Brass Bronze Bushing, Made-to-Order Lubricated Brass.

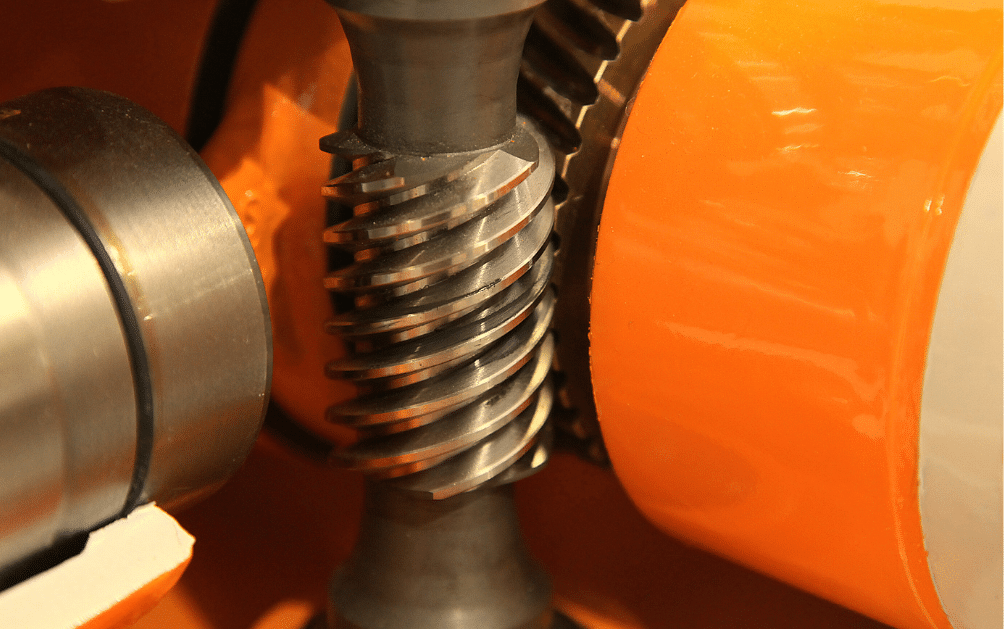

Brass Bearings provide high performance and low maintenance, minimizing costs and downtime. Their non-galling characteristics enable reliable dry operation and durability at high temperatures. We offer custom designs, engineering support, and quick turnaround. Check out our catalogs, including the Brass Sleeve Bearing and Sleeve Bushing Catalog. While specializing in custom machined brass components, we also work with bronze and other alloys to meet your specific requirements.

Continuous Availability

Precision Brass Parts and High-Quality Standard Components for Reliable Applications

Request a custom brass bearing prototype!

01. Brass Bushing Products

Brass and Flange Bronze Bushings provide dependable performance, supported by expert assistance and comprehensive online resources.

02. Brass Bushing Design

We are a Chinese supplier of high-performance alloys, specializing in bronze bushings and standard parts. We manufacture machined and turned components, including engineering-supported prototypes and high-volume orders.

03. Brass Bearing By Size

As a china supplier of sustainable steel and bronze products, we offer high-performance brass bearings and bronze bushings for all applications.

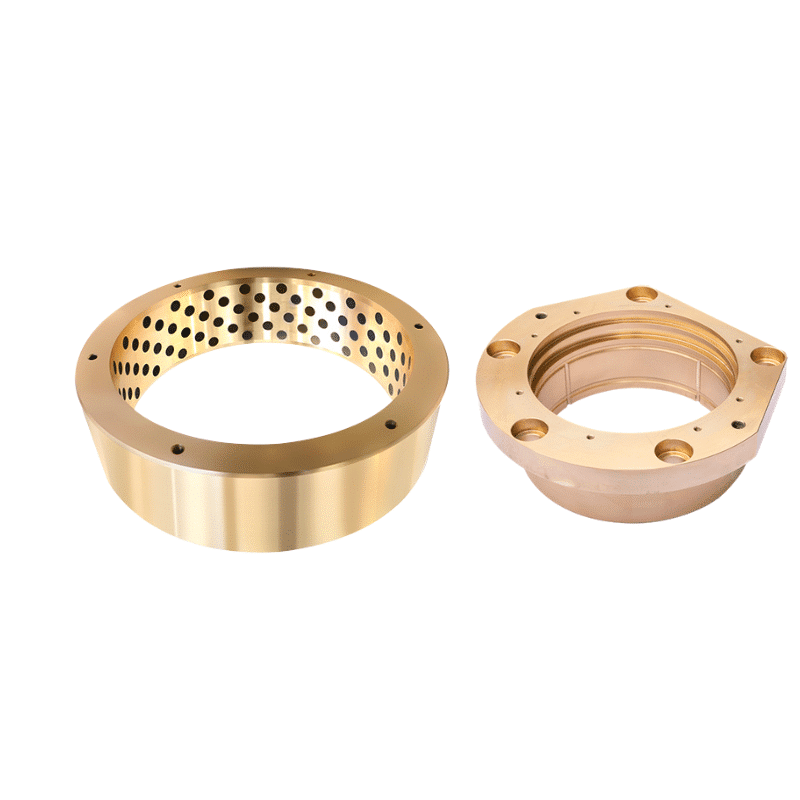

brass bearing and bushing

Custom Brass Bushing Prototyping with Instant Quotes

We enhance the self-lubricating bearing industry with exceptional service, trusted partnerships, and enduring value. Our products support steel manufacturers in meeting their sustainability goals. Discover our extensive selection of brass and aluminum bronze flange bushings in various materials and sizes, along with sleeve and plain bearings available for immediate shipping. Bronze sleeve bushings offer strength and durability, while brass bushings excel in corrosion resistance, thermal conductivity, machinability, and softness for industrial use. For a broad selection and custom options, visit online brass bushing suppliers at www.bronzelube.com.

