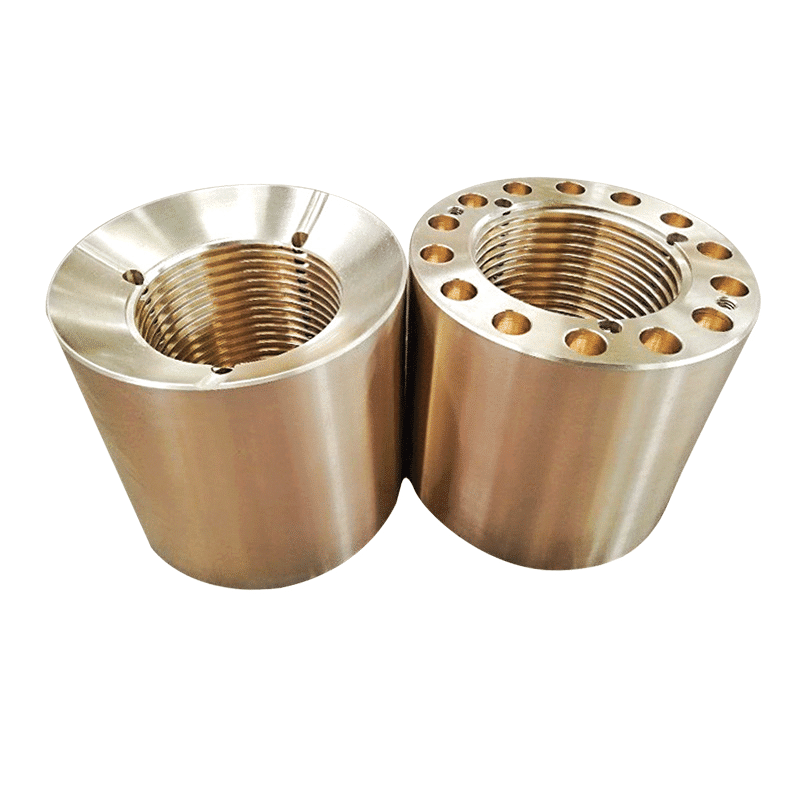

bronze Nuts, Self-Lubricating Bronze Nuts

About us

Self-Lubricating Bronze Nuts, Durable Bronze Nuts – Shop Now for Industrial Needs!

Our company produces bronze nuts for OEMs, service, and maintenance companies, meeting precise specifications necessary for a variety of industrial applications. We provide outsourced machining services for bronze nuts, crafting precise components based on designs provided by our clients. Get Custom Bronze Nuts for Your Machinery – Request a Quote Now!

External Lubrication Bronze Nuts, Oilless Graphite, Precision Bronze Nuts for Industrial Applications – Explore Our Range!

Our bronze nuts are specifically designed and manufactured to operate with external lubrication. Utilizing a superior range of bronze alloys and compatible lubricants available in the market, these nuts can be used across a wide spectrum of operating conditions.

Manufacturing of bronze nuts using various alloys, and these nuts are produced according to the specific designs provided by your clients. Bronze nuts, due to their self-lubricating properties and corrosion resistance, are widely used in industrial applications where durability and reliability are crucial.

Bronze nuts manufacture are of high quality and meet the diverse needs of clients drawings.

Self Lubricating Bronze Nuts, Need Bronze Nuts? Find Top-Quality Options Here – Order Online!

We specialize in manufacturing components used in complex tools and special machines, focusing on precision washers and related parts. Enhance Performance with Self-Lubricating Bronze Nuts – Buy Now!

Our self-lubricating bronze nuts are ideal for continuous operation in hard-to-reach areas where manual lubrication is challenging. They’re also suitable for environments where oil or grease lubrication isn’t feasible or preferred. maintenance-free, they offer durability, longevity, and reduced maintenance time compared to externally lubricated nuts.

Design Customization: Work closely with clients to understand their specific needs and translate those needs into detailed designs. This may include the shape, size, thread pitch, and any special features like self-locking mechanisms or specific finishes.

Graphite Plug Nuts, Bronze alloys for Bronze Nuts

Industrial-Grade Bronze Nuts – Competitive Prices & Excellent Service! Our bronze nuts feature machined holes or grooves filled with graphite plugs, serving as the lubricant between the shaft and the nut. These graphite inserts create a slippery coating, ensuring continuous and reliable lubrication between the surfaces. This type of nut is commonly known in the market as self-lubricating nuts, plugged graphite, graphited, or simply self-lubricating.

Material Selection: Choose the appropriate bronze alloy based on the EN standards or other relevant specifications that best meet the performance requirements of the application. Each alloy has its unique properties, such as tensile strength, corrosion resistance, and thermal conductivity.

Finishing: Depending on the application, bronze nuts may require specific surface treatments, such as plating, to enhance their corrosion resistance or to meet aesthetic requirements.

