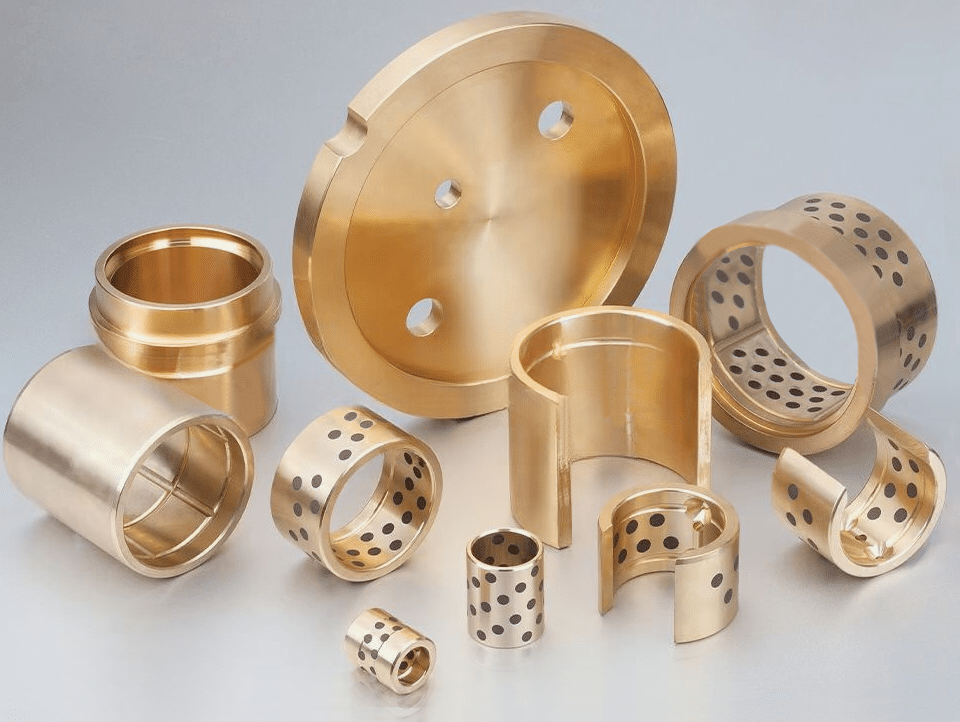

Non-Ferrous Metals Phosphor Bronze to BS 1400: PB2 Bronze Bushing and Bearing

About us

PB2 Phosphor Bronze alloy is recognized for its excellent shock resistance, strength, machinability, and corrosion resistance.

The PB2 Phosphor Bronze, which is often used in manufacturing bushings and bearings, is a non-ferrous metal alloy noted for its resilience to impact and corrosion, as well as its strength and machinability. The alloy primarily consists of copper with significant tin content and smaller amounts of other elements like zinc, nickel, lead, phosphorus, aluminum, and iron. This composition provides a balance of durability and workability, making it suitable for heavy-duty components in engineering applications.

Leaded, Phosphor And Aluminium Bronzes Bearing,

Search Our Material Alloy

PB2 Phosphor Bronze

Phosphor bronze is a popular choice for bearings due to its excellent strength, durability, and low coefficient of friction, which is enhanced by the inclusion of phosphorus and tin. Custom materials for phosphor bronze bearings can be tailored according to specific application needs.

The material is available in various forms, such as solid or hollow continuous cast and centrifugal cast, with a range of outside diameters, inside diameters, and lengths. These specifications, alongside the mechanical properties like tensile strength and hardness, guide manufacturers in selecting the appropriate PB2 Phosphor Bronze for specific uses, ensuring that components like bushings and bearings can withstand the mechanical stresses they will encounter in service.

Typical Uses: This material is typically utilized in the creation of heavy-duty gears, bearings, bushes, and worm wheels. It is also used in a variety of general engineering components that require robustness against shock.

PB2 Bronze Bearing, Self-Lubricating Properties

Typical applications for PB2 Bronze include heavy-duty gears, bearings, bushings, worm wheels, and other general engineering components that require the strength to handle high shock resistance. The material’s machinability is rated at 2, which implies moderate ease of machining, and its pressure tightness and weldability are both rated at 3 on an unspecified scale, likely suggesting average performance in these areas.

Bronze Material: Bronze is chosen for its self-lubricating properties and resistance to wear. It’s often used in applications where there’s a need for a hard-wearing material that can operate with minimal lubrication.

PB2 Phosphor Bronze Bearing

Given its robust properties, PB2 Bronze is well-suited for applications that demand a combination of strength and resistance to wear and fatigue, making it a reliable material for bushings and bearings in machinery and equipment used across various industries.

Chemical Composition:

- Copper (Cu): Remainder

- Tin (Sn): 11 – 13%

- Zinc (Zn): 0.30% max

- Nickel (Ni): 0.50% max

- Lead (Pb): 0.25% max

- Phosphorus (P): 0.15 – 0.8%

- Aluminium (Al): 0.005% max

- Iron (Fe): 0.15% max

Phosphor bronze is a popular choice for bearings due to its excellent strength, durability, and low coefficient of friction, which is enhanced by the inclusion of phosphorus and tin. Custom materials for phosphor bronze bearings can be tailored according to specific application needs. Here’s an overview of what phosphor bronze typically includes and how it can be customized:

Composition

Copper: The primary component, providing good corrosion resistance and conductivity.

Tin: Increases mechanical properties and wear resistance.

