearings can replace rolling bearings.

Robotics Thrust Washer, Self-lubricated

High Performance Self-lubricating Washer

Robot arms equipped with bushings are integral to advanced robotics in industrial automation. As a solutions provider, we specialize in robotic solutions, offering OEM services that encompass self-lubricating bearing design and implementation, along with programmable controllers, motion control, and information systems integration. Our expertise extends to various industrial sectors, including food manufacturing and pharmaceuticals.

Our range of robotics bearings facilitates swift application discovery. From self-lubricating thrust washers to maintenance-free thrust washer bearings, we ensure frictionless operation between components. These bearings find extensive use in automation, particularly in robot arm joints, owing to their lightweight, space-efficient design and high-speed capability.

Our thrust bearing washer parts play a crucial role in detecting the angles of robot joints, providing accurate angle information when paired with dedicated sensors. Notably, they offer superior environmental resistance compared to optical sensors and contribute to device compactness due to their thin and lightweight construction. Moreover, their hollow shape facilitates easy cable routing within robot joints.

We offer two variants: radial and axial types, each tailored to different detection requirements.

Steel Industry

Engineered Bushings: Applications & Industries

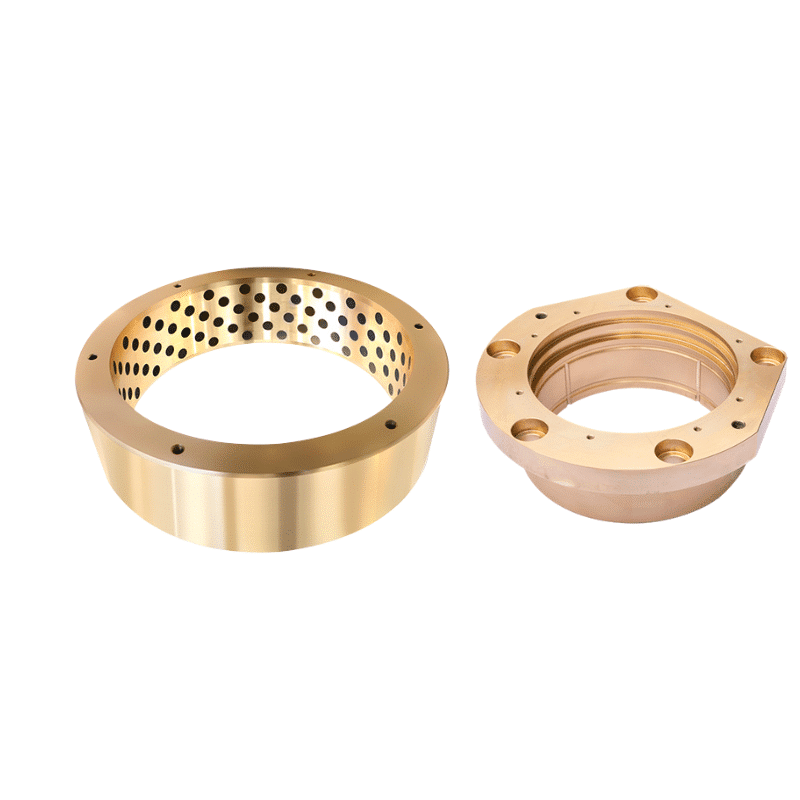

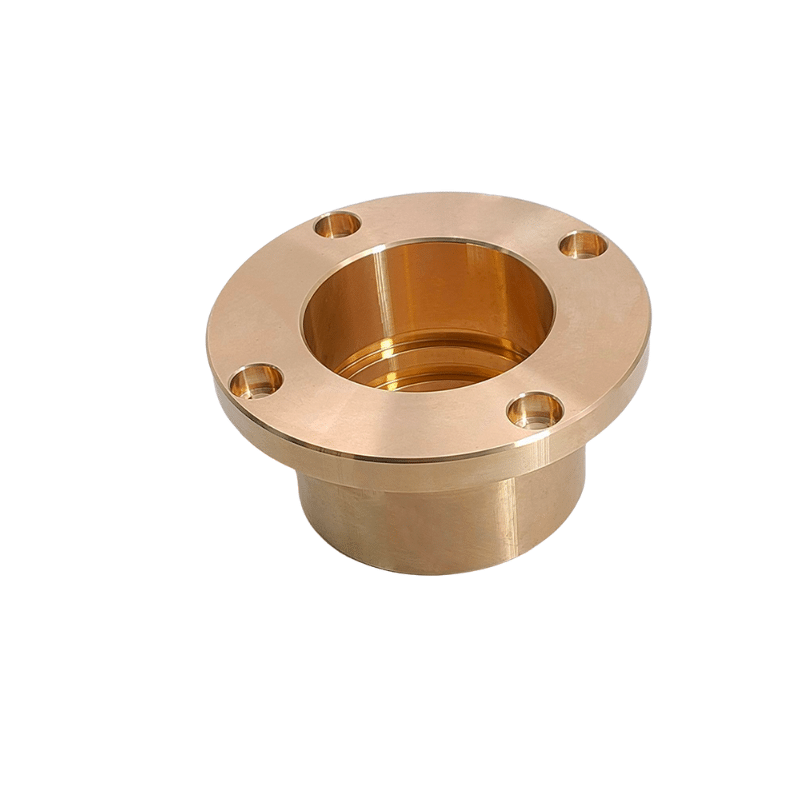

Bearings Bushing Units: Information On Various Series Of Sliding Bearing Bushing Material With Improved Functions For Applications That Require Properties Such As Housing Rigidity, Cleanliness, Corrosion-Resistance And Ease Of Mounting. Custom Bimetal Bushes & Part Manufacturing Service To Your Exact Specification. Quote Now! See “wrapped bearings” or “slide bearings” for individual bearings. * See “metal sliding bearing” for units consisting of bearings with a self-lubricating