Delivering Reliable Container Spreader Bronze Bushing and Slide Plate Parts for General Handling Equipment in Ports

In the bustling world of port operations, reliability, safety, and productivity are paramount. At VIIPLUS, we understand the unique challenges faced by operators in the industry, and we are proud to design and manufacture top-quality container spreaders bronze bushing and bronze slide plate parts for general handling equipment.

Experience

Our particular bronze alloy is known for its strength, durability, and excellent wear resistance, making it suitable for use in various industrial applications, such as the production of heavy-duty machinery parts, bearings, bushings, and gears.

Bronze Bearing Solutions

Container lift spreaders are crucial pieces of equipment in the shipping industry. They are designed to lift and handle large containers safely and efficiently. A key component in these spreaders is the bronze bushing.

24/7 Support

A bronze bushing, also known as a bronze bearing, is a type of bearing that’s made of bronze, a durable and wear-resistant material. These bearings are designed to reduce friction and wear between mechanical parts, contributing to smoother operation and extended equipment lifespan.

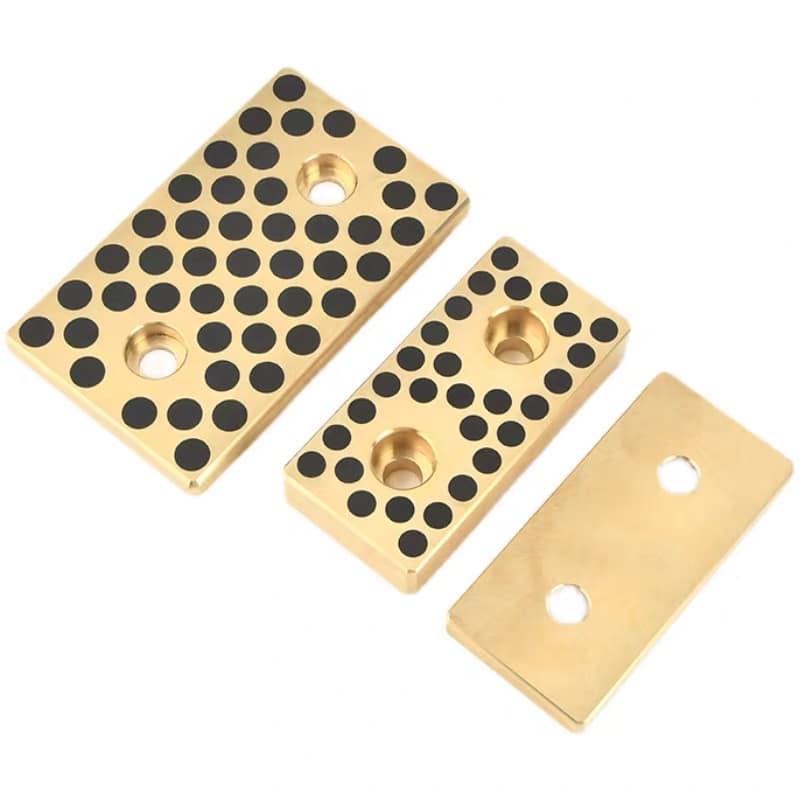

