Aluminum Bronze

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Aluminum Bronze

Explore Our Selection Of ALUMINUM BRONZE Alloys For Your Bearing And Bushing Needs!

Oversized Bronze Bearings- Aluminum Bronze Material Selection

Leather crafting is the practice of making leather into craft objects or works of art, using shaping techniques.

Aluminum Bronze Sleeve Bearing – Custom Size, aluminium bronze material

Beautifully crafted leather products.

Aluminum bronze alloys stand out for their exceptional strength, corrosion resistance, and durability against wear. One popular grade, C95400, offers impressive mechanical properties and superior resistance to both wear and corrosion. While typically supplied in cast form, it can be heat-treated for even greater strength, making it suitable for rigorous applications. C62300 Aluminum Bronze Bearing Manufacturer, C62300 Aluminum Bronze Flange Bearing Supplier from China

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

Bronze Bearing Materials, Bronze Alloys Product Selection

Products lineup

Aluminum Bronze Product Selection

Viiplus Aluminum Bronze Alloys

Aluminum bronzes are renowned for their superior strength and corrosion resistance compared to other bronze alloys. They offer distinct advantages like resistance to tarnishing, low corrosion rates in atmospheric conditions, minimal oxidation at high temperatures, and low reactivity with sulfurous compounds and exhaust products. Additionally, their exceptional resistance to seawater corrosion makes them ideal for marine applications.

Highlighted Aluminum Bronze Alloys:

C95400 Aluminum Bronze

- Characteristics: A versatile aluminum bronze with excellent metal-to-metal wear resistance. It remains tough, hard, and resistant to abrasion and deformation under high compressive loads, even when paired with dissimilar metals.

- Applications: Ideal for components requiring long service life, reduced maintenance costs, and low friction, performing well even during temporary lubrication failure.

- Properties: Among the strongest and most corrosion-resistant alloys, with excellent machinability and weldability.

- Spec Sheet: Download for detailed specifications.

C95900 Aluminum Bronze

- Characteristics: A harder alternative to C95400, providing enhanced wear properties.

- Applications: Frequently used in forming, bending, and drawing operations, particularly with stainless steel. Also suitable for stamping presses, forming rolls, and draw dies.

- Industries: Popular in die, mold, and roll-forming industries.

- Spec Sheet: Available for comprehensive details.

C63000 Nickel Aluminum Bronze:

- Characteristics: An extruded aluminum bronze with added nickel, delivering exceptional strength and toughness.

- Applications: Found in the energy sector, aviation, marine industries, and industrial machinery. Ideal for valve stems, high-strength bushings, valve guides, gears, ship propellers, and shafts.

- Spec Sheet: Download for comprehensive information.

C63020 Nickel Aluminum Bronze:

- Characteristics: A martensitic nickel aluminum bronze alloy that is extra high-strength and heat-treated. The strongest in its category, it can sometimes replace beryllium copper.

- Spec Sheet: Downloadable for comprehensive properties.

C95510 Nickel Aluminum Bronze:

- Characteristics: A continuously cast, heat-treated nickel aluminum bronze alloy with excellent strength and toughness.

- Applications: Ideal for landing gear bushings, valve components, and other high-strength applications.

C64200 Silicon Aluminum Bronze:

- Characteristics: A silicon-enhanced wrought bronze alloy that ensures size consistency compared to cast versions.

- Applications: Preferred for marine hardware and power line equipment due to its reliable performance.

Each aluminum bronze alloy boasts unique characteristics and applications, making them suitable for diverse industrial and marine requirements. When selecting an aluminum bronze, consider the mechanical needs, environmental factors, and desired performance for the best fit.

Common Bronze Alloys: Here are some of the most frequently used alloys in oversized bronze bearings. The properties listed reflect centrifugally cast bronze and are provided for informational purposes only, not as a design guide.