bearing design and size.For specialized applications demanding enhanced performance, our range includes custom bimetal bushes tailored precisely to your specifications. Whether it’s housing rigidity, cleanliness, corrosion-resistance, or ease of mounting, we prioritize delivering solutions that meet your unique requirements. Contact us now for a personalized quote and explore our extensive selection of wrapped bearings or slide bearings for individual needs. Additionally, for units comprising bearings with a self-lubricating design and various sizes, refer to our offerings under “metal sliding bearing.”

*Focus on bearing business 10+ years, rich experience help select the best match self-lubricating bearing.

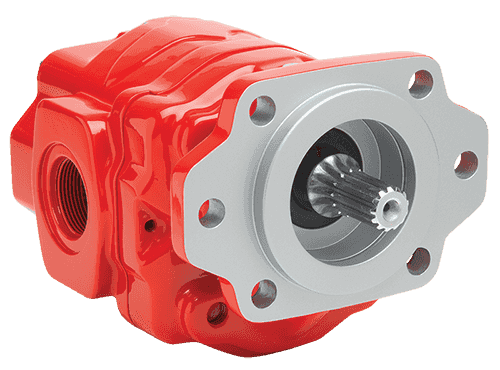

Hydraulics Bushings

Hydraulic systems

We manufacture a wide range of copper alloy self lubricating bush engineered for the hydraulics industry. Pump & Valve and Actuation. In the hydraulic market, our self-lubricating bearing products are offered for many applications. Mostly used in.

- Piston pumps and motors

- Vane pumps

- Gear pumps and motors

- Gas cylinders

Industrial Machinery

Bearings & Bushings

Custom Size

Bushings solutions will most notably benefit transmissions and truck brakes as well as agricultural, mechanical handling and lifting applications. They boast a high load capacity and very good resistance to fatigue strength at high temperatures.We serve the industrial machinery segment of our customer base by providing various self-lubricating bushes options for this highly specialized business segment.

Fluid Power

SPECIAL MANUFACTURING

Power transmission & control industry

To serve our customers’ full range of industrial motion needs, we focus on growing our power transmission bushing. Our expanding oilless bushes portfolio is anchored in many years of engineered bearings china and established engineering expertise in power transmission. We manufacture a wide range of sliding bearings specifically engineered for the Fluid Power.Valve & Pump Bushing …

