Brass Bushing Sleeves in Bronze Alloys from Our Metal Services.

Our continuous cast brass bushing sleeve is suitable for various industries, including fluid power, oil and gas, and machine tools. If you have questions about our services, our Brass Sleeve Bushing Bearings offer exceptional quality and long-lasting performance for your machinery needs. Manufactured with precision, these bearings are perfect for applications requiring durability and reliability. Enhance your equipment’s functionality—discover more about our Brass Sleeve Bushing Bearings today!

Custom Parts Services and Prototyping!

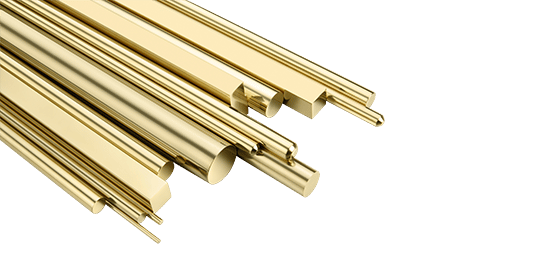

Special Bronze Alloys And Aluminium Bronze Bearing, Search Our Material Alloy

Metal Bushings

Brass Bronze Bushing Sleeve

The right material at the right time—helping our customers save time and money. Call us today to discuss your application! Standard Size Brass Sleeve Bushings: Discover Your Ideal Fit Explore our diverse range of standard size brass sleeve bushings to satisfy all your machinery needs. With various sizes available, you’re sure to find the perfect fit for your application. Click the link below to browse our selection and secure the ideal brass sleeve bushing for your equipment. Find Your Perfect Standard Size Brass Sleeve Bushing: Custom Size Brass Sleeve Bushings: Personalized Solutions for Your Unique Requirements Looking for a custom size brass sleeve bushing? We’ve got you covered. Our made-to-order bushings ensure a perfect fit for your specific machinery needs. Request a quote today by clicking the link below, and let us provide you with a tailor-made solution for your application.

Our offerings include continuous cast bronze bushings, along with brass sleeve bearings, as well as oilless bearings made from bronze. We specialize in providing these high-quality components to meet various industrial needs and applications.

Our customers have placed their trust in us because we provide top-notch brass bushing sleeve materials that significantly contribute to their overall profitability. They rely on our products to enhance their operations and maximize their financial success in a competitive market.

Brass bushings are indeed indispensable in metallurgical equipment due to their unique combination of properties that make them ideal for reducing friction, wear, and corrosion in demanding environments. Here’s a more detailed look at their applications and benefits:

Applications in Metallurgical Equipment:

-

Rolling Mills:

-

Function: Brass bushings are used in rolling mills to support heavy loads and high temperatures, ensuring smooth operation and alignment of rollers.

-

Benefit: They help in reducing wear on roller bearings and other critical components, thereby extending the lifespan of the equipment.

-

-

Forging Equipment:

-

Function: In forging presses and hammers, brass bushings reduce friction between moving parts, which is crucial for maintaining precision and efficiency.

-

Benefit: They contribute to the longevity of the equipment by minimizing wear and tear.

-

-

Casting Machinery:

-

Function: Brass bushings are used in casting machinery to prevent wear on components, ensuring smooth and efficient operation.

-

Benefit: They help in maintaining the integrity of the machinery, reducing downtime and maintenance costs.

-

-

Extrusion Presses:

-

Function: These presses require high precision and smooth movement, which is facilitated by brass bushings.

-

Benefit: They help in maintaining alignment and reducing wear on moving parts, ensuring consistent performance.

-

-

Material Handling Equipment:

-

Function: Brass bushings are used in conveyor systems, cranes, and other material handling equipment to reduce friction and wear.

-

Benefit: They improve the efficiency and longevity of the equipment, reducing the need for frequent maintenance.

-

Benefits of Brass Bushings:

-

Corrosion Resistance:

-

Importance: In metallurgical processes, equipment is often exposed to harsh environments and high temperatures. Brass bushings resist corrosion, ensuring durability and reliability.

-

-

Wear Resistance:

-

Importance: The excellent wear resistance of brass bushings reduces the frequency of replacements and maintenance, leading to cost savings and increased uptime.

-

-

Thermal Conductivity:

-

Importance: Good thermal conductivity helps in dissipating heat, maintaining consistent temperatures within the equipment, and preventing overheating.