Product Quality Index

Energy Generation

Brass Sleeve, Flange, and Thrust Bushings & Bearings (Size-Sorted)

Custom Brass Bushing Supplier

Explore our industrial sleeve bearings, quick disconnect bushings, and flanged sleeve bearings. We offer custom CuAl10Ni3Fe2-C aluminum bronze brass bushings for food and chemical machinery, prized for their high heat resistance. Request a quote for pricing and lead times on your project. With extensive customization options, we deliver high-quality brass bushings tailored to your industrial needs.

Brass Bushings by Size – BronzeLube

Bushings and Bearings: Sleeve, Flange, Thrust

Brass bronze bushings, crafted from solid bronze and optionally self-lubricating with graphite, come in standard and customizable sizes. Our offerings include oilless slide bearings, bronze bushings, graphite-plugged bushings, and PTFE-embedded solid cast bushings.

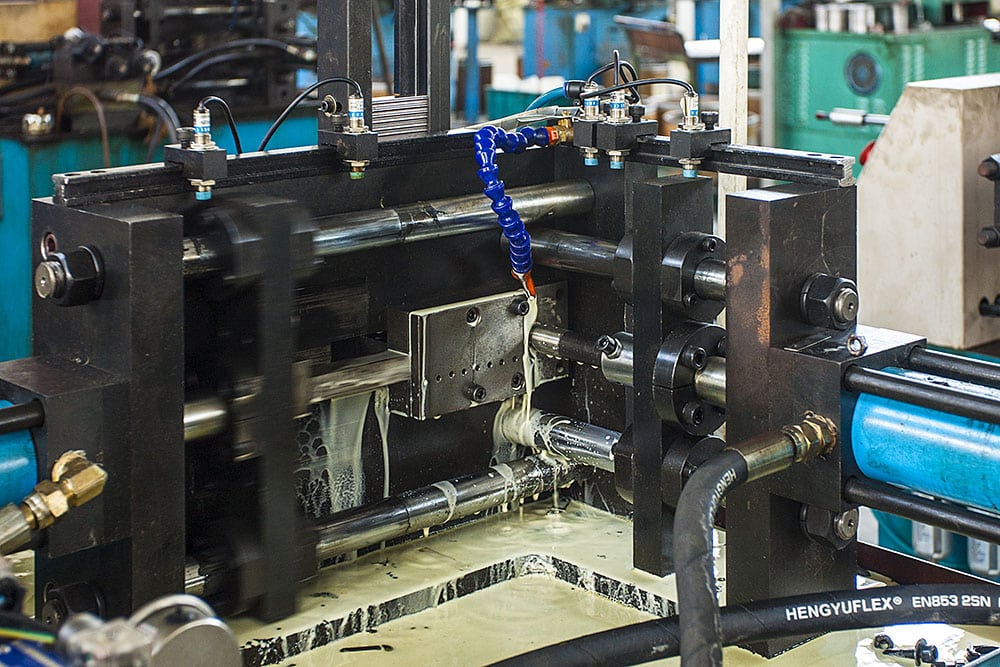

CNC Machining Services – Custom Parts in Days

Our solid bronze, custom groove, and aluminum bronze bushings are perfect for parts subject to severe water and corrosion. We keep a large inventory sourced directly from the manufacturer, bypassing intermediaries.

Bronze Bushing Material – ASTM Copper Alloy

Obtain instant quotes for online CNC-machined metal or bronze parts. Our available bronze alloys include CuAl10Fe5Ni5, CuAl10Fe2, CuAl9, CuAl10Ni3Fe2, and CuAl11Fe6. Custom chemical compositions can be requested.

Wide Selection of Cast Bronze Bushings: Metric and Inch Sizes, Available with or without Graphite.

Durable, Cost-Effective Brass and Flange Bushings for Motion Parts.

Enhance creativity, efficiency, and profitability with Superior Bearing & Supply’s brass and bronze bushings, featuring self-lubricating aluminum bronze options in various configurations.

Custom Brass Bushing Services

Self-Lubricating Copper Brass Bearing Sleeve…Factory Price

Ensure your project’s success with high-quality self-lubricating copper bearings, delivered promptly and accurately. We specialize in premium bearing bushings, performance alloys, and innovative composites. Benefit from our affordable, precise, and timely online CNC machining service. Choose from a variety of “Made in China” bronze bushings or request custom sizes to meet your needs. To get a quote or place an order, visit the spec page and complete the Customs Form. We offer a wide selection of brass bushing metal bearings.

Brass vs. Bronze Bushings: Materials, Bearings, and Sleeve Options.

We specialize in manufacturing custom brass bushings, machined parts, and bronze components, all tailored to your specific applications. Metal & Bronze – Available in various sizes. Our engineering experts design high-performance bearings and materials to meet your custom needs. Bronze sleeve bearings are more durable than softer brass bushings, providing greater resistance to shock, wear, and corrosion, which results in longer lifespans. Need custom bronze bearing prototypes? Contact us for a quote today!

Custom Machined Graphite-Impregnated Bronze Bushing – Fast Delivery.

CNC machining services deliver custom parts like bushings, bearings, and thrust washers in just days, utilizing high-performance alloys for harsh environments. Our offerings are customizable with resizing, oil grooves, or graphite. We provide precision brass and bronze bushings in optimal diameters and lengths, enhancing applications and promoting safer, more sustainable technologies. Our durable materials are essential in everyday products, driving advancements in various industries, including agriculture and construction. We specialize in brass and bronze bearing bushings, along with CNC turning and milling processes.

