Customization of Quality CuAl10Ni5Fe4 Nickel Aluminum Bronze Rings: Industrial Precision Bushing Parts

CuAl10Ni5Fe4 aluminum bronze bearings are an excellent choice for applications requiring high strength, wear resistance, corrosion resistance, and self-lubricating properties. Their versatility and durability make them suitable for a wide range of industrial and marine applications.

Bushings, often unacknowledged, play a critical role in a wide array of industrial applications. From construction equipment and automotive to electrical systems and heavy machinery, bushings are pivotal to the smooth operation and long lifespan of these machines. Today, we will spotlight the customization of CuAl10Ni5Fe4 Nickel Aluminum Bronze Rings, a notable type of bushing that enhances the overall performance and durability of various industrial machinery.

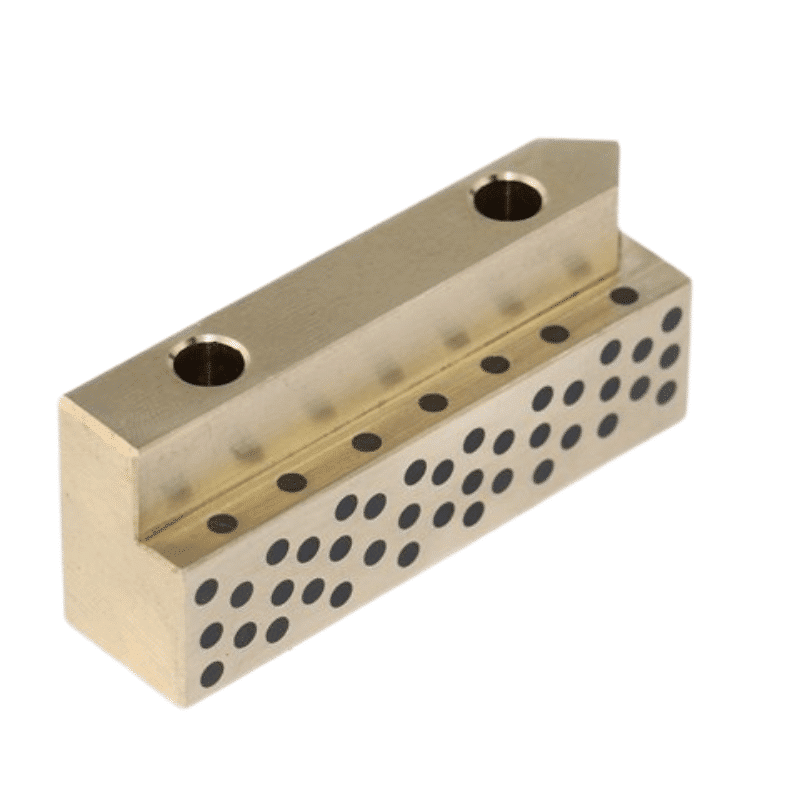

Nickel Aluminum Bronze Rings, selection of CuAl10Ni5Fe4 aluminum bronze bearings

specializing in Nickel Aluminum Bronze Ring Bushing

Nickel Aluminum Bronze, specifically the CuAl10Ni5Fe4 variant, is a high-strength alloy known for its excellent wear and corrosion resistance, good machinability, and exceptional toughness. These qualities make Nickel Aluminum Bronze Rings an ideal choice for demanding industrial applications where durability, wear resistance, and performance are paramount.

These bushings can handle high loads and harsh conditions while providing superior performance. They are also resistant to shocks, making them a popular choice in industries such as aerospace, marine, automotive, and heavy machinery.

Customization of CuAl10Ni5Fe4 Nickel Aluminum Bronze Rings

Customization is at the core of modern industrial manufacturing. Recognizing this, we offer tailor-made solutions for Nickel Aluminum Bronze Rings, ensuring they meet the unique requirements of your applications.

