pins and bushings by size

pins and bushings by size

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

pins and bushings by size

Exploring the SEA 795 Bushing: A Key Component in Mechanical Systems

In the world of mechanical parts and components, the SEA 795 bushing stands out for its unique characteristics and applications. This post delves into what makes the SEA 795 bushing a critical component in various machinery, exploring its specifications, uses, benefits, and maintenance guidelines.

What is the SEA 795 Bushing?

The SEA 795 bushing is a mechanical element used in various machines to provide smooth and stable rotational movement. Made from high-quality materials, it’s designed to withstand heavy loads and reduce friction between moving parts.

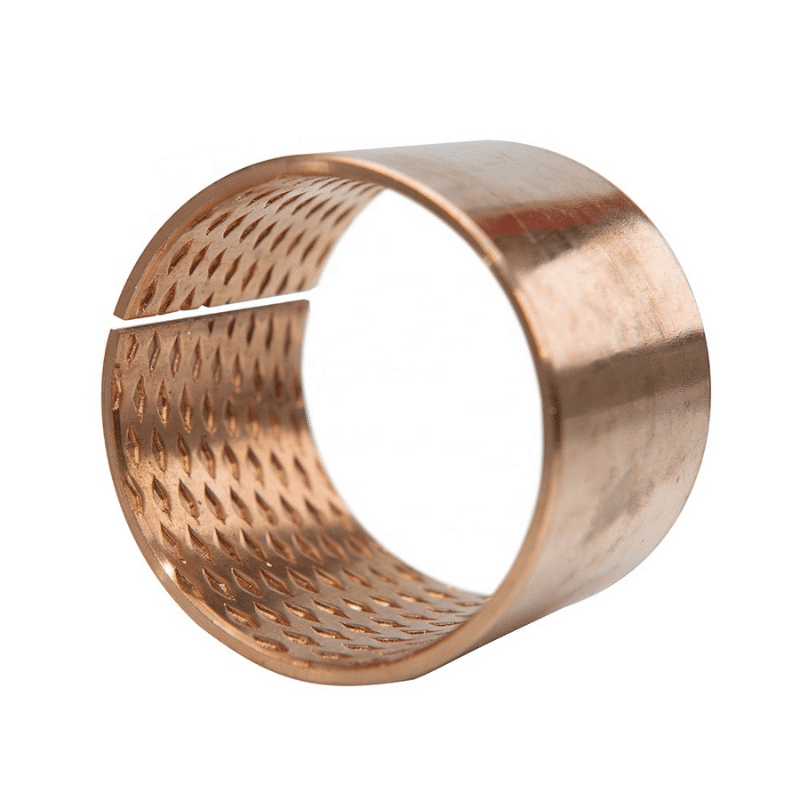

Unveiling the SAE 795 Bronze Bushing: Revolutionizing Friction Management with Graphite Housing Pins and Bushings by Size

Graphite Bushings and Bearings, graphite type self lubrication bush

Solid lubricants, Embedded, Aluminum bronze bearings with embedded solid lubricant, Bronze bearings with embedded solid lubricant, High-strength brass bearings with embedded solid lubricant, Special high-strength brass bearings with embedded solid lubricant

Use SAE 795 Bronze Bushing— Offering Superior Performance In Hundreds Of Applications Replacing Carbon Bearings. SAE 795 Bronze Bushing is Suited for Submerged and High-Temperature Applications.

In the realm of mechanical engineering and design, the integration of advanced materials and innovative designs is crucial. The SAE 795 Bronze Bushing with cavities for housing graphite is a prime example of such innovation. This blog post explores the intricate design, applications, and advantages of this specialized bushing.

Understanding the SAE 795 Bronze Bushing with Graphite

The SAE 795 bronze bushing is known for its robustness and durability. What sets this variant apart is its unique design that includes cavities specifically engineered to house graphite. This integration plays a pivotal role in the bushing’s functionality.

Technical Specifications

- Material Composition: Discuss the high-grade bronze used in the bushing, emphasizing its wear resistance and strength.

- Graphite Housing: Explain how the graphite cavities are incorporated into the bronze matrix and the role of graphite in reducing friction and enhancing lubrication.

- Dimensions and Tolerances: Detail the standard sizes, shapes, and allowable tolerances of the bushing.

- Load Capacity and Temperature Range: Highlight the bushing’s ability to withstand high loads and operate effectively across various temperature ranges.

Applications and Benefits

- Industrial Machinery: Illustrate how this bushing is used in high-load, high-friction environments, like manufacturing equipment.