Precision Self-Lubricating Brass Bushings at Competitive Prices

Non-Ferrous Bushes and CNC Machined Parts Manufacturer – You design it, we produce it. We offer extensive CNC machining capabilities and materials tailored to your needs. Enjoy high-quality, rapid custom prototyping and manufacturing services. Experience fast online CNC machining with quick lead times and interactive quotes—upload your CAD file today. Specializing in Copper Casting, Die Casting, Aluminum Bronze Bushings, and self-lubricating bronze machined parts. We are a global OEM/ODM service provider offering comprehensive “One-Stop Service” solutions.

Bushing Finder – Bronzelube.com

We manufacture custom bronze bushings tailored to your specific needs.

Brass Bushings by Size: The Importance of Proper Sizing

Brass bushings play a crucial role in various industrial and mechanical applications by acting as bearings that minimize friction and wear between moving components. Selecting the correct size is essential for maximizing their performance and lifespan, making it critical to understand the factors that influence sizing.

At Bronzelube, we specialize in custom-standard bearings, engineered and designed to your specifications. Brass bushings are utilized across a wide range of industries such as automotive, electrical, and mechanical systems. Known for their durability, wear resistance, and low friction, they are ideal for high-demand applications.

Choosing the Right Brass Bushing Manufacturer

When selecting a brass bushing manufacturer, consider these key factors to ensure you receive a product that meets your requirements:

- Quality: Quality varies between manufacturers. Opt for a supplier known for producing high-quality bushings with rigorous material standards and strict quality control processes.

- Experience: A manufacturer with a solid track record and several years of experience is more likely to provide reliable, high-quality products.

- Customization: If you require custom bushings, choose a manufacturer capable of delivering products to your exact specifications.

- Cost: While price is important, it should be balanced with quality, customization options, and the overall value you receive.

- Lead Time: A manufacturer with quick turnaround times can ensure timely delivery for your projects.

- Technical Support: Choose a manufacturer offering robust technical support to help with product questions and selection.

By keeping these factors in mind, you can find a reliable manufacturer for standard or customized brass bushings, ensuring a successful outcome for your project.

Factors Influencing the Size of Brass Bushings

Several factors affect the appropriate sizing of brass bushings, including:

- Load Capacity: The size of the bushing must support the application’s load, accounting for the size of moving parts and operational speed.

- Friction: Proper sizing minimizes friction, improving efficiency and reducing wear.

- Operating Conditions: Environmental factors like temperature, humidity, and exposure to corrosive elements influence bushing performance and should guide size selection.

- Cost: Larger bushings tend to be more expensive, so it’s important to balance size with cost constraints.

Custom Bronze Parts – Quick Quotes and Fast Turnaround

Bronzelube offers custom bronze bushings with a wide range of sizes available. For any bushing requirement, including those for high-load applications, we can provide quick quotes and timely delivery. Our team of experts is ready to assist you with tailored solutions for your specific needs.

Determining the Right Bushing Size

- Load Capacity: Start by assessing the load your application requires. Select a bushing size that provides the necessary support to minimize wear.

- Friction: Consider how the bushing will interact with the moving parts. Choose a size that reduces friction and enhances efficiency.

- Operating Conditions: Evaluate the environmental conditions the bushing will face, and select a size suited to these specific conditions.

- Cost: Ensure the chosen size balances performance with budgetary considerations.

Conclusion

Proper sizing is crucial for the optimal performance of brass bushings. By considering load capacity, friction, operating conditions, and cost, you can choose the right bushing size for your application. Bronzelube provides a variety of brass bushings in multiple styles and sizes, ensuring durability and excellent wear resistance.

Explore Our Brass Bushing Range

Our continuously expanding product range ensures a steady supply of high-quality brass bushings. With optimized logistics and a vast inventory, Bronzelube is committed to maintaining a continuous product supply for our customers. Visit our website to browse our wide selection of bushings, or contact our experts for a customized solution.

Advantages and Disadvantages: Bronze vs. Plastic Bushings

When selecting bushings, it’s essential to understand the benefits and limitations of bronze and plastic options:

Bronze Bushings:

- Pros: Higher strength, better performance when lubricated, suitable for higher speeds and loads, and excellent corrosion resistance.

- Cons: Higher cost, heavier weight, and may require more complex installation.

Plastic Bushings:

- Pros: Cost-effective, lightweight, chemical resistant, and quieter operation.

- Cons: Lower load capacity, higher friction, and less durability than bronze.

Conclusion

The choice between bronze and plastic bushings depends on your application’s needs. Consider factors like cost, load capacity, durability, and environmental conditions to select

Custom Bearing Manufacturers – Made To The Highest Standards

Self Lubricating Brass Bushing By Size Material: Self Lubricant bushing (Bronze with Solid lubricants)

Self-lubricating brass bushings are a type of bushing made from bronze material that contains solid lubricants. These lubricants are incorporated into the material during the manufacturing process, which eliminates the need for external lubrication. The result is a maintenance-free bushing that provides reliable performance in a range of applications.

Self-lubricating brass bushings come in a variety of sizes to suit different needs. The size of the bushing you choose will depend on the specific requirements of your application. Below, we will discuss some of the key factors to consider when selecting the right self-lubricating brass bushing by size.

Self Lubricating Brass Bushing Load Capacity

The load capacity of a self-lubricating brass bushing is an essential factor to consider when selecting the right size. This refers to the maximum amount of weight or pressure the bushing can withstand without becoming damaged. The load capacity is influenced by the bushing’s internal diameter, wall thickness, and length. To ensure you choose the right size, you need to know the expected load capacity of the application in which the bushing will be used.

