Maintenance lubrication bushing parts

Specialized Maintenance Bushing Lubrication

High performance lubricating bushing, bushing lubrication!

Vehicle aftermarket bushing product range in high quality. Check our website out to find top-quality bushing parts for vehicles. Visit our website! Find your Car Parts Here. Visit our Website. Find out more. Premium Products. Get more information.

Professional maintenance bushing bearings: We design our equipment to perform and to last. But that’s not all. Our dealers provide the support you expect so you can keep working – no matter where your work is performed. With industry-leading warranties and service and support you can count on. You’ll always feel confident in your decision to choose bushings, because with plain bearings, you get more than just the machine.

Bushing Lubrication – Standard Plain Bearings Professionals

Self-lubricating slide bearings with dry lubricating, standardized parts. Manufacturing stocks an inventory of plain bronze sleeve bushings in industry standard sizes. We offer a range of Metal Plain Bearings and Bushings for Heavy Duty applications. The range includes Spherical Plain Bearings, Sintered bearings, … Solid Bronze Bearings. For heavily loaded applications. Can be supplied with lubrication pockets, grooves or through holes.

Low-friction self-lubricating bearings

Low-friction self-lubricating bearings not only furnish heightened safety and stability but also assist amusement parks in reducing maintenance costs and time. With the continual advancements in technology, we have every reason to believe that future amusement park facilities will be even safer, more reliable, and durable. From the information provided, it appears you’re discussing the advantages of wrapped bronze bushings, specifically those made from the FB090 copper alloy bearing. Wrapped bronze bushings, made entirely from phosphor bronze CuSn8, offer a range of benefits in various industries, particularly where heavy-duty applications are concerned. Here’s a summarized version of the benefits:

Wrapped bronze plain bearings – long service interval

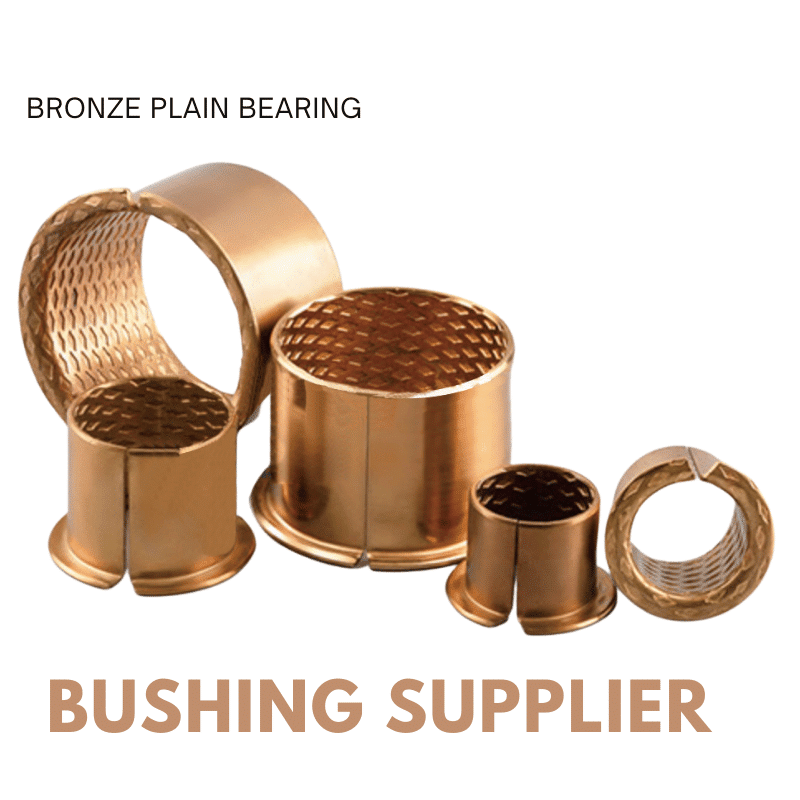

Bronze Plain Bearing, Wrapped Bronze Bushing – high-maintenance, Bronze Plain Bearing, Material – Characteristics: Sliding elements made of solid tin bronze (CuSn8) with diamond-shaped lubrication pockets, which serves as a lubricant reservoir. The plain bushes bearings are suitable for grease and oil lubrication. Wrapped Bronze With Lubrication Pockets – low-maintenance.

