The Essential Guide to Lubricating Bronze Flanged Bushings

About us

bronze bushing lubrication, Flanged Bushes, self-lubricating bronze bushing

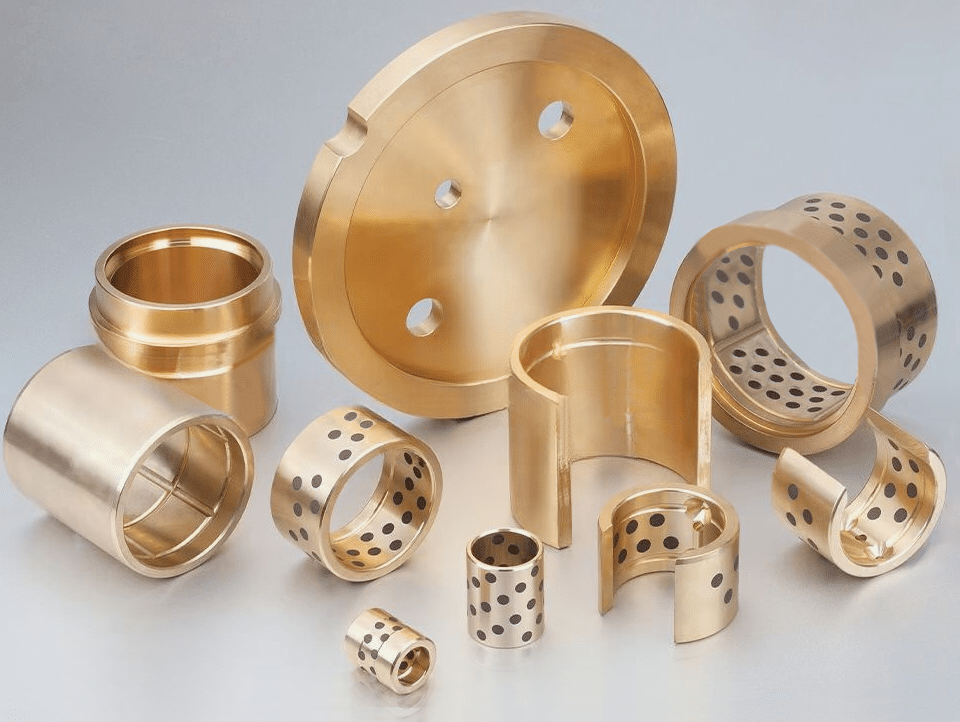

Bronze flanged bushings are a staple in many mechanical systems, known for their durability and low maintenance requirements. However, to ensure they operate efficiently and extend their lifespan, proper lubrication is crucial. In this guide, we’ll explore the best practices for lubricating bronze flanged bushings, helping you keep your machinery running smoothly.

Proper lubrication of bronze flanged bushings is essential for maintaining their performance and extending their lifespan. By choosing the right lubricant, applying it correctly, and following best practices, you can ensure your bushings operate smoothly and efficiently. Whether you’re dealing with high-speed machinery or equipment exposed to harsh conditions, a well-lubricated bushing can make all the difference in the reliability and longevity of your mechanical systems.

Understanding Bronze Flanged Bushings, self-lubricating bronze bushing

Bronze flanged bushings are cylindrical bearings with a flange on one end. This flange helps with alignment and reduces axial movement, making them ideal for various applications, including automotive, industrial machinery, and agricultural equipment. The bronze material offers excellent wear resistance, good load capacity, and corrosion resistance.

Why Lubrication Matters, self-lubricating bronze bushing

Lubrication plays a vital role in the performance of bronze flanged bushings. It reduces friction between the bushing and the shaft, minimizes wear, and helps dissipate heat. Proper lubrication also prevents contaminants from entering the bearing, which can cause premature failure.

Types of Lubricants, self lubricated bearing

When it comes to lubricating bronze flanged bushings, you have several options:

Oil: Light to medium-grade oils are suitable for high-speed applications. They offer excellent penetration and cooling properties. Oils can be applied manually or through an automated lubrication system.

Grease: Grease is ideal for low to medium-speed applications and environments where re-lubrication is difficult. It provides a thicker barrier, which can be beneficial in dirty or wet conditions. Lithium-based or molybdenum disulfide greases are commonly used.

Dry Lubricants: In situations where traditional lubricants are not feasible, dry lubricants such as graphite or molybdenum disulfide powders can be used. These are particularly useful in high-temperature environments or where oil and grease can attract dust and debris.

Lubrication Methods

Manual Application: For smaller systems or when automated systems are not practical, manual lubrication can be effective. Use a brush, oil can, or grease gun to apply the lubricant directly to the bushing and shaft interface. Ensure the area is clean before application.

Automated Systems: For larger systems or continuous operation, automated lubrication systems can deliver a consistent supply of lubricant. These systems can be programmed to apply the right amount of lubricant at regular intervals, ensuring optimal performance and reducing maintenance time.

Self-Lubricating Bushings: Some bronze bushings are impregnated with lubricants during manufacturing. These self-lubricating bushings slowly release lubricant during operation, reducing the need for regular maintenance.