Self Lubricating Brass Bushing Friction Coefficient

The friction coefficient of a self-lubricating brass bushing is another crucial factor to consider when selecting the right size. This refers to the level of resistance to motion between the bushing and the shaft. The friction coefficient is influenced by the type of solid lubricants incorporated into the bushing material, as well as the size and shape of the bushing. It is important to choose a bushing with the appropriate friction coefficient for your application to ensure optimal performance.

Self Lubricating Brass Bushing Temperature Range

The temperature range of a self-lubricating brass bushing is also an essential factor to consider when selecting the right size. The bushing’s temperature range refers to the minimum and maximum temperature it can withstand without becoming damaged. This is influenced by the type of solid lubricants used in the bushing material, as well as the size and shape of the bushing. It is important to choose a bushing with a temperature range that is appropriate for your application.

Self Lubricating Brass Bushing Size Selection

When selecting the right self-lubricating brass bushing by size, you need to consider all of the factors discussed above. You should also take into account the specific requirements of your application, such as the operating environment and the expected load capacity. It is also essential to consider the compatibility of the bushing with the shaft and other components in the system.

In summary, self-lubricating brass bushings are an excellent choice for a range of applications. By considering factors such as load capacity, friction coefficient, and temperature range, you can select the right size to ensure optimal performance and reliability. When choosing a self-lubricating brass bushing, it is important to work with a reputable supplier who can provide expert advice and high-quality products to meet your needs.

Your Trusted Custom Size Brass Bushing Supplier: Delivering Excellence Tailored to Your Needs

If you have a design challenge, solution. Combining our engineering expertise with dynamic production capabilities, we have developed stronger, longer-lasting brass bearing parts for a broad spectrum of markets.

Click on the links below to learn more about our work on custom components and gears.

Are you looking for a reliable supplier of custom size brass bushings that meet your specific requirements? Look no further! We pride ourselves on being a recognized provider of tailor-made brass bushings, designed to suit a wide range of industries and applications.

Why Choose Us as Your Custom Size Brass Bushing Supplier?

- Precision Engineering: Our state-of-the-art manufacturing facilities employ advanced technology and skilled craftsmanship to create custom brass bushings with precise dimensions and impeccable finishes, ensuring a perfect fit and optimal performance.

- Wide Range of Materials: We offer a comprehensive selection of brass and bronze materials, including CuZn25Al5, CuAl10Ni, CuSn12Pb, CuSn7ZnPb, and more, to cater to your unique needs and application requirements.

- Custom Design and Manufacturing: Our team of expert engineers collaborates with you to develop the ideal custom brass bushing solution for your project. We meticulously design and manufacture bushings tailored to your specifications, ensuring compatibility and optimal performance.

- Quality Assurance: We adhere to strict quality control measures to ensure that each custom brass bushing meets or exceeds industry standards. You can trust that our products are of the highest quality, providing reliable performance and longevity.

- Competitive Pricing: We believe in offering our clients exceptional value by providing top-quality custom size brass bushings at competitive prices. Our efficient manufacturing processes and economies of scale enable us to deliver premium products without compromising on quality or affordability.

- Outstanding Customer Service: Our commitment to customer satisfaction is unmatched. Our knowledgeable and experienced team is available to answer any questions, provide expert guidance, and ensure the timely delivery of your custom size brass bushings.

Partner with Us for Custom Size Brass Bushings

Choose us as your trusted custom size brass bushing supplier, and experience the difference of working with a dedicated partner committed to your success. Contact us today to discuss your requirements, request a quote, or learn more about our custom brass bushing solutions. Let us help you elevate your business with our unparalleled products and expertise.

Brass bushings size chart

Brass bushings are widely used in mechanical applications as a means to reduce friction and wear between rotating or sliding machine parts. They are typically made from a copper and zinc alloy, known as brass, which provides good strength, durability, and corrosion resistance. In order to select the right brass bushing for a specific application, it is important to understand the different size options available.

Brass bushings are available in a wide range of sizes to fit different shaft diameters and bore sizes. The most common sizing method for brass bushings is the inner diameter (ID) and outer diameter (OD) dimensions. The ID dimension is the diameter of the inner hole of the bushing, while the OD dimension is the diameter of the outer surface of the bushing.

To help with the selection of the appropriate size brass bushing, a size chart is typically used. This chart will list the available sizes of brass bushings, along with their corresponding ID and OD dimensions. The chart may also include other relevant information, such as the length of the bushing, the material it is made from, and the maximum load capacity.

For example, a typical brass bushing size chart may list the following sizes:

- 1/4″ ID x 3/8″ OD x 1/2″ Length

- 3/8″ ID x 1/2″ OD x 3/4″ Length

- 1/2″ ID x 5/8″ OD x 1″ Length

- 5/8″ ID x 3/4″ OD x 1-1/4″ Length

- 3/4″ ID x 7/8″ OD x 1-1/2″ Length

- 7/8″ ID x 1″ OD x 1-3/4″ Length

- 1″ ID x 1-1/4″ OD x 2″ Length

It is important to note that this is just an example of a possible brass bushing size chart, and that the actual sizes and dimensions listed may vary depending on the manufacturer or supplier. It is always recommended to consult the manufacturer’s specifications and technical data sheets to ensure that the selected brass bushing is appropriate for the specific application and load requirements.

In addition to the ID and OD dimensions, other important factors to consider when selecting a brass bushing include the operating conditions, such as the temperature, humidity, and type of lubrication used, as well as the required load capacity and expected lifespan. By considering all of these factors, it is possible to select the right brass bushing for the application, ensuring optimal performance, longevity, and reliability.