Bronze Wrapped Lubrication Flanged Bushes Bearings

The wrapped bronze bushing bearings have been developed for slow speed, high load applications, especially suited for oscillating motion and are perfect for the construction. Bronze Plain Flanged Bushes, Wrapped Bronze With Lubrication Holes – low-maintenance.

Wrapped flanged bushings, low-maintenance plain bearings with lubrication holes, Bearing Design Lubrication Bushing Materials – Features

- Sliding elements made of solid tin bronze (CuSn8) with lubrication holes that act as lubricant reservoirs. Thanks to the holes, more lubricant can be stored, thus extending maintenance intervals. These plain bearings are only suitable for grease lubrication.

Advantages of Wrapped Bronze Bushings FB090 Copper Alloy Bearing:

- Extended Service Life:

- Once installed, these bushings offer a prolonged trouble-free running time.

- This longevity means users will not have to replace the bushing frequently, which in turn reduces maintenance and replacement costs.

- Higher Load Capacity:

- The bushings can endure higher load ratings.

- Machinery and equipment using this bearing can operate more effectively, handling heavier loads without compromising performance.

- Noise Reduction:

- The bushings operate quietly, ensuring a noise-free environment.

- This results in a more conducive working environment, potentially leading to higher employee productivity and efficiency.

- Energy Efficient and Environmentally Friendly:

- Using these bushings results in energy savings and a reduction in emissions.

- Factories employing these bearings can therefore contribute to environmental conservation by reducing their carbon footprint.

Applications: Wrapped bronze bushings are ideal for slow-speed, heavy load applications, especially in industries like construction, mining, quarrying, agriculture, and automotive. The design often includes diamond-shaped lubricating holes on the surface, which further enhances their efficiency and reduces the need for frequent lubrication.

In essence, wrapped bronze bushings offer a combination of durability, efficiency, and environmental benefits, making them a preferred choice for heavy-duty applications. For businesses, investing in such high-quality bearings can result in significant long-term savings and operational efficiencies.

Advantages of the FB090 Wrapped Bronze Bushing:

- Extended Service Life:

- Consumers benefit from a longer operational lifespan once they purchase and utilize the FB090 bushing.

- Its long-lasting performance signifies superior quality, reducing the frequency of replacements and subsequently, the associated costs.

- Enhanced Load Capacity:

- The FB090 bushing boasts a high load-bearing capability.

- Equipment fitted with this bearing can operate more effectively under substantial loads.

- Quiet Operation:

- The bushing’s operation is notably silent, contributing to a peaceful work environment.

- A quieter workspace can boost employee efficiency, enhancing overall factory productivity.

- Energy and Environmental Benefits:

- The high-grade FB090 bushing promotes energy conservation and reduced consumption.

- Factories using this bearing can achieve goals of environmental preservation by minimizing energy use and emissions.

In summary, the FB090 Wrapped Bronze Bushing offers a blend of longevity, load-bearing capacity, silent operation, and eco-friendly benefits, making it an excellent choice for various applications.

Bushings and plain bearings are crucial components in many mechanical systems, providing a wear-resistant interface between two parts, usually between a rotating and a stationary component. One of the critical aspects of their functionality and longevity is lubrication. Proper lubrication reduces friction, minimizes wear, and prolongs the life of the bearing. Here’s a breakdown of lubrication as it relates to bushings and plain bearings:

Types of Lubrication for Bushings and Plain Bearings:

- Hydrodynamic Lubrication:

- Here, a continuous lubricant film separates the bearing surface from the shaft, preventing metal-to-metal contact. The relative motion between the surfaces causes the lubricant to form this film.

- Boundary Lubrication:

- In situations where full-film lubrication is difficult, a thin film covers the bearing surfaces. This film isn’t thick enough to completely separate the surfaces, so some asperity contact may occur. Special additives in the lubricant can help prevent wear in these conditions.

- Mixed Lubrication:

- This is a combination of hydrodynamic and boundary lubrication. A portion of the bearing surface is separated by a lubricant film, while other areas might have asperity contact.

- Solid Lubrication:

- Solid materials, such as graphite or PTFE (Polytetrafluoroethylene), are used to reduce friction. These are often embedded in self-lubricating bearings or applied as a coating.

- Grease Lubrication:

- Grease is a semi-solid lubricant and is often used in applications where liquid lubricants are unsuitable. It remains in place, offering long-lasting lubrication, and can also act as a sealant to prevent contaminants from entering the bearing.

Factors Affecting Lubrication:

- Load: Higher loads can squeeze out lubricants, requiring more robust or more frequent lubrication.