Our engineers work closely with clients to understand their specific needs. Factors such as the load, operating conditions, desired lifespan, and other specifics of the machinery are taken into account. The rings are then designed and manufactured with precision to match these requirements, while ensuring optimal performance.

We follow stringent quality control measures throughout the production process, right from selecting the raw materials to the final product. The aim is to deliver a product that not only fits the precise specifications but also meets the highest standards of quality and durability.

Centrifugal, Sand, Customized Bronze Bearings For All Your Industrial Needs

Custom Size and Material: Casting Solid Bronze Bearings

CuAl10Ni5Fe4 Nickel Aluminum Bronze in Bearing Bushings

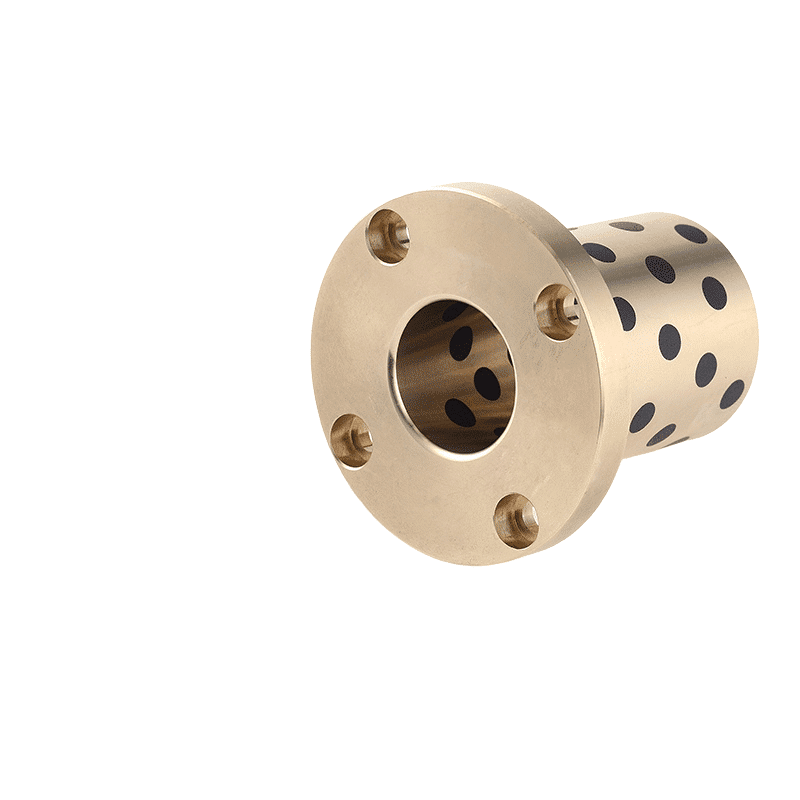

Considering the exceptional properties of CuAl10Ni5Fe4, it’s no surprise that it’s a preferred material for bearing bushings in various industries such as aerospace, marine, automotive, and heavy machinery.

The bearing bushings made from this alloy can handle high loads and harsh conditions while providing superior performance. They offer a combination of high strength, excellent wear resistance, and low friction, making them an ideal solution for bearings in demanding industrial applications.

Furthermore, the excellent machinability of CuAl10Ni5Fe4 allows for the production of bushings with high precision and tight tolerances, enhancing their performance in various applications.

Conclusion

The unique combination of properties exhibited by the CuAl10Ni5Fe4 Nickel Aluminum Bronze alloy makes it a superior material for manufacturing bearing bushings. Its exceptional wear resistance, strength, toughness, and good machinability ensure that bearing bushings made from this material will deliver reliable and long-lasting performance, even under the most challenging operating conditions.

Whether you’re in the marine, aerospace, automotive, or heavy machinery industry, bearing bushings made from CuAl10Ni5Fe4 can contribute significantly to the efficient and smooth operation of your equipment. To learn more about this remarkable material or to discuss your specific bushing requirements, don’t hesitate to get in touch with us.

