Brass & Brass Alloys

Experience the Strength of Self-lubricating Bearings

Exploring the Versatility of Brass & Brass Alloys: A Comprehensive Guide

Brass and brass alloys stand as stalwarts in the realm of metal alloys, revered for their versatility, affordability, and commendable mechanical properties. From intricate ornaments to heavy-duty industrial components, brass finds its application across a spectrum of industries. In this comprehensive guide, we delve into the intricacies of brass and its alloys, shedding light on their properties, applications, and manufacturing processes.

Brass alloys are widely recognized for their excellent properties as materials for sliding bearings. They offer a combination of strength, durability, and resistance to wear and corrosion, which makes them suitable for various industrial applications where reliable performance is essential.

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

Understanding Brass:

Brass, an alloy primarily composed of copper and zinc, occupies a significant position in the metallurgical landscape. The proportions of copper and zinc in brass can vary, giving rise to a multitude of brass alloys, each tailored to meet specific requirements. One of the defining characteristics of brass is its golden hue, which can vary from reddish to yellowish tones depending on the alloy composition.

Brass and brass alloys stand as pillars of the metallurgical industry, offering a harmonious blend of properties that cater to diverse applications. From the gleaming facades of architectural marvels to the intricate components of industrial machinery, brass continues to leave an indelible mark across domains. As technology advances and demands evolve, the adaptability and versatility of brass ensure its enduring relevance in the ever-changing landscape of materials engineering.

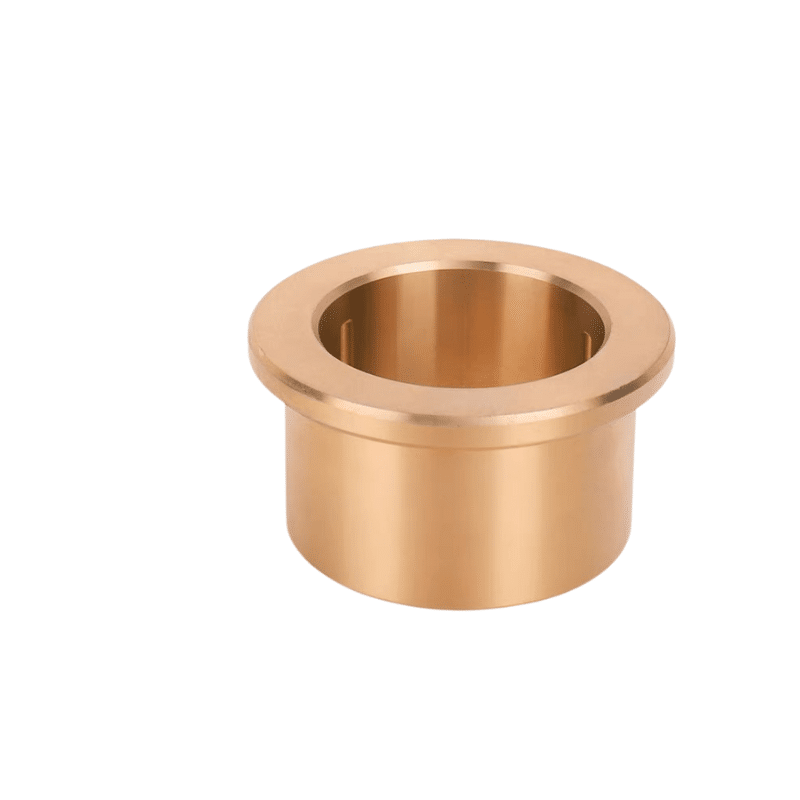

Customization: Manufacturers offer a variety of brass bearing options, including standard cylindrical brass bushings, flanged oilless bushings, thrust washers, and slide plates. They also provide custom design options for solid lubricant bearings and materials to meet unique requirements.

Maintenance-Free Operation: Brass alloys are used in self-lubricating slide bearings that facilitate smooth motion with minimal friction, eliminating the need for frequent maintenance and reducing downtime.

Material Forms: Brass and other sliding bearing materials are initially cast as ingots, slabs, or bars, and are processed into various forms such as plates, strips, and sheets for different applications.

Properties of Brass, Self-lubricating Brass Bushing:

Brasses exhibit a unique combination of properties that render them indispensable in various applications. Firstly, they boast commendable corrosion resistance, making them suitable for environments where exposure to moisture and other corrosive elements is prevalent. Additionally, brass alloys offer moderately high strength, ensuring structural integrity in diverse settings. Notably, certain compositions exhibit exceptional ductility and excellent forming characteristics, allowing for intricate shaping processes such as pressing, deep drawing, rolling, and machining.

Self-Lubricating Properties: Graphite-filled brass bearings are known for their self-lubricating properties due to the graphite plugs within the bearings acting as solid lubricants. This reduces friction and minimizes the need for external lubrication, making them suitable for applications where regular lubrication may be impractical or challenging.

Material Composition: Brass bearings are made from a combination of copper, tin, and other alloying elements. The specific alloy ZCuZn25Al6Fe3Mn3 is highlighted for its exceptional performance, reliability, and durability across a wide range of industrial applications.

Applications: Brass bearings are used in industries such as automotive, marine, and heavy machinery. They serve as connections and attachments between the cylinder and the load in hydraulic cylinder applications, ensuring safety, reliability, and performance.

Performance Indicators: The performance of brass bearings is determined by their chemical composition and indicators like density, hardness, thermal conductivity, tensile strength, and lubrication conditions.

Influence of Sliding Time: The dry sliding tribological behavior of brass alloy bearings, such as C93700 bearing bronze, is influenced by the sliding time, which is important for understanding the longevity and maintenance requirements of these bearings in applications.

Brass strip is a versatile metal product that is widely used across various industries due to its unique properties. Here’s a summary of the information provided by the search results:

Product Description: Brass strips are manufactured to various standards such as ASTM, JIS, EN, DIN, GB, and GB/T 2059-2000. They are made from materials like C2680, H62, H65, H68, H70, H80, etc., and have a composition primarily of copper (Cu) and zinc (Zn). The thickness ranges from 0.01-2.0mm, and the width can vary from 2-600mm. Brass strips have a copper content between 62%-71.5% and a hardness of 85~145HV. They are utilized in the production of precision instruments, ship parts, gun shells, and more. They are also used in water tank belts, water supply and drainage pipes, corrugated pipes, condenser pipes, bullet casings, and various punched products with complex shapes, small hardware, lighting, pipe fittings, zippers, plaques, rivets, springs, and sedimentation filters.

-

Application Fields: Brass strips are appreciated for their adaptability and precision in crafting intricate components in electronics, automotive parts, and decorative elements. They are used in construction and design for detailed architectural elements and custom fixtures, providing structural support and aesthetic enhancement. Their thin and elongated form ensures flexibility and ease of integration.

-

Product Range: The product range includes tubing, rod, sheet, and strip, all of which are valued for their durability and workability. These brass products are used for creating detailed architectural elements and custom fixtures, offering structural support, electrical conductivity, and aesthetic enhancement.

-

Material Properties: Brass strip is known for its excellent plasticity (best in brass), high strength, good machinability, and ease of welding. It is very stable against general corrosion but can be prone to corrosion cracking.

For more detailed information, you can visit the provided URLs from the search results. If you have any specific questions about brass strips, feel free to ask!

Explore Other Alloys

Suggested Searches: C86200, C86300, C93200, C95400