The Guide to Self-Lubricating Bearings for Electric Motors in the Marine Industry

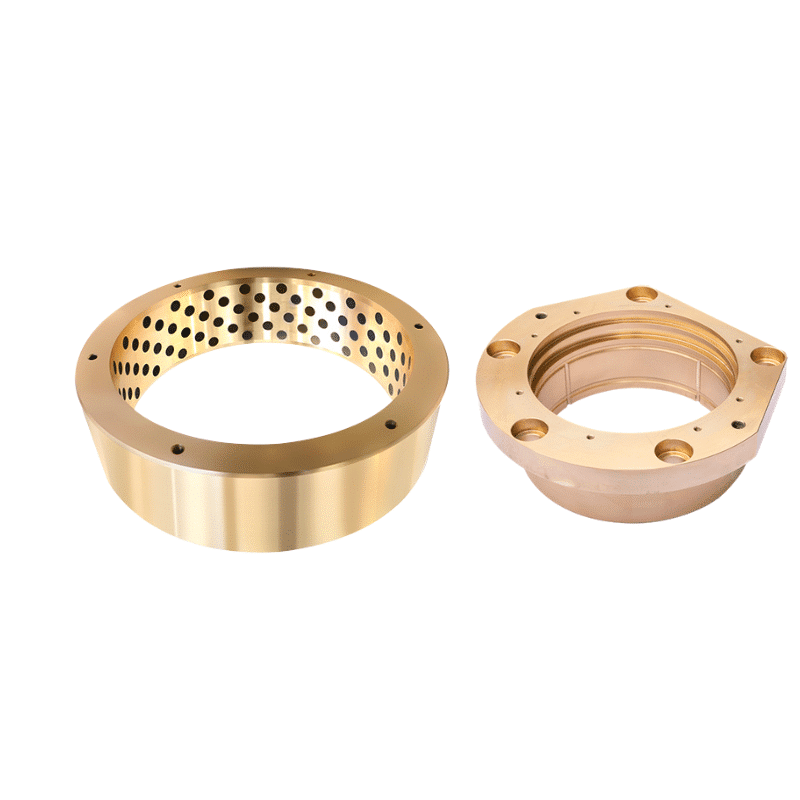

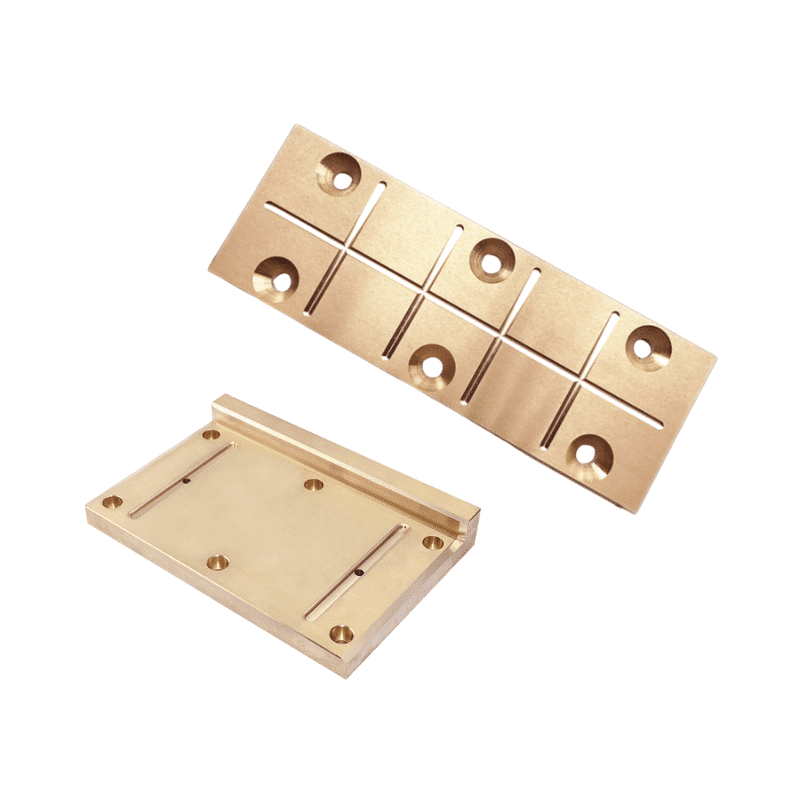

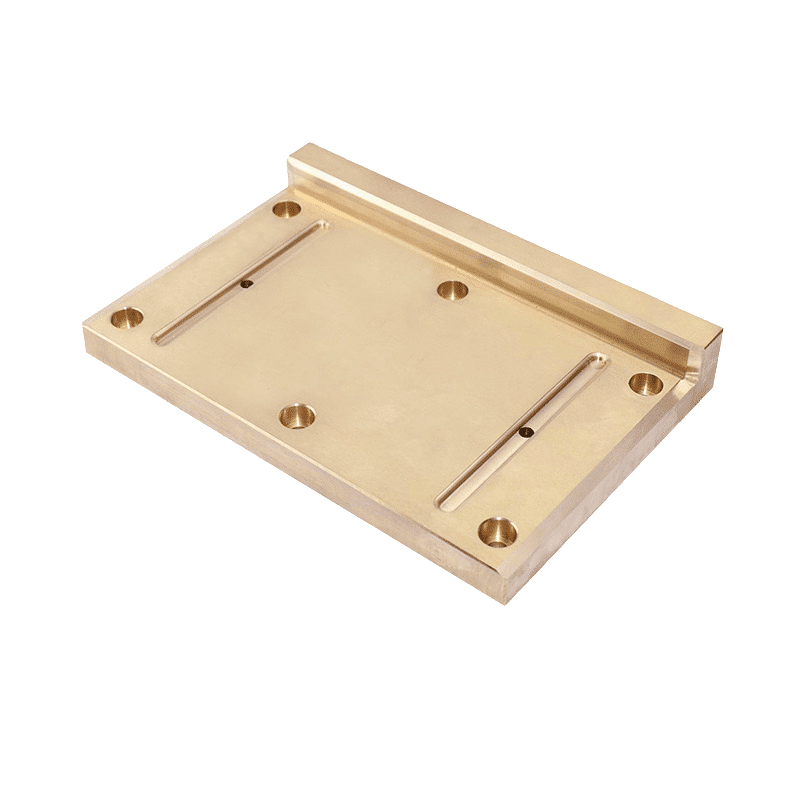

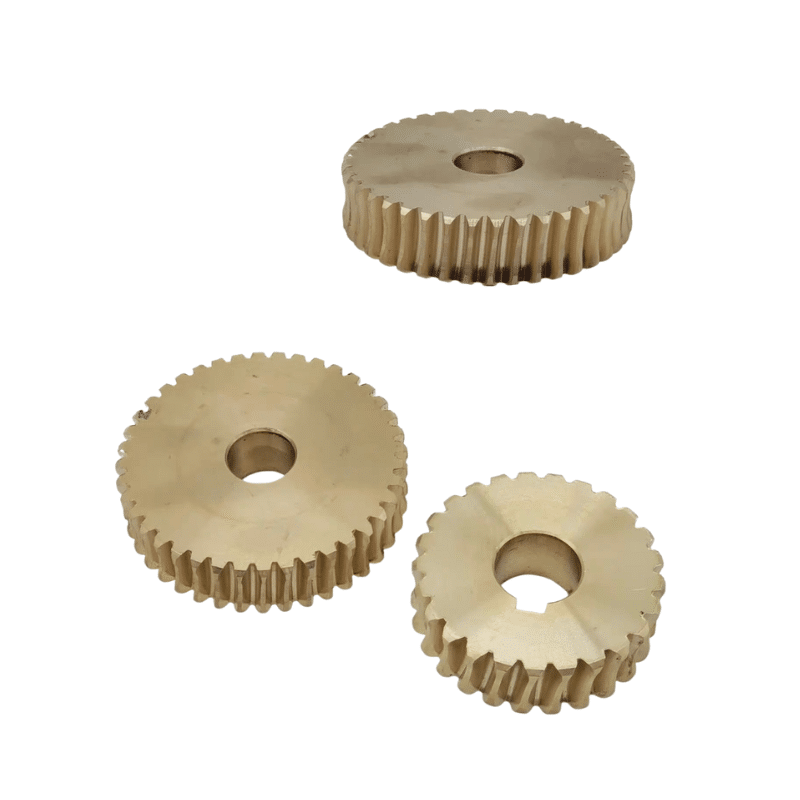

Gears are the workhorses of the mechanical world. Whether they are found in a vehicle’s transmission, a factory’s machinery, or the propulsion system of a marine vessel, gears play a vital role in converting power into motion. One critical aspect of gear systems is the bushing—the sleeve-like component that provides a surface for rotational or sliding parts. Traditionally, these have required external lubrication to function effectively. However, advances in material science have paved the way for self-lubricating bushings, particularly those made from cast bronze and impregnated with graphite. This article explores the advantages of these self-lubricating bronze graphite bushings