Aluminum Bronze Strip

Experience the Strength of Self-lubricating Bearings

Exploring The Aluminum Bronze Strip

Aluminum Bronze, also known as ALU BRONZE, is a type of copper alloy that contains aluminum as its primary alloying element. It is valued for its high strength, excellent corrosion resistance, and good casting properties.

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

key points about Aluminum Bronze and its applications in the form of strips and rails:

Composition: Aluminum Bronze typically contains about 9-11% aluminum along with other elements such as iron, nickel, and manganese.

Properties: It has a high strength-to-weight ratio, good mechanical properties, and excellent resistance to both seawater and many chemical environments.

Corrosion Resistance: It is particularly resistant to corrosion in marine environments, making it a popular choice for applications involving saltwater.

Aluminum Bronze Rail: Rails are elongated pieces that can be used for structural support or as a guide in mechanical systems. In the context of Aluminum Bronze, rails might be used:

In heavy-duty machinery where a strong and corrosion-resistant guide is needed.

As part of a track system in environments where standard metals would corrode quickly.

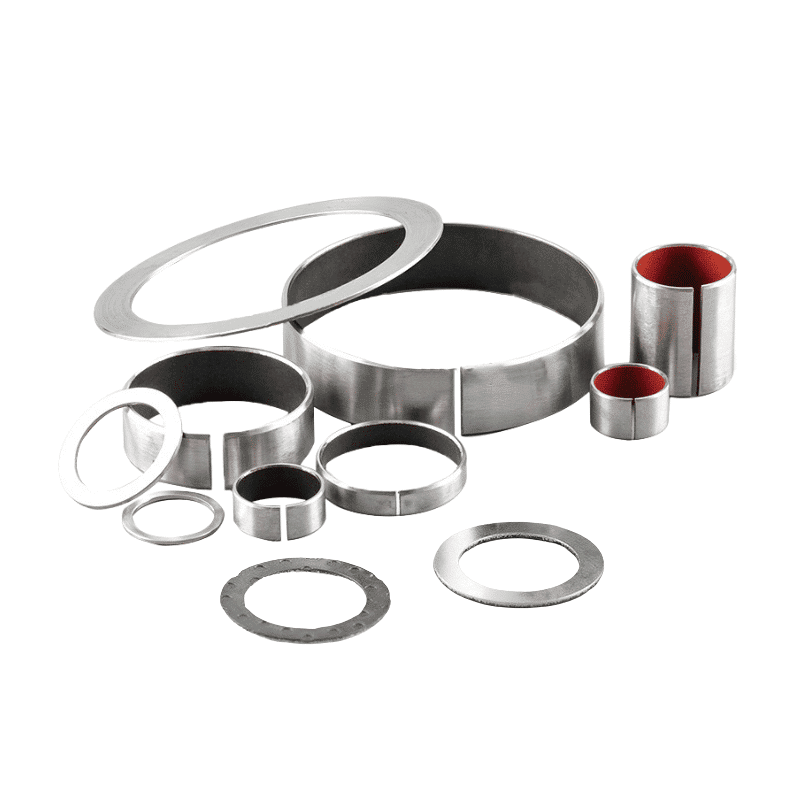

Aluminum Bronze Strips, Nickel Aluminum Bronze Bearing Pads Graphite Self Lubricating Bronze Alloy Free Sliding Plates

Applications: Aluminum Bronze is used in a variety of industries for applications that require its specific properties. Some common uses include:

Marine Applications: Propellers, ship fittings, and other parts that are exposed to saltwater.

Valves and Pumps: For components that must resist corrosion and maintain strength under pressure.