-

-

Self-Lubricating Properties:

-

Importance: Some brass alloys have self-lubricating properties, which reduce the need for additional lubrication, simplifying maintenance and reducing operational costs.

-

-

Machinability:

-

Importance: Brass is easy to machine, allowing for the production of bushings with precise dimensions and tight tolerances, ensuring a perfect fit and optimal performance.

-

-

Cost-Effectiveness:

-

Importance: Brass bushings are generally more cost-effective than alternatives like bronze or steel, making them a preferred choice for many metallurgical applications.

-

Summary:

Brass bushings are critical components in metallurgical equipment, offering a range of benefits that enhance the performance, efficiency, and longevity of the machinery. Their corrosion and wear resistance, combined with good thermal conductivity and cost-effectiveness, make them an excellent choice for various demanding applications in the metallurgical industry. By reducing friction and wear, brass bushings help maintain smooth operation and extend the life of the equipment, ultimately contributing to lower operational costs and increased productivity.

Self-lubricating brass sleeve bushings are a highly efficient and cost-effective solution for a wide range of industrial applications. Their unique properties make them an excellent choice for reducing friction, wear, and maintenance requirements in various types of machinery. Below is a detailed overview of the benefits, applications, and comparisons with oil and grease lubricated bearings:

Key Features of Self-Lubricating Brass Sleeve Bushings:

-

Low Friction:

-

Benefit: Engineered to provide low friction and smooth operation, these bushings reduce energy consumption and minimize wear and tear on machinery.

-

-

Self-Lubricating:

-

Benefit: Designed with self-lubricating properties, these bushings require minimal maintenance and reduce downtime, making them a cost-effective solution.

-

-

Versatile Applications:

-

Benefit: Suitable for a wide range of applications, including gearboxes, pumps, motors, and automotive components, making them ideal for various industries.

-

-

Customizable Sizes:

-

Benefit: Available in customizable sizes to meet specific requirements, ensuring a perfect fit for different applications.

-

Benefits of Self-Lubricating Brass Sleeve Bushings:

-

Maintenance-Free:

-

Benefit: Eliminates the need for periodic lubrication, saving time and resources.

-

-

Longer Service Life:

-

Benefit: Reduces friction and wear, resulting in a longer lifespan and lower replacement costs.

-

-

Increased Reliability:

-

Benefit: Less prone to contamination, improving the overall reliability of machinery.

-

-

Environmentally Friendly:

-

Benefit: Reduces environmental impact associated with lubricant disposal and the risk of soil or water contamination.

-

-

Wide Temperature Range:

-

Benefit: Can operate under a broad range of temperatures, making them suitable for various environments.

-

-

Reduced Noise and Vibration:

-

Benefit: Minimizes noise and vibration, leading to a more comfortable and quieter working environment.

-

Comparison with Oil and Grease Lubricated Bearings:

-

Maintenance:

-

Self-Lubricating Bushings: Maintenance-free.

-

Oil/Grease Lubricated Bearings: Require regular maintenance.

-

-

Contamination Risk:

-

Self-Lubricating Bushings: Lower risk of contamination.

-

Oil/Grease Lubricated Bearings: More susceptible to contamination.

-

-

Environmental Impact:

-

Self-Lubricating Bushings: More eco-friendly.

-

Oil/Grease Lubricated Bearings: Potential environmental concerns.

-

-

Application:

-

Self-Lubricating Bushings: Suitable for extreme temperatures and harsh environments.

-

Oil/Grease Lubricated Bearings: May not perform as well in extreme conditions.

-

Our Bronze Alloys:

-

Leaded Bronze (SAE 660):

-

Properties: Good machinability, wear resistance, and excellent anti-friction properties.

-

Applications: Medium-load applications.

-

-

Aluminum Bronze (C95400):

-

Properties: Exceptional strength and corrosion resistance.

-

Applications: Heavy-duty applications in harsh environments.

-

-

Manganese Bronze (C86300):

-

Properties: High strength, wear resistance, and good machinability.

-

Applications: High-load applications.

-

-

Tin Bronze (C90500):

-

Properties: Good wear resistance, corrosion resistance, and strength.

-

Applications: General-purpose applications.

-

-

Phosphor Bronze (C51000):

-

Properties: High fatigue resistance and low friction.

-

Applications: Low maintenance and long service life requirements.

-

Our Metal Services:

-

Customized Bushing Sleeves:

-

Service: Tailored to specific requirements, including dimensions, tolerances, and material grade.

