Revolutionizing Mining Operations:

Bronze Bushes with Graphite Inserts as Tower Mill Intermediate Shaft Bush Replacements

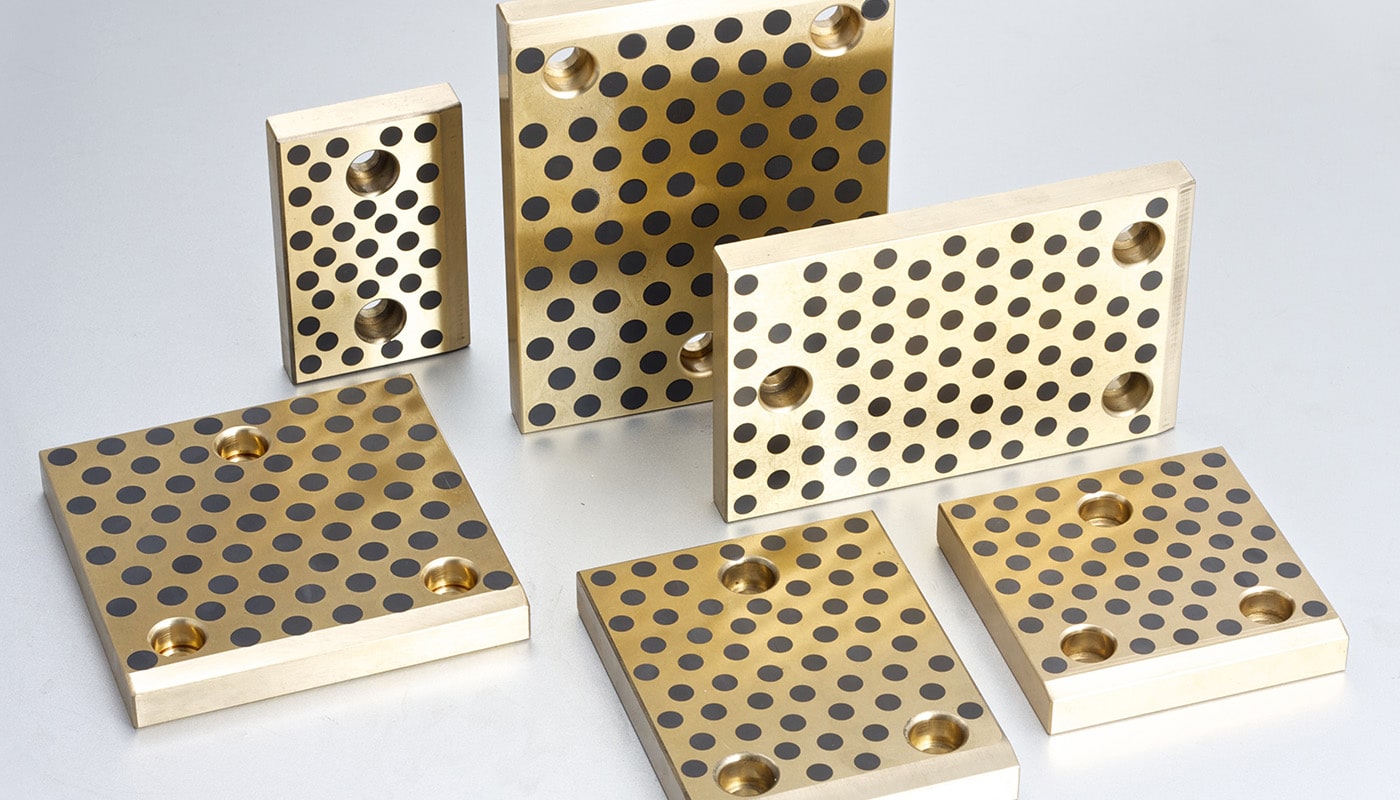

BRONZE WEAR PLATE, Custom Made Sliding/Wear Plates

Graphite slide plates

Ground Bronze Wear Plates from Spidoni not only offer resilience and durability but also versatility to fit a myriad of industrial needs. From mining and shipbuilding to power transmission and the oil and gas sectors, these wear plates are designed to provide reliable service. And with the added advantage of graphite plugs, users can expect even longer wear life and consistent performance. For more detailed information or assistance in choosing the right wear plate for your application, don’t hesitate to reach out to Spidoni’s expert sales team. They are equipped to guide you through every step of the process, ensuring that your operational needs are met efficiently and effectively. Graphite slide plates are suitable for environments that require durability under extreme temperatures, often replacing PTFE (Polytetrafluoroethylene), 25% glass-filled slide plates. These graphite plates are widely used in various industrial applications that involve sliding movements, heat, and high pressure.