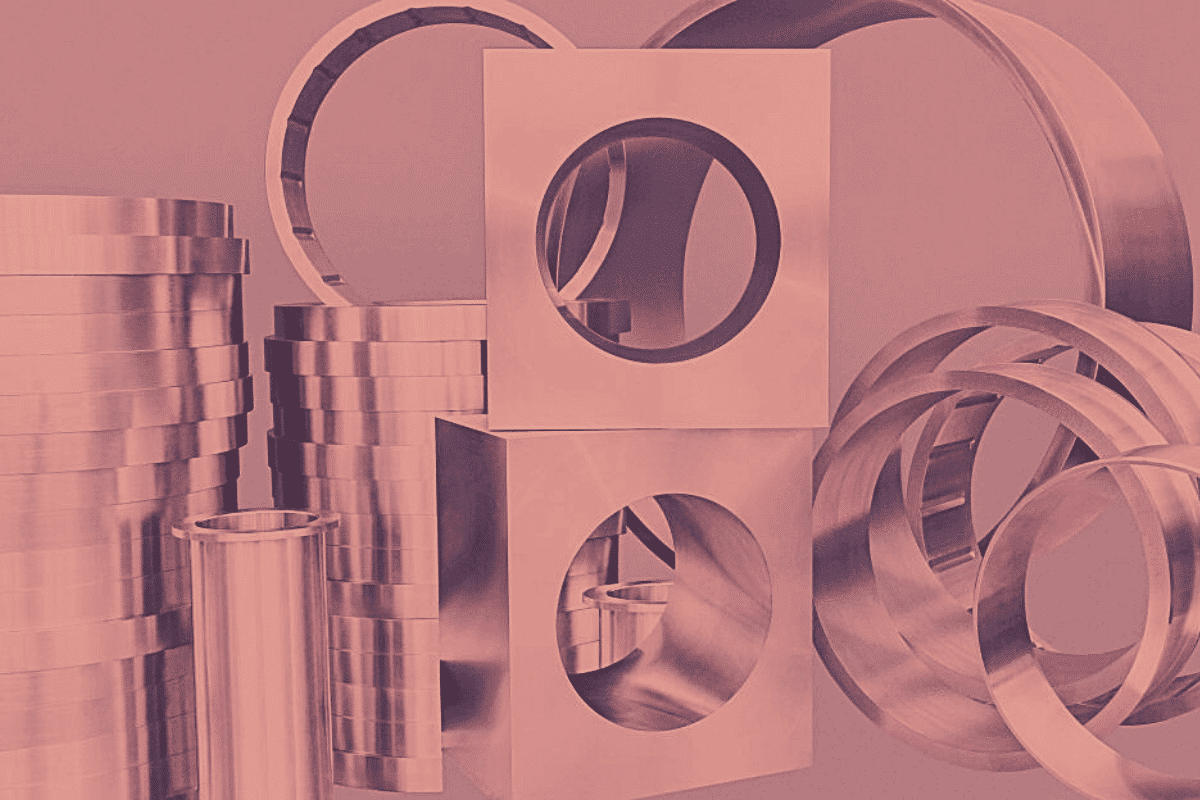

Flange bronze bushing by size

Flange bronze bushings are commonly used in mechanical applications to reduce friction and wear between rotating or sliding machine parts. These bushings feature a flanged design, which provides additional support and stability, as well as a means to secure the bushing in place. To select the right flange bronze bushing for a specific application, it is important to understand the different size options available and consult a size chart.

Flange bronze bushings are available in a range of sizes, which are typically identified by the inner diameter (ID) and flange diameter (FD). The ID dimension is the diameter of the inner hole of the bushing, while the FD dimension is the diameter of the flange on the outer surface of the bushing.

A typical flange bronze bushing size chart may include the following sizes:

- 1/2″ ID x 3/4″ Flange bronze bushing by size

- 5/8″ ID x 7/8″ Flange bronze bushing by size

- 3/4″ ID x 1″ Flange bronze bushing by size

- 7/8″ ID x 1-1/8″Flange bronze bushing by size

- 1″ ID x 1-1/4″Flange bronze bushing by size

- 1-1/4″ ID x 1-1/2″Flange bronze bushing by size

- 1-1/2″ ID x 1-3/4″Flange bronze bushing by size

- 1-3/4″ ID x 2″ Flange bronze bushing by size

- 2″ ID x 2-1/4″ Flange bronze bushing by size

It is important to note that this is just an example of a possible flange bronze bushing size chart, and that the actual sizes and dimensions listed may vary depending on the manufacturer or supplier. It is always recommended to consult the manufacturer’s specifications and technical data sheets to ensure that the selected flange bronze bushing is appropriate for the specific application and load requirements.

In addition to the ID and FD dimensions, other important factors to consider when selecting a flange bronze bushing include the thickness of the flange, the length of the bushing, and the material it is made from. Flange bronze bushings are typically made from a copper and tin alloy, known as bronze, which provides good strength, durability, and corrosion resistance.

When selecting a flange bronze bushing, it is important to consider the specific application and load requirements, as well as the operating conditions, such as temperature, humidity, and type of lubrication used. By taking all of these factors into account and consulting a size chart, it is possible to select the right flange bronze bushing for the application, ensuring optimal performance, longevity, and reliability.

Custom Brass Bearings

Custom brass bearings are an essential component of many mechanical systems, providing a smooth, low-friction surface between moving parts. The brass material offers excellent corrosion resistance and durability, making it ideal for a wide range of applications. In this article, we will explore the benefits and uses of custom brass bearings.