Bronze Wheels: An Insight into Machined Parts

Industrial components are made from a myriad of materials, each selected for their unique properties that enhance the function and longevity of machinery. One such material is bronze. Known for its durability, wear resistance, and machinability, bronze has long been a popular choice in the fabrication of several machine components, including wheels. In this blog post, we delve into the world of bronze wheels and their role as machined parts in various industries.

Bronze as a Choice Material

Bronze, an alloy predominantly composed of copper and tin, is highly valued in industrial applications for its unique properties. These include:

- Corrosion Resistance: Bronze offers excellent resistance to corrosion, making it ideal for components used in challenging environments where they may be exposed to elements that cause corrosion.

- Wear Resistance: Due to its superior wear resistance, bronze ensures a longer lifespan for machine parts, including wheels, which are prone to wear and tear.

- Machinability: Bronze alloys are easy to machine, making them ideal for manufacturing complex components like wheels with precision and efficiency.

- Thermal Conductivity: Bronze is a good conductor of heat, which aids in preventing overheating in machinery, particularly in parts like wheels that often generate significant heat during operation.

Bronze Wheels as Machined Parts

Bronze wheels are often used in heavy-duty applications because of their durability and strength. They are typically found in heavy machinery, conveyor systems, and other applications where high load capacity and impact resistance are required.

Machining bronze wheels is a precise process that requires advanced technology and skilled workmanship. The process begins with the selection of the right bronze alloy, based on the specific requirements of the application. The alloy is then cast or extruded into a rough shape before it undergoes several machining processes to achieve the final, intricate design of the wheel.

These processes may include turning, milling, and grinding to ensure the wheel’s dimensions, surface finish, and other critical specifications meet the exact requirements. Finally, the machined bronze wheel undergoes rigorous testing to ensure it meets quality standards and can withstand the demands of its intended application.

Conclusion

Bronze wheels play a critical role in various industries, thanks to the excellent properties of the bronze alloys from which they are made. Their durability, wear resistance, and ability to withstand harsh conditions make them a reliable component in heavy machinery and other industrial applications.

By understanding the importance of these machined parts, we strive to offer high-quality bronze wheels that meet the unique needs of our customers. With a strong focus on precision and quality, our bronze wheels are designed to improve the efficiency and longevity of your machinery. Please feel free to reach out to us for more information or to discuss your specific requirements.

CuAl10Ni5Fe4 Bronze Wheel and Worm Gear Bush Machining: Customizing Quality Components

Industrial machinery heavily relies on robust and precisely machined parts to ensure their efficient operation and longevity. Components such as wheels, worm gear bushings, and custom machined bronze rings play vital roles in many mechanical systems. This blog post will focus on the use of the CuAl10Ni5Fe4 bronze variant in manufacturing these crucial parts, highlighting the customization process and the value they bring to various industries.

CuAl10Ni5Fe4 Bronze: A Robust Material for Wheel and Worm Gear Bush

CuAl10Ni5Fe4, a high-strength alloy of Nickel Aluminum Bronze, is known for its excellent wear resistance, superior strength, and impressive corrosion resistance, making it an excellent choice for heavy-duty industrial components. Its high load bearing capacity, good machinability, and excellent heat dissipation properties further make it an ideal material for parts like wheels and worm gear bushings.

Bronze Wheels

Bronze wheels made from CuAl10Ni5Fe4 are highly durable and capable of withstanding extreme conditions. The alloy’s high strength and wear resistance enable these wheels to handle significant loads and resist wear, recognized to extended operational life and reduced maintenance needs.

The manufacturing process involves precise machining techniques to ensure the wheels meet the required dimensions and specifications. We use advanced machining technologies and follow strict quality control procedures to ensure the wheels’ quality, durability, and performance.

Worm Gear Bushings

Worm gear bushings, often subjected to high loads and friction, benefit greatly from the properties of CuAl10Ni5Fe4 bronze. The superior wear resistance and strength of the alloy result in bushings that can endure heavy loads and high-speed operations without compromising their performance or integrity. The machinability of the alloy also allows for precise manufacturing of the bushings to fit the specific needs of the machinery.

