bearing failure analysis

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

bearing failure analysis

Innovative solutions

Viiplus is good in the design, development and manufacture of high performance self-lubricating bearings, plain bearings, sliding plates and thrust washers.

Sealing solutions

Offer standard seals and custom engineered bearings solutions to increase uptime, improve machine reliability, reduce friction and power losses, and extend lubricant life.

Lubrication solutions

From specialized lubricants to state-of-the-art lubrication systems and lubrication management ser vices, bearing lubrication solutions from Viiplus can help to reduce lubrication related downtime and lubricant consumption.

How To Choose The Right Self-lubricating Bearing For Your Company

A good plain bearing supplier can make a massive difference for you company.

- Plain bearing failure analysis is important in every link

The purpose of plain bearing failure analtsis and inspecting damaged bearings and their mating parts is to determine the probable causes of the bearing failure and to avoid any future failures.

Plain Bearing life and bearing failures solution

Causes of plain bearing failure

Here Are The Seven Most Common Reasons Why Plain Bearings Fail:

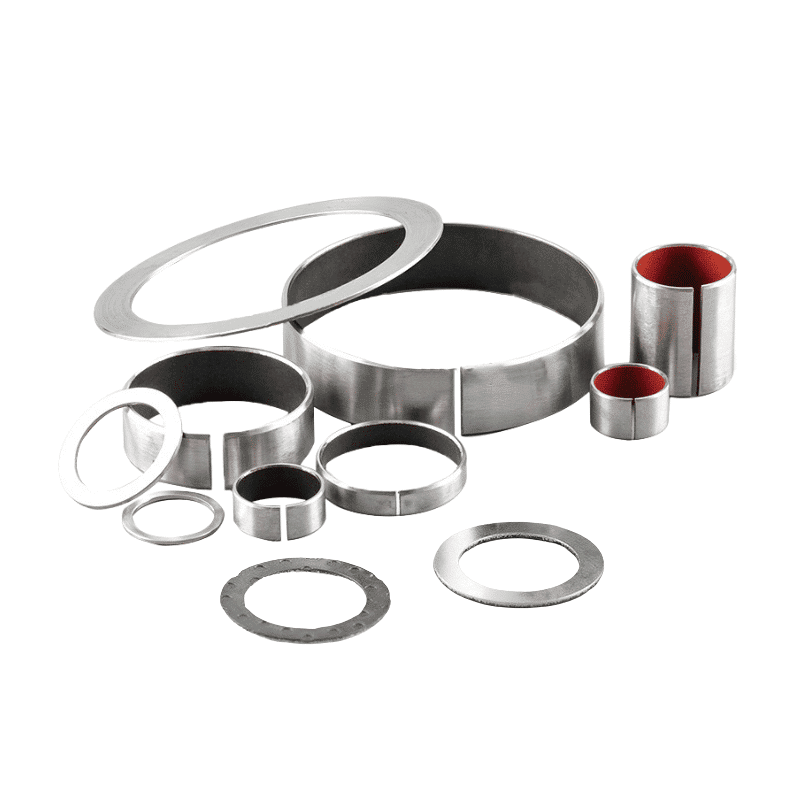

Types of Plain Bearings (Bushings)

EXPLORE MORE BUSHINGS & BEARINGS,SELF-LUBRICATING ‘S BENEFITS

Quality materials you can rely on Quality/Reliability Material allows for compact design Common to One Piece Compact Bushing Design…