Benefits of Custom Brass Bearings

Custom brass bearings offer many benefits over other bearing materials. One of the primary advantages is their excellent wear resistance, making them ideal for high-load applications. Brass bearings are also highly corrosion-resistant, making them suitable for use in harsh environments where moisture and other corrosive agents are present.

Another advantage of brass bearings is their ability to self-lubricate, reducing the need for additional lubrication. This reduces maintenance costs and increases the overall efficiency of the system. Brass bearings also offer good thermal conductivity, which makes them suitable for high-temperature applications.

Uses of Custom Brass Bearings

Custom brass bearings are widely used in a variety of industries, including automotive, marine, and industrial applications. They are commonly used in pumps, compressors, and other equipment that requires a smooth, low-friction surface between moving parts.

In the automotive industry, brass bearings are used in a variety of applications, including steering systems, transmissions, and engines. They are also used in marine applications, including boat propellers, rudders, and shafts. In industrial applications, brass bearings are used in machinery such as conveyor systems, fans, and turbines.

Custom brass bearings are available in a variety of shapes and sizes, making them suitable for a wide range of applications. They can be customized to meet specific requirements, such as high load capacity or low friction. This versatility makes them an excellent choice for many different types of machinery and equipment.

Conclusion

Custom brass bearings offer many benefits over other bearing materials, including excellent wear resistance, corrosion resistance, and self-lubrication. They are widely used in a variety of industries, including automotive, marine, and industrial applications. With their versatility and customizability, brass bearings are an excellent choice for any application that requires a smooth, low-friction surface between moving parts.

Cast Copper Alloy (Bearing Bronze) Material Composition

A brass bush bearing, also known as a brass sleeve bearing or brass plain bearing, is a type of bearing that is commonly used in mechanical applications to reduce friction and wear between rotating or sliding machine parts. These bearings consist of a cylindrical sleeve, typically made from a copper and zinc alloy, known as brass, which is designed to fit snugly around a shaft or other machine part. The brass sleeve may be lined with a low-friction material, such as PTFE or graphite, to further reduce friction and wear.

One of the main advantages of brass bush bearings is their simplicity and durability. They have no moving parts, so there is little to no risk of mechanical failure or breakdown. They are also relatively easy to install and maintain, and can provide long-lasting performance even under heavy loads and high speeds.

Brass bush bearings are available in a range of sizes to fit different shaft diameters and bore sizes. The most common sizing method for brass bush bearings is the inner diameter (ID) and outer diameter (OD) dimensions. The ID dimension is the diameter of the inner hole of the bearing, while the OD dimension is the diameter of the outer surface of the bearing.

In addition to the standard brass bush bearings, which are solid cylinders, there are also flanged brass bush bearings, which have a flange on one end to provide additional support and stability. Flanged brass bush bearings are particularly useful in applications where axial loads or misalignment may be a concern.

When selecting a brass bush bearing, it is important to consider the specific application and load requirements, as well as the operating conditions, such as temperature, humidity, and type of lubrication used. By taking all of these factors into account, it is possible to select the right brass bush bearing for the application, ensuring optimal performance, longevity, and reliability.

In summary, brass bush bearings are a simple and durable solution for reducing friction and wear between rotating or sliding machine parts. They are available in a range of sizes and can be lined with low-friction materials for even greater performance. By selecting the right brass bush bearing for the application, it is possible to ensure optimal performance, longevity, and reliability.

Bronze Bushings Online – Large Inventory

Special Offers, And More! Small Minimum Order. In Stock. Order Online. Types: Non ferrous Bushes Graphite Impregnated Bushings

We offer the broadest range of properties among today’s bronze bearing materials, Bronze bushings – Centrifugal Castings, a Wide range of copper-based materials. Pre-turned or finalized ready for assembly parts. Bronze & Brass Alloys Bearing. Sliding Bearings, Bushings.

High-quality raw material, Not all metal and bronze is the same. That is why we choose the most renowned non-ferrous metal plants as our suppliers. Only the best raw materials can ensure exceptionally good products. The people who ultimately benefit from the quality of our raw materials are our customers. Precision Brass Bearing & Bushing Production. Our State-Of-The-Art Manufacturing Processes Are Another Factor That Guarantees Precision And Dimensional Stability. Our Service Is The Basis For Your Success!

| Type | Chemical Composition mass % | Mechanical properties | |||||||||||||

| UNS NO | Cu | Sn | Al | Fe | Mn | Ni | Si | p | Zn | Tensile strength

Mpa(Min) |

Yield strength

Mpa (Min) |

Elongation

% (Min) |

hardness

(HB) |

||

| Tin bronze | C83600 | 84.0-86.0 | 4.0-6.0 | 0.005 | 0.3 | __ | 1 | 4.0-6.0 | 0.005 | 0.05 | 4.0-6.0 | 248 | 131 | 15 | 60 |

| C84400 | 78.0-82.0 | 2.3-3.5 | 0.005 | 0.4 | __ | 1 | 6.0-8.0 | 0.005 | 1.5 | 7.0-10.0 | 207 | 103 | 16 | 55 | |

| Special brass | C86200 | 60.0-66.0 | 0.20 | 3.0-4.9 | 2.0-4.0 | 2.5-5.0 | 1.00 | 0.20 | 22.0-28.0 | 621 | 310 | 18 | 180 | ||