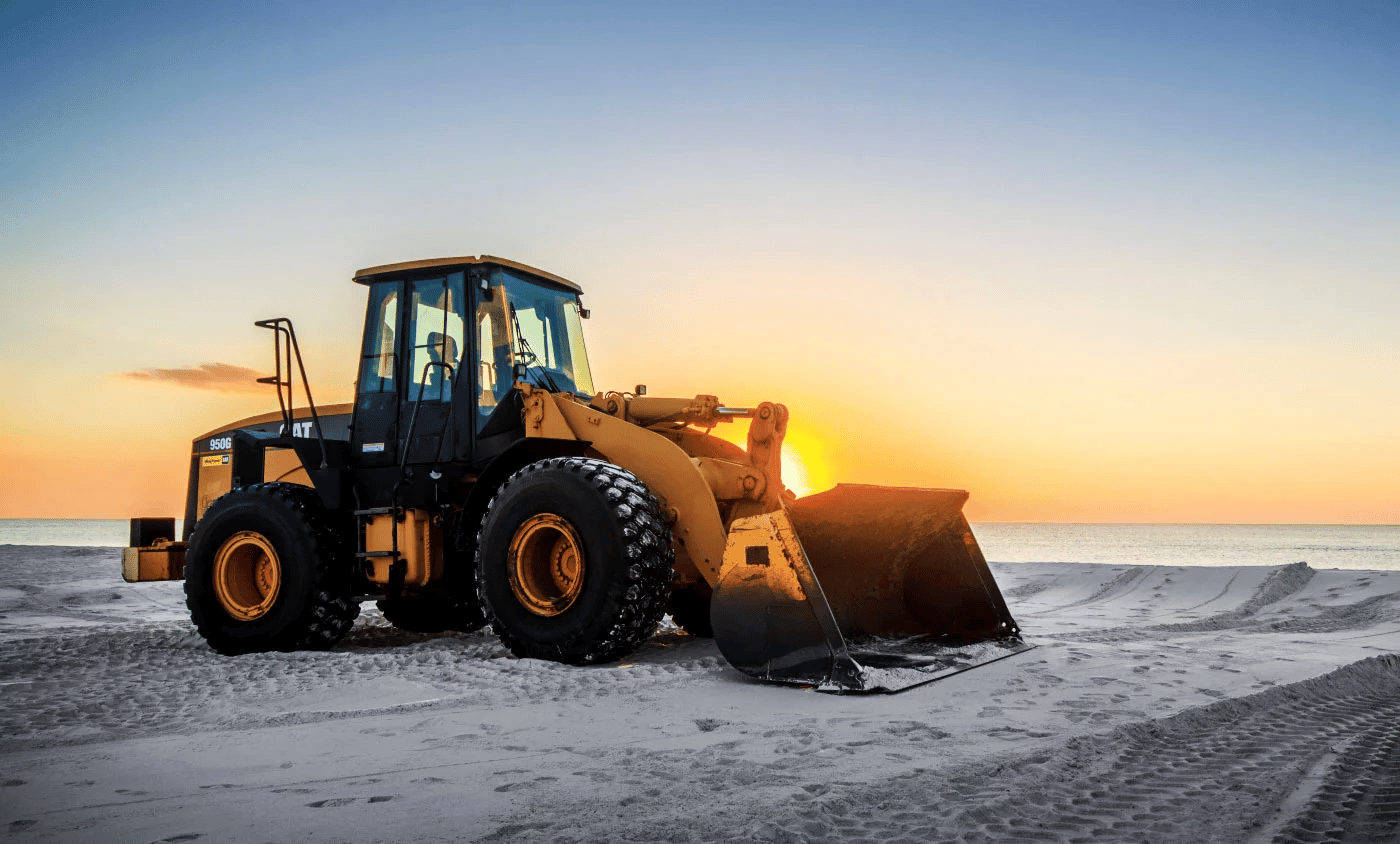

Construction

A RELIABLE, LIGHTER, GREASELESS BEARING SOLUTION

Your Partner for Self-lubricating Bearing Technology. We manufacture a wide range of sliding bearings specifically engineered for the construction and other equipment., maintenance-free solution with an extended service life. To ensure reliable operation under high-intensity working conditions, bearings play a very important role in construction machinery. Self-lubricating bearings can provide more reliable performance compared with traditional bearings.

Impact-resistant, dust-resistant, high-strength self-lubricating bearings not only solve the problem of lubrication but also reduce noise and extend the service life, especially in harsh mines and field operations of equipment

● Bucket

● Connecting rod

● Small arm

● Big arm

● Oil cylinder

● Pivot wheel

● Guide wheel

Self-lubricating Bearings markets

LOOKING FOR A SELF-LUBRICATING BEARING?We Build Bushings & Bearings To Enhance The Way We Live – Application Examples

Fiber Reinforced Composite bushing bearings are available as bushes, sheets, plates, bearing segments and special types, depending on the particular material type.

Engineered self-lubricating bearing solutions can provide a reliable and low-maintenance solution for various industrial applications. Such bearings are designed with materials and coatings that provide low friction and self-lubricating properties, reducing wear and increasing durability. With an engineering partner, you can get custom solutions from prototype to production, tailored to your specific needs and operating conditions, ensuring optimal performance and efficiency.