Custom Machined Bronze Rings

Custom machined bronze rings, much like wheels and bushings, need to be resilient, durable, and precise. The CuAl10Ni5Fe4 bronze is an excellent choice for these rings as well, owing to its strength, corrosion resistance, and machinability. Our team works closely with clients to understand their unique requirements and create custom rings that align perfectly with their operational needs.

Conclusion

The role of robust materials like CuAl10Ni5Fe4 bronze cannot be overstated in the world of industrial machinery. Its unique properties make it an ideal choice for components like wheels, worm gear bushings, and custom machined rings. By offering high-quality and precisely machined parts, we aim to enhance the efficiency and longevity of your machinery, resulting in more effective operations and reduced downtime.

Should you require more information about our CuAl10Ni5Fe4 bronze wheels, worm gear bushings, or custom machined bronze rings, or if you’d like to discuss your specific needs, please do not hesitate to reach out to us.

Implementing Bronze Bushings in Bridge and Infrastructure Projects

Unnoticed but vital, bushings play an essential role in the durability and longevity of critical structures like bridges and dams. As pivotal load-bearers, these components withstand considerable weights while providing essential wear surfaces in environments where long-lasting performance is not just desirable but critical. To meet these exacting demands, our superior bronze rings and components utilize our profound expertise in bronze alloy engineering.

The locations where these bushings are installed often expose them to corrosion from salt and other water-borne minerals and particles. Despite these harsh conditions, they must deliver flawless performance over many decades. Through the use of the centrifugal casting process, we can offer a superior product that caters to every application, small or large, accommodating sizes exceeding 15′ in diameter. For projects demanding corrosion resistance, such as lock and dam applications, we offer net-shaped chain link components crafted from continuous cast nickel aluminum bronze material.

Looking for Assistance with a New Project?

Are you ready to explore new possibilities? Let’s redefine the boundaries of what’s possible, together. Reach out to our team of metal experts for your project needs.

Contact Us

Our Sales Engineers are not just industry specialists—they’re also well-versed in the needs and nuances of their respective markets. Through regular customer satisfaction research, we strive to understand not just our own business but also the critical issues facing our clients and their industries. Your success drives our success.

Explore All Markets

Browse Our Solutions Gallery

Viiplus is trusted by companies worldwide, crafting components that thrive in high-heat, high-wear, and high-corrosion environments—from the ocean depths to the surface of Mars. To explore a diverse range of solutions completed using our bronze bushing, click the link below.

View Solutions Gallery

Speak with the Metal Experts

Contact Us

Whether you have questions about our products or need technical advice, our team of metal experts is ready to assist. Let’s achieve success together.

Unleashing the Power of Bronze: Comprehensive Bronze Bearing and Bushing Solutions

At the heart of countless industrial applications, bronze bushings and bearings hold the key to ensuring smooth, efficient operation and longevity. Whether it’s precision bronze bushings, CuAl10NiFe4 bronze bushes, CuAl10Ni graphite aluminum bronze bearings, or self-lubricating graphite bushings, each variant has unique characteristics that make it an invaluable component in various settings. In this blog, we’ll explore the diverse range of bronze bushings and bearings we offer and their applicability across industries.

Versatility in Bronze Bushings and Bearings

Our comprehensive selection caters to the specific needs of diverse industries. Among our offerings:

- CuAl10NiFe4 Bronze Bush and CuAL10Ni5Fe4 Nickel Aluminum Bronze Bearing: These variants exhibit excellent wear resistance, superior strength, and impressive corrosion resistance, making them suitable for heavy-duty applications.

- CuAl10Ni Graphite Aluminum Bronze Bearing and CuAl10Fe5Ni5 Aluminum Bronze Bushing: These bearings and bushings are popular for their high load-bearing capacity, excellent heat dissipation properties, and self-lubricating capabilities. They’re perfect for high friction and high-load applications.