-

-

Machining Services:

-

Service: State-of-the-art facilities for precise and accurate manufacturing.

-

-

Surface Treatment:

-

Service: Various treatments to enhance performance and durability, including plating, polishing, and anti-corrosion coatings.

-

-

Quality Assurance:

-

Service: Rigorous quality control processes to meet the highest industry standards.

-

-

Technical Support:

-

Service: Expert advice and support for optimal selection and application.

-

Conclusion:

Self-lubricating brass sleeve bushings offer numerous advantages over traditional oil and grease lubricated bearings, including reduced maintenance, longer service life, and increased reliability. They are suitable for a wide range of applications and environments, making them a versatile and cost-effective solution for various industries. Our comprehensive range of bronze alloys and metal services ensures that we can meet your specific needs with high-quality, customized solutions. For more information or to request a quote, please contact our knowledgeable team.

Precision Bronze Brass Bushing Sleeves: Standard Sizes and Custom Solutions

Upgrade your machinery with our high-quality Brass Sleeve Bushing Bearings, designed to deliver unmatched performance, durability, and reliability. Whether you need standard sizes or custom solutions, our advanced manufacturing capabilities and expertise ensure that we meet your specific requirements.

Why Choose Our Brass Sleeve Bushing Bearings?

-

Unparalleled Quality:

-

Manufactured with precision using state-of-the-art equipment and rigorous quality control processes.

-

Consistent, stable, and reliable performance for demanding applications.

-

-

Wide Range of Standard Sizes:

-

Our standard-size bronze bushings are available in various dimensions to suit your needs.

-

If you don’t see the size you need, we offer custom solutions tailored to your specifications.

-

-

Advanced Alloy Development:

-

We specialize in developing high-performance copper alloys, including:

-

High-strength, high-conductivity alloys

-

Wear-resistant and corrosion-resistant alloys

-

Lead-free, environmentally friendly alloys

-

High-speed, free-cutting alloys

-

High-precision forging alloys

-

-

These alloys are engineered to meet the most demanding application requirements.

-

-

Custom Shaped Molds:

-

Our foundries can create high-precision, custom-shaped molds to produce nearly 10,000 shapes and specifications.

-

This capability ensures we can deliver the exact product you need, no matter how unique your requirements.

-

-

Industry Applications:

-

Our precision bronze brass bushing sleeves are trusted in a wide range of industries, including:

-

Automobile manufacturing

-

Rail transit

-

Shipbuilding

-

Energy and electric power

-

Construction machinery

-

Mining machinery

-

Medical equipment

-

5G communications

-

Consumer electronics

-

New energy

-

High-voltage power transmission and transformation

-

-

Benefits of Our Brass Sleeve Bushing Bearings

-

Enhanced Performance: Reduce friction, wear, and energy consumption in your machinery.

-

Durability: Engineered for long service life, even in harsh environments.

-

Cost-Effective: Minimize maintenance and replacement costs with our high-quality bushings.

-

Versatility: Suitable for a wide range of applications across multiple industries.

-

Custom Solutions: Tailored to meet your exact specifications and requirements.

Our Manufacturing Capabilities

-

Precision Manufacturing:

-

Utilizes high-precision equipment to ensure tight tolerances and consistent quality.

-

Online testing equipment guarantees every product meets the highest standards.

-

-

Alloying Expertise:

-

Advanced alloy development to create materials with superior properties, such as:

-

High strength

-

Excellent conductivity

-

Wear and corrosion resistance

-

Environmental sustainability

-

-

-

Customization:

-

Ability to produce custom shapes, sizes, and specifications to meet unique application needs.

-

Stable supply of nearly 10,000 shapes and specifications.

-

Industries We Serve

Our precision bronze brass bushing sleeves are integral to the success of various industries, including:

-

Automobile Manufacturing: Ensuring smooth operation and longevity of automotive components.

-

Rail Transit: Reducing friction and wear in rail systems for safer and more efficient transportation.

-

Shipbuilding: Providing corrosion-resistant solutions for marine environments.

-

Energy and Electric Power: Supporting reliable performance in power generation and transmission systems.

-

Construction and Mining Machinery: Enhancing durability and efficiency in heavy-duty equipment.

-

Medical Equipment: Delivering precision and reliability in critical healthcare applications.

-

5G Communications and Consumer Electronics: Supporting advanced technologies with high-performance components.

-

New Energy: Contributing to the development of sustainable energy solutions.