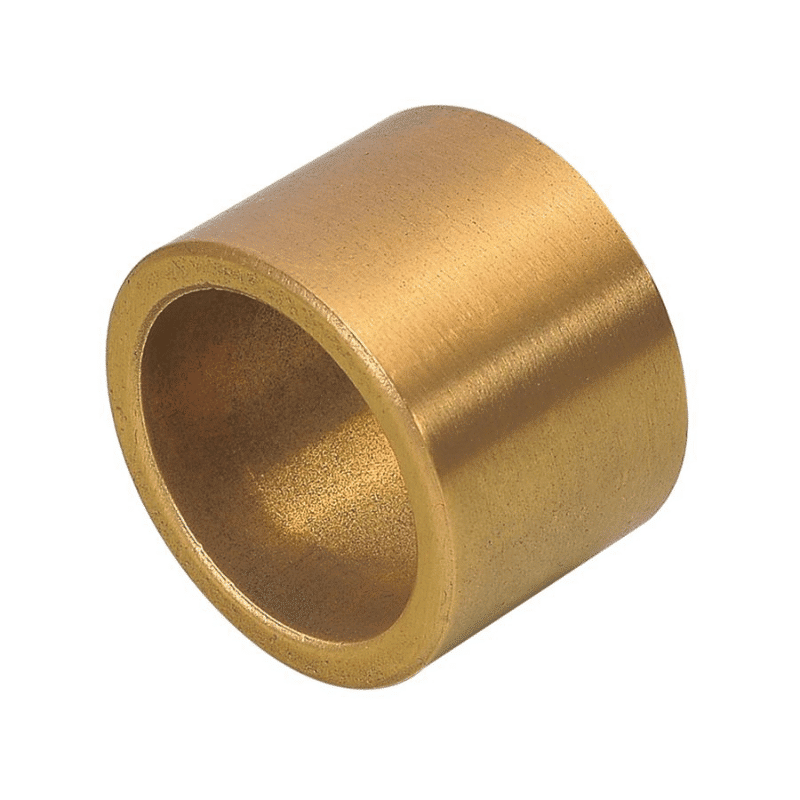

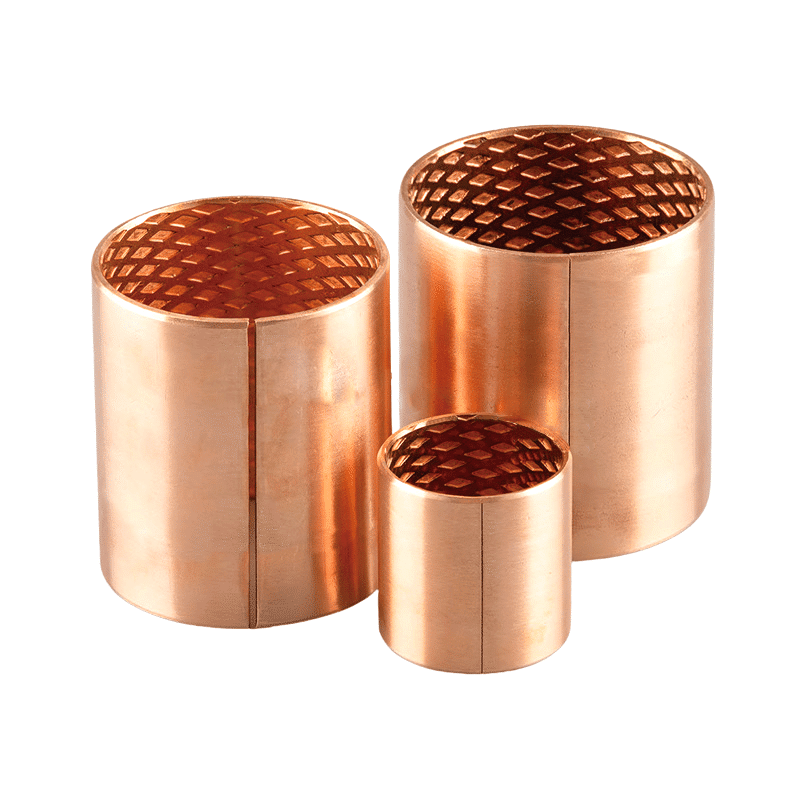

Bearings and Bushings: Due to its self-lubricating properties and wear resistance.

Fasteners: Bolts, nuts, and screws that are used in corrosive environments.

Explore Other Alloys

Suggested Searches: C86200, C86300, C93200, C95400