Aluminium bronzes – Bronze alloys bearings & plate

About us

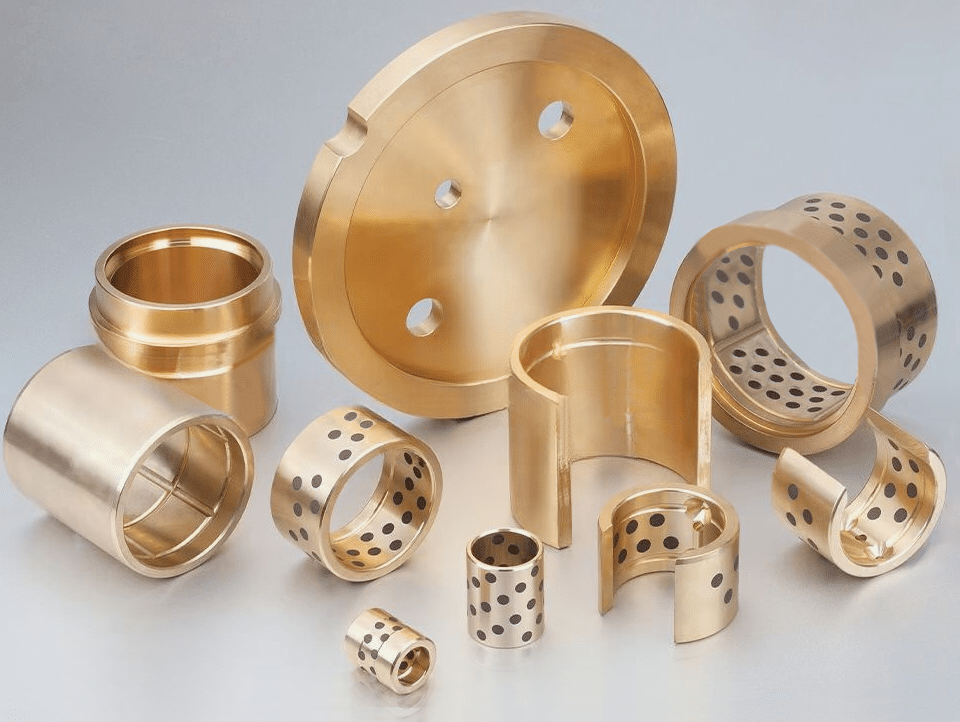

Custom-Made Aluminium bronzes Bearing and plate

Aluminium bronzes provide superior hardness and resistance compared to other bronze alloys, making them ideal for applications requiring high corrosion resistance, particularly in marine environments.

Type Of Bearing

Unlocking the Power of Aluminium Bronzes: A Deep Dive into Bearings and Slide Plates

Aluminium bronzes offer superior hardness and resistance compared to other bronze alloys. They are ideal for applications where high corrosion resistance is crucial, such as with Bronze Alloys CC333G and CC331G.

In the world of industrial machinery and engineering, selecting the right materials can be the difference between average performance and outstanding durability and efficiency. Aluminium bronzes, with its exceptional properties, stands out as a material of choice, particularly for components like bearings and slide plates that are crucial to machinery operation. This blog post explores why aluminium bronzes is an excellent choice for these applications and how it can elevate the performance and lifespan of machinery.

What is Aluminium Bronzes, CUAL11NI?

Aluminium bronzes is an alloy primarily composed of copper and aluminium, often enhanced with elements like iron, nickel, or manganese to improve specific properties. This alloy is renowned for its strength and hardness, which surpass many other bronze alloys, while still maintaining an impressive resistance to corrosion and wear. These characteristics make it ideal for high-stress environments, especially where corrosion and wear are significant concerns.

Benefits of Aluminium Bronzes in Bearings & Aluminium Bronzes Slide Plates

High Load-Bearing Capacity: Aluminium bronzes bearings are capable of handling high loads and stresses, making them suitable for heavy machinery and high-load applications. This robustness ensures that the bearings maintain their integrity and functionality over long periods, even under harsh conditions.