Product Quality Index

Energy Generation

Slide Plates Oilless Bronze plate with Solid Graphite Inserts

Slide plates, bronze plates, and custom products all play crucial roles in various industries, especially where heavy machinery and high friction are involved. These components often have custom specifications to match the unique requirements of different applications.

Slide Bronze Plate: Bronze Wear Plates Graphite Inserts Replacements

Graphite Inserts characteristics include:

Ground Bronze Wear Plates: A Guide to Graphite Plugged Wear Plates

Spidoni’s Ground Bronze Wear Plates are a reliable choice for durable and efficient wear solutions. When embedded with graphite plugs, these plates provide enhanced longevity and low maintenance, making them suitable for various industrial applications. Here’s an overview of the specifications, training, deployment, and the significance of quarterly check-ups.

Basic Plan:

1. Wear Plate Specifications:

Offerings: Spidoni’s wear plates are available up to 14″ wide and 144″ long, with widths extendable up to 20″ for special requirements.

Alloys Available: Customers can select from Bearing Bronze/CDA 932, Aluminum Bronze/CDA 954, and Manganese Bronze/CDA 863.

Grinding Accuracy: Spidoni guarantees a grinding thickness accuracy of +/- .002.

2. Secondary Processing:

Cutting & Grinding: Plates can be saw-cut up to 190″, with blunt grinding available up to 108″, including square and rectangular options, facilitated by our 5 in-house saws.

Graphite Plugging: Our self-lubricating graphite plugs enhance lubrication and wear resistance, ensuring smoother operations and longer wear plate life.

Training Setup:

Spidoni provides training sessions for those unfamiliar with wear plate installation or maintenance, covering:

Installation techniques.

Maintenance practices.

Benefits and applications of graphite plugs.

Basic troubleshooting.

Deployment:

After selecting an alloy and completing training, deployment includes:

Positioning and securing the wear plate properly.

Placing graphite plugs adequately (if chosen).

Testing for alignment and functionality.

Monitoring wear to schedule maintenance or replacements as needed.

Quarterly Check-Up:

Regular maintenance is vital for optimal performance and longevity. We recommend:

Inspecting for signs of unusual wear or damage.

Checking the functionality of graphite plugs and replacing them if necessary.

Adjusting or realigning plates if movement occurs.

Scheduling replacements or upgrades based on the wear plate’s condition.

Graphite Inserts characteristics include:

Bronze Plates:Bronze plates are highly durable and possess excellent load-bearing capacity. Resistant to wear and corrosion, they are ideal for high-stress applications and can enhance the strength and longevity of slide plates.

Exceptional Load Capacity: Bronze plates can carry heavy loads without deformation or breakage.

High-Temperature Resistance: The graphite content offers excellent thermal resistance, enabling effective operation under high heat conditions.

Self-Lubricating: Graphite provides self-lubrication, reducing friction and wear on moving parts.

Durability: These plates are designed to endure wear and tear during prolonged heavy use.

Reduced Maintenance: The self-lubricating feature minimizes the need for routine lubrication, lowering maintenance time and costs.

Graphite Bronze Wear Plate Slide Plates C954 Bronze

Slide plates are components designed to offer a low-friction surface for linear movement, typically consisting of an upper plate that slides freely over a lower plate. They can be fabricated from various materials such as graphite, bronze, and PTFE, each offering unique benefits for specific applications.

We can create slide plates to any specification.

Our Graphite Bronze Wear Plate Slide Plates, made with Oilless Bronze Bushes and Solid Graphite Inserts using C954 Bronze, are highly durable and suited for high-heat and high-pressure environments. The graphite provides excellent thermal resistance and reduced friction, while the robust C954 Aluminum Bronze enhances the plates’ load-bearing capacity, enabling them to withstand substantial loads.

Oilless Bronze Bush with Solid Graphite Inserts

These bushings are self-lubricating bearings ideal for heavy load applications where traditional lubrication is impractical. C954 bronze offers high strength and excellent load-bearing capacity, ensuring durability.

Solid graphite inserts provide a consistent, low-friction surface that minimizes wear. As the bearing moves, graphite rises to the surface, forming a film that reduces friction and extends the bearing’s lifespan.

