Get Industry- Self-lubricating Bronze Bushing & Bearings Today!

Experience the Strength of Self-lubricating Bearings

Bushing Design Guides, Plain Bearing Lubrication, Manufacturer of standard inch and metric sleeve bearings and bushings.

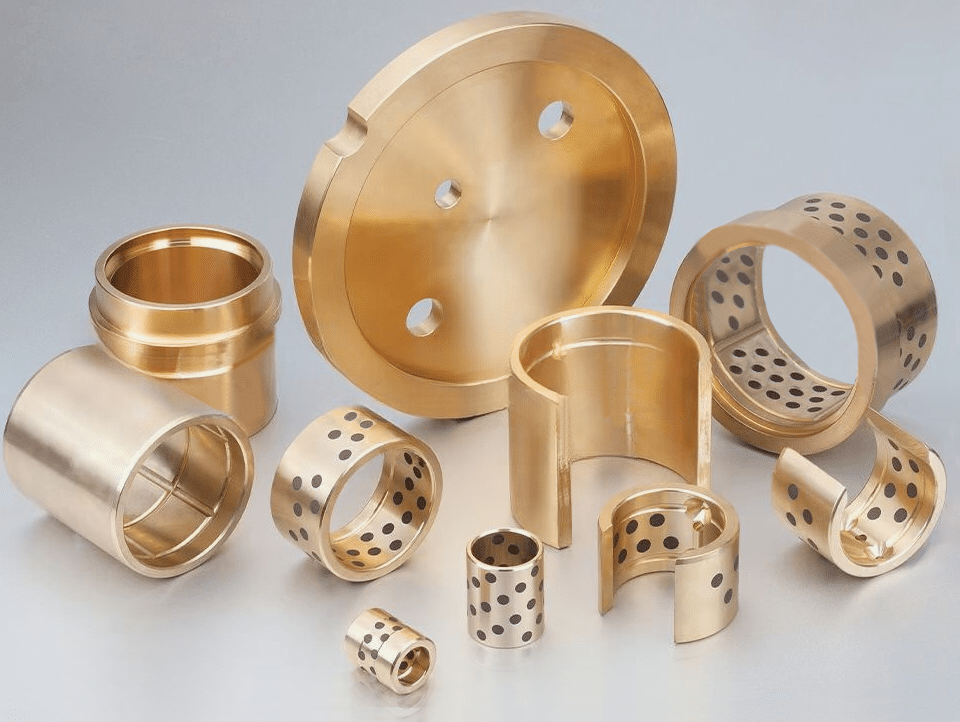

Comprehensive design guides detailing the manufacturing processes for self-lubricating bearings and bushings. Standard sizes are also available in other materials, such as no-lead bronze, aluminum bronze, and manganese bronze. Special requests are welcomed, with flexible stocking arrangements or custom manufacturing delivery schedules.

Bushing Manufacturing – Expert Design Guides Available! Steel-backed PTFE-lined inch flanges.

Flanges – Inch – Steel Backed PTFE Lined Bushings “Sliding Bushing” – low carbon steel backing, sintered bronze interlayer, PTFE lined ID surface.

Self-lubricating bronze bearings are a type of bearing that incorporates solid lubricants into their material composition to reduce friction and eliminate the need for external lubrication. These bearings are designed to operate with minimal maintenance and are particularly useful in applications where conventional lubrication methods may be impractical or impossible to implement.

Metric to Imperial Size Plain Bushing Design and Material Type: Cylindrical and flanged, thrust washerMaterial options include bronze, brass, or steel, depending on the application requirements. Cylindrical and flanged configurations offer versatility in installation, while thrust washer designs ensure optimal performance under axial loads. With precise metric and imperial sizing options, these plain bushings cater to diverse engineering needs across industries.

plain bearings – Design Guide, Metric Sleeves, Cast Bronze – Metric Flanges.

This Design Basics Guide will detail the composition of self-lubricating metal bearings, including how to correctly select them and more. available as sleeves, flanges, and plates, produced in both inch and metric sizes. Typical applications include material handling, hydraulic cylinders, lifting equipment, and agricultural machinery.

Self-lubricating bronze bearings are a type of bearing that incorporates solid lubricants into their material composition to reduce friction and eliminate the need for external lubrication. These bearings are designed to operate with minimal maintenance and are particularly useful in applications where conventional lubrication methods may be impractical or impossible to implement.

- Materials: They are typically made from a bronze alloy, which is known for its good thermal conductivity, corrosion resistance, and ability to distribute loads evenly.