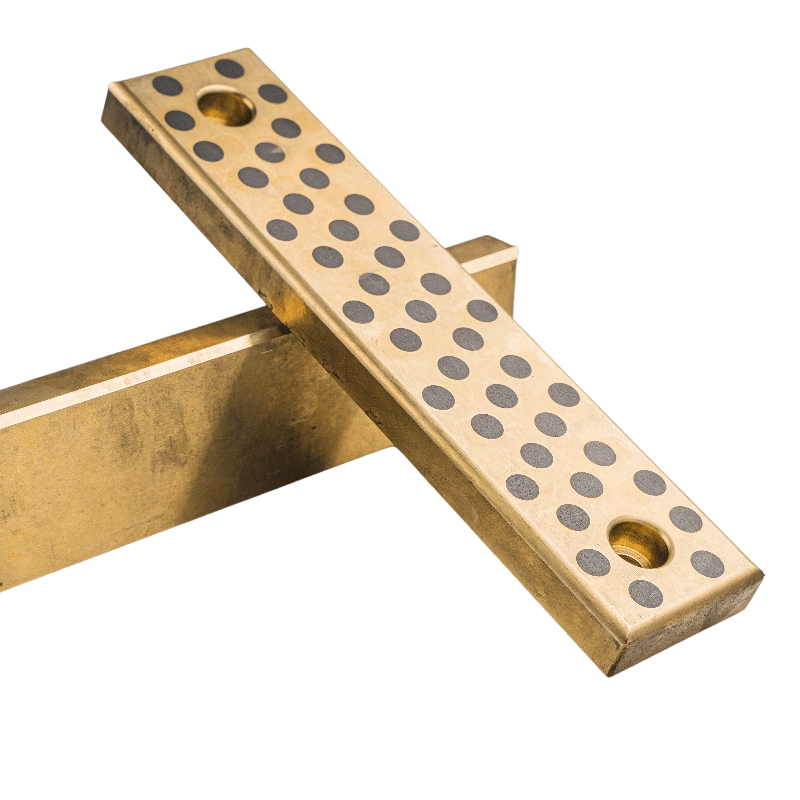

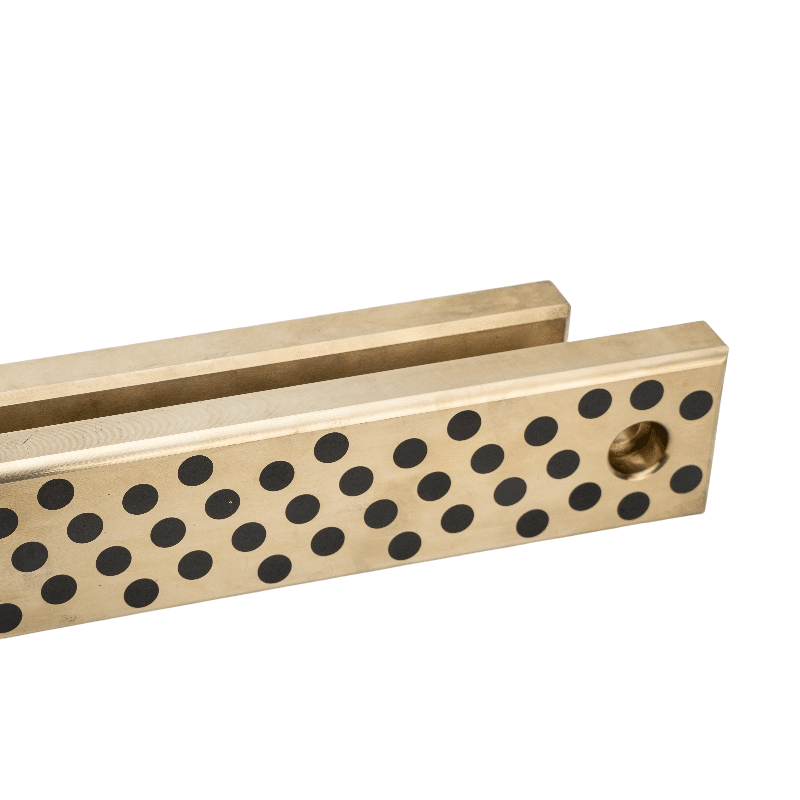

Excellent Wear Resistance: The wear resistance of aluminium bronzes is one of its most celebrated features. In components like slide plates, where metal-to-metal wear is a common issue, aluminium bronzes stands up to the challenge, reducing wear and extending the life of both the slide plates and the counter surfaces.

Superior Corrosion Resistance: Exposure to corrosive environments can drastically reduce the life of metal components. Aluminium bronzes alloys, with their excellent corrosion resistance, are ideal for use in marine environments and other settings where exposure to corrosive substances is a concern.

Good Emergency Running Properties: In situations where lubrication might fail or be insufficient, aluminium bronzes bearings can still perform well due to their ability to handle metal-on-metal contact without significant damage, a trait known as good emergency running properties.

Design Custom Aluminium bronzes Parts & International Standards: Search Our Material Alloy

Aluminum bronze, Oversized Bronze Bearings- Alloy Selection

Aluminum bronze bearing alloys are a category of materials used for various applications that require high strength, toughness, and corrosion resistance. These alloys consist of Aluminum, Copper, and small amounts of other elements like Nickel, Iron, and Manganese. Common aluminum bronze alloy types include C63000 (Aluminum 10% Nickel 5% Iron), C63200 (Aluminum 5% Nickel), C95500 (Aluminum 10% Iron), and Cual10Fe5Ni5.

Applications range from marine, oil and gas, industrial bearings, and components in heavy machinery. Self-lubricating properties can also be found in Aluminum bronze alloys, offering reduced wear and maintenance costs. As with any industrial material choice, it is essential to consider the specific requirements, such as mechanical properties and environmental conditions, when choosing an Aluminum Bronze alloy for an application.

