JF800 bimetallic thrust washer

JF800 bimetallic thrust washer

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

JF800 bimetallic thrust washer

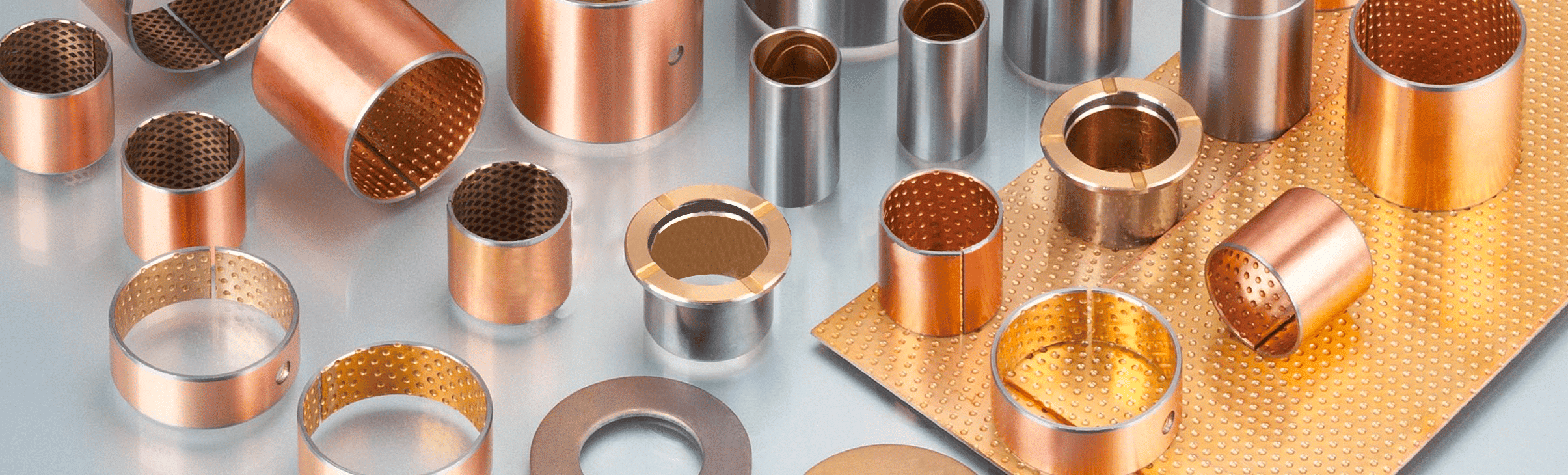

The JF800 bimetallic thrust washer, also known as JF800WC, is a type of self-lubricating bearing that is widely used in various industries for applications that require high load capacity and good wear resistance. Bimetallic thrust washers with CuPb10Sn10 alloy are a reliable choice for applications requiring high load capacity and resistance to wear and fatigue. They are customizable and can be designed to be self-lubricating, offering a practical solution for a wide range of industrial applications

CuPb10Sn10 Alloy Bimetallic Thrust Washers, JF800 bimetallic thrust washer. SAE 792

Bimetallic thrust washers with the CuPb10Sn10 alloy are engineered to handle axial forces in mechanical systems, ensuring alignment along the central shaft. This specific bimetallic composition, with roughly 80% copper, 10% lead, and 10% tin, delivers superior load capacity, excellent high-temperature fatigue resistance, and commendable wear resistance.

Key Features and Uses:

Material Traits: The CuPb10Sn10 alloy in these washers is chosen for its balanced attributes, making it ideal for applications that demand high-load capacity and low-friction performance at high speeds.

Construction Details: Featuring a steel base with a sintered lead bronze layer, these washers may also include lubrication pockets for enhanced self-lubrication, facilitating a maintenance-free operation.

Customization Options: There is a variety of customization choices available, including cylindrical bushes, thrust washers, and sliding plates, tailored to meet specific operational needs.

Industrial Applications: Predominantly found in automotive, industrial machinery, and heavy-duty equipment, these washers play a crucial role in engines, gearboxes, suspension systems, pumps, compressors, and construction machinery.

Self-Lubrication Feature: Certain models are designed to be self-lubricating, minimizing maintenance demands and prolonging component lifespan.

Standards and Durability:

Compliance with SAE 792: These bearings align with the SAE 792 standard, ensuring they meet established benchmarks for plain bearings.

Corrosion Protection: Typically, the steel backing is bronze-plated to enhance corrosion resistance, adding to the durability of the bearings.

Operational Considerations:

Suitable Conditions: They are best suited for scenarios involving high specific loads, oscillatory movements, and lower frequencies.

Lubrication Needs: While designed to be low-maintenance, some bearings may require periodic lubrication based on the application and design specifics.

In summary, CuPb10Sn10 alloy bimetallic thrust washers are a dependable selection for demanding applications, offering customization, self-lubricating properties, and compliance with industry standards, catering effectively to a broad spectrum of industrial needs.

JF800 bimetallic thrust washer, JF800WC

JF800WC denotes JF800 bimetallic bearings enhanced with a bronze alloy surface. Here’s an overview:

Composition: These bearings are constructed with a base of low-carbon steel and a top layer of sintered lead-tin bronze alloy.

Functionality: They are engineered for use in medium to high-speed settings and can endure high-impact loads, making them suitable for automotive engines, motorcycles, and heavy-duty machinery.

Characteristics: JF800 bearings are known for their durability and adaptability, fitting for use in sleeve bearings, thrust washers, and other applications where strong performance is essential.

Customization and Availability: Available in various dimensions, these bearings can also be tailored to meet specific needs.

Suppliers: A range of manufacturers produce JF800 bearings, offering options for both bulk purchasing and specialized customizations.

These bearings are recognized for their robust and dependable performance, catering to a broad spectrum of industrial demands.

JF800 bimetallic bearing’s features and specifications:

Construction and Composition:

- The JF800 bimetallic bearing is constructed from a steel base with a CuPb10Sn10 bronze alloy overlay.

- This bronze layer is sintered to the steel, forming a durable composite material.

- The bronze surface may feature indents that serve as grease reservoirs, boosting the bearing’s self-lubricating capabilities.

Self-Lubrication Features:

- Designed for operation without the need for external lubrication, the JF800 bearing incorporates solid lubricants in the bronze layer.

- These lubricants release particles during operation to diminish friction and wear.

Mechanical Attributes:

- The steel backing ensures high load capacity, enabling the bearing to support substantial loads.

- Enhanced wear resistance due to the bronze layer contributes to the bearing’s longevity.

- Its self-lubricating nature ensures low friction and smooth performance.

Usage Scenarios:

- Ideal for moderate to high load conditions and suitable for intermittent or oscillating motions.

- Widely utilized in sectors like automotive, agriculture, construction, and industrial machinery.

Technical Specifications:

- Greased applications: Max operating temperature is 150°C.

- Oil-lubricated applications: Max operating temperature is 250°C.

- Max static load: 300 N/mm².

- Max dynamic load: 140 N/mm².

- Greased applications: Max sliding speed is 2.5 m/s, with a maximum PV factor of 2.8.

- Coefficient of friction ranges from 0.05-0.12 for greased applications and 0.04-0.12 for oil-lubricated applications.

Product Availability:

- Offered in standard cylindrical bushes and thrust washers in metric sizes.

- Options for non-standard parts, strips, and special designs upon request.

For optimal selection, particularly for applications with moderate to high loads and varying movements, consulting with suppliers or manufacturers of self-lubricating bearings is recommended to ensure the best fit for specific needs.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.