Plain Bearings, Self-lubricating Bushings Manufacturer, Sourcing China Bearings Online

custom Plain Bearings Components

Components manufactured to your exact specifications

Sliding Bearing Materials

Improve & extend the performance of Brass Bushing

Ask The Expert

Engineering assistance & self-lubricating material selection support.

Engineered Self-lubricating Bearing Solutions

Your engineering partner from prototype to production

Providing Innovative Customer Solutions

Global implementation of quality bushing system

The company’s engineers are also good at optimizing and predicting bearing performance because they have the necessary tools and experience to perform testing and validation.

Slide bearings for every need.Long-term experience in the slide bearing industry. Widely used in the hydraulic industry, forging machine tool industry, plastics machinery industry port machinery, office, fitness machinery, textile machinery, food package, filling machinery, chemical machinery, automobile, shipbuilding industry, construction machinery, and so on.

2025 Bearing Industry Forecast Briefing CHINA VIIPLUS Friction technology solutions

Application filed, According to market data, The global bearing market size was USD 102.2 billion in 2018, of which the automotive market accounted for the largest market share.

The reason is that the growing demand for vehicles with technologically advanced solutions has led to an increase in global automotive production.

Until 2025, the global bearing market will grow at a compound annual growth rate of 9.1%.

The railway and aerospace sectors will become the fastest-growing sectors, due to the growth of global travel and the acceleration of railway construction in developing countries.

In addition, the surge in demand for small single-aisle aircraft and helicopters in emerging economies is expected to further boost growth.

Region growing

Regionally, forecast based on market data, sales in the Asia-Pacific region is expected to grow at the fastest pace, exceeding USD60 billion by 2025.

China is one of the main markets, due to the rapidly growing production of machinery and vehicles, as well as a strong market for after-sales services for industrial equipment and automobiles, China’s sales will grow rapidly in the foreseeable years.

In addition, it is estimated that India’s strong construction and mining equipment market will greatly promote local economic growth.

At the same time, the European region is expected to achieve favorable growth in 2020-2025 due to sustained economic growth and increased investment.

In addition, demand in mature markets in the US, Western Europe, and Japan is driven by a rebound in car production and a healthy fixed investment environment.

Increased sales of high-value bearings (such as large diameter, custom bearings), and applications in heavy machinery and wind turbines are also expected to drive growth in North America.

In the Middle East and Africa, the rapid development of urban infrastructure has had a positive impact on overall growth.

Self-lubricating Bearing Trends

The market is expected to be driven by increased demand for specialized bearing solutions that meet specific requirements and challenges in different industries.

There will also be an increasing demand for bearings with lower maintenance requirements, higher efficiency, easier assembly, and longer service life.

Manufacturers are therefore constantly working to improve product design to improve performance and energy efficiency, as predicted by market data.

They use special materials to make raceways, cages, rolling elements, and redesigned raceways contours.

In addition, advances in sealing and lubrication technologies, as well as the use of lightweight materials in high-performance products, have brought great promise to manufacturers.

The growing demand for high-performance bearings has led manufacturers to integrate advanced sensor units into their products.

The sensor unit facilitates digital monitoring of the product’s axial movement, deceleration, acceleration, rotational speed, and load capacity.

In addition, the emergence of the Industrial Internet of Things (IIoT) has encouraged the adoption and continuous monitoring of interconnected devices and machinery.

This trend has also had a positive impact on the bearing market.

VIILPUS Plain Bearings & Bushings

Metal-Polymer bearing: low friction coefficient, high wear resistance

Engineering plastic bearings: self-lubricating, low friction

Reinforced fiber bearings: wear resistance, corrosion resistance

Metal and bimetal bearings: high load capacity

For more material features, please see the menu “Product Information” or visit the VIIPLUS official website: https://www.viiplus.com/

About Us

VIIPLUS is a professional sliding bearing company with a mature production process, excellent research, and development team, the company aims at high quality, high quality, to provide customers with a good user experience, look forward to working with you. VIIPLUS is working to create an ideal world that minimizes friction losses through research into sliding bearing and surface engineering techniques. With research and development, testing, and production in the United States, Germany, France, Brazil, Slovakia, and China, VIIPLUS has collaborated with customers worldwide to design and develop efficient and environmentally friendly tribological solutions.VIIPLUS engineers bring their expertise and love of tribology to the automotive, aerospace, and industrial manufacturing sectors. For more information about VIIPLUS bearings, please visit the VIIPLUS bearing website: www.bronzelube.com

Engineered Plain Bushing Solutions

Engineering Assistance | Material Selection | Component Geometry

Request for quotation.