Aluminum bronze alloys are often used in high-load applications and offer exceptional resistance to both corrosion and oxidation. They are highly suitable for marine use due to their impressive resistance to galvanic action.

| Alloy | Other | Tensile (psi) | Yield (psi) | Elongation (%) | Brinell |

|---|---|---|---|---|---|

| C95400 | 9C | 85,000 | 32,000 | 12 | 170 |

| C95500 | 9D | 95,000 | 42,000 | 10 | 195 |

| C95900 | – | 90,000 | 52,000 | 0.5 | 289 |

Superior Wear Resistance & Strength. Custom Aluminum Bronze Bearings

Tailor-Made for Your Needs.

Eu in tincidunt sed in integer sit nisl ipsum at vitae aliquet in quis.

Oversized Bronze Bearings – Alloy Selection, Aluminum Bronze Parts

High Strength & Corrosion Resistance!

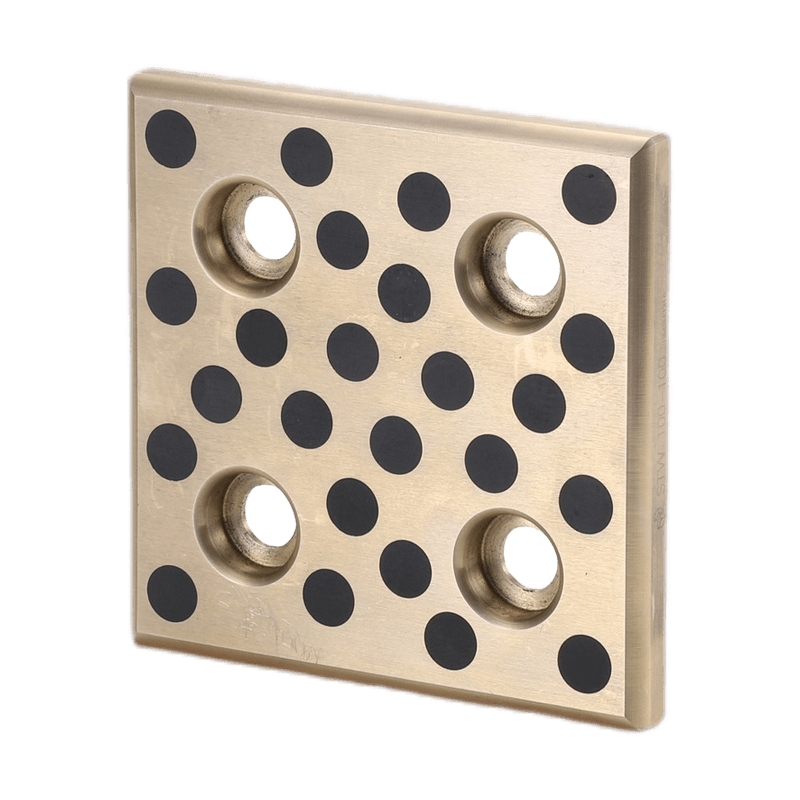

Precision Aluminum Bronze Plates. Explore custom sizes and find the perfect fit for your application.

Aluminum Bronze Bearings & Plates. Durable, Reliable, and Built for Tough Environments.

Applications of Aluminum Bronze

Beautifully crafted leather products.

These alloys are frequently used in marine equipment, pump and valve components, and shafts, especially for managing seawater, acidic mine waters, non-oxidizing acids, and various industrial fluids. Additional applications include robust sleeve bearings and machine tool ways. Aluminum bronze castings are known for their corrosion resistance, strength, toughness, and wear resistance, combined with good casting and welding properties.

Choosing the right bronze alloy for an application requires careful consideration of the desired physical, mechanical, and metallurgical characteristics. Various factors influence the selection process, and picking the appropriate alloy is essential to ensure maximum resistance to wear and corrosion, ultimately leading to a longer service life.

Trusted By Industry Customers. Optimal Strength And Corrosion Resistance.

Durable Aluminum Bronze Bearing and Slide Plates

Purchase Direct!

Leather crafting is the practice of making leather into craft objects or works of art, using shaping techniques.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.