Phosphorus: Improves strength, stiffness, and fatigue resistance.

Customization Options

Alloy Variations: Adjusting the percentages of tin and phosphorus can tailor the material properties. Higher tin content improves wear resistance, while more phosphorus can increase hardness and strength.

Additives: Elements like lead, zinc, or nickel might be added in small amounts to enhance machinability, strength, or corrosion resistance.

Heat Treatments: Thermal processes can alter the mechanical properties, such as increasing hardness or enhancing ductility.

Form Factors: Phosphor bronze can be produced in various forms such as sheets, rods, or specific bearing shapes, depending on the manufacturing requirements.

Applications

Phosphor bronze bearings are used in a variety of applications where durability and resistance to wear and fatigue are crucial. 、

Custom phosphor bronze materials are designed to meet specific performance standards required by unique applications, ensuring optimal functionality and longevity. If you have a particular specification or requirement for your phosphor bronze bearing, manufacturers can often create a bespoke alloy or product form to meet these needs.

Bronze is a family of alloys that primarily consists of copper and tin, with other elements added to enhance specific properties. Each type of bronze has unique characteristics that make it suitable for different applications. Here’s a more detailed overview of the various types of bronze bearings you mentioned:

-

Bronze SAE660: This is a high-strength, high-ductility bronze that is often used for its fatigue resistance and ability to withstand high loads. It is typically used in applications where high strength and wear resistance are required.

-

Leaded (Tin) Bronze C93200: This bronze contains lead, which acts as a solid lubricant. It has excellent machinability and is often used in applications where self-lubrication is needed, such as in automotive and marine components.

-

Phosphor Bronze PB1: Phosphor bronze is known for its excellent electrical and thermal conductivity, as well as its corrosion resistance. PB1 is a type of phosphor bronze that is often used in electrical contacts and connectors due to its springiness and resistance to tarnishing.

-

Leaded Bronze LB2: This bronze alloy contains lead, which enhances its machinability and provides a self-lubricating effect. It is commonly used in bearings and bushings where a low coefficient of friction is desired.

-

Leaded Bronze LB4: Similar to LB2, LB4 is a leaded bronze with a higher lead content, which can improve its lubricity and machinability even further. It is often used in applications with heavy loads or where a high degree of wear resistance is required.

-

Phosphor Bronze PB2: This is another type of phosphor bronze with a higher phosphorus content, which can improve the alloy’s hardness and strength. It is often used in applications where a combination of electrical conductivity and mechanical strength is needed.

-

Aluminium Bronze BS2874: Aluminium bronzes are known for their high strength and resistance to corrosion, especially in seawater. BS2874 is a specific grade that is often used in marine applications and for components that will be exposed to saltwater or other corrosive environments.

-

Aluminium Bronze CA104: This is a high-strength aluminium bronze with good corrosion resistance. It is often used in high-stress applications where a combination of strength and corrosion resistance is required.

-

Aluminium Bronze NES833: This is a high-alloy aluminium bronze with excellent mechanical properties and corrosion resistance. It is often used in applications that require high strength and resistance to seawater and other corrosive environments.

-

Aluminium Bronze C63000: This is a general-purpose aluminium bronze with good strength and corrosion resistance. It is often used in marine applications and for components that will be exposed to corrosive environments.

-

Aluminium Bronze 63200: Similar to C63000, this is another grade of aluminium bronze that is known for its good mechanical properties and corrosion resistance. It is often used in applications where a combination of strength and corrosion resistance is needed.

Bearings made from these bronze alloys can be manufactured through various casting methods, including centrifugal casting and continuous casting. Centrifugal casting is a process where molten metal is poured into a rotating mold, which helps to distribute the material evenly and create a denser, more uniform structure. Continuous casting, on the other hand, involves pouring molten metal into a continuously moving mold, which allows for the production of long, continuous lengths of material.

The choice of casting method and bronze alloy will depend on the specific requirements of the application, including factors such as load capacity, speed, temperature, and environmental conditions. Each type of bronze bearing offers unique benefits and is chosen based on the specific needs of the application it will be used in.

PB2 Phosphor Bronze, Phosphor Bronze Bearing

Experience the Strength of Self-lubricating Bearings

Bronze Material: PB2 Phosphor Bronze

PB2 Phosphor Bronze – Buy Now, Seeking robust bushings & bearings? Our PB2 Phosphor Bronze meets rigorous standards. Exceptional quality assured. Order Today.

Bearing Bushing: A bearing bushing is a simple bearing that can reduce friction between a rotating part (the shaft) and the stationary part (the housing). It’s typically a cylindrical sleeve that fits around the shaft.

Phosphor bronze alloys like Pb2 are known for their excellent wear resistance, fatigue resistance, and mechanical properties, making them suitable for various industrial applications such as gears, bushings, and bearings.

Related Specifications:

- AS 1565-1985: C90810

- AS 1565-1974: 90706

- SAE: 65

- UNS: C90800

Premium PB2 Phosphor Bronze Bushings

Enhance your machinery with our durable PB2 Bronze bushings. Superior shock resistance. Ideal for heavy-duty applications. Get a quote now!

Reliable Phosphor Bronze Components: Need top-grade PB2 Bronze components? Look no further for shock-resistant bushings & bearings. Shop now for premium engineering materials!”

PB2 Bronze Bushings Bearings for Heavy Duty

Dependable PB2 Phosphor Bronze bearings. Exceptional corrosion resistance & strength. Perfect for engineering solutions. Contact us today!