Precision Machined Blanks, Finished Parts

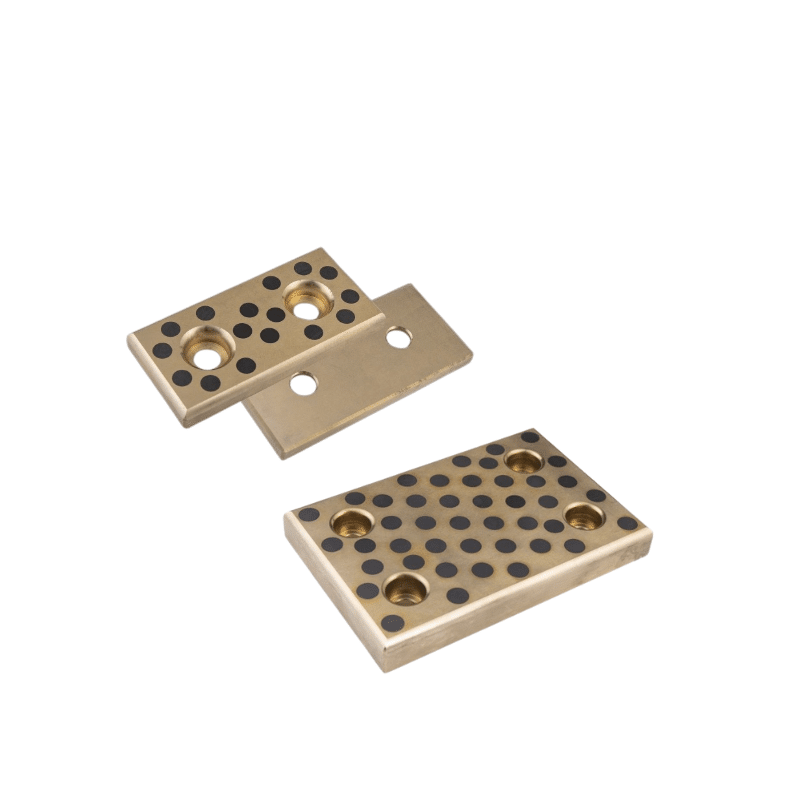

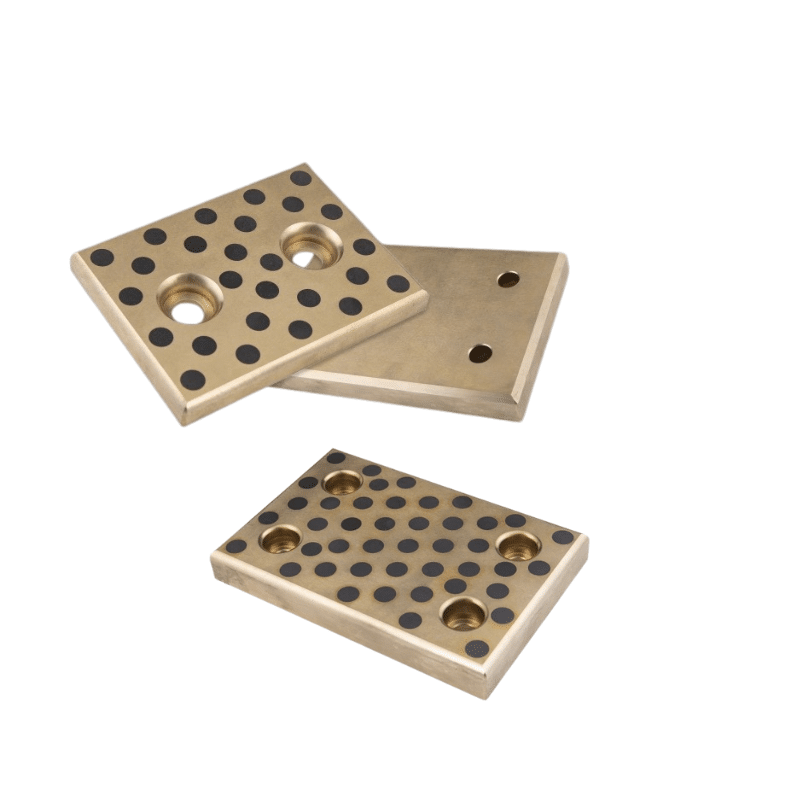

Experience the Strength of Self-lubricating Bearings

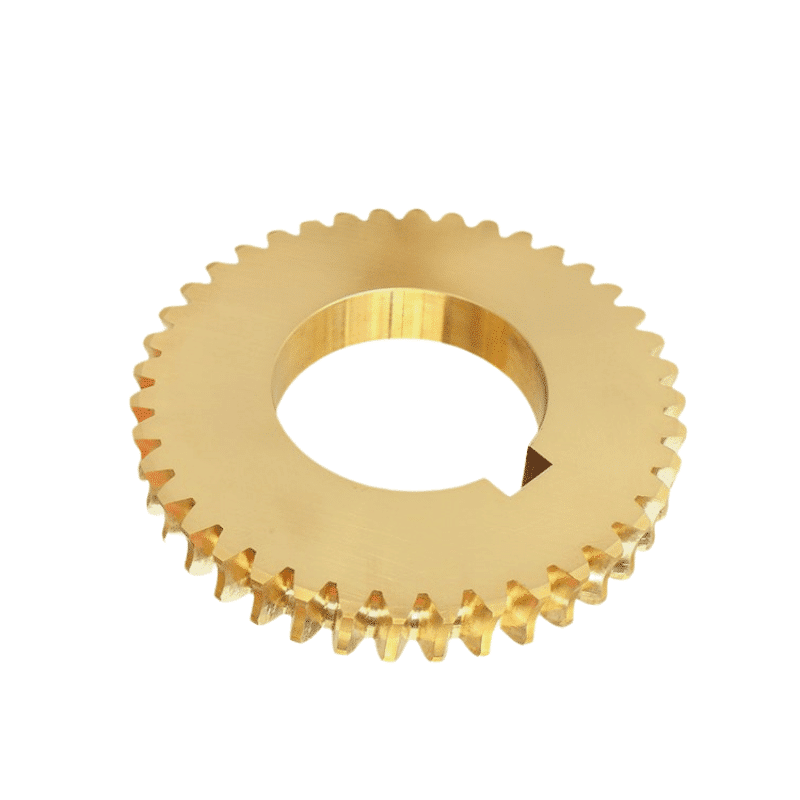

Bronze Gear Blanks: Precision Machined Blanks

In the world of mechanical engineering and manufacturing, precision is paramount. One of the critical components in many machinery setups is the gear. Gears are essential for transmitting motion and power efficiently. Among various materials used for gear manufacturing, bronze stands out for its excellent properties, including wear resistance, high strength, and durability. In this context, Bronze Gear Blanks, particularly Precision Machined Blanks, play a crucial role.

What are Bronze Gear Blanks?

Bronze gear blanks are pre-formed, semi-finished pieces of bronze that are designed to be further processed into functional gears. Bronze, an alloy typically composed of copper and tin, offers several advantages such as high corrosion resistance, excellent wear properties, and good machinability. These attributes make bronze an ideal material for gears that need to operate under high-stress conditions or in environments where lubrication is minimal.

The Importance of Precision Machined Blanks

Precision Machined Blanks take the concept of gear blanks a step further. These blanks are either ground or milled to specific tolerances before reaching the final machining stage. This pre-processing offers several significant benefits:

We specialize in manufacturing bronze gear blanks in quantities ranging from very low numbers to thousands. Our services include cutting keyways, drilling holes, and more to meet your specific requirements. A

Applications of Bronze Gear Blanks, Precision Machined Blanks

Bronze gear blanks are used across various industries due to their versatility and reliability. Some common applications include:

Automotive Industry: Gears in vehicles, particularly in transmissions and differentials, benefit from the durability and wear resistance of bronze.

Industrial Machinery: Heavy machinery often requires robust gears that can withstand continuous operation and high loads. Bronze gears are ideal for these demanding conditions.

Marine Equipment: The corrosion-resistant properties of bronze make it suitable for gears used in marine environments where exposure to saltwater is common.

Bronze Gear Blanks, Precision Machined Blanks

Bronze Gear Blanks, especially Precision Machined Blanks, are essential components in the manufacturing of high-quality gears. Their ability to save time, ensure consistency, and enhance material properties makes them invaluable in various industrial applications. By investing in precision machined blanks, manufacturers can achieve superior gear performance, reduce production costs, and improve overall efficiency. As technology and machining techniques continue to advance, the role of these precision components will only become more significant in the quest for mechanical excellence.

Custom Online CNC Machining Services

Get instant quotes for custom metal and self-lubricating bronze parts with our online CNC machining service. Create prototypes and production parts in just days!