- Casting Bronze Bearing (C95800, CuAl10Ni): These bearings, made from specific bronze alloys, offer excellent machinability, durability, and resistance to wear and corrosion.

- JDB Aluminum Bronze Bushings (CuAl10Fe5Ni / CuAl10Ni): Renowned for their exceptional strength and corrosion resistance, these bushings are suitable for a broad range of applications.

- Bronze Sleeve Bushings in Various Materials: We offer a wide array of sleeve bushings made from different materials, tailored to meet specific operational needs.

- Spherical Plain Bearings CuAl10Ni Graphite Aluminum Bronze Bearing: These bearings, designed to handle radial and axial loads, are made from robust and corrosion-resistant bronze alloys.

Efficient Delivery for a Variety of Industries

We work diligently to ensure the components you need are available when you need them. We pride ourselves on our ability to accommodate small minimum orders, offer competitive pricing, and provide comprehensive engineering and account management support. Our online parts configurator makes it easier than ever to find the right component for your specific needs.

Custom Sizes and a Free Quote

We offer an extensive range of both inch and metric sizes, including bespoke bushing sizes to meet your unique requirements. Ready to learn more? Contact us today for a free quote or sample.

We’re here to help you find the right bronze bushing or bearing solution for your needs. Whether you require a precision bronze bushing, a self-lubricating graphite bushing, or a nickel aluminum bronze bearing, we have the knowledge and expertise to assist. Get in touch with us to learn more.

Your Ultimate Source for Plain Bearings and Semi-Finished Bronze Products

When it comes to designing and building machinery that lasts, the choice of components can make all the difference. Plain bearings and semi-finished bronze products, with their unique properties and advantages, play a critical role in many industrial and manufacturing applications. Let’s delve into the array of products we offer and how they can fit into your projects.

Plain Bearings

Plain bearings, also known as bushings, are simple components that provide a bearing surface for rotary applications. Designed to reduce friction and wear, they’re key to the efficient and smooth operation of various types of machinery.

Bronze Plain Bearings

When it comes to durability and longevity, bronze plain bearings are hard to beat. Known for their excellent load-carrying capacity and corrosion resistance, these bearings are particularly well-suited to applications involving heavy loads and harsh environments.

Semi-Finished Bronze Products

We offer a wide range of semi-finished bronze products that can be further machined and treated to meet your specific requirements. These products offer flexibility in the manufacturing process, allowing you to create custom components that perfectly match your specifications.

Among the semi-finished products we offer, you’ll find:

- Brass: A versatile alloy of copper and zinc, brass offers good strength, excellent corrosion resistance, and superior machinability.

- Special Brass: Designed for specific applications, special brass alloys offer properties such as enhanced strength, improved resistance to wear and corrosion, or increased thermal conductivity.

- Phosphor Bronze: Known for its resilience, high fatigue resistance, and excellent electrical conductivity, phosphor bronze is commonly used in electrical contacts, springs, and various types of bearings.

- Aluminum Bronze: These alloys combine strength and excellent corrosion resistance, making them ideal for heavy-duty applications in harsh environments.

- High Copper Alloys: With their excellent electrical and thermal conductivity, high copper alloys are ideal for applications such as electrical connectors and heat sinks.

- Gunmetal: An alloy of copper, tin, and zinc, gunmetal offers good strength, resistance to wear and corrosion, and excellent machinability.

- Copper: With its excellent electrical and thermal conductivity, copper is often used in electrical applications and heat transfer equipment.

- Cast Bronze (Copper-Tin): Offering superior strength and corrosion resistance, cast bronze is ideal for heavy-duty applications such as gears and bearings.

- Cast High Lead Bronze: This alloy provides exceptional wear resistance and excellent machinability, making it suitable for bearings and other wear-resistant applications.

At our facility, we are committed to providing the highest quality plain bearings and semi-finished bronze products. Contact us today to learn more about our product offerings and how we can assist you with your project needs.