- Lubricants: The solid lubricants used can include materials such as graphite, molybdenum disulfide (MoS2), or other dry film lubricants. These are embedded within the bearing material to provide a continuous lubricating effect.

- Maintenance-Free: Since the lubrication is built into the bearing material, there is no need for regular greasing or oiling, which simplifies maintenance and can extend the life of the equipment.

- Applications: These bearings are suitable for environments where dust, water, or other contaminants might interfere with the lubrication process. They are also used in applications with high temperatures or where the bearing must operate without frequent access for maintenance.

- Performance: While self-lubricating bronze bearings can operate without additional lubrication, their performance can still be influenced by factors such as load, speed, and temperature. It’s important to select the right bearing for the specific application conditions.

- Environmentally Friendly: The use of solid lubricants can reduce the environmental impact of lubrication, as there is no need for the disposal of used lubricants or the risk of contamination from leaks.

- Longevity: Although these bearings are designed to be maintenance-free, they still have a finite lifespan and will eventually need to be replaced. However, this is generally longer than that of bearings that require regular lubrication.

- Cost: While self-lubricating bronze bearings may have a higher initial cost compared to standard bearings, the reduced maintenance and longer service life can result in cost savings over time.

- Compatibility: They are compatible with a wide range of materials and can be used in various industries, including automotive, aerospace, and industrial machinery.

- Design: These bearings can come in various designs such as plain bearings, bushings, or as components in more complex bearing assemblies.

When selecting self-lubricating bronze bearings, it’s important to consider the specific requirements of the application, including the operating conditions and the environmental factors that the bearing will be exposed to. Proper selection and installation can ensure the reliability and longevity of the bearing in service.

Type of material: metal base

| Material correspondence table | ||||||||

| Material code Codes |

China GB1176-87 |

internationality ISO 1338 |

Germany DIN |

Japan JIS |

U.S. ASTM(UNS) |

U.K. BS |

France NF |

Applicable |

| JDB650 High strength alloy copper |

ZCuZn25Al6 Fe3Mn3 |

GCuZn25Al6 Fe3Mn3 |

DIN1709 G-CuZn25Al5 |

H5102 CAC304 |

B30-92 C86300 |

HTB2 | High load, low speed, general use | |

| JDB650 S1 High strength alloy copper |

ZCuZn25Al6 Fe3Mn3 |

GCuZn25Al6 Fe3Mn3 |

DIN1709 G-CuZn25Al5 |

H5102 CAC304 |

B30-92 C86300 |

HTB2 | Ultra high load, low speed, high load | |

| JDB650 S2 Cast tin bronze |

ZCuSn5 Pb5Zn5 |

GCuPb5 Sn5Zn5 |

DIN1705 G-CuSn5ZnPb |

H5111 BC6 |

B30-92 C83600 |

LG2 | CuPb5 Sn5Zn5 |

medium load, low speed |

| JDB650 S3 Cast aluminum bronze |

ZCuAl9Fe4 Ni4Mn2 |

GCuAl10 FeNi5 |

DIN17656 G-CuAl10Ni |

H5114 AlBC3 |

B30-92 C95500 |

AB2 | CuAl10 Fe5Ni5 |

Medium load, medium speed, general use |

| JDB(HT250) cast iron |

GB5675-85 HT250 |

FC250 | ASTM Class40 |

medium load, low speed | ||||

Chart: Base Material for Self-Lubricating Bearings

| Code | Material Composition | Density (g/cm³) | Hardness | Tensile Strength (N/mm²) | Elongation (%) | Coefficient of Linear Expansion (10^-5/°C) | Operating Temperature (°C) | Maximum Dynamic Load (N/mm²) | Maximum Line Speed (m/min, Dry) | Max. PV (N/mm² * m/min) | Compression Set 300N/mm² |

|---|---|---|---|---|---|---|---|---|---|---|---|

| JDB650 | CuZn25Al6Fe3Mn3 | 8.0 | HB > 210 | >750 | >12 | 1.9 | -40 to +300 | 100 | 15 | 200 | <0.01 |

| JDB650 S1 | CuZn25Al6Fe3Mn3 | 8.0 | HB > 250 | >800 | >8 | 1.9 | -40 to +150 | 120 | 15 | 200 | <0.005 |

| JDB650 S2 | CuAl9Fe4Ni4Mn2 | 8.5 | HB > 150 | >800 | >15 | 1.9 | -40 to +400 | 150 | 20 | 60 | <0.04 |