-

High-Voltage Power Transmission and Transformation: Ensuring safety and efficiency in power infrastructure.

Get Started Today

Don’t compromise on the performance and longevity of your machinery. Invest in our premium Brass Sleeve Bushing Bearings to experience unparalleled quality and durability. Whether you need standard sizes or custom solutions, our team is ready to assist you.

Contact us today to learn more about our products, discuss your requirements, or request a quote. Let us help you find the perfect bushing sleeve for your application!

Why Wait? Upgrade Your Machinery Now!

Click the link below to explore our product offerings and discover how our Brass Sleeve Bushing Bearings can benefit your business. Our dedicated team is here to provide expert guidance and support every step of the way.

Learn More About Our Brass Sleeve Bushing Bearings

By choosing our precision bronze brass bushing sleeves, you’re not just investing in a product – you’re investing in the future of your machinery and the success of your business. Let us help you achieve peak performance and efficiency with our high-quality solutions. Contact us today!

Customized High-Strength Brass Gear Reducer with High-Temperature Resistant Flange and Integrated Copper Turbine

A customized high-strength brass gear reducer with a high-temperature resistant flange and integrated copper turbine is a specialized mechanical component designed for use in demanding applications that require precise speed control, torque transmission, and resistance to high temperatures.

Features of the customized gear reducer:

- High-strength brass gears: These gears are made from a high-strength brass alloy, providing excellent wear resistance and durability, even under extreme operating conditions.

- High-temperature resistant flange: The flange is designed to withstand high temperatures, ensuring that the gear reducer maintains its structural integrity and optimal performance even in harsh environments.

- Integrated copper turbine: The copper turbine is an integral part of the gear reducer, offering improved thermal conductivity and heat dissipation. This feature ensures that the gear reducer operates efficiently while minimizing the risk of overheating.

- Customization: The gear reducer can be tailored to meet specific application requirements, including gear ratios, torque capacities, and mounting configurations. This level of customization ensures optimal performance and seamless integration into existing systems.

- Compact design: The gear reducer's compact design allows for easy installation and minimal space requirements, making it suitable for use in various industries and applications.

Applications of the customized gear reducer:

- Industrial machinery: This gear reducer can be used in various industrial machines, including conveyors, mixers, and extruders, where precise speed control and high torque transmission are necessary.

- Robotics and automation: The gear reducer is suitable for use in robotic and automation systems, providing accurate and consistent motion control.

- Automotive industry: The high-temperature resistant flange and integrated copper turbine make this gear reducer ideal for automotive applications, such as engine cooling systems and turbochargers.

- Aerospace and defense: The gear reducer's ability to withstand extreme temperatures and harsh environments makes it suitable for aerospace and defense applications, including aircraft engines, missile systems, and satellite propulsion systems.

- Power generation: The gear reducer can be used in power generation equipment, such as gas turbines and steam turbines, to optimize speed control and torque transmission.

Customized high-strength brass gear reducer with a high-temperature resistant flange and integrated copper turbine offers several advantages, including durability, thermal efficiency, and customization options. Its diverse applications make it a valuable component in various industries, ranging from industrial machinery and robotics to aerospace and power generation.

Supplying Connecting Rod Oil-Impregnated Copper Sleeve, Oil-Free Wear-Resistant Sleeve, and Copper Alloy Bearing Sleeve Series

We offer a range of copper sleeves, including connecting rod oil-impregnated copper sleeves, oil-free wear-resistant sleeves, and copper alloy bearing sleeves, suitable for various applications and industries. These products provide reliable performance, durability, and reduced maintenance requirements.

- Connecting Rod Oil-Impregnated Copper Sleeve: These sleeves are designed for use in connecting rods and other applications where continuous lubrication is necessary. The oil-impregnated material ensures a constant supply of lubricant, reducing friction and wear on moving parts. This feature results in improved efficiency and extended service life.

- Oil-Free Wear-Resistant Sleeve: The oil-free wear-resistant sleeves are designed for applications where external lubrication is not desirable or possible. These sleeves are made from a self-lubricating material that provides a low friction surface, reducing wear and ensuring reliable operation even in the absence of external lubrication.

- Copper Alloy Bearing Sleeve Series: The copper alloy bearing sleeves are made from a range of copper alloys, each designed to provide specific performance characteristics and benefits. These sleeves offer excellent wear resistance, corrosion resistance, and thermal conductivity, making them suitable for a wide variety of applications.

