Bronze Glidlager: A Reliable Solution for Efficient Friction Management

In the world of mechanical engineering and industrial applications, efficient friction management is essential for smooth operations and prolonged equipment lifespan. Among the various solutions available, bronze glidlager (also known as bronze plain bearings or bronze sleeve bearings) stand out as a reliable and versatile choice. This article aims to explore the characteristics, advantages, and applications of bronze glidlager, shedding light on why they continue to be a popular choice for friction management in diverse industries.

Experience

Self-Lubrication Properties: CuSn8P glidlager have inherent self-lubricating properties due to the phosphor bronze composition. This feature significantly reduces the need for additional external lubrication, making them a low-maintenance solution for friction management.

Bronze Bearing Solutions

Superior Wear Resistance: CuSn8P glidlager exhibit exceptional wear resistance, making them suitable for demanding applications. The phosphor bronze alloy, with its inherent hardness and strength, ensures extended service life, even in high-load and high-friction environments.

24/7 Support

Low Friction Coefficient: CuSn8P glidlager offer a low friction coefficient, resulting in reduced energy consumption and improved efficiency. The smooth surface and self-lubricating properties of phosphor bronze contribute to minimal friction, enabling smooth operation and minimizing wear and tear.

Understanding Bronze Glidlager cusn8 material

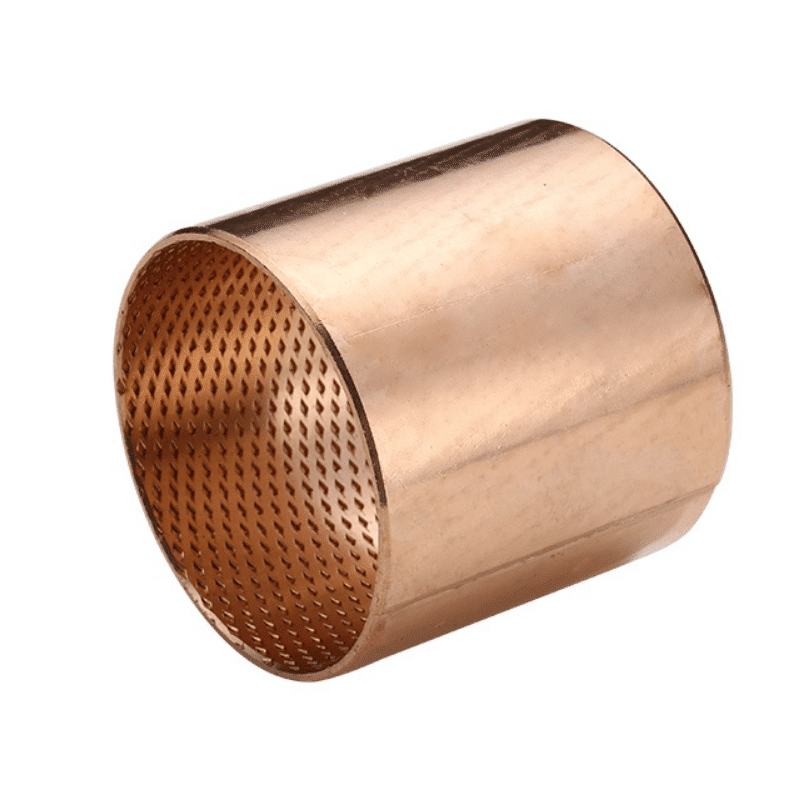

Bronze glidlager are self-lubricating bearings composed primarily of bronze, a versatile alloy consisting of copper and tin. The composition can vary, with additional elements like zinc, lead, or aluminum included to enhance specific properties. These bearings typically have a cylindrical shape with a hole in the center to accommodate the shaft.

Versatile Applications: CuSn8P glidlager find applications across a wide range of industries. They are commonly used in automotive components, machinery, appliances, hydraulic systems, and many other mechanical systems that require reliable friction management. The versatility of CuSn8P glidlager makes them a preferred choice in numerous industrial sectors.

Advantages of Bronze Glidlager:

Self-Lubrication: One of the primary advantages of bronze glidlager is their self-lubricating property. The material composition allows for the retention and distribution of lubrication throughout the bearing’s surface, reducing friction and wear.

High Load Capacity: Bronze glidlager exhibit excellent load-bearing capabilities, making them suitable for heavy-duty applications. The bronze alloy’s inherent strength, combined with the lubricating properties, enables these bearings to withstand high loads and provide stable performance.

Low Maintenance: Due to their self-lubricating nature, bronze glidlager require minimal maintenance compared to other bearing types. The self-lubrication reduces the need for external lubrication systems or frequent re-lubrication, resulting in cost savings and increased operational efficiency.

Resistance to Corrosion and Wear: Bronze glidlager exhibit commendable resistance to corrosion and wear, making them suitable for applications in harsh or corrosive environments. The bronze alloy’s inherent durability and lubricating properties protect the bearing surface, ensuring extended operational life.