- Speed: At high speeds, there’s a need for lubricants with good film strength. Conversely, low speeds might not generate a sufficient hydrodynamic film.

- Temperature: High temperatures can cause some lubricants to break down or evaporate. The choice of lubricant should be compatible with the operational temperature range of the bearing.

- Environment: In dusty or corrosive environments, the lubricant should also serve as a protective barrier against contaminants.

Benefits of Proper Lubrication:

- Reduced Wear: Lubrication minimizes direct contact between the bearing and shaft, leading to reduced wear.

- Lower Friction: Proper lubrication ensures that friction is minimized, leading to smoother operation and reduced heat generation.

- Dissipation of Heat: Lubricants can help carry away heat generated due to friction.

- Protection: Lubricants can protect the bearing surface from corrosion and contaminants.

Conclusion:

Lubrication is a critical aspect of bushing and plain bearing operation. The right type and amount of lubricant, applied correctly, can significantly extend the life of the bearing, reduce maintenance requirements, and enhance the efficiency of the mechanical system. Proper lubrication practices are crucial for the optimal performance of bushings and plain bearings.

Bushings and bearings play a critical role in mechanical systems, offering a wear-resistant interface between two components. The choice of material and construction for the bushing often determines its lubrication requirements. Let’s delve into the lubrication needs and characteristics of the various bushing types you mentioned:

1. Solid Bronze Bushings:

- Material: Pure bronze or phosphor bronze.

- Lubrication: Typically, these bushings require external lubrication. Oil or grease is used to reduce friction and wear. Periodic re-lubrication is necessary, especially in high-load or high-speed applications.

2. Sintered Bronze Bushings:

- Material: Porous bronze material produced through a powder metallurgy process.

- Lubrication: These bushings are often impregnated with oil during the manufacturing process. The porous structure allows the oil to be released slowly during operation, providing self-lubrication. However, in some cases, periodic re-lubrication might be necessary, especially in demanding environments.

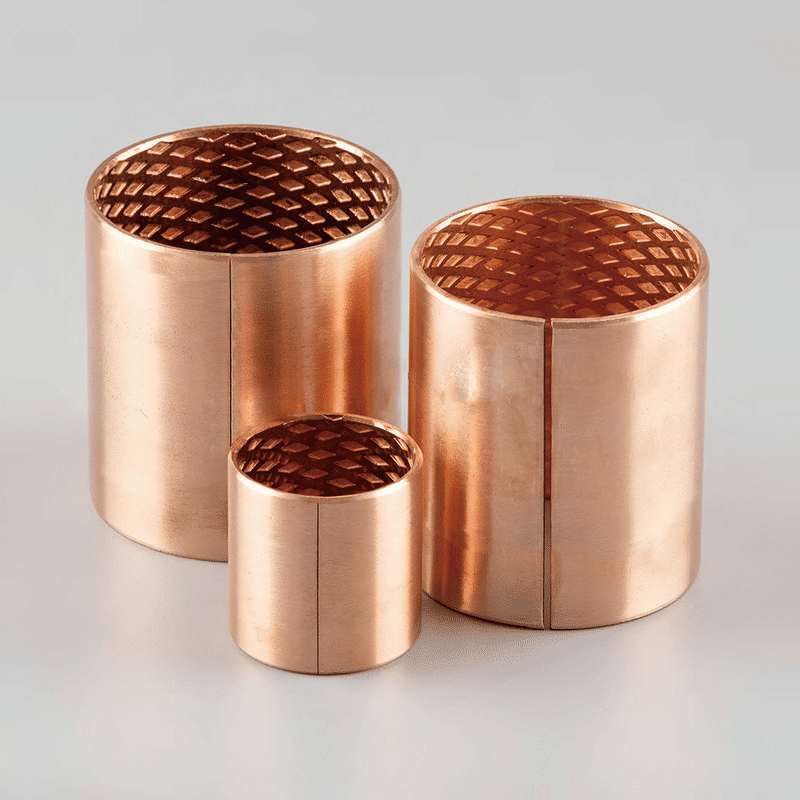

3. Wrapped Bronze Bushings:

- Material: Thin sheets of bronze, often with indentations or holes, wrapped into cylindrical shapes.

- Lubrication: The surface indentations or holes typically act as lubrication reservoirs. These bushings may come pre-lubricated or might require initial lubrication. The lubrication reservoirs help extend re-lubrication intervals, but periodic maintenance is still needed in most applications.

