Carbon Graphite Bearings Bushing: High Performance, Quality, and Maintenance-Free Solution for Diverse Industries

Carbon Bearing Bronze Alloy Bush: Graphite-Prompt Lead Times, Competitive Pricing, and Small Minimum Order Quantity.

Durable and Versatile

Brass alloy is chosen for its excellent mechanical properties, including high strength, corrosion resistance, and thermal conductivity. The combination of these characteristics with self-lubricating properties makes self-lubricated brass alloy bushings highly durable and versatile. They can withstand demanding operating conditions, such as high speeds, oscillating movements, and varying temperatures. Additionally, the bushings are suitable for a wide range of applications, including automotive, industrial machinery, appliances, and more.

Noise Reduction

Friction and wear in bushing applications can generate unwanted noise and vibrations. Self-lubricated brass alloy bushings help mitigate this issue by reducing friction and minimizing metal-to-metal contact. The self-lubricating film acts as a cushion, absorbing vibrations and dampening noise. This feature is especially advantageous in applications where quiet operation is essential, such as precision machinery or equipment used in noise-sensitive environments.

24/7 Support

Self-lubricated brass alloy bushings offer significant advantages in terms of performance, reliability, and reduced maintenance requirements. By incorporating self-lubricating properties into a durable brass alloy, these bushings minimize friction, wear, and noise, ensuring smooth operation and extended service life. Their versatility makes them suitable for various industries and applications. Whether you require reliable components for automotive systems, industrial machinery, or other equipment, self-lubricated brass alloy bushings provide an excellent solution to enhance performance and reduce maintenance costs.

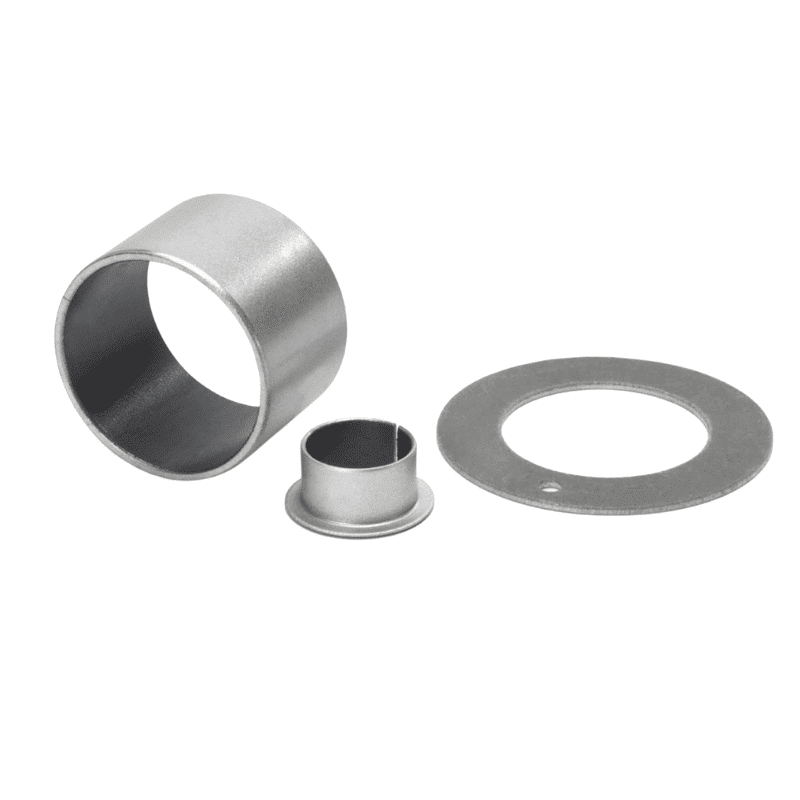

Carbon bearing bronze alloy bushes, self-lubricating

Carbon bearing bronze alloy bushes are vital components in various industries, providing excellent wear resistance and load-bearing capabilities. When sourcing these essential components, it is crucial to consider factors such as lead times, pricing, and minimum order quantities. In this article, we will explore the advantages of carbon bearing bronze alloy bushes with graphite, emphasizing their prompt lead times, competitive pricing, and small minimum order quantities.

Carbon Bronze Graphite Bushings Prompt Lead Times:

Time is of the essence in today’s fast-paced industries, where production schedules and project timelines are constantly evolving. Carbon bearing bronze alloy bushes with graphite offer exceptional lead times, ensuring that you receive your orders in a timely manner. By leveraging advanced manufacturing processes and efficient production techniques, suppliers can fulfill orders promptly, minimizing downtime and allowing you to meet your project deadlines.

Carbon bronze graphite bushings and bearings offer exceptional performance, versatility, and reliability for various industries. By partnering with a trusted manufacturer specializing in these components, you gain access to high-quality products, customization options, expert guidance, and timely delivery. Investing in top-notch carbon bronze graphite bushings and bearings will enhance the efficiency and longevity of your machinery and equipment, ultimately contributing to the success of your operations.