Bearring Bushing

Applications of Bronze Glidlager

Bronze glidlager find extensive applications across numerous industries, including:

- Automotive Industry: These bearings are utilized in various automotive components such as engine parts, suspension systems, and gearbox assemblies, where high-load capacity and resistance to wear are crucial.

- Industrial Machinery: Bronze glidlager are commonly employed in industrial machinery, including pumps, compressors, conveyors, and machine tools. Their self-lubrication and high-load capacity make them ideal for such heavy-duty applications.

- Construction and Mining: In the construction and mining sectors, bronze glidlager are used in equipment like excavators, loaders, and crushers. These bearings withstand extreme loads and offer reliable performance in challenging conditions.

- Aerospace and Defense: Aerospace and defense applications often demand reliable and durable components. Bronze glidlager are utilized in aircraft landing gear, missile systems, and various mechanical linkages, thanks to their ability to handle high loads and adverse conditions.

Bronze Bushings CuSn8

Bronze glidlager solutions

Bronze glidlager provide an excellent solution for efficient friction management in a wide range of industrial applications. Their self-lubricating nature, high load capacity, low maintenance requirements, and resistance to corrosion and wear make them a preferred choice across industries. As technology continues to advance, bronze glidlager will likely evolve further, catering to the ever-increasing demands of the modern industrial landscape.

Tin bronze bushing

Efficient Bearings for Radial and Axial Applications

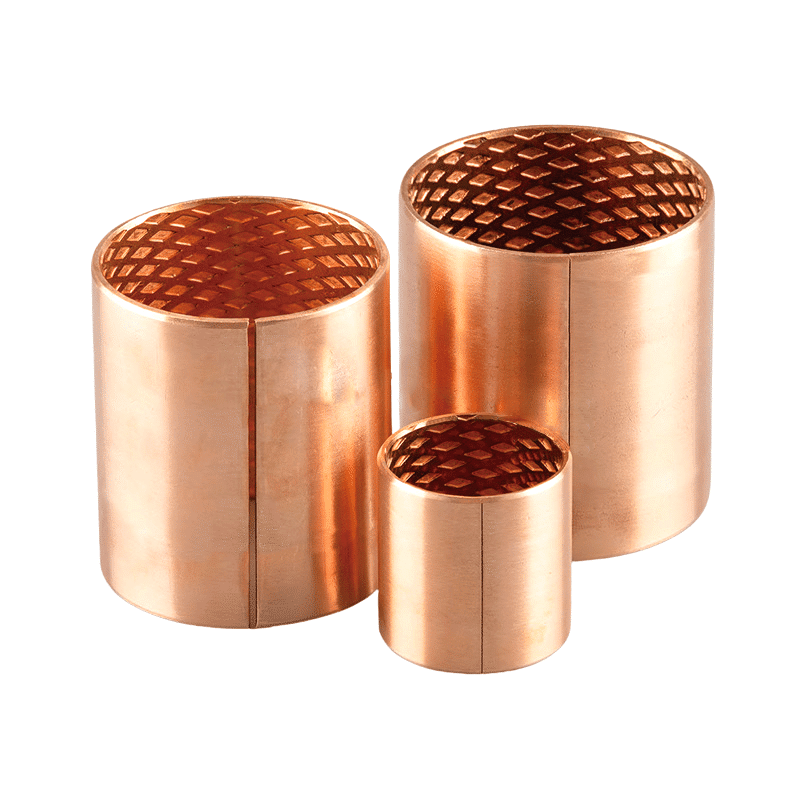

Bronze glidlager, available both with and without flanges, are designed to provide reliable performance in both radial and axial applications. These bearings are equipped with diamond-shaped lubrication indents on their bearing surface, enhancing their lubrication capabilities and ensuring smooth operation. This article delves into the features and benefits of bronze glidlager, highlighting their suitability for various mechanical systems.

CuSn8P glidlager, made from phosphor bronze, offer several advantages that contribute to their effectiveness in friction management. With superior wear resistance, low friction coefficient, self-lubricating properties, and corrosion resistance, CuSn8P glidlager are a reliable choice for various mechanical systems. Their versatile applications and durable performance make them a preferred bearing option across industries. When it comes to efficient friction management, CuSn8P glidlager are a dependable solution that ensures smooth operation and extended equipment lifespan.

Milling bronze bushes

Features of Bronze Glidlager:

Bronze glidlager possess several noteworthy features that contribute to their effectiveness in friction management:

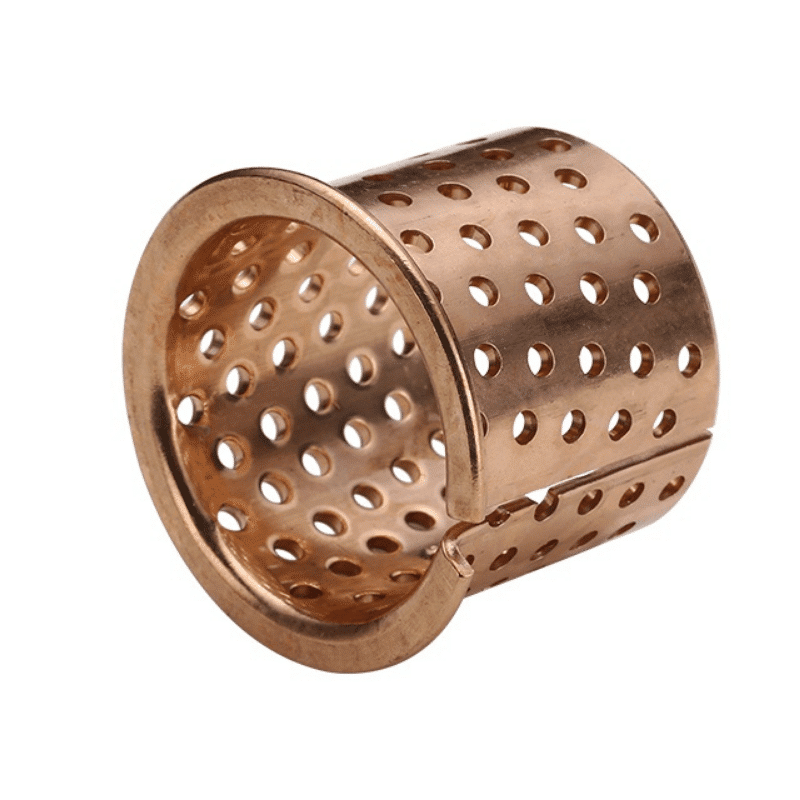

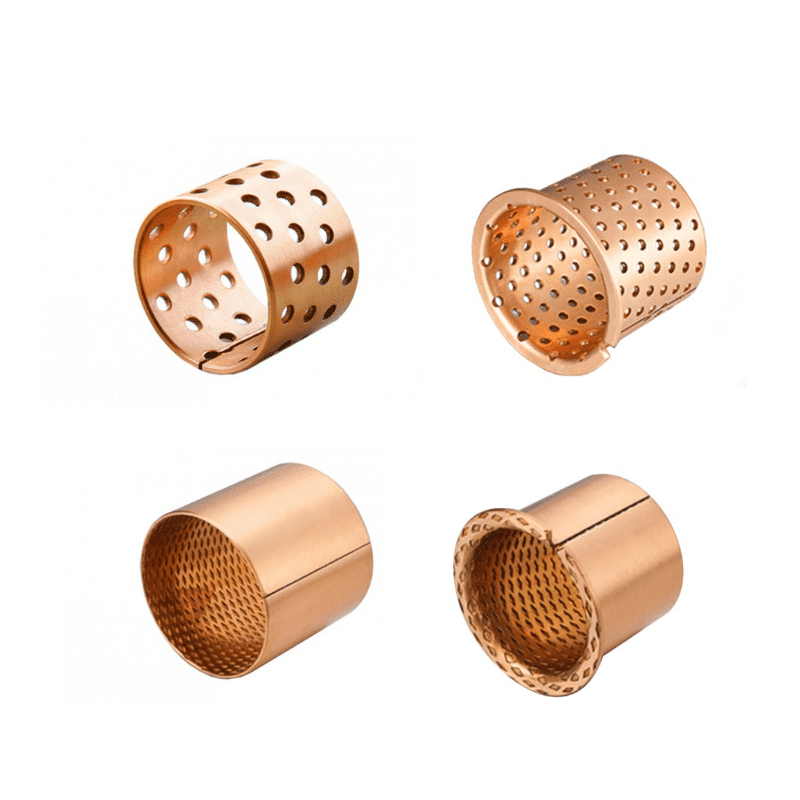

- Radial and Axial Application: These bearings are designed to handle both radial and axial loads, making them versatile for a wide range of mechanical systems. Whether the application involves rotational motion or linear movement, bronze glidlager can efficiently support the load and minimize friction.

- Flanged and Non-Flanged Options: Bronze glidlager come in both flanged and non-flanged variants. The flanged bearings have an extended rim, providing additional support and stability, while the non-flanged bearings offer simplicity and ease of installation. The choice between the two depends on the specific requirements of the application.

- Diamond-Shaped Lubrication Indents: Bronze glidlager feature diamond-shaped lubrication indents on their bearing surface. These indents serve as reservoirs for lubricants, ensuring a continuous and efficient supply of lubrication to minimize friction and wear. The lubrication indents enhance the overall performance and longevity of the bearings.

Bronze Glidlager – CuSn8 Materials & norms

Bronze glidlager, available with or without flanges, are reliable bearings designed to handle both radial and axial loads efficiently. Their diamond-shaped lubrication indents ensure optimal lubrication, reducing friction and enhancing durability. These bearings find widespread use in numerous industries, thanks to their high load capacity, self-lubrication, and versatility. Whether it’s in automotive, industrial, or construction applications, bronze glidlager play a vital role in ensuring smooth and reliable operation.

CuSn8P Composition: CuSn8P glidlager are composed primarily of copper (Cu) and tin (Sn), with phosphorus (P) added as an alloying element. This phosphor bronze alloy is renowned for its excellent mechanical properties, making it a reliable choice for bearing applications.