in reduction gear systems, which are commonly used to decrease input speed (such as from a marine turbine) to a lower, more useful output speed (like driving a ship’s propeller).

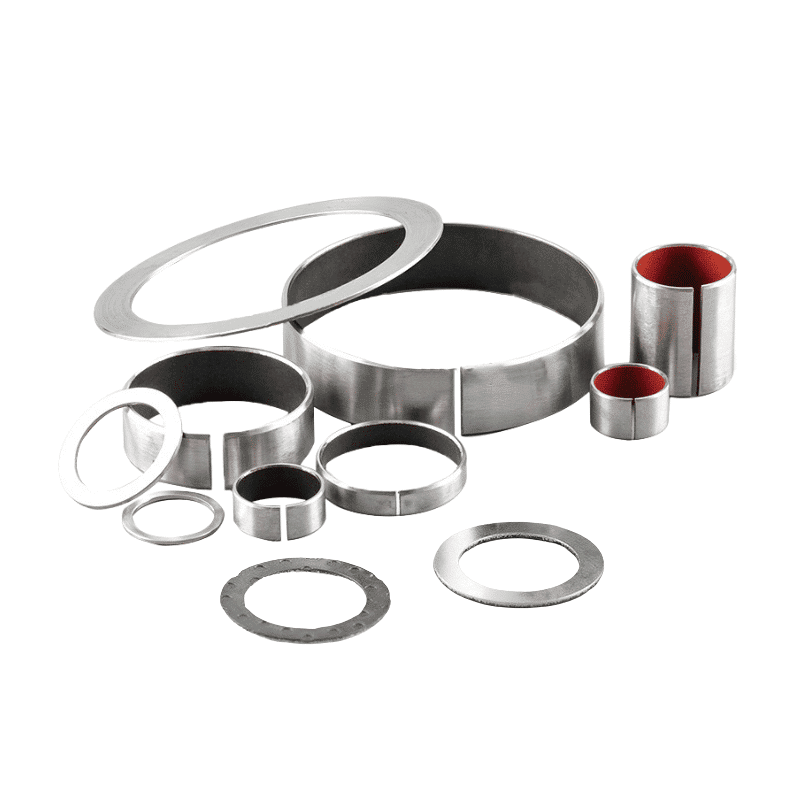

Specializing In electric motor shaft bushings

electric motor shaft bushings Supplier

Selecting the right self-lubricating bearing for electric motors in marine applications is a complex but essential task. By carefully considering the parameters outlined above, you can design a bearing that meets the demanding standards of reliability, efficiency, and environmental responsibility that the marine industry requires.

For more information or consultation on designing the ideal self-lubricating bearing for your application, feel free to reach out to our team of experts.

Remember, the right bearing not only enhances the performance of your electric motor but also significantly contributes to the conservation of marine ecosystems. Choose wisely!

Parameters For Designing A Self-Lubricating Bearing

For more information on how to select the perfect self-lubricating bushing for your electric motor, feel free to contact our team of experts. Your motor deserves the best, and we’re here to help you provide just that.

Operational Speed

- Minimum RPM: The minimum revolutions per minute the motor operates at.

- Maximum RPM: The maximum revolutions per minute achievable.

- Average RPM: The average operational speed for typical usage.

Operating Temperature Range

- Minimum Temperature: The lowest temperature the bearing will experience.

- Maximum Temperature: The highest temperature the bearing will experience.

Load Characteristics

- Radial Load: The force acting perpendicular to the axis of rotation.

- Axial Load: The force acting parallel to the axis of rotation.

- Combined Load: A combination of radial and axial loads if applicable.