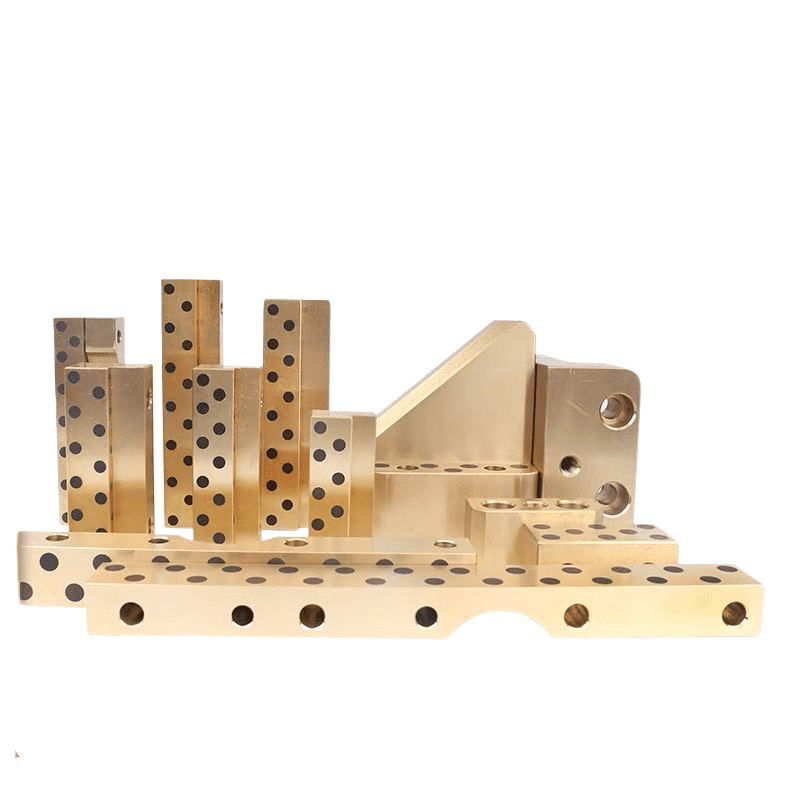

CuAl10Fe5Ni5-C Custom Groove Plate

CuAl10Fe5Ni5-C Custom Groove Plate

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

CuAl10Fe5Ni5-C Custom Groove Plate

Bronze Wear Plate (CuAl10Fe5Ni5-C)

Understanding Aluminum Bronze Grades and Bearing and Bushings Uses

Material Composition:

CuAl10Fe5Ni5, often referred to as a type of Nickel Aluminum Bronze (NAB), is a copper alloy that is primarily composed of copper, aluminum, iron, and nickel. The exact alloy designation you provided indicates:

- 10% Aluminum (Al)

- 5% Iron (Fe)

- 5% Nickel (Ni)

- The balance being primarily Copper (Cu)

CuAl10Fe5Ni5-C / CC333G Groove Plate: An Insight

CuAl10Fe5Ni5

In the realm of industrial applications, the importance of the right material cannot be overstated. The CuAl10Fe5Ni5-C alloy, also known as CC333G, stands out, especially when molded into groove plates. Let’s delve deeper into understanding this material and its significance when crafted into groove plates.

Bronze Wear Plate (CuAl10Fe5Ni5-C)

Material Composition:

- Copper (Cu): 80-89%

- Aluminum (Al): 9-11%

- Iron (Fe): 4.5-5.5%

- Nickel (Ni): 4.5-5.5%

- Other elements: Traces to balance the composition

Properties:

- High Strength: Excellent mechanical strength, suitable for high-load applications.

- Wear Resistance: Superior resistance to wear and galling, extending the service life of components.

- Corrosion Resistance: Good resistance to corrosion, especially in marine environments.

- Machinability: Can be machined to precise dimensions and custom groove patterns.

Applications:

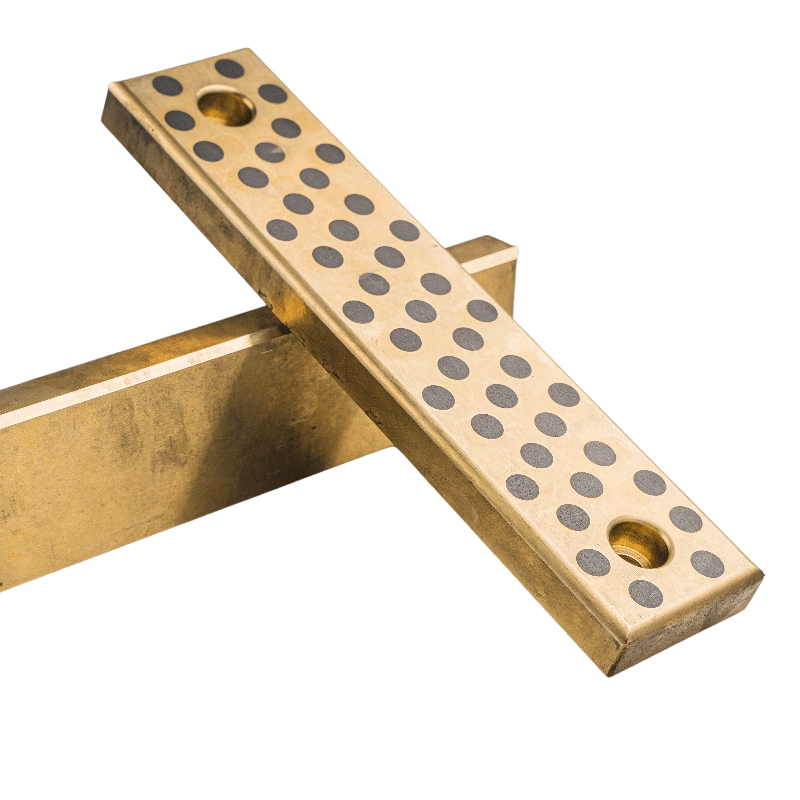

- Industrial Machinery: Used in various heavy-duty machinery parts, such as bushings, bearings, and sliding elements.

- Marine Equipment: Ideal for components exposed to seawater and other harsh environments.

- Construction Equipment: Utilized in high-stress and high-wear conditions.

Custom Groove Plates:

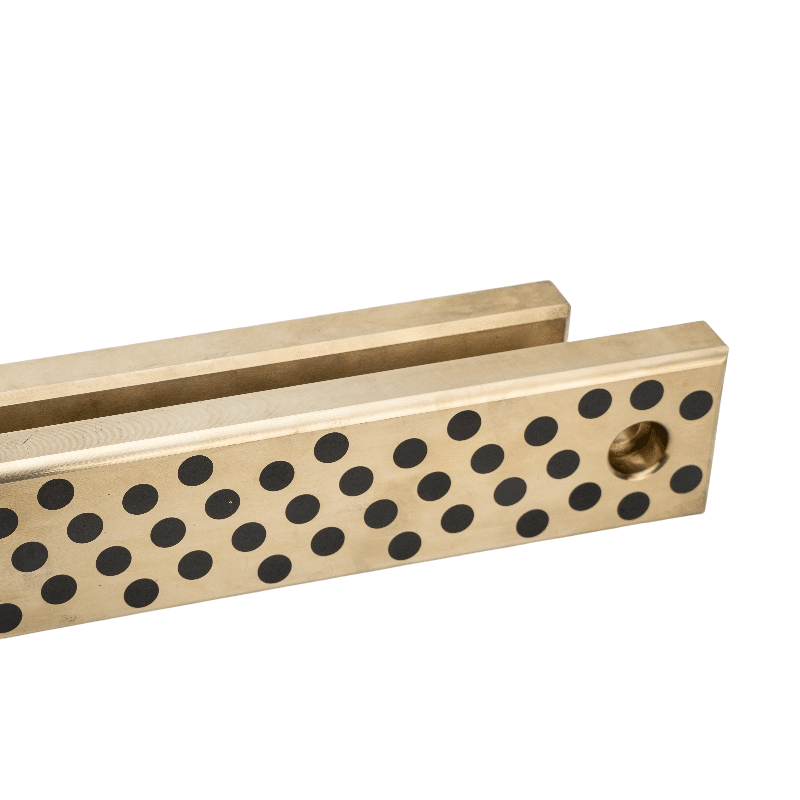

- Custom Grooves: Wear plates can be customized with specific groove patterns to enhance lubrication and reduce friction in specific applications.

- Precision Machining: Grooves are typically machined to exact specifications to meet the requirements of the application.

Ordering and Specification:

When ordering custom bronze wear plates, it’s essential to provide the following details:

- Dimensions: Length, width, and thickness of the wear plate.

- Groove Pattern: Detailed specifications of the groove pattern required.

- Quantity: Number of wear plates needed.

- Application Details: Information on the intended use to ensure the material and design meet the application requirements.

If you need further assistance with specific dimensions, groove patterns, or suppliers for bronze wear plates, feel free to provide more details.