Applications of the copper sleeve series:

- Automotive industry: The copper sleeves are suitable for use in various automotive applications, such as engine components, transmissions, and suspension systems, where they can provide reduced friction and improved efficiency.

- Industrial machinery: The copper sleeves can be used in a range of industrial machines, including pumps, compressors, and conveyor systems, ensuring smooth operation and reduced wear on moving parts.

- Aerospace and defense: The copper sleeves are ideal for use in aerospace and defense applications, such as aircraft engines, missile systems, and satellite propulsion systems, where they can provide reliable performance and reduced maintenance requirements.

- Power generation: The copper sleeves can be employed in power generation equipment, such as gas turbines and steam turbines, to optimize speed control and torque transmission.

- Marine engineering: The copper sleeves are suitable for use in marine engineering applications, including propeller shafts, rudder bearings, and other hydraulic components, where they can provide reduced friction and improved efficiency.

In summary, we supply a range of copper sleeves, including connecting rod oil-impregnated copper sleeves, oil-free wear-resistant sleeves, and copper alloy bearing sleeves, designed to provide reliable performance and durability in various applications and industries. These products offer several advantages, such as reduced friction, improved efficiency, and extended service life, making them a valuable component for a wide range of industries.

Supplying Connecting Rod Oil-Impregnated Copper Sleeve, Oil-Free Wear-Resistant Sleeve, and Copper Alloy Bearing Sleeve Series

We offer a range of copper sleeves, including connecting rod oil-impregnated copper sleeves, oil-free wear-resistant sleeves, and copper alloy bearing sleeves, suitable for various applications and industries. These products provide reliable performance, durability, and reduced maintenance requirements.

- Connecting Rod Oil-Impregnated Copper Sleeve: These sleeves are designed for use in connecting rods and other applications where continuous lubrication is necessary. The oil-impregnated material ensures a constant supply of lubricant, reducing friction and wear on moving parts. This feature results in improved efficiency and extended service life.

- Oil-Free Wear-Resistant Sleeve: The oil-free wear-resistant sleeves are designed for applications where external lubrication is not desirable or possible. These sleeves are made from a self-lubricating material that provides a low friction surface, reducing wear and ensuring reliable operation even in the absence of external lubrication.

- Copper Alloy Bearing Sleeve Series: The copper alloy bearing sleeves are made from a range of copper alloys, each designed to provide specific performance characteristics and benefits. These sleeves offer excellent wear resistance, corrosion resistance, and thermal conductivity, making them suitable for a wide variety of applications.

Applications of the copper sleeve series:

- Automotive industry: The copper sleeves are suitable for use in various automotive applications, such as engine components, transmissions, and suspension systems, where they can provide reduced friction and improved efficiency.

- Industrial machinery: The copper sleeves can be used in a range of industrial machines, including pumps, compressors, and conveyor systems, ensuring smooth operation and reduced wear on moving parts.

- Aerospace and defense: The copper sleeves are ideal for use in aerospace and defense applications, such as aircraft engines, missile systems, and satellite propulsion systems, where they can provide reliable performance and reduced maintenance requirements.

- Power generation: The copper sleeves can be employed in power generation equipment, such as gas turbines and steam turbines, to optimize speed control and torque transmission.

- Marine engineering: The copper sleeves are suitable for use in marine engineering applications, including propeller shafts, rudder bearings, and other hydraulic components, where they can provide reduced friction and improved efficiency.

In summary, we supply a range of copper sleeves, including connecting rod oil-impregnated copper sleeves, oil-free wear-resistant sleeves, and copper alloy bearing sleeves, designed to provide reliable performance and durability in various applications and industries. These products offer several advantages, such as reduced friction, improved efficiency, and extended service life, making them a valuable component for a wide range of industries.

Customized Hydraulic Machinery Arch Gate Self-Lubricating Graphite Copper Sleeve and Corrosion-Resistant Aluminum Bronze Bearing Sleeve

We provide customized hydraulic machinery components, including self-lubricating graphite copper sleeves and corrosion-resistant aluminum bronze bearing sleeves, specifically designed for use in arch gates and other water engineering applications. These components offer reliable performance, durability, and reduced maintenance requirements, making them ideal for use in harsh environments.

Features of the customized hydraulic machinery components:

- Self-Lubricating Graphite Copper Sleeve: The graphite copper sleeve contains embedded graphite particles that provide continuous lubrication during operation, reducing friction and wear on the bearing surfaces. This feature eliminates the need for external lubrication and maintenance, resulting in increased reliability and reduced downtime.

- Corrosion-Resistant Aluminum Bronze Bearing Sleeve: The aluminum bronze bearing sleeve is made from a durable and corrosion-resistant alloy, providing excellent wear resistance and long service life. This material choice is ideal for applications exposed to corrosive environments, such as water engineering projects.

- Customization: The hydraulic machinery components can be tailored to meet specific application requirements, including size, load capacity, and material properties. This level of customization ensures optimal performance and seamless integration into existing hydraulic systems.

Applications of the customized hydraulic machinery components:

- Arch Gates: These components are specifically designed for use in arch gates, providing smooth operation and reduced wear on moving parts. The self-lubricating graphite copper sleeve and corrosion-resistant aluminum bronze bearing sleeve ensure reliable performance and extended service life, even in harsh environments.

- Flood Control and Water Management: The customized hydraulic machinery components can be employed in flood control and water management systems, such as sluice gates and dams, to minimize wear and ensure long-lasting operation.

- Water and Wastewater Treatment: The components are suitable for use in water and wastewater treatment facilities, where they can help maintain the efficient operation of pumps, mixers, and other hydraulic equipment.

- Irrigation Systems: The customized hydraulic machinery components can be used in irrigation systems, such as pumps and valves, ensuring smooth operation and reduced wear on moving parts.

- Hydroelectric Power Generation: In hydroelectric power plants, the customized hydraulic machinery components can be used in turbines and other equipment, providing reliable performance and reduced maintenance requirements.

In summary, we provide customized hydraulic machinery components, including self-lubricating graphite copper sleeves and corrosion-resistant aluminum bronze bearing sleeves, designed for use in arch gates and other water engineering applications. These components offer reliable performance, durability, and reduced maintenance requirements, making them ideal for use in harsh environments and various hydraulic applications.

Customized High-Temperature Resistant Bimetallic Bearings for 450 Load Machine Edge with Self-Lubricating Joint Bearings

We offer customized high-temperature resistant bimetallic bearings specifically designed for use in 450 load machines, featuring self-lubricating joint bearings for optimal performance and durability. These bearings are suitable for various applications and industries that require high-temperature resistance and efficient operation.

Features of the customized high-temperature resistant bimetallic bearings:

- High-temperature resistance: These bearings are designed to withstand high temperatures, ensuring that the bearings maintain their structural integrity and optimal performance even in harsh environments.

- Self-lubricating joint bearings: The self-lubricating joint bearings provide continuous lubrication during operation, reducing friction and wear on bearing surfaces. This feature eliminates the need for external lubrication and maintenance, resulting in increased reliability and reduced downtime.

- Customization: The high-temperature resistant bimetallic bearings can be tailored to meet specific application requirements, including size, load capacity, and material properties. This level of customization ensures optimal performance and seamless integration into existing systems.

- Durability: The bimetallic construction offers excellent wear resistance and long service life, making these bearings ideal for applications with high loads and challenging operating conditions.

Applications of the customized high-temperature resistant bimetallic bearings:

- Industrial machinery: These bearings can be used in various industrial machines, including conveyors, mixers, and extruders, where precise speed control and high-temperature resistance are necessary.

- Automotive industry: The high-temperature resistant bimetallic bearings are suitable for automotive applications, such as engine cooling systems and turbochargers.

- Aerospace and defense: The bearings' ability to withstand extreme temperatures and harsh environments makes them suitable for aerospace and defense applications, including aircraft engines, missile systems, and satellite propulsion systems.

- Power generation: The high-temperature resistant bimetallic bearings can be used in power generation equipment, such as gas turbines and steam turbines, to optimize speed control and torque transmission.

- Heavy-duty machinery: These bearings are ideal for use in heavy-duty machinery, such as construction equipment and mining machinery, where high load capacities and high-temperature resistance are required.

In summary, we offer customized high-temperature resistant bimetallic bearings with self-lubricating joint bearings for 450 load machine edge applications. These bearings provide several advantages, including durability, thermal efficiency, and customization options. Their diverse applications make them a valuable component in various industries, ranging from industrial machinery and automotive to aerospace and power generation.

Customized Hydraulic Gate Open-Close Equipment for Water Engineering with Corrosion-Resistant High-Strength Brass Self-Lubricating Copper Slide Plate

We offer customized hydraulic gate open-close equipment for water engineering, featuring corrosion-resistant high-strength brass self-lubricating copper slide plates for optimal performance and durability. These equipment are designed for various applications and industries that require reliable performance and reduced maintenance requirements.

Features of the customized hydraulic gate open-close equipment:

- Corrosion resistance: The equipment is designed to withstand corrosive environments, making them ideal for water engineering applications. The high-strength brass self-lubricating copper slide plate provides excellent corrosion resistance and long service life.

- Self-lubricating copper slide plate: The self-lubricating copper slide plate provides continuous lubrication during operation, reducing friction and wear on the sliding surfaces. This feature eliminates the need for external lubrication and maintenance, resulting in increased reliability and reduced downtime.

- Customization: The hydraulic gate open-close equipment can be tailored to meet specific application requirements, including size, load capacity, and material properties. This level of customization ensures optimal performance and seamless integration into existing hydraulic systems.

- Durability: The high-strength brass construction offers excellent wear resistance and long service life, making this equipment ideal for applications with high loads and challenging operating conditions.

Applications of the customized hydraulic gate open-close equipment:

- Flood control and water management: The equipment is suitable for use in flood control and water management systems, such as sluice gates and dams, to ensure reliable and efficient operation.

- Water and wastewater treatment: The hydraulic gate open-close equipment can be used in water and wastewater treatment facilities, where they can help maintain the efficient operation of pumps, mixers, and other hydraulic equipment.

- Irrigation systems: The equipment can be used in irrigation systems, such as pumps and valves, ensuring smooth operation and reduced wear on moving parts.

- Hydroelectric power generation: The equipment can be used in hydroelectric power plants, providing reliable performance and reduced maintenance requirements.

In summary, we offer customized hydraulic gate open-close equipment for water engineering with corrosion-resistant high-strength brass self-lubricating copper slide plates. These equipment provide several advantages, including durability, corrosion resistance, and customization options. Their diverse applications make them a valuable component for various hydraulic equipment used in water engineering, from water treatment and irrigation systems to hydroelectric power generation and flood control.

Customized Self-Lubricating Wear-Resistant Bronze with Graphite Copper Sleeve Bearings, with Aluminum Content Generally Not Exceeding 11.5%

We offer customized self-lubricating wear-resistant bronze with graphite copper sleeve bearings designed for various applications requiring high strength and wear resistance. The aluminum content in the bronze is generally not more than 11.5%, and sometimes small amounts of iron, nickel, manganese, and other elements are added to further improve the performance. Aluminum bronze can be heat-treated for strengthening, and it has higher strength and better resistance to high-temperature oxidation than tin bronze.

Features of the customized self-lubricating wear-resistant bronze with graphite copper sleeve bearings:

- High strength: The bearings have high strength and are suitable for applications with high loads, such as screws, nuts, copper sleeves, sealing rings, and other wear-resistant components.

- Wear resistance: The bearings have excellent wear resistance, making them suitable for use in various wear-resistant components and machinery parts.

- Self-lubricating: The graphite copper sleeve bearings provide continuous lubrication during operation, reducing friction and wear on the bearing surfaces. This feature eliminates the need for external lubrication and maintenance, resulting in increased reliability and reduced downtime.

- Corrosion resistance: The bearings have good corrosion resistance and are suitable for use in various environments, including atmospheric, freshwater, and seawater.

Applications of the customized self-lubricating wear-resistant bronze with graphite copper sleeve bearings:

- Automotive industry: The bearings can be used in various automotive applications, such as engine components, transmissions, and suspension systems, where they can provide reduced friction and improved efficiency.

- Industrial machinery: The bearings can be used in a range of industrial machines, including pumps, compressors, and conveyor systems, ensuring smooth operation and reduced wear on moving parts.

- Aerospace and defense: The bearings are ideal for use in aerospace and defense applications, such as aircraft engines, missile systems, and satellite propulsion systems, where they can provide reliable performance and reduced maintenance requirements.

- Power generation: The bearings can be employed in power generation equipment, such as gas turbines and steam turbines, to optimize speed control and torque transmission.

In summary, we offer customized self-lubricating wear-resistant bronze with graphite copper sleeve bearings designed to provide reliable performance and durability in various applications and industries. These bearings offer several advantages, such as high strength, wear resistance, self-lubrication, and corrosion resistance, making them a valuable component for a wide range of industries.