Bearring Bushing

Carbon Graphite Bronze Bearings & Bushings Competitive Pricing

Pricing is a crucial aspect when choosing suppliers for carbon bearing bronze alloy bushes. These components are widely used across industries, and finding a supplier that offers competitive pricing can significantly impact your overall costs. Carbon bearing bronze alloy bushes with graphite provide an excellent balance between performance and affordability. By incorporating graphite into the alloy, the material’s properties are enhanced, allowing for a reduction in overall costs without compromising quality. Suppliers who specialize in these alloys can offer competitive pricing options, helping you optimize your budget without sacrificing reliability.

Self-Lubricating Properties: The self-lubricating properties of brass alloy bushings offer several advantages. Firstly, they eliminate the need for external lubrication, reducing maintenance costs and labor. This is particularly beneficial in hard-to-reach or inaccessible areas where regular lubrication would be challenging. Secondly, the self-lubricating feature ensures consistent and reliable lubrication over time, even in applications with high temperatures, heavy loads, or intermittent operation. As a result, the bushings maintain their performance and protect the mating surfaces from excessive wear and damage.

Bronze Bearing Bushing

Bearing Bronze Alloy Bushes With Graphite Small Minimum Order Quantity

For businesses of all sizes, managing inventory and optimizing cash flow are essential. Carbon bearing bronze alloy bushes with graphite are available with small minimum order quantities, allowing you to procure the required quantity without being burdened by excess inventory. This flexibility is particularly beneficial for small to medium-sized enterprises or projects with specific demands. By partnering with suppliers who offer small minimum order quantities, you can efficiently manage your inventory, reduce storage costs, and ensure a consistent supply of these crucial components.

Reduced Noise and Vibration:

Friction and vibrations in bushing applications can result in unwanted noise and disturbance. Graphite bearings bushings effectively mitigate these issues, as they possess excellent vibration-damping properties. The self-lubricating graphite layer acts as a cushion, absorbing vibrations and reducing noise generation during operation. This feature is particularly beneficial in precision machinery, equipment, and applications that require quiet and smooth performance.

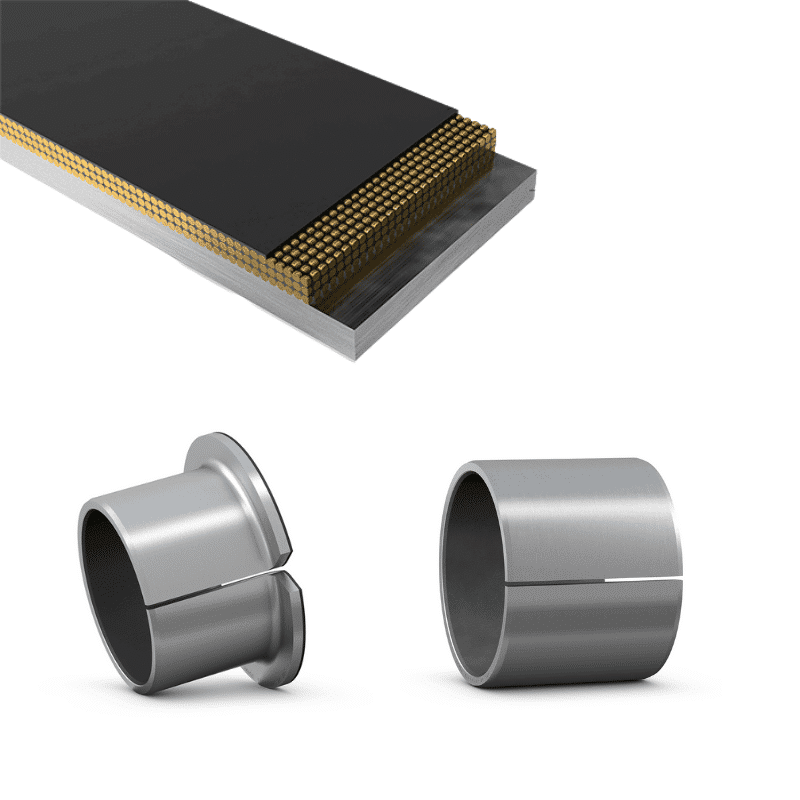

carbon steel backed ptfe composite bearing

Sourcing carbon steel bearing bronze composite ptfe bushes

When sourcing bushings for demanding applications, carbon steel bearing bronze composite PTFE (polytetrafluoroethylene) bushes have become a popular choice. These bushes combine the strength and durability of carbon steel and bearing bronze with the excellent low-friction properties of PTFE. In this article, we will explore the advantages of sourcing carbon steel bearing bronze composite PTFE bushes and their ability to enhance performance and durability in various applications.