Find Bronze Nuts for Any Application – Shop Our Wide Selection! Leaded, Phosphor And Aluminium Bronze Bearing,

Search Our Material Alloy

Bronze Nuts for Industrial Applications,Bronze Nut Manufacturing Process

We provide competitive pricing and prompt delivery worldwide for bronze nuts tailored to industrial needs. From single nuts and prototypes to large production runs, we cater to diverse requirements. Collaborating closely with clients, we offer technical guidance and recommendations based on extensive experience with bronze, high tensile brass, and aluminum bronze materials for nut manufacturing. Manufacturing Process: The manufacturing process can vary depending on the design and volume requirements. It may involve casting, forging, or machining processes. Ensure that the process can achieve the desired tolerances and surface finishes. Reliable Bronze Nuts Supplier – Trusted by Industries Worldwide!

Self-lubricating bronze nuts are a type of fastener that incorporates lubrication into the material itself, reducing friction and wear. They are commonly used in applications where regular lubrication is not feasible or where the environment is harsh. Here’s a brief overview of the types you’ve mentioned:

- Bearing Lock Nuts: These are designed to securely lock a bearing in place on a shaft. They often feature a unique design that allows for easy installation and removal while maintaining a tight grip on the bearing.

- Shaft Locknuts: Similar to bearing lock nuts, these are used to lock components onto a shaft. They can be tightened to a specific torque to ensure a secure fit without the risk of over-tightening.

- Bearing Retaining Nuts: These nuts are used in conjunction with a bearing to prevent it from moving along the shaft. They can be adjusted to provide the correct amount of pre-load on the bearing.

- RIV Nuts (also known as Rivet Nuts): These are blind nuts that can be installed from one side of a panel or part. They are inserted into a pre-drilled hole and then pulled up to form threads internally, providing a means to attach components without needing access to both sides.

- Coupling Nuts: These are used to connect two pieces of threaded rod or to join two sections of a shaft. They are typically designed for applications that require a strong and secure connection.

- T-Slot Nuts: These nuts are designed to fit into T-slots, which are common in machine tool tables and fixtures. They allow for easy alignment and positioning of components along the slot.

- Trapezoidal Nuts (Cylindrical): These are a type of nut with a trapezoidal thread that provides a self-locking feature. They are often used in applications where vibration might cause a standard nut to loosen.

Each type of nut serves a specific purpose and is designed to meet the needs of different mechanical systems and environments. The self-lubricating property of bronze makes these nuts suitable for applications where there is limited access for maintenance or where the use of lubricants is not practical.

Bronze Specialization

With our seasoned technical team and advanced machinery specializing in bronze, we excel not only in producing standard nuts but also in crafting intricate and challenging bronze components.

Our expertise and flexibility enable us to manufacture non-standard bronze nuts for unconventional applications and complex designs. Additionally, we can integrate screw thread shafts and precision threaded ports into wear plates, bushings, and other bronze parts, offering solutions like flanged bronze nuts.

Bronze Nut Manufacturing and Machining

We ensure thorough traceability throughout the entire manufacturing process, starting from the receipt of raw materials, through bronze casting, to final machining. Our capabilities allow us to swiftly produce bronzes, high tensile brasses, and aluminum bronzes meeting international standards.

Our stocked bronzes include tin bronzes, leaded bronzes, aluminum bronzes, and high tensile brasses conforming to EN 1982 and ASTM standards. Some of the common alloys we offer are:

- The codes you’ve listed refer to specific material standards for copper and copper alloys as defined by the European Norm (EN) 1982. This standard provides specifications for the composition, properties, and applications of various copper and copper alloy materials. Here’s a breakdown of each code you’ve mentioned:

- EN 1982 CC493K / CuSn7ZnPb: This refers to a copper alloy with a composition that includes tin (CuSn7) and a small amount of lead (Pb). The “K” typically indicates a specific temper or condition of the material, such as a particular hardness or strength level.

- EN 1982 CC483K / CuSn12-C: This is a copper-tin alloy with approximately 12% tin content (CuSn12). The “C” in the code suggests it is a cast material, and the “K” again likely refers to a specific temper or condition.

- EN 1982 CC482K / CuSn11Pb2-C: This material is a leaded bronze with 11% tin (CuSn11) and 2% lead (Pb2). The “C” indicates it is cast, and “K” refers to its temper or condition.

- EN 1982 CC333G / CuAl10Fe5Ni5-C: This is a copper alloy with aluminum (CuAl10), iron (Fe5), and nickel (Ni5). The “G” might indicate a specific grade or quality level, and “C” signifies that it is cast.

- EN 1982 CC762S / CuZn25Al5Mn4Fe3-C: This code represents a copper-zinc-aluminum alloy with 25% zinc (CuZn25), 5% aluminum (Al5), 4% manganese (Mn4), and 3% iron (Fe3). The “S” could denote a specific grade or quality, and “C” indicates it is cast.

These alloys are used in a variety of applications due to their unique properties, such as high strength, good corrosion resistance, and excellent casting characteristics. The specific composition of each alloy is tailored to meet the demands of different industrial and engineering uses. If you need more detailed information on the properties or applications of these materials, it would be best to consult the full EN 1982 standard or a materials engineering reference.