| C86300 | 60.0-66.0 | 0.20 | 5.0-7.5 | 2.0-4.0 | 2.5-5.0 | 1.00 | 0.20 | 22.0-28.0 | 758 | 427 | 14 | 225 | |||

| C86400 | 56.0-62.0 | 0.50-1.5 | 0.50-1.5 | 0.40-2.0 | 0.1-1.5 | 1.00 | 0.50-1.5 | 34.0-42.0 | 450 | 170 | 20 | 105 | |||

| C86500 | 55.0-60.0 | 1.00 | 0.50-1.5 | 0.40-2.0 | 0.10-1.5 | 一一 | 0.40 | 36.0-42.0 | 483 | 172 | 25 | 130 | |||

| Silicon brass | C87400 | >79.0 | — | 0.80 | — | 一_ | ― | 1.00 | 2.5-4.0 | 12.0-16.0 | 379 | 165 | 18 | 100 | |

| C87500 | >79.0 | 一一 | 0.50 | 3.0-5.0 | 12.0-16.0 | 462 | 207 | 21 | 134 | ||||||

| C87850 | 74.0-78.0 | 0.30 | 一_ | 0.09 | 0.10 | 0.20 | 0.10 | 27-3.4 | 0.05-0.2 | Rem. | 448 | 172 | 8 | 103 | |

| Tin bronze | C90300 | 86.0-89.0 | 7.5-9.0 | 0.01 | — | 1.00 | 0.30 | 0.01 | 1.50 | 3.0-5.0 | 303 | 152 | 18 | 70 | |

| C90500 | 86.0-89.0 | 9.0-11.0 | 0.01 | 0.20 | 1.00 | 0.30 | 0.01 | 1.50 | 1.0-3.0 | 300 | 172 | 10 | 75 | ||

| C90700 | 88.0-90.0 | 10.0-12.0 | 0.01 | 0.15 | — | 0.50 | 0.50 | 0.01 | 1.50 | 0.50 | 276 | 172 | 10 | 80 | |

| C90800 | 85.0-89.0 | 11.0-13.0 | 0.01 | 0.15 | 0.50 | 0.25 | 0.01 | 0.30 | 0.25 | 280 | 150 | 5 | 90 | ||

| C91600 | 86.0-89.0 | 9.7-10.8 | 0.01 | 0.20 | — | 1.2-2.0 | 0.25 | 0.01 | 0.30 | 0.25 | 303 | 152 | 16 | 85 | |

| C91700 | 84.0-87.0 | 11.3-12.5 | 0.01 | 0.20 | 1.2-2.0 | 0.25 | 0.01 | 0.30 | 0.25 | 303 | 152 | 16 | 85 | ||

| Leaded

tin bronze |

C93200 | 81.0-85.0 | 67-7.5 | 0.01 | 0.20 | 1.00 | 6.0-8.0 | 0.01 | 1.50 | 2.0-4.0 | 241 | 138 | 10 | 65 | |

| C93400 | 82.0-85.0 | 7.0-9.0 | 0.01 | 0.20 | 一 | 1.00 | 7.0-9.0 | 0.01 | 1.50 | 0.80 | 234 | 138 | 10 | 60 | |

| C93500 | 83.0-86.0 | 4.3-6.0 | 0.01 | 0.20 | — | 1.00 | 8.0-10.0 | 0.01 | 0.05 | 2.00 | 221 | 110 | 10 | 60 | |

| C93700 | 78.0-82.0 | 9.0-11.0 | 0.01 | 0.70 | — | 0.50 | 8.0-11.0 | 0.01 | 1.50 | 0.80 | 241 | 138 | 10 | 60 | |

| C93800 | 75.0-79.0 | 6.3~7.5 | 0.01 | 0.15 | — | 1.00 | 13.0-16.0 | 0.01 | 1.50 | 0.80 | 207 | 110 | 10 | 55 | |

| C93900 | 76.5-79.5 | 5.0-7.0 | 0.01 | 0.40 | — | 0.80 | 14.0-18.0 | 0.01 | 1.50 | 1.50 | 172 | 110 | 7 | 63 | |

| C94000 | 69.0-72.0 | 12.0-14.0 | 0.01 | 0.25 | — | 0.5-1.0 | 14.0-16.0 | 0.01 | 0.05 | 0.50 | 172 | 110 | 7 | 80 | |

| C94100 | 72.0-79.0 | 4.5-6.5 | 0.01 | 0.25 | — | 1.00 | 18.0-22.0 | 0.01 | 1.50 | 1.00 | 172 | 117 | 7 | 50 | |

| C94300 | 67.0-72.0 | 4.5-6.0 | 0.01 | 0.15 | — | 1.00 | 23.0-27.0 | 0.01 | 1.50 | 0.80 | 145 | 103 | 7 | 48 | |

| Aluminum bronze | C94500 | Rem. | 6.0-8.0 | 0.01 | 0.15 | — | 1.00 | 16.0-22.0 | 0.01 | 1.50 | 1.20 | 172 | 83 | 7 | 50 |

| C95200 | 86.0Min | — | 8.5-9.5 | 2.5-4.0 | — | — | — | — | — | — | 469 | 179 | 20 | 125 | |

| C95210 | 86.0Min | .010 | 8.5-9.5 | 2.5-4.0 | 1.00 | 1.00 | — | 0.25 | 0.05 | 0.50 | 469 | 179 | 20 | 125 | |

| C95220 | Ren. | — | 9.5-10.5 | 2.5-4.0 | 0.50 | 2.50 | — | 485 | 195 | 20 | 150 | ||||

| C95400 | 83.0Min | — | 10.0-11.5 | 3.0-5.0 | 0.50 | 1.50 | — | 586 | 221 | 12 | 170 | ||||