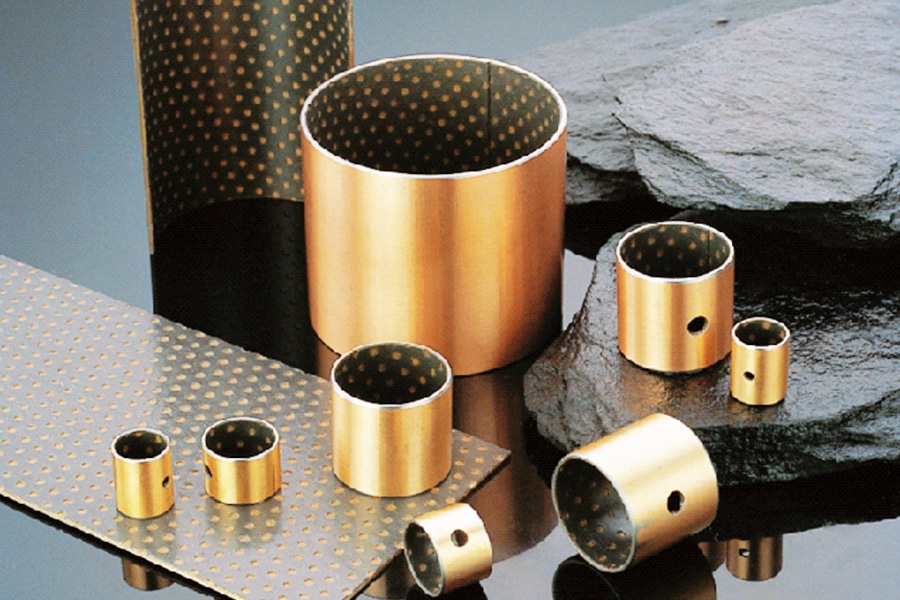

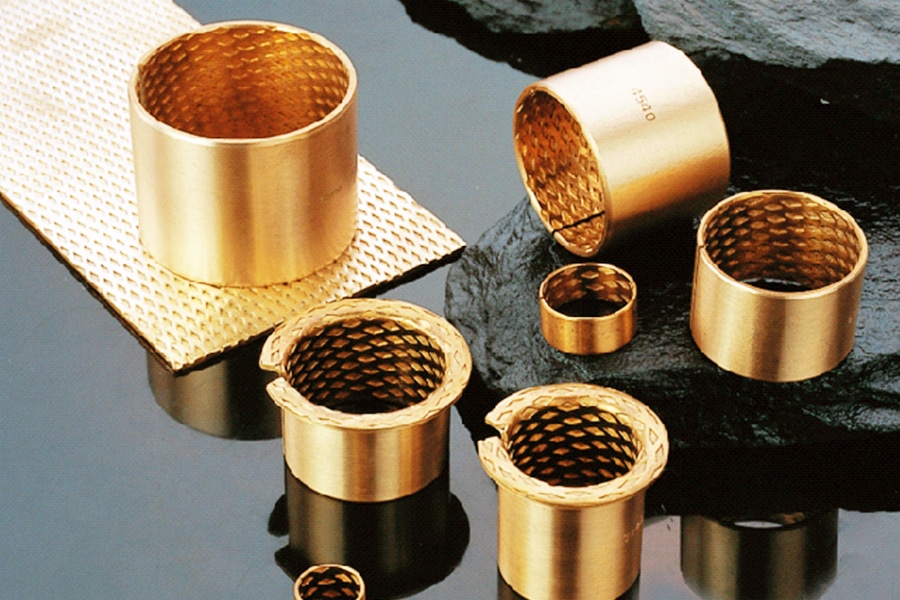

Self-lubricating bushings can vary considerably in both material and design style.