In conclusion, Graphite Bronze Wear Plate Slide Plates and Oilless Bronze Bushings with Solid Graphite Inserts are high-performance components designed for high-heat and high-pressure environments. Their self-lubricating properties lower maintenance needs, prolong system life, and enhance overall efficiency.

Oilless Custom Products

Custom products are specifically designed to meet the unique requirements of various applications, ensuring an ideal fit and optimal performance. These include bespoke slide plates, bronze plates, bushings, bearings, and other industrial components.

For instance, Graphite Bronze Wear Plate Slide Plates can be tailored to the precise dimensions and performance criteria of a given application. Likewise, Oilless Bronze Bushes with Solid Graphite Inserts can be customized for specific dimensions and load-bearing capacities.

In summary, whether slide plates, bronze plates, or other custom components, each is crucial for efficient operations across industries. Customization ensures these parts meet application needs, enhancing performance, reducing maintenance, and extending the lifespan of machinery and equipment.

Pipe Bronze Wear Slide Plates

Pipe bronze wear slide plates are engineered to enhance movement and minimize friction in piping systems. Made from durable bronze, they resist wear and corrosion, making them ideal for high-stress environments. These plates effectively support heavy loads, reducing pipe wear and extending their lifespan while lowering maintenance costs.

Many slide plates feature graphite inserts, which further improve performance by offering a self-lubricating surface. This reduces friction, leading to smoother operations and less pipe wear.

Bronze bearings are also commonly used in machinery for their excellent load-bearing capacity and wear resistance. Their durability and corrosion resistance make them a dependable choice for diverse applications.

Similar to slide plates, bronze bearings may incorporate graphite inserts for self-lubrication, beneficial in environments where regular lubrication is impractical. These inserts provide a consistently low-friction surface that minimizes wear, enhances the bearing’s lifespan, and boosts overall system efficiency.

Recent technological advances have improved the production of high-quality bronze components like wear slide plates and bearings, designed for superior performance in demanding conditions. The addition of graphite enhances their durability and efficiency by providing a self-lubricating surface, ultimately reducing maintenance costs and extending the lifespan of machinery and equipment.

Bronze Slide b earring & wear plate with Graphite Inserts

In contrast to PTFE, which can degrade under high heat, graphite has exceptional thermal resistance and stability. This makes it an ideal material for use in applications that may expose the component to intense heat. The graphite provides a low coefficient of friction, reducing wear and tear and increasing the lifespan of the equipment.

In a mining environment, machinery and equipment are exposed to intense wear and tear due to the harsh conditions, heavy loads, and continuous operation. Regular maintenance and replacement of worn-out parts are crucial to keep the operations running smoothly and efficiently. One such component that often requires replacement is the wear plate.

In such applications, Graphite Bronze Wear Plate Slide Plates can be an excellent choice for replacement. These plates, made from durable materials like bronze and graphite, are designed to withstand the harsh conditions commonly found in mining environments.

Oilless Self-Lubricating Bronze Wear Plate

Graphite bronze wear plates, in particular, combine the high load capacity of bronze and the excellent self-lubricating properties of graphite. They are thus perfect for high-pressure, high-heat systems. These slide plates can handle a more significant amount of stress, have a longer lifespan, and require less maintenance compared to other types of slide plates.

Graphite Inserts in Wear Plates

Incorporating graphite inserts into wear plates significantly enhances their durability and performance under heavy loads and high-temperature conditions. Graphite, with its exceptional self-lubricating properties, provides a low friction surface that reduces wear and tear, minimizes heat generation, and extends the operational lifespan of the equipment.

C954 Bronze Wear Plate

Moreover, graphite inserts can handle substantial pressure and continuous sliding motions, making them ideal for mining equipment that operates non-stop. The bronze component of these plates, particularly if made from C954 bronze, further adds to the strength and durability. C954 bronze is highly resistant to wear and corrosion, making it suitable for use in mining applications.

Bronze Wear Plate

To summarize, Graphite Bronze Wear Plate Slide Plates are an excellent replacement for wear plates in a mining environment due to their enhanced durability, resistance to high temperatures and pressures, and self-lubricating properties. The incorporation of graphite inserts in these plates significantly extends their operational lifespan, reduces maintenance needs, and contributes to overall operational efficiency.

BRONZE OILLESS BEARING MATERIAL

Special parts request