| C95410 | 83.0Min | — | 10.0-11.5 | 3.0-5.0 | 0.50 | 1.5-2.5 | — | 586 | 221 | 12 | 170 | ||||

| C95500 | 78.0Min | — | 10.0-11.5 | 3.0-5.0 | 3.50 | 3.0-5.5 | — | 655 | 290 | 10 | 192 | ||||

| C95510 | 78.0Min | 0.20 | 9.7-10.9 | 2.0-3.5 | 1.50 | 4.5-5.5 | — | — | — | 0.30 | 655 | 345 | 8 | 248 | |

| C95520 | 74.5Min | 0.25 | 10.5-11.5 | 4.0-5.5 | 1.50 | 4.2-6.0 | 0.03 | 0.15 | — | 0.30 | 862 | 655 | 2 | 262 | |

| C95800 | 79.0Min | — | 8.5-9.5 | 3.5-4.5 | 0.8-1.5 | 4.0-5.0 | 0.03 | 0.10 | — | 586 | 241 | 18 | 159 | ||

| C95900 | Ren. | ■■ | 12.0-13.5 | 3.0-5.0 | 1.50 | 0.50 | — | 515 | 345 | 1 | 241 | ||||

what does non-ferrous mean

Non-ferrous metals are alloys or metals that do not contain any appreciable amounts of iron. All pure metals are non-ferrous elements, except for iron (Fe), which is also called ferrite from the Latin ‘ferrum,’ meaning “iron.”

We manufacture all types of metal graded. We are specialized in Ferrous and Non–Ferrous Bushes. We supplies to all types of mechanical or engineering industries …

Browse & discover brass bearing and bushing. Read customer reviews & find best sellers. Free shipping on qualified orders. Free, easy returns on millions of items.

Nhigh-qualityonthat-Ferrous Bushes. A.Gunmetal Bronze Bushes are high corrosion-resistant quality product which is used for general castings.

Non-ferrous bushings

Bronze bushings are high quality products for general castings. Phosphor bronze bushings have good anti-friction properties and are malleable for heavy-duty applications where lubrication is questionable. Aluminum bronze bushings/parts are corrosion resistant alloys with excellent strength and are typically used in impellers/bushings.

Non-ferrous bushings automotive use and are manufactured in our high tech manufacturing unit under the control of competent and knowledgeable professionals.

Manufacturer of Non-Ferrous Bushes

Centrifugally cast & CNC machined copper and bronze alloy castings – built to custom specs. Companies Who Depend on Us to Supply High QualityHigh-Quality Parts on Time at a Reasonable Price.

Casting Section: Sand Casting and

- Sand casting is a process that utilizes non-reusable sand molds to form metal castings. …

- Green sand (an aggregate of sand, pulverized coal, bentonite clay, and water) has traditionally been used in sand casting, however modern chemically bonded molding systems are becoming more popular.

What is centrifugal casting?

Centrifugal casting is the technology and method of injecting liquid metal into the high-speed rotating casting, so that the liquid metal does centrifugal motion to fill the casting and form the casting. Because of the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form a free surface of the casting. A cylindrical inner hole can be obtained without a core; Help to eliminate gases and inclusions in liquid metals; It affects the crystallization process of metal and improves the mechanical and physical properties of castings.

Phosphor Bronze Bushes

We also have a range of bushings and parts made from phosphor bronze. This material is friction-resistant and malleable, which makes it ideal for heavy-duty applications. As a result, our busbar/component arrays have all these characteristics, as well as other features such as dimensional and rotational accuracy, high tensile strength, and the ability to withstand high temperatures and pressures.

Gunmetal Bronze Bushes

Gunmetal is a top quality material ideal for general castings. Its applications include all types of automotive bearings, automotive spare parts, engines and machinery. We use it to produce an appreciable range of bushings and parts. These durable products are used in different industries, including automotive. These products are characterized by high dimensional accuracy, high tensile strength, ability to withstand high temperature and pressure, high rotational accuracy and easy mounting.

Aluminum bronze bushing partsAluminum bronze bushing parts, bronze parts are ideally used in the automotive industry because of its high tensile strength and corrosion resistance. It is very popular for use in different industries as it can withstand excessive heat and pressure. Moreover, it has a subtle luster and strength that gives longevity to any product.

Corrosion resistant alloys have excellent strength and are generally used for impellers/shaft sleeves.

Precision Bronze Bushings – Standard & Custom Bearings, CNC Machining & More

Quick-turn prototypes and short runs for all industries. High-quality, low-cost CNC machining with fast quotes in minutes and parts delivered in days. Quality bronze bushings made in China. Order today! Bushing, thrust washers, and sliding plates available. Highlights: Quick quotes, excellent customer service, and specialized materials. Professional online CNC machining service—affordable, on-time, and precise. Extensive inventory of bearing bronze alloys in various shapes and sizes. Wrapped bronze bushings—quickly finished and machined. Custom-machined, centrifugally cast bronze bushings, strips, washers, and wear plates. Specialized self-lubricating bearings designed to meet strict customer specifications, conserve materials, and improve efficiency with advanced techniques.

Brass Bushing OEM & ODM & Design Services

Bronze Bushings – Explore Our Catalogues & Brass Bearing OEM/ODM Services at China’s Large-Scale Foundry

Designed to excel beyond the competition, we provide high-quality, cost-effective brass bearing bushings. Along with a wide selection of stock products, we offer custom engineering and fabrication for both high and low-volume orders. We manufacture metric and inch dimensions with cost-effective pricing, low minimum quantities, expert knowledge, and fast delivery. Highlights include a comprehensive catalog, custom bronze bushings, precision machining, and on-time, budget-friendly delivery of solid bronze bearings and slide plates.