| JDB650 S3 | CuSn5Pb5Zn5 | 8.9 | HB > 70 | >200 | >10 | 1.8 | -40 to +400 | 60 | 10 | 60 | <0.05 |

| JDB650 S4 | CuSn12 | 9.05 | HB > 80 | >260 | >8 | 1.8 | -40 to +400 | 70 | 10 | 80 | <0.005 |

| JDB (HT250) | HT250 | 7.0 | HB > 190 | >250 | >5 | 1.0 | -40 to +400 | 90 | 8 | 40 | <0.015 |

| JDB (Gcr15) | Gcr15 | 7.8 | HRC > 58 | >1500 | >15 | 1.1 | -40 to +400 | 200 | 5 | 150 | <0.002 |

This table presents a detailed comparison of the material compositions, properties, and typical applications of different self-lubricating bearing materials.

Leaded, Phosphor And Aluminium Bronzes Plates and Bearing,

Wear Plates – Mold and Die Products, Search Our Material Alloy

Explore Our Composite Metal Bushing Design Guides – Learn to Manufacture Like a Pro!”

About us

comprehensive Guides for Self-Lubricating Bearings & Bushings, select manufacturing process and material – done!

Unlock Bushing Manufacturing Secrets With Our Design Guides! When manufacturing bronze components, it’s important to consider the specific alloy used, as different bronze alloys (such as phosphor bronze, leaded bronze, or aluminum bronze) have varying properties that make them better suited for different applications. Additionally, the manufacturing process can affect the final properties of the bronze piece, such as its hardness, tensile strength, and conductivity.