- Automotive Sector: Discuss its application in areas of vehicles that require robust, self-lubricating bushings.

- Renewable Energy: Mention its use in wind turbines or other renewable energy equipment where longevity and low maintenance are crucial.

Advantages of the SAE 795 Bronze Bushing with Graphite

- Self-Lubrication: Elaborate on how the graphite cavities provide consistent lubrication, reducing the need for external lubricants.

- Longevity and Reliability: Emphasize its extended service life and reliability under demanding conditions.

- Environmental Resistance: Discuss its resistance to corrosion and various environmental factors.

Maintenance and Care

- Inspection Tips: Provide guidance on regular inspections for wear or damage.

- Environmental Considerations: Offer advice on maintaining the bushing in different environmental conditions.

- Replacement Recommendations: Offer insight into recognizing when replacement is necessary and best practices for replacement procedures.

Conclusion

The SAE 795 Bronze Bushing with cavities for housing graphite represents a significant advancement in bushing technology. By combining the strength and durability of bronze with the self-lubricating properties of graphite, this bushing offers unparalleled efficiency and longevity, making it an ideal choice for a wide range of industrial applications.

Exploring SAE 795 Bronze Bushings: A Key Material in Industrial Applications

Introduction to SAE 795 Bronze Alloy

In the realm of industrial bronze alloys, SAE 795 stands out as a notable player, commonly referred to as Copper-Lead Bronze. This material is extensively used in manufacturing bearings and components for high-friction applications. The amalgamation of copper and lead in its composition grants SAE 795 exceptional corrosion resistance and wear resistance. These attributes make it an ideal choice for parts that demand low maintenance and longevity.

The Importance of Material Selection in Industrial and Mechanical Design

Choosing the right material is crucial in industrial and mechanical design to ensure component performance and durability. SAE 795 bronze exhibits remarkable performance in specific applications, particularly in environments subjected to high friction and heavy loads. Its unique chemical composition and physical properties are tailored to meet challenging industrial demands.

Variability in Material Designations Across Standards

One intriguing aspect of SAE 795 as a copper-based bearing material is the variability in its material grade designations across different national and international standards. For instance, what’s known as SAE 795 in one standard might have a different designation in another. This variance is seen across standards like the American ASTM, European EN, and Chinese GB standards. Each of these may offer copper alloys similar to SAE 795 in composition and performance, but under different grade numbers.

Applications and Advantages

SAE 795’s primary application lies in bearings, where its properties are put to excellent use. The alloy’s ability to withstand corrosive environments while maintaining structural integrity under high-load and high-friction conditions makes it a preferred material for heavy machinery, automotive applications, and various industrial machines.

Environmental and Health Considerations

Given its lead content, handling and usage of SAE 795 require adherence to safety and environmental regulations. Lead, a toxic element, mandates careful consideration in terms of exposure and disposal. Therefore, industries using SAE 795 must ensure proper safety protocols to mitigate health risks.

The selection of SAE 795 bronze bushings in industrial applications highlights the importance of material science in achieving efficiency, durability, and reliability in machinery and components. Its tailored composition suits specific needs, while the variability in international standards reflects the global nature of material science and engineering.

Technical Specifications

- Material Composition: Discuss the materials used in the bushing, such as bronze, steel, or composite materials.

- Dimensions and Tolerances: Detail the standard sizes and allowable tolerances of the bushing.

- Load Capacity: Explain the maximum load the bushing can handle.

- Temperature Range: Describe the temperature range within which the bushing operates effectively.

Applications of the SEA 795 Bushing

- Industrial Machinery: Highlight how it’s used in heavy machinery for manufacturing, construction, etc.

- Automotive: Discuss its role in automotive suspension systems or other parts.

- Aerospace: If applicable, mention its use in aircraft or spacecraft components.

Benefits of Using the SEA 795 Bushing

- Durability: Emphasize its long life and resistance to wear and tear.

- Efficiency: Explain how it reduces energy consumption by minimizing friction.

- Versatility: Illustrate its suitability for various applications due to its robust design.

Maintenance and Care Tips

- Regular Inspection: Advise on how often to inspect the bushing for wear or damage.

- Lubrication: Provide recommendations on suitable lubricants and lubrication intervals.

- Replacement Guidelines: Offer tips on recognizing when the bushing needs to be replaced and steps for replacement.

Conclusion

The SEA 795 bushing is more than just a mechanical part; it’s a vital component that enhances the efficiency and longevity of various machines. Understanding its specifications, applications, and maintenance needs can help ensure optimal performance and durability.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.