Exploring the Characteristics and Applications of CuAl10Ni Alloy (C95500)

About us

Introduction to CuAl10Ni: A Robust Copper Alloy

CuAl10Ni, often referred to by its specification number C95500 or the trade name 1400 AB2, represents a fascinating blend of metals primarily used in engineering and industrial applications. This alloy is a type of bronze, a broader category that traditionally involves copper and tin. However, CuAl10Ni distinguishes itself by incorporating about 10% aluminum (Al) and a significant proportion of nickel (Ni), which are not typical components in standard bronze.

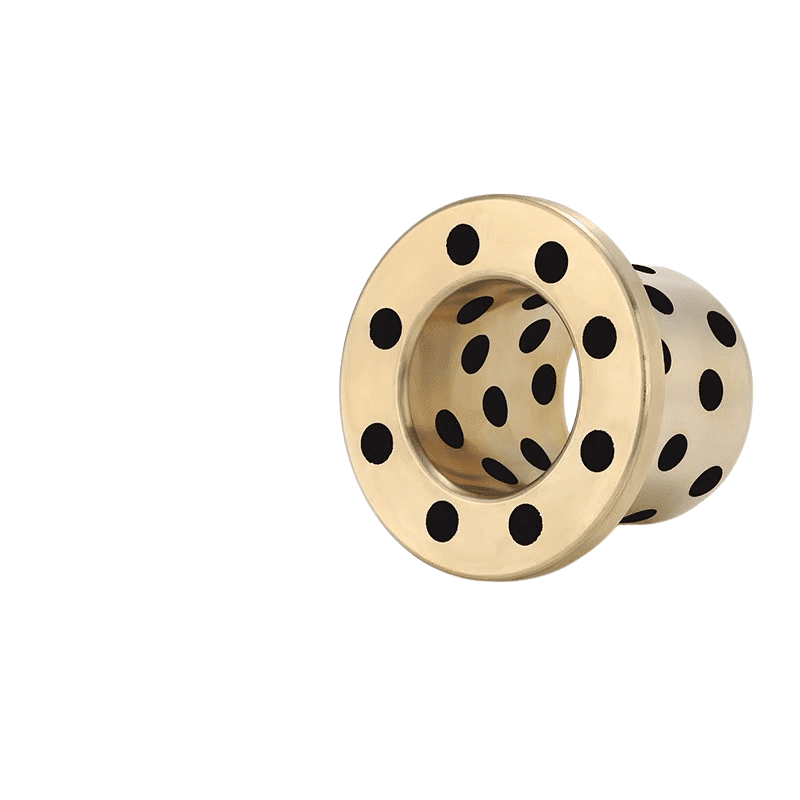

CuAl10Ni base embedded Solid Lubricants bearing, The Composition and Properties of C95500

The designation C95500 is assigned by the Copper Development Association (CDA) in the United States, categorizing it as part of the copper-nickel alloys, also known as nickel silvers. The addition of nickel not only enhances the alloy’s strength but also significantly improves its resistance to corrosion and erosion, especially in marine environments. Moreover, the presence of aluminum contributes to the hardness and durability of the alloy, making it an excellent choice for heavy-duty applications.

CuAl10Ni Bronze Bushings: The Champion of Corrosion Resistance

Don’t let harsh environments slow you down. Our CuAl10Ni bronze bushings thrive in marine, chemical, and high-salinity conditions, offering unparalleled corrosion resistance. Keep your operations smooth and maintenance to a minimum with the bushing designed to withstand the elements. Ready to resist? Reach out now!

Applications of CuAl10Ni Alloy

Experience Innovation with CuAl10Ni Self-Lubricating Bronze Bushings: Why settle for frequent replacements? Our CuAl10Ni bushings are embedded with solid lubricants like graphite, ensuring continuous smooth operation without the constant need for upkeep. Perfect for demanding applications where durability and low friction are paramount. Upgrade your components today and feel the difference!