4. PTFE Composite Bearings:

- Material: Metal-backed with a layer of PTFE (Polytetrafluoroethylene) composite material.

- Lubrication: These are self-lubricating bearings. The PTFE layer offers a low friction surface, eliminating the need for additional lubrication. They are ideal for applications where maintenance is challenging or where contamination from external lubricants is a concern.

5. POM Composite Bearings:

- Material: Metal-backed with a layer of POM (Polyoxymethylene) composite material.

- Lubrication: POM composite bearings often have lubrication pockets filled with grease. While the POM layer provides some inherent lubrication, the grease reservoirs further enhance the bearing’s low-friction properties. Depending on the application, they might require occasional re-lubrication.

In Summary:

- Solid and Wrapped Bronze Bushings: Typically require external lubrication, either initially or periodically.

- Sintered Bronze Bushings: Offer self-lubrication due to oil impregnation but might need occasional re-lubrication.

- PTFE and POM Composite Bearings: Generally self-lubricating, with PTFE bearings rarely requiring external lubrication and POM bearings possibly needing occasional re-lubrication.

The choice of bushing and its lubrication regime will depend on the specific application, operating conditions, and maintenance capabilities. Proper lubrication practices will ensure optimal performance and extended life for the bushing.

Sliding Bearings: Offering Safety and Stability to Amusement Parks

Self-lubricating bearings provide numerous tribological solutions to amusement parks, including metal composite bearings and fiber-reinforced composite material products. Whether in moist, dry, cold, or hot conditions, self-lubricating bearings deliver exceptional performance, ensuring the steady and safe operation of recreational devices. Flanged Plain Bearings and Sleeve Bearings (WITH FIXING HOLES) Are maintenance and downtime issues causing challenges with renewable energy applications?

Bushings & Bearings – Sleeve, Flange, Thrust Bearing

These stainless steel backing PTFE composite bushing bearings are strong, wear resistant, and excellent at handling shock loads. Corrosion-Resistant Flanged Sleeve Bearings. Metric Bearings and Bushings – sleeve, flange, thrust bearing washer. In various amusement parks and recreational areas of our daily life, sliding bearings play a pivotal role. Whether it’s roller coasters, carousels, or other diverse recreational facilities, sliding bearings provide essential support for these devices, ensuring their safe and steady operation.

Tracks, chassis, wheel frames, axles, and pulleys in large-scale facilities such as roller coasters, carousels, and Ferris wheels all employ sliding bearings. These components endure extensive usage every day. Any malfunction can not only diminish the experience of visitors but might also pose potential harm. Additionally, due to the openness of amusement parks, these devices are easily affected by humidity and other harsh conditions, leading to bearing wear or corrosion.

Bushings & Bearings – Sleeve, Flange, Thrust Bearing

These stainless steel backing PTFE composite bushing bearings are strong, wear resistant, and excellent at handling shock loads. Corrosion-Resistant Flanged Sleeve Bearings. Metric Bearings and Bushings – sleeve, flange, thrust bearing washer. In various amusement parks and recreational areas of our daily life, sliding bearings play a pivotal role. Whether it’s roller coasters, carousels, or other diverse recreational facilities, sliding bearings provide essential support for these devices, ensuring their safe and steady operation.

Tracks, chassis, wheel frames, axles, and pulleys in large-scale facilities such as roller coasters, carousels, and Ferris wheels all employ sliding bearings. These components endure extensive usage every day. Any malfunction can not only diminish the experience of visitors but might also pose potential harm. Additionally, due to the openness of amusement parks, these devices are easily affected by humidity and other harsh conditions, leading to bearing wear or corrosion.

Why Low-Friction Self-Lubricating Bearings Are the Solution

Conventional bearings require periodic lubrication and maintenance, undeniably escalating the operational costs and maintenance duration of amusement parks. Whenever equipment needs lubrication or maintenance, they must be halted, resulting in operational delays and revenue losses.

Low-friction self-lubricating bearings, however, bring a revolutionary change to amusement parks. These bearings not only offer high load capacity, longevity, and minor bearing tolerances but also eliminate the need for additional lubrication, substantially cutting down maintenance requirements. This ensures that amusement park facilities can operate continuously for extended periods, all the while ensuring the safety of visitors.Choose from our selection of self-lubricating bearing bushings, including oil-embedded sleeve bearings, dry-running sleeve bearings, and more. We Help Grow Your Business Rapidly