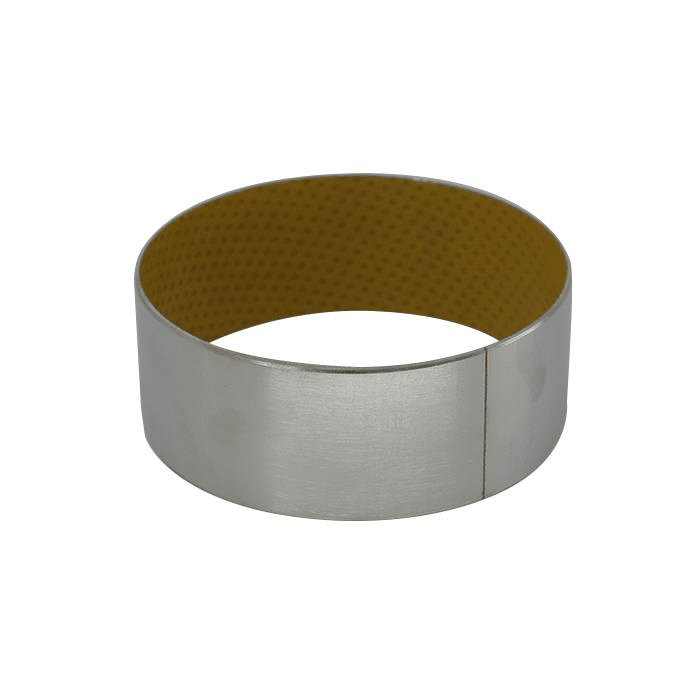

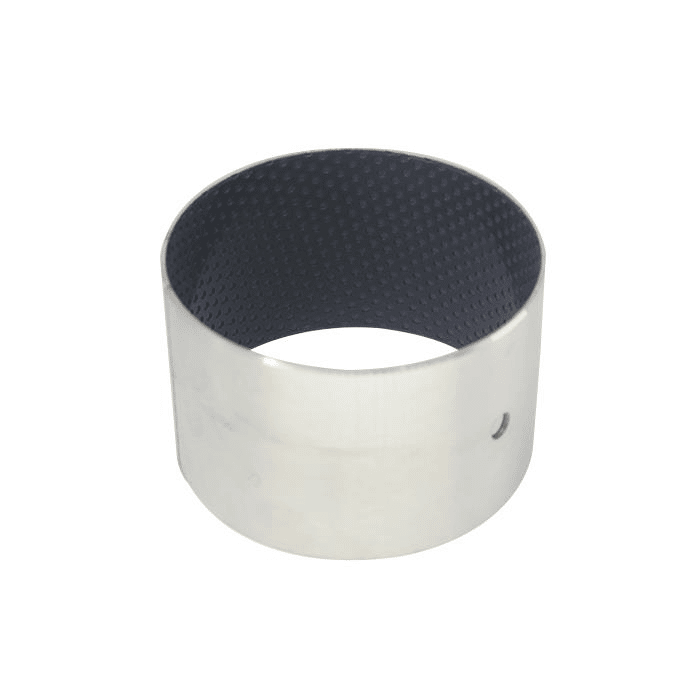

Metal – PTFE Bushing

Carbon steel self-lubricating, Metallic composite self-lubricating bearing.

Composite Bushing DX

Marginal Pb-free self-lubricating bearings

Graphite Plugged Bronze Bushing

Self-lubricating bearings: flanged-sleeve bearings made of plugged graphite bronze C86300 are available.

Metal-ploymer POM Bushing

Marginal pb-free self-lubricating bearing

Bimetal Bearing Bushing

Bimetallic self-lubricating Bearings

Wrapped Bronze Bearing

Monometallic self-lubricating bearing, Bronze self-lubricating bearing with through holes

Bearing Service & Supply – Your Industrial Supplier

We offers the industry’s trusted bearing failure analysis, as well as causes of bearing failure and plain bearing bushes products.

The plain bearings are ideal for earth moving machinery, drilling machinery, industrial equipment and more.

Quality plain bearing products and tribology solutions to customers around the world

Properly specified, self-lubricating bearings reduce maintenance costs, extend bearing life, and are more environmentally friendly.

Plain bearing failures reduce a plant’s operating efficiency, increase downtime, drive cost of operations up and, in the worst cases, may injure workers.

Self-lubricating bronze bearing, Sliding Dry Bearings – Environmentally friendly for many years

WHAT ARE THE MOST FREQUENT CAUSES OF BEARING FAILURE FOR YOUR BEARING APPLICATIONS?

While it may seem like common sense, standard wear and tear is one of the leading causes of plain bearing failure.

Improperlubrication is the major cause of sliding bearing failure.

Bearings can only achieve maximum performance levels with adequate lubrication.

Plain bush bearings type

- Cylindrical bushings bearing

- Flanged bushings sleeve

- Thrust Washers

- Strips

Stay up to date

Get the latest plain bearing bush product information and special offers via email.

Did you know that external environmental factors and improper mounting are the most common causes of bearing failure? The bearing type, application and situation are all unique, so you must carefully consider a number of factors before coming to a conclusion about what’s causing your bearings to fail.

COMMON FACTORS THAT LEAD TO PLAIN BEARING FAILURE – FAILURE ANALYSIS

CONTAMINATION

Causes: Dirt, abrasive grit, link, dust, steel chips from contaminated work areas, dirty hands or tools, or foreign matter in lubricants or cleaning solutions.

