Oilless Wear Slide Plates: The Ultimate Guide

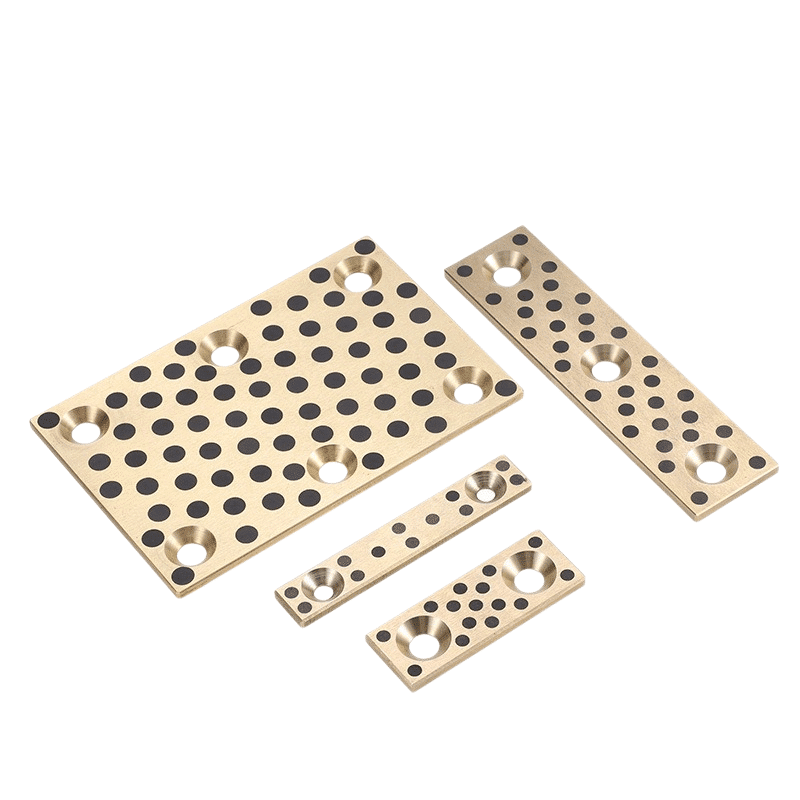

Oilless slide plates, also known as oil-free slide plates, are components used in various industries, especially in plastic mold manufacturing. Wear plates are essential components in various machinery, acting as a protective shield against wear and tear. Traditional wear plates often require lubrication to function optimally. However, the advent of oilless wear plates has revolutionized the industry by offering a lubrication-free solution. Let’s delve deeper into the world of oilless wear plates and explore some popular sizes. In the ever-evolving world of engineering and manufacturing, the quest for materials that reduce friction, improve performance, and enhance the lifespan of components is perpetual. One such groundbreaking innovation is the use of solid lubricant embedded bushes, specifically those made from high-strength brass, ZCuZn24Al6Fe4Mn3. This article will focus on the features, benefits, and applications of these oilless wear plates, available in various widths.

Specialized Oilless Wear Plates, Solid Lubricant Embedded Bushes: A Deep Dive into High-Strength Brass, ZCuZn24Al6Fe4Mn3 Oilless Wear Slide Plates

Solid Lubricant Embedded Bushes & Oilless Wear Slide Plates

Function: Oilless slide plates are designed to provide smooth and frictionless movement between components, reducing wear and tear while enhancing efficiency in sliding applications.

Solid lubricant embedded bushes are self-lubricating components that don’t require external lubrication sources. These bushes have solid lubricants embedded within their structure, which gradually release as the bush wears, ensuring low friction and smooth operation over time.

Oilless wear slide plates, as the name suggests, operate without the need for additional lubrication. They are designed with materials that reduce friction inherently, ensuring a smooth operation and a longer lifespan for the machinery they’re part of.

Oilless wear slide plates are a testament to how technology and innovation can lead to more efficient and hassle-free solutions. Whether you’re in the automotive, industrial, or any other sector, there’s an oilless wear plate tailored to meet your needs.

Remember, the sizes mentioned are hypothetical and may vary based on the manufacturer and specific requirements. Always consult with a professional or the manufacturer for exact specifications.

High-Strength Brass, ZCuZn24Al6Fe4Mn3 slide plate

Materials: The Slide plates are typically made from materials like graphite or bronze, which possess self-lubricating properties, eliminating the need for external lubrication

The ZCuZn24Al6Fe4Mn3 composition is a high-strength brass that exhibits exceptional wear resistance, making it a favored choice for manufacturing solid lubricant embedded bushes. Its unique composition includes:

- Copper (Cu)

- Zinc (Zn)

- Aluminum (Al)

- Iron (Fe)

- Manganese (Mn)

The combination of these elements imparts the brass with high strength, excellent corrosion resistance, and the ability to maintain its properties even under high-temperature conditions.

Specialized Oilless Slide Plates

Advantages: Oilless slide plates offer benefits such as reduced maintenance, improved operational efficiency, and cost-effectiveness due to their self-lubricating nature.

Varieties: Various types of oil-free slide plates are available to suit different requirements, including standard components and specialized designs.

These plates play a critical role in ensuring smooth operations in machinery and equipment across multiple industries.

- JSOVP: This might be a brand name, a model, or a specific type of wear plate. Without additional context, it’s hard to pin down its exact meaning.

- Oilless: This refers to the fact that the wear plate does not require lubrication. Oilless or self-lubricating materials have become popular in various industries because they reduce maintenance requirements and can operate in environments where lubrication is difficult or undesirable.

- Wear Plate: A wear plate is a piece of special material that is used to protect or shield more expensive machinery. These plates are subjected to a lot of wear and tear, hence the name. Their purpose is to extend the life of the machinery they protect.

- Graphite: This indicates that the wear plate incorporates graphite in its composition. Graphite is known for its lubricating properties. When embedded in a metal matrix, it can provide self-lubricating properties to the material, making it suitable for applications where lubrication is challenging.

| Standard No. | L | W | T |

| JSOVP 25×305×5 | 25 | 5.3 | |

| ISOVP 30×305×6 | 305 | 30 | 6.3 |

| JSOVP 40×605×8 | 40 | 8.3 | |

| JSOVP 35×605×10 | 35 | 10.3 | |

| JSOVP 50×605×10 | 50 | 10.3 | |

| JSOVP 40×605×12 | 40 | 12.3 | |

| JSOVP 80×605×12 | 605 | 80 | 12.3 |

| JSOVP 60×605×16 | 60 | 16.3 | |

| JSOVP 80×605×20 | 80 | 20.3 | |

| JSOVP 100×605×20 | 100 | 20.3 |

| Unit (mm) | ||||||

| Standard No. | W | L | W, | ₂ | L | L2 |

| JESW-28×75 | 75 | 45 | 15 | |||

| JESW-28×100 | 28 | 100 | 50 | |||

| JESW-28×150 | 150 | 100 | 25 | |||

| JESW-38×75 | 75 | 45 | 15 | |||

| JESW-38×100 | 38 | 100 | 50 | 25 | ||

| JESW-38×150 | 150 | 100 | ||||

| JESW-48×75 | 75 | 45 | 15 | |||

| JESW-48×100 | 100 | 50 | ||||

| JESW-48×125 | 48 | 125 | 75 | |||

| JESW-48×150 | 150 | 100 | 25 | |||

| JESW-48×200 | 200 | 150 | ||||

| JESW-58×75 | 75 | 45 | 15 | |||

| JESW-58×100 | 58 | 100 | 50 | |||

| JESW-58×150 | 150 | 100 | ||||

| JESW-75×75 | 75 | 25 | ||||

| JESW-75×100 | 100 | 50 | 25 | |||

| JESW-75×125 | 75 | 125 | 75 | |||

| JESW-75×150 | 150 | 100 | ||||

| JESW-75×200 | 200 | 150 | ||||

| JESW-100×100 | 100 | 50 | ||||

| JESW-100×125 | 125 | 75 | ||||

| JESW-100×150 | 150 | 100 | 25 | |||

| JESW-100×200 | 100 | 200 | 25 | 150 | ||

| JESW-100×250 | 250 | |||||

| JESW-100×300 | 300 | 200 | 50 | |||

| JESW-125×125 | 125 | 50 | 75 | |||

| JESW-125×150 | 150 | 100 | ||||

| JESW-125×200 | 200 | 150 | 25 | |||

| JESW-125×250 | 125 | 250 | 37.5 | |||

| JESW-125×300 | 300 | 200 | 50 | |||

| JESW-125×350 | 350 | 75 | ||||

| JESW-150×150 | 150 | 100 | ||||

| JESW-150×200 | 150 | 200 | 100 | 25 | 150 | 25 |

| JESW-150×250 | 250 | 200 | ||||

JESW Oilless Wear Plate: A Comprehensive Guide

In the world of machinery, wear plates play a pivotal role, ensuring smooth operation and longevity of equipment. Among the variants, the JESW Oilless Wear Plate has carved a niche for itself, especially with its unique composition of Material 650# combined with Graphite. Let’s dive into its specifics and understand its size chart.

1. Introduction to JESW Oilless Wear Plate

The JESW Oilless Wear Plate is designed to offer high-performance wear resistance without the need for lubrication. Its distinguishing factor lies in its material composition: Material 650# blended with Graphite. This combination ensures reduced friction, increased durability, and a longer lifespan for the machinery components.

2. Material Composition

a. Material 650#

Material 650# is a specialized material known for its exceptional wear resistance and durability. It’s often used in heavy-duty applications, making it an ideal choice for wear plates.

b. Graphite

Graphite is a naturally occurring form of carbon that is known for its excellent lubricating properties. When embedded into wear plates, it offers inherent lubrication, eliminating the need for external sources.

3. JESW Oilless Wear Plate Size Chart

(Note: The following size chart is hypothetical as the actual sizes were not provided.)

| Standard No. | Size (Length x Width) |

|---|---|

| JESW-001 | 40mm x 40mm |

| JESW-002 | 60mm x 60mm |

| JESW-003 | 80mm x 80mm |

| JESW-004 | 100mm x 100mm |

| JESW-005 | 120mm x 120mm |

4. Applications

The JESW Oilless Wear Plate finds its applications in various industries, including automotive, manufacturing, and heavy machinery. Its self-lubricating property ensures minimal maintenance, making it a favorite among equipment manufacturers and users.

5. Conclusion

The JESW Oilless Wear Plate, with its unique combination of Material 650# and Graphite, is a testament to the advancements in material science. It promises durability, reduced maintenance, and efficient operations, making it a valuable component in various machinery.

If you plan to use this guide for publishing, ensure that you validate the sizes and details with actual product specifications.

| Unit (mm) | |||||||

| Standard No. | W | L | W, | L | d | h | Mounting Bolt |

| JUWP-18×50 | 50 | 20 | |||||

| JUWP-18×75 | 75 | 45 | |||||

| JUWP-18×100 | 18 | 100 | 70 | 6.5 | 1.5 | M6 | |

| JUWP-18×150 | 150 | 60 | |||||

| JUWP-28×50 | 50 | 20 | |||||

| JUWP-28×75 | 75 | 45 | |||||

| JUWP-28×100 | 28 | 100 | 70 | ||||

| JUWP-28×150 | 150 | 60 | |||||

| JUWP-38×50 | 50 | 20 | 10 | 0.8 | M8 | ||

| JUWP-38×75 | 75 | 45 | |||||

| JUWP-38×100 | 38 | 100 | 70 | ||||

| JUWP-38×150 | 150 | 60 | |||||

| JUWP-48×75 | 75 | 45 | |||||

| JUWP-48×100 | 100 | 70 | |||||

| JUWP-48×125 | 48 | 125 | 95 | ||||

| JUWP-48×150 | 150 | 60 | |||||

| JUWP-75×75 | 75 | 45 | |||||

| JUWP-75×100 | 100 | 70 | 10 | 0.8 | M8 | ||

| JUWP-75×125 | 75 | 125 | 45 | 95 | |||

| JUWP-75×150 | 150 | 60 | |||||

| JUWP-100×100 | 100 | 70 | |||||

| JUWP-100×125 | 100 | 125 | 70 | 95 | |||

| JUWP-100×150 | 150 | 60 | |||||

| Unit (mm) | ||||||

| Standard No. | W | L | W, | ₂ | L | L2 |

| JTWP-28×75 | 75 | 45 | 15 | |||

| JTWP-28×100 | 100 | 50 | ||||

| JTWP-28×125 | 28 | 125 | 75 | 25 | ||

| JTWP-28×150 | 150 | 100 | ||||

| JTWP-38×75 | 75 | 45 | 15 | |||

| JTWP-38×100 | 100 | 50 | ||||

| JTWP-38×125 | 38 | 125 | 75 | 25 | ||

| JTWP-38×150 | 150 | 100 | ||||

| JTWP-48×75 | 75 | 45 | 15 | |||

| JTWP-48×100 | 100 | 50 | ||||

| JTWP-48×125 | 48 | 125 | 75 | |||

| JTWP-48×150 | 150 | 100 | 25 | |||

| JTWP-48×200 | 200 | 150 | ||||

| JTWP-58×75 | 75 | 45 | 15 | |||

| JTWP-58×100 | 58 | 100 | 50 | |||

| JTWP-58×150 | 150 | 100 | 25 | |||

| JTWP-75×75 | 75 | 25 | ||||

| JTWP-75×100 | 100 | 50 | ||||

| JTWP-75×125 | 75 | 125 | 75 | |||

| JTWP-75×150 | 150 | 100 | ||||

| JTWP-75×200 | 200 | 150 | ||||

| JTWP-100×100 | 100 | 50 | ||||

| JTWP-100×125 | 125 | 75 | ||||

| JTWP-100×150 | 100 | 150 | 25 | 100 | 25 | |

| JTWP-100×200 | 200 | 150 | ||||

| JTWP-100×250 | 250 | 50 | 200 | |||

| JTWP-125×150 | 150 | 100 | ||||

| JTWP-125×200 | 125 | 200 | 37.5 | 150 | ||

| JTWP-125×250 | 250 | 200 | ||||

| JTWP-150×150 | 150 | 100 | ||||

| JTWP-150×200 | 150 | 200 | 100 | 25 | 150 | |