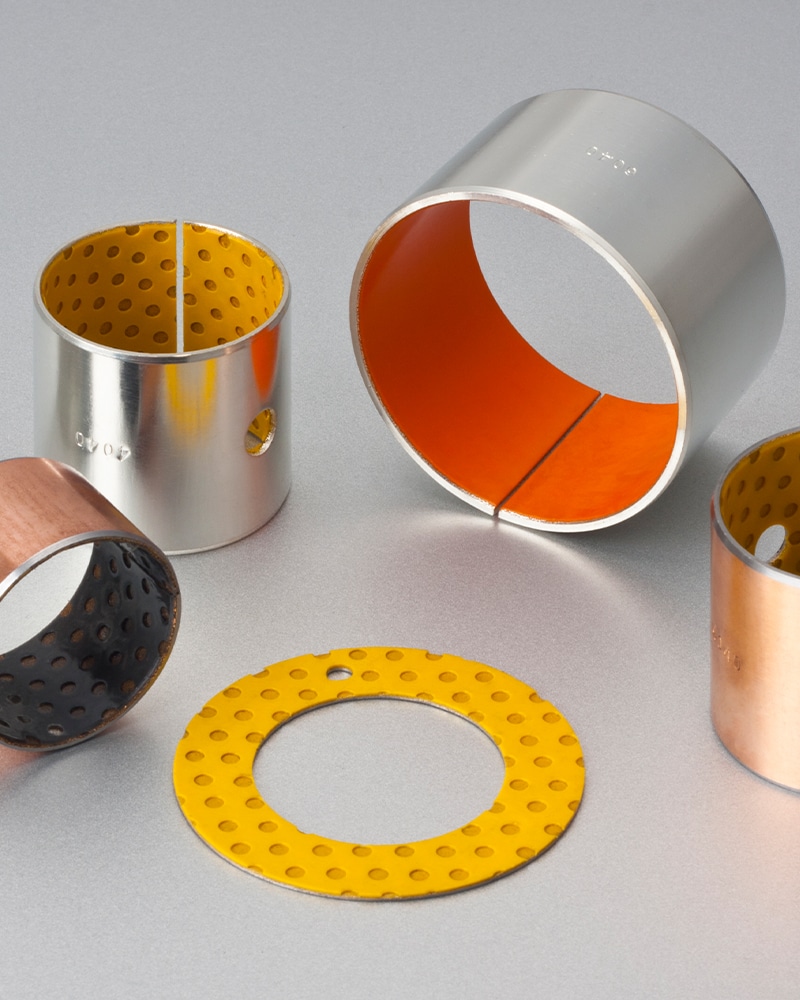

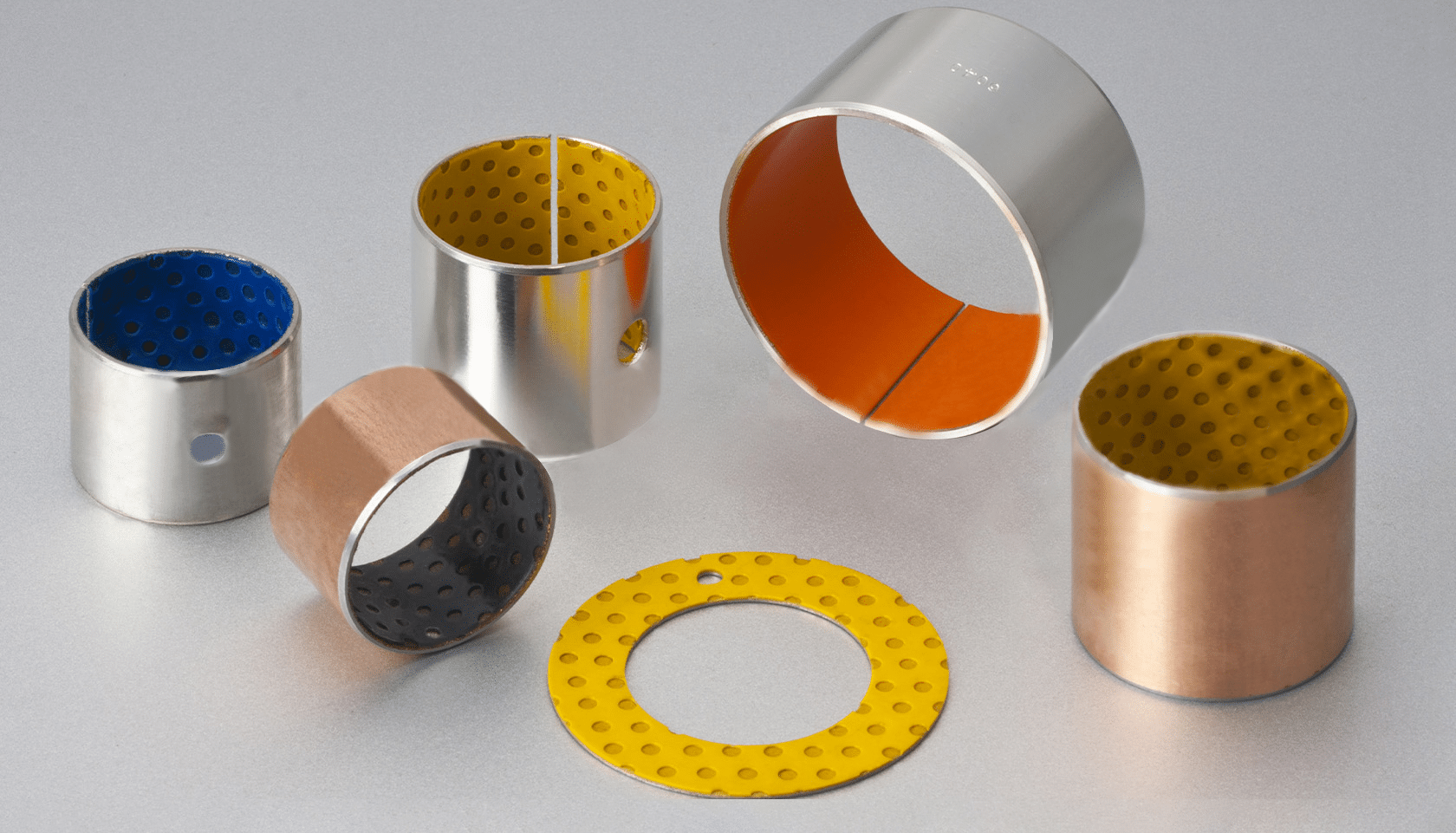

Wrapped Bearing technology, Design Guides!

Wrapped Bearing technology, Design Guides!

Wrapped composite sliding bearings

Wrapped composite sliding bearings are engineered solutions used to reduce friction and wear between moving parts in various mechanical applications. These bearings are known for their durability, low maintenance, and excellent sliding and wear characteristics. The specific type you’re inquiring about, tin-plated steel/PTFE (Polytetrafluoroethylene) wrapped composite sliding bearings, adhere to the standards set by DIN 1494/ISO 3547.

Construction and Material: Tin-plated Steel Backing: The steel backing provides strength and dimensional stability to the bearing. Tin plating offers additional corrosion resistance and reduces the coefficient of friction, which helps in reducing wear.

PTFE (Polytetrafluoroethylene): This is a high-performance plastic known for its excellent non-stick properties, low friction coefficient, and resistance to wear and chemical corrosion. PTFE is often used in bearings to enhance their performance in applications where lubrication may not be present or feasible.

Standards: DIN 1494/ISO 3547: These are the German (DIN) and International Organization for Standardization (ISO) standards that define the dimensions, tolerances, and performance characteristics of the bearings. Adherence to these standards ensures compatibility and interchangeability with other components designed to these specifications.

Maintenance-free Operation: One of the key benefits of these bearings is that they require minimal maintenance. The combination of the durable steel backing and the low-friction PTFE layer means that they can operate effectively for extended periods without the need for frequent lubrication or adjustments.

Composite Bushing Design Excellence – Access Our Detailed Guides Now!

Wrapped sliding bearings, also known as wrapped bushings, are a type of bearing that incorporates a steel or metal backing with a sliding layer made from materials such as POM (Polyoxymethylene), which is a type of engineering thermoplastic. These bearings are designed to provide low friction and high wear resistance, making them suitable for a wide range of applications where there is relative motion between parts.

Construction and Material: Steel Backing: The bearing has a steel support structure that provides the necessary strength and stability.

POM Sliding Layer: POM is chosen for its excellent mechanical properties, including high stiffness, good chemical resistance, and low friction characteristics. It is also self-lubricating, which can reduce the need for external lubrication.

Standards: DIN 1494/ISO 3547: These standards define the dimensions and tolerances for wrapped sliding bearings. Compliance with these standards ensures that the bearings will fit and function as expected in a wide range of applications.

Low-maintenance: These bearings are designed to be low-maintenance, which can reduce downtime and the cost of operation in industrial applications.

Discover Efficient Manufacturing With Our Bushing Design Guides!

Enhance Your Skills with Our Bushing Manufacturing Guides! Wrapped bushings made from Bronze CuSn8 and CuSn6P are engineered components used in applications where high strength, excellent wear resistance, and good conductivity are required. The use of these bronze alloys in the construction of wrapped bushings ensures that they can withstand the rigors of demanding environments while maintaining the necessary physical properties for smooth operation.

Bronze CuSn8 (DIN 17662) CuSn8 is a phosphor bronze alloy that contains 8% tin. This high tin content, combined with the presence of phosphorus, results in a material with superior wear resistance and strength. It is known for its excellent spring properties and is often used in applications where these characteristics are critical. They are lightweight and compact, available as sleeve bushings, flange bearings, washers, and plates. These products are produced in both inch and metric sizes.

Applications of CuSn8 Wrapped Bushings:

- Bearings and Bushings: Due to their high strength and wear resistance, CuSn8 wrapped bushings are ideal for use in plain bearings and bushings where lubrication may not always be present.

- Springs and Fasteners: The springiness of CuSn8 makes it suitable for the manufacture of springs and fasteners that need to maintain their shape and integrity under stress.

- Hydraulic Components: CuSn8’s resistance to corrosion makes it a good choice for hydraulic components that are exposed to various mediums.

- Electrical Contacts: The conductivity of CuSn8 bronze makes it suitable for use in electrical contacts where wear resistance is also important.

CuSn6P (DIN 1494 / ISO 3547): CuSn6P is a tin phosphor bronze alloy with 6% tin and a specific phosphorus content that enhances its wear resistance and strength. This alloy is known for its good spring properties and is widely used in a variety of industrial applications due to its balance of strength and conductivity.

Our line of rolled (wrapped) bushings features diamond-shaped lubrication indents on the bearing surfaces. These bushings are ideally suited for thin-wall applications. The indents serve as lubricant reservoirs, ensuring excellent and prolonged service.

For applications that are sealed or difficult to maintain, we also offer this product with self-lubricating graphite-filled diamond or circular indents.

Special Plain Bearing and Bushing in various industries

Special plain bearing bronze products are utilized across various industries including automotive, architecture, construction equipment, and more.Our self-lubricating bronze bushings are designed to provide a prolonged service life under the following conditions: Key areas of application include: Steelworks, Naval construction, Onshore and offshore operations, Lifting, hoists, and winches,Power transmission and gearboxes, Hydromechanical equipment and mobile structures, Public works, mining, and tunneling machinery, Valves and pumps,Renewable energy sectors such as hydroelectric, wind, and solar power generation.

High-performance Self-Lubricated Bearings

Enhance technology and reduce costs with self-lubricating metal bearings. Experience the solutions from viiplus.com. Simplifying technology from concept to final product – with our product services, you can effortlessly locate the right bearing bushing for your needs and incorporate it into your design. Explore new services and exclusive promotions for our self-lubricating plain bearings.