Due to its remarkable mechanical properties and corrosion resistance, CuAl10Ni (C95500) is extensively used in applications where robustness and longevity are critical. Some common applications include:

Marine hardware: The alloy’s resistance to saltwater makes it ideal for fittings, propellers, and underwater fastenings.

Components: Its strength and lightweight nature make it suitable for various parts.

Industrial machinery: Components such as bearings, gears, and pump parts that require high strength and resistance to wear and tear are often made from this alloy.

Understanding 1400 AB2, Designed for Durability

The term “1400 AB2” might refer to a specific grade or formulation within the broader category of CuAl10Ni alloys, although without more context, its exact implications are somewhat ambiguous. It is possible that this designation is used by specific manufacturers or industries to denote a variant of the CuAl10Ni alloy tailored for particular applications or mechanical properties.

Stay Strong Under Pressure with CuAl10Ni Bronze Bushings

Whether it’s aerospace, marine, or industrial machinery, our CuAl10Ni bushings offer the high-strength solution you need to ensure peak performance under pressure. These bushings are not just tough; they’re smart, designed to last longer and perform better. Push your limits with our advanced bushings—contact us now!

CuAl10Fe5Ni5-C/CC333G/CuAl10Ni/2.0975/C95800/C95500 Bronze Bearing Custom Parts

Our CuAl10Fe5Ni5-C bronze alloy, also known under designations such as CC333G, CuAl10Ni, 2.0975, C95800, and C95500, is a copper-based alloy renowned for its high strength, wear resistance, and exceptional corrosion resistance across various environments. This alloy is ideal for applications in marine components, bushings, and valve seats, where its durability and toughness ensure reliable performance under demanding conditions.

Available Bearing Forms in Standard Dimensions

Main Base Alloy

| Phy. Performance. & Chemical Compositions |

CuZn25Al6FeMn3

Bronze Bushing |

CuZn25Al6FeMn3

Bronze Bushing |

CuSn5Pb5Zn5

Bronze Bushing |

CuAl10Ni Bronze Bushing | CuSn12 Bronze Bushing | Cast Iron HT250 |

| Cu% | 65 | 65 | 85 | 80 | 88 | |

| Sn% | 5 | 12 | ||||

| Pb% | 5 | |||||

| Zn% | 25 | 25 | 5 | |||

| Ni% | 5 | |||||

| Al% | 6 | 6 | 10 | |||

| Fe% | 5 | |||||

| Mn% | 4 | 4 | ||||

| Dengity g/cm 3 |

8.0 | 8.0 | 8.8 | 8.3 | 8.8 | 7.3 |

| Hardness | >210 | >180 | >70 | >150 | >80 | >160 |

| Tensile Strength | >750 | >550 | >200 | >500 | >360 | >250 |

| Elongation | >12 | >12 | 15 | >10 | >8 | |

| Coefficient of linear expansion |

1.9·10 -5 /℃ | 1.9·10 -5 /℃ | 1.8·10 -5 /℃ | 1.6·10 -5 /℃ | 1.8·10 -5 /℃ | 1.0·10 -5 /℃ |

| Limit Temp. | 300~400 | 300~400 | 400 | 400 | 400 | 400 |

| Max. Load N/mm 2 | 100 | 80 | 60 | 50 | 70 | 10 |

| Max. Speed m/min | 15 | 15 | 10 | 20 | 10 | 15 |

| Max. PV N/mm2·m/min | 200 | 200 | 200 | 200 | 200 | 40 |

| 400N/mm2 | <0.01 | <0.01 | <0.05 | <0.04 | <0.05 | <0.015 |

CuAI10Ni is a copper alloy enriched with aluminum and nickel, renowned for its robust mechanical properties and wear resistance. This material is especially suited for manufacturing sliding bearings for saltwater applications due to its following characteristics:

Corrosion Resistance: Thanks to its aluminum content, CuAI10Ni alloy typically exhibits superior corrosion resistance compared to pure copper or standard copper alloys, particularly in saltwater environments.