CuAl10Fe2 Bronze Bearing

Composition: This alloy typically contains 76-83% copper, 8.5-10.5% aluminum, and 2-4% iron, with minimal amounts of other elements such as nickel and lead.

Key Features:

Mechanical Strength: High tensile strength, often exceeding 600 MPa, making it suitable for heavy-load applications.

Corrosion Resistance: Excellent resistance to seawater and other corrosive environments, which is crucial for marine applications.

Ductility: Good ductility allows for deformation without fracture, enhancing its usability in dynamic applications.

Applications: Commonly used in marine environments for components like valve bodies, propeller hubs, and wear plates due to its robust performance against corrosion and mechanical stress

CuAl10Ni5Fe5 Bronze Bearings

Composition: This alloy consists of approximately 76-83% copper, 10% aluminum, 4-6% nickel, and 4-5.5% iron.

Key Features:

Enhanced Strength: Offers superior mechanical properties with a yield strength of around 250 MPa and tensile strength up to 650 MPa.

Corrosion Resistance: Exceptional resistance to corrosion in harsh environments, particularly in marine applications.

Self-Lubricating Properties: The presence of nickel enhances its wear resistance and self-lubricating capabilities, making it ideal for high-speed applications.

Applications: Widely used in the marine industry for components such as bushings, thrust washers, and other structural parts where durability and resistance to wear are critical

Design Custom Parts & Aluminium bronzes Made From High-Strength Alloy

Aluminium bronze is a copper alloy enriched with aluminum to enhance the strength and hardness of copper while maintaining its excellent conductivity and corrosion resistance. Aluminium bronze alloys are widely used for manufacturing bearings, plates, and custom parts due to their superior mechanical properties and corrosion resistance.