Carbon steel bearing bronze composite PTFE bushes offer significant advantages in terms of performance, durability, and versatility. The combination of carbon steel, bearing bronze, and PTFE provides enhanced strength, reduced friction, and self-lubricating properties. These bushes excel in demanding applications, ensuring reliable operation, extended service life, and reduced maintenance requirements. With the availability of reputable suppliers, sourcing carbon steel bearing bronze composite PTFE bushes has become more accessible, enabling industries to enhance their equipment’s performance and durability. Sourcing carbon steel bearing bronze composite PTFE bushes has become increasingly convenient due to the availability of reputable suppliers and distributors. These suppliers specialize in providing high-quality bushings that meet industry standards and specifications. They offer a wide range of sizes and configurations, ensuring compatibility with different shafts and housings. Working with experienced suppliers allows for ease of sourcing, ensuring reliable and timely delivery of the required bushes to meet project or production needs.

Expert Bushings and Support:

Carbon Bronze Graphite Bushings & Bearings Manufacturer

When sourcing carbon bearing bronze alloy bushes with graphite, considering lead times, pricing, and minimum order quantities is paramount. These factors can significantly impact the efficiency and cost-effectiveness of your operations. By choosing suppliers that offer prompt lead times, competitive pricing, and small minimum order quantities, you can streamline your procurement process, optimize costs, and ensure a steady supply of high-quality carbon bearing bronze alloy bushes with graphite. Embracing these advantages will enable you to meet project deadlines, enhance your bottom line, and maintain a competitive edge in your industry. In various industries, the demand for reliable and durable bushings and bearings is ever-present. Carbon bronze graphite bushings and bearings have emerged as popular choices due to their exceptional performance and versatility. This article highlights the significance of carbon bronze graphite bushings and bearings and the benefits of partnering with a trusted manufacturer specializing in their production.

Choosing the right carbon bronze graphite bushings and bearings can be a complex process. A reliable manufacturer provides expert guidance and support, leveraging their knowledge and experience to assist you in selecting the most suitable components for your application. They understand the challenges and demands of various industries and can offer valuable insights to ensure optimal performance and longevity of the bushings and bearings.

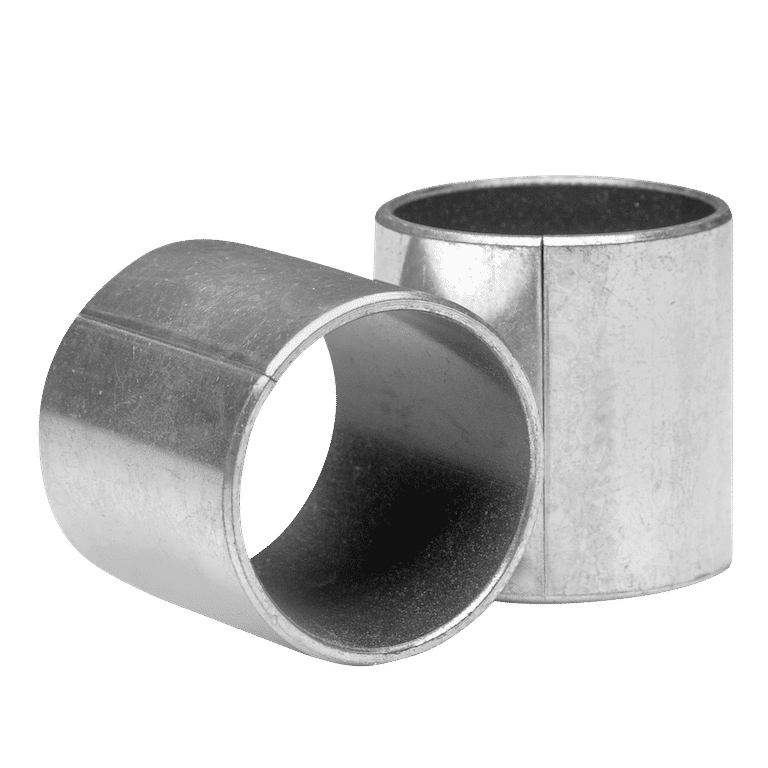

Carbon Bronze Graphite Bushings & Bearings

Partnering with a reputable carbon bronze graphite bushings and bearings manufacturer ensures that you receive high-quality products. Such manufacturers utilize advanced manufacturing processes, including precision machining and state-of-the-art technologies, to create components that meet stringent industry standards. From material selection to production, these manufacturers prioritize quality control measures, ensuring that each bushing and bearing delivers reliable performance and longevity.

Timely Delivery and Supportive Services:

A reputable manufacturer values prompt delivery and customer satisfaction. They maintain efficient production processes and robust supply chain management to ensure timely delivery of your orders. Additionally, they provide comprehensive customer support, addressing inquiries, offering technical assistance, and resolving any issues that may arise during the procurement process or during product usage.