Enhanced Lubrication: Specific lubrication plugs can further enhance bearing performance. These plugs are designed to provide lubrication regularly or continuously during operation, reducing friction and wear, especially under harsh conditions.

Maintenance-Free Design: The maintenance-free design of these sliding bearings means they can operate without regular upkeep, which is extremely beneficial for applications in hard-to-reach or harsh environments such as those involving saltwater.

Mechanical Properties of the Material: The high strength and hardness of CuAI10Ni alloy help the bearings withstand heavy loads while maintaining stability in shape and dimensions.

Emergency Running Features: Bearings made from CuAI10Ni alloy can perform under emergency conditions, even with insufficient lubrication, which is crucial in some critical applications.

Alloy Heat Treatment: CuAI10Ni can be optimized through proper heat treatment processes to enhance its mechanical properties and wear resistance, further improving its performance in harsh environments like saltwater.

Design Features: The design of the bearings can include special seals or protective measures to prevent the intrusion of saltwater and other corrosive fluids.

Bearings made from this material are suitable for marine engineering, shipbuilding, offshore platforms, and other applications that involve exposure to saltwater. However, other factors such as operating temperature, load conditions, speed, and expected lifespan should also be considered when designing and selecting bearings.

Product Features of Self-Lubricated Bronze Bushing Bearings

1. No Oil Supply System Needed

These bearings eliminate the need for oil supply devices, oil holes, and grooves. This simplification reduces the costs associated with the fuel supply system, including processing and assembly, ultimately lowering manufacturing expenses.

2. Reduced Operating Costs

The use of self-lubricating bearings substantially cuts down on the need for lubricating oil and equipment maintenance, while also eliminating the risks associated with oil shortages.

3. Streamlined Design Process

The absence of oil simplifies the design and structure, reducing costs and saving design time. Additionally, using self-lubricating bearings can enhance mechanical properties, extend service life, and improve reliability.

4. Environmental Benefits

With no need for waste oil recycling, these bearings are environmentally friendly, promoting cleaner production practices.

5. Versatile Mechanical Applications

As essential parts of the mechanical industry, these bearings are crucial for normal machine operation. They are designed to withstand high loads and adverse conditions such as foreign body intrusion, extreme temperatures, and imperfect maintenance, which would typically cause galling in general sliding bearings.

Usage Notes

- Where possible, design using standard specifications.

- Ensure there are no foreign bodies in the assembly.

- After use, a solid lubricant may form a black or gray-black film on the sliding surface. Do not scrub this off; it is usual.

- Applying lubricating oil to the grinding parts before assembly can shorten the running-in period, facilitating smoother machinery operation.

- When assembling, press in slowly; avoid hammering to prevent bearing damage and deformation.

- Select appropriate materials for different parts to improve mechanical performance and extend the bearing’s service life.

- For high-load, reciprocating movements, consider using screw fixation.

- In environments like fresh water, seawater, or maritime settings, use stainless steel or surface plating.

Bearing Features

- Flexible Design and Wide Applications: Eliminating the need for an oil-feeding system simplifies and economizes the design process. These bearings can be tailored to meet specific requirements, significantly reducing mechanical maintenance and oil costs.

- Functional in the Absence of Oil: These bearings begin to transfer lubricant onto the wear parts as soon as movement starts, achieving self-lubrication. This feature is invaluable in settings where oiling is difficult, ensuring excellent lubrication even under low-speed, high-load conditions.

- Cost Efficiency: Traditional mechanical designs often require frequent maintenance and environmental clean-up due to oil use, which increases costs. Self-lubricating bearings eliminate these needs, reducing lubrication costs and environmental impact.

- High-Performance Under High Load and Low Speed: Made from high-strength rotational cast copper and using specially formulated graphite as lubricant, these bearings are designed to perform optimally under tough conditions.

- Superior Abrasion Resistance: Especially effective in challenging conditions such as alternating, swinging movements, or frequent starts and stops, ensuring consistent lubrication throughout the equipment’s operation.

- Excellent Chemical and Corrosion Resistance: The lubricants, made from abrasion-resistant materials like graphite and PTFE, and the customizable metallic matrix provide robust chemical and corrosion resistance.

