High-Performance Graphite Strips, Bronze Strips

Experience the Strength of Self-lubricating Bearings

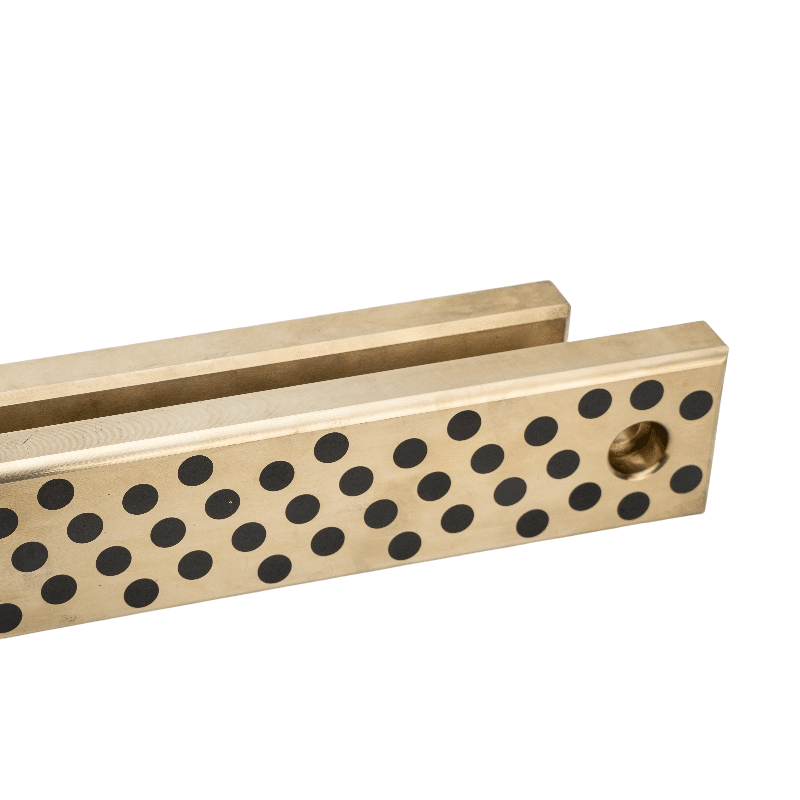

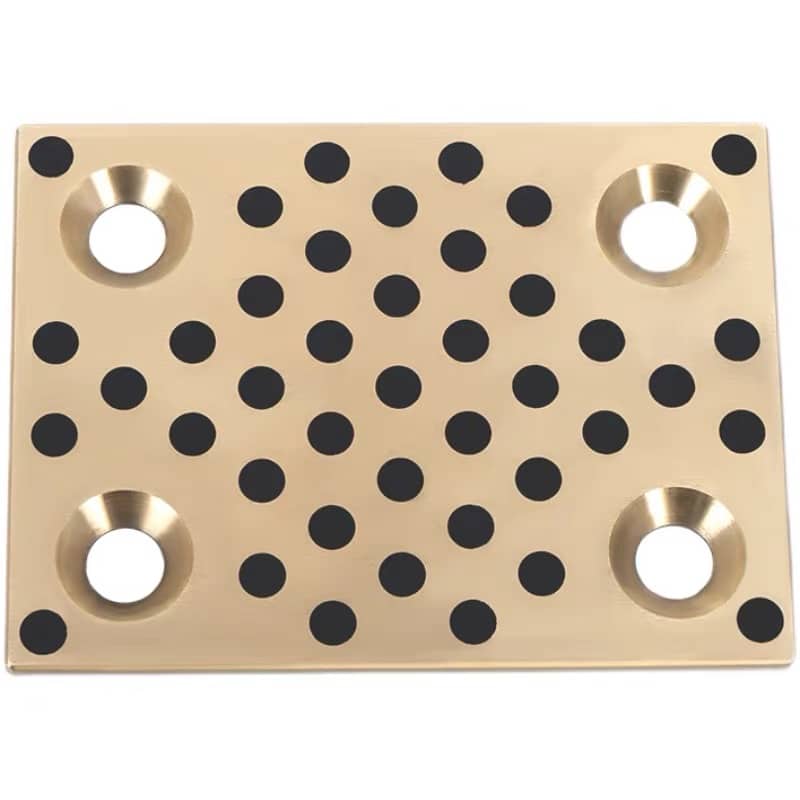

Bronze wear strips, Wear Plate

Bronze wear strips with graphite are specialized components designed for various industrial applications. They are made from solid aluminum bronze, which is known for its strength, durability, and resistance to wear and corrosion. The inclusion of self-lubricating graphite ensures smooth operation and reduces the need for additional lubrication, making them highly efficient and low-maintenance.

Maintenance free Bronze graphite Strips Standard Sizes & Custom Sizes

Standard sizes typically refer to dimensions that are commonly in demand and readily available. These might include various lengths, widths, and thicknesses suitable for general applications.

Custom sizes are tailored to specific requirements of different projects or machinery. They can be manufactured to meet unique dimensions, shapes, and specifications provided by the user to fit particular applications.

Applications

- Heavy machinery

- Industrial equipment

- Construction equipment

- Marine applications

- Automotive components

Focusing on graphite plugs and oil-impregnated graphite components

- Wear Plates: These are plates made from various materials that resist wear. When they include graphite, typically as embedded plugs or an impregnated layer, they reduce friction and improve the wear characteristics, making them ideal for high-load applications where lubrication is crucial.

- Wear Strips: Similar to wear plates, wear strips are used to protect the surfaces that come into frequent contact with moving parts. Graphite can be embedded in these strips to enhance their self-lubricating properties.

- Gibs: Gibs are components used in machinery to guide or control linear movement. Incorporating graphite (either as plugs or an impregnated material) helps reduce friction between the moving parts, which is essential for maintaining the precision and efficiency of the machine.

- Graphite Plugs: These are typically inserted into alloys in wear products to provide lubrication. The graphite slowly releases lubricant as the material wears, which continuously maintains a low-friction surface.

- Oil-Impregnated Graphite: This involves graphite that has been impregnated with oil to enhance its natural lubricating properties. It’s particularly useful in applications where maintaining a regular lubrication schedule is difficult or where traditional lubricants might attract dirt and debris, leading to increased wear.