What is a Groove Plate?

A groove plate typically refers to a metal plate that contains grooves or channels. These grooves can be designed for various purposes, such as aiding in lubrication, directing the flow of fluids, or assisting in the movement of parts. The design and specifications of these grooves can vary based on the application.

CuAl10Fe5Ni5-C / CC333G: A Quick Recap

The CC333G alloy is a unique blend of copper, aluminum, iron, and nickel. It offers:

- High Strength: With a tensile strength of 650 Mpa.

- Corrosion Resistance: Thanks to the presence of aluminum and nickel.

- Excellent Wear Resistance: Making it ideal for parts that face friction or movement.

- Machinability: Facilitating crafting intricate groove designs.

Benefits of CC333G Groove Plates:

- Durability: Given the inherent strength of the CC333G alloy, groove plates made from this material can withstand substantial stresses and loads.

- Enhanced Lubrication: The grooves can house lubricants, reducing friction and ensuring smoother operation of machinery.

- Corrosion Resistance: Especially useful in environments exposed to moisture or corrosive elements.

- Versatility: Suitable for various applications, from machinery to construction to transportation equipment.

- Customizability: The alloy’s machinability ensures that groove designs can be tailored to specific requirements.

Potential Applications:

Given their unique properties, CuAl10Fe5Ni5-C / CC333G groove plates find applications in:

- Hydraulic Systems: Directing the flow of hydraulic fluids.

- Machinery: As components where lubrication channels are required.

- Construction Equipment: In areas prone to wear and tear.

- Bearings and Bushings: Helping in consistent lubrication and reducing wear

Here’s a brief overview of the alloy and its properties:

Properties:

- Strength and Hardness: The addition of aluminum, iron, and nickel provides a combination of increased strength and hardness compared to pure copper or simpler bronze alloys.

- Corrosion Resistance: NABs, in general, have excellent resistance to seawater corrosion due to the formation of a tough adherent oxide film. This makes them particularly suitable for marine applications.

- Wear Resistance: The alloy’s hardness gives it good wear resistance, which is why it’s used in bearing applications.

- Ductility: Despite its hardness and strength, the alloy retains good ductility, which is a characteristic of many copper-based alloys.

- Antigalling: It has good resistance to galling, which can be beneficial in sliding applications.

Applications of CuAl10Fe5Ni5-C / CC333G Bronze Slide Plates

- Marine Hardware: Due to its excellent corrosion resistance, it’s often used for propellers, ship’s hardware, and other marine equipment.

- Bearings & Bushings: The wear resistance and anti-galling properties make it suitable for bearing plates, bushings, and other sliding applications.

- Valve Components: It’s used in the manufacture of valve components due to its combination of strength, wear resistance, and corrosion resistance.

- Pump Components: Similarly, the alloy is used in pump components that need to resist wear and corrosion.Thanks to its unique properties, the CuAl10Fe5Ni5-C / CC333G bronze slide plate finds applications in:

- Shipbuilding: For components that come into direct contact with seawater.

- Heavy Machinery: Where wear resistance and strength are paramount.

- Valve and Pump Components: Offering durability and efficient operation in demanding conditions.

- Bridge Bearings: Providing support and allowing controlled movement in bridge structures.

Weldability:

Welding of nickel aluminum bronzes can be challenging due to the risk of hot cracking, but with the right technique and filler materials, it can be done successfully.

Machinability:

It’s generally tougher to machine than pure copper but can be machined with the use of sharp tools and the right techniques.

Heat Treatment:

Certain heat treatments can be applied to improve the mechanical properties, such as solution annealing followed by quenching.

It’s worth noting that the specific properties and behavior of this alloy can vary depending on the exact composition, processing, and heat treatment. If you have any specific questions or need further information about CuAl10Fe5Ni5, please let me know!

Why Choose CuAl10Fe5Ni5-C / CC333G Over Other Bronzes?

- Durability: Its wear and corrosion resistance ensures a longer lifespan.

- Cost-Efficient: While the initial investment might be higher, the long-term benefits in terms of reduced replacements and maintenance make it cost-effective.

- Environmental Resistance: Especially suited for applications exposed to challenging environmental conditions, such as marine or industrial atmospheres.

Conclusion:

CuAl10Fe5Ni5-C / CC333G groove plates are a testament to the blend of innovative design and superior material. Their combination of strength, corrosion resistance, and wear resistance ensures that they deliver optimal performance in demanding industrial settings. If you’re on the lookout for reliable and high-performing groove plates, this material should be on your radar.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.