- Competitive Pricing and Enhanced Performance: Compared to similar products, these bearings offer longer service hours, reduced maintenance needs, extended replacement periods, and superior performance, making them a cost-effective solution.

Insert Graphite Bronze Bushing: Enhancing Performance With Self-Lubrication

Experience the Strength of Self-lubricating Bearings

CuAl10Ni (C95500), or 1400 AB2 Bonze Bushing, Outperform, Outlast

CuAl10Ni Self-Lubricating Bronze Bushings: The Ultimate in Wear Resistance

An interesting application of bronze alloys is in the creation of “Insert Graphite Bronze Bushing.” These bushings incorporate graphite, a form of carbon known for its excellent lubricative properties. By embedding graphite within the bronze matrix, these bushings reduce friction and wear in mechanical systems, enhancing efficiency and durability. Graphite bronze bushings are particularly useful in scenarios where regular lubrication is difficult or where operational conditions are harsh, such as in high-temperature environments.

Keep your operations running longer and more efficiently with bushings that are built to outlast. CuAl10Ni’s excellent wear resistance means less downtime and more productivity. Ideal for applications requiring endurance and reliability. Invest in the best—upgrade to CuAl10Ni today!

CuAl10Ni (C95500), or 1400 AB2 Bonze Bushing

Maintenance-Free Plain Bearings with Lubrication Plugs. Self-Lubricating Bearings for Heavy-Duty Use, Ideal for Challenging Conditions: Maintenance-free plain bearings equipped with lubrication plugs are ideal for heavy loads, high temperatures, vibrations, and corrosive environments. Utilizing CuAI10Ni with specialized lubrication plugs, these bearings are also perfectly suited for applications involving salt water.

CuAl10Ni (C95500), or 1400 AB2, is more than just a typical bronze alloy. Its enhanced composition with aluminum and nickel offers superior mechanical properties and corrosion resistance, making it a preferred choice in various demanding applications from marine to aerospace industries. The innovative use of graphite in bronze bushings further showcases the versatility and adaptability of CuAl10Ni in overcoming engineering challenges. As industries continue to evolve, the role of such advanced materials becomes increasingly crucial in achieving technological advancements and operational efficiencies.

Unlock the Power of Durability with CuAl10Ni Self-Lubricating Bronze Bushings! Experience unmatched performance and reliability in your industrial applications. Our CuAl10Ni bronze bushings reduce maintenance costs, extend equipment lifespan, and operate flawlessly in high-load and high-temperature conditions. Opt for the strength and resistance that keeps you moving forward. Contact us today for a consultation and see what CuAl10Ni can do for you!

Insert Graphite Bronze Bushing: CuAl10Ni Bronze Enhancing Performance with Self-Lubrication, Enhance Your Machinery with Cual10Ni Slide Bearings

Unmatched Performance in extreme conditions. Cual10Fe5Ni5 bearings for top efficiency & longevity. Click to explore our range! CuAl10Ni bronze is a high-performance material suited for applications that require high strength, wear resistance, corrosion resistance, and stability at high temperatures. If you have specific applications or technical questions about this material, I am more than willing to help.

Bearings made from high-quality CuAl10Ni substrate embedded with solid lubricants typically have a high load capacity, low friction coefficient, excellent wear resistance, and chemical stability. Some manufacturers emphasize that their products can be used for extended periods without maintenance and are designed to withstand very high static and dynamic loads. Cual10Fe5Ni5 Aluminum Bronze Bearings: Optimized for Heavy-Duty Applications. Experience the strength of C95500 material in your slide bearings. Visit us for specs & pricing!

CuAl10Ni Bronze Plate High Performance Meets High Efficiency, Premium C95500 Bronze Bearings Available Now

Boost Your Equipment Reliability with our durable and wear-resistant Cual10Ni slide bearings. Get a quote today!

Exploring the Special Bronze Material:

CuAl10Ni Bronze and Its Unique Properties