What to look for: Denting of rolling elements and raceways, causing vibration

How to fix it: Filter the lubricant, clean work areas, tools, fixtures, and hands to reduce the risk of contamination.

IMPROPER MOUNTING

Causes: Improper installation of the mounting. In most instances, bearings should be mounted with a press fit on the rotating ring.

What to look for: These are some of the prevalent conditions that can cause denting, wear, cracked rings, high operating temperature, early fatigue, and premature failure of bearings (among many others).

-Mounting bearings on shafts by applying pressure or blows to the outer race

-Mounting bearings into a housing by pressing on the inner ring

-Loose shaft fit

-Loose housing fit

-Excessive tight fits

-Out of round housings

-Poor finish on the bearing seat

How to fix it: Install mountings properly, and provide training to ensure all employees understand the difference between a properly and improperly installed mounting.

MISALIGNMENT

Causes: Commonly caused by bent shafts, out-of-square shaft shoulders, out-of-square spacers, out-of-square clamping nuts or improper installation due to loose fits. Misalignment can result in overheating and separator failure.

What to look for: A wear path not parallel to raceway edges on the raceway of the non-rotating ring.

How to fix it: Inspect shafts and housings for runout of shoulders and bearing seats, use precision grade locknuts.

FALSE BRINELLING

Causes: The rapid movement of the balls in the raceway while the equipment is idle. The quickly moving elements remove the lubrication, and lack of rotation in the bearing does not allow fresh lubricant to return to the spot.

What to look for: Linear wear marks in axial direction at the rolling element pitch, no raised edges as opposed to marks due to incorrect mounting.

How to fix it: Eliminate or absorb external vibration, and use lubricants containing anti-wear additives.

Plain bearing failures can occur for a variety of reasons, often related to the construction, material selection, production, and operational conditions of the bearing. Here’s a summary of the key points regarding plain bearing failure based on the search results provided:

-

Common Causes of Failure: The basic causes of damage and failure of plain or sliding bearings can include errors during production (such as inadequate budgeting, material mistakes, and irregularities during production and installation), errors during exploitation, wear during long-term operation, and other factors like unforeseen exposure to overload or direct mechanical or chemical damage during operation.

-

Failure Manifestations: Failures and damages are often manifested as wear, breakage, and plastic deformation of the material. These can be categorized into two types related to material properties: those connected to the strength of the material (like fracture and plastic deformation) and those related to tribological processes (like wear and tear).

-

Diagnostic Models: Vibration analysis and thermal analysis are crucial for the early detection of plain bearing failures. These diagnostic models can help detect problems at their formation stage, which is essential for system maintenance, reliability, and economic considerations.

-

Failure Mechanisms: The most frequent manifestation of failure in sliding bearings is wear, which can be abrasive, adhesive, or due to surface fatigue. Other types of wear are less common. These indicators are important when defining a bearing condition monitoring program.

-

Importance of Lubrication: Lubrication plays a critical role in the life and performance of plain bearings. Issues such as inadequate gap, inadequate supply of lubricants, or inadequate lubricant characteristics can lead to bearing failure.

-

Detection and Prevention: Monitoring technologies like vibration and temperature monitoring can help in the detection of bearing issues before they lead to complete failure. Proper maintenance and understanding of the bearing’s operating conditions are vital in preventing failures.

-

Systematic Failure Analysis: Incorrect assembly, use, and maintenance are often the main causes of bearing failure. A systematic failure analysis involves using various techniques, including microscopic investigation, chemical composition analysis, and metallographic analysis, to determine the cause and mechanism of failure.

-

Bearing Materials: The choice of bearing materials is critical, with special bearing steels being commonly used for their fatigue resistance, wear resistance, high hardness, and stiffness. Heat treatment procedures are essential to ensure the required properties of the bearing materials.

-

Cage Design: The cage in rolling bearings is important for managing the rolling element arrangement and acts as a potential weak link. Cage materials can vary based on operating conditions.

-

Environmental Factors: External factors such as corrosive media or hard abrasive particles can cause damage and premature failure if they enter the bearing.

By understanding these aspects, engineers and maintenance personnel can take appropriate measures to prevent plain bearing failures, or at least predict and diagnose them before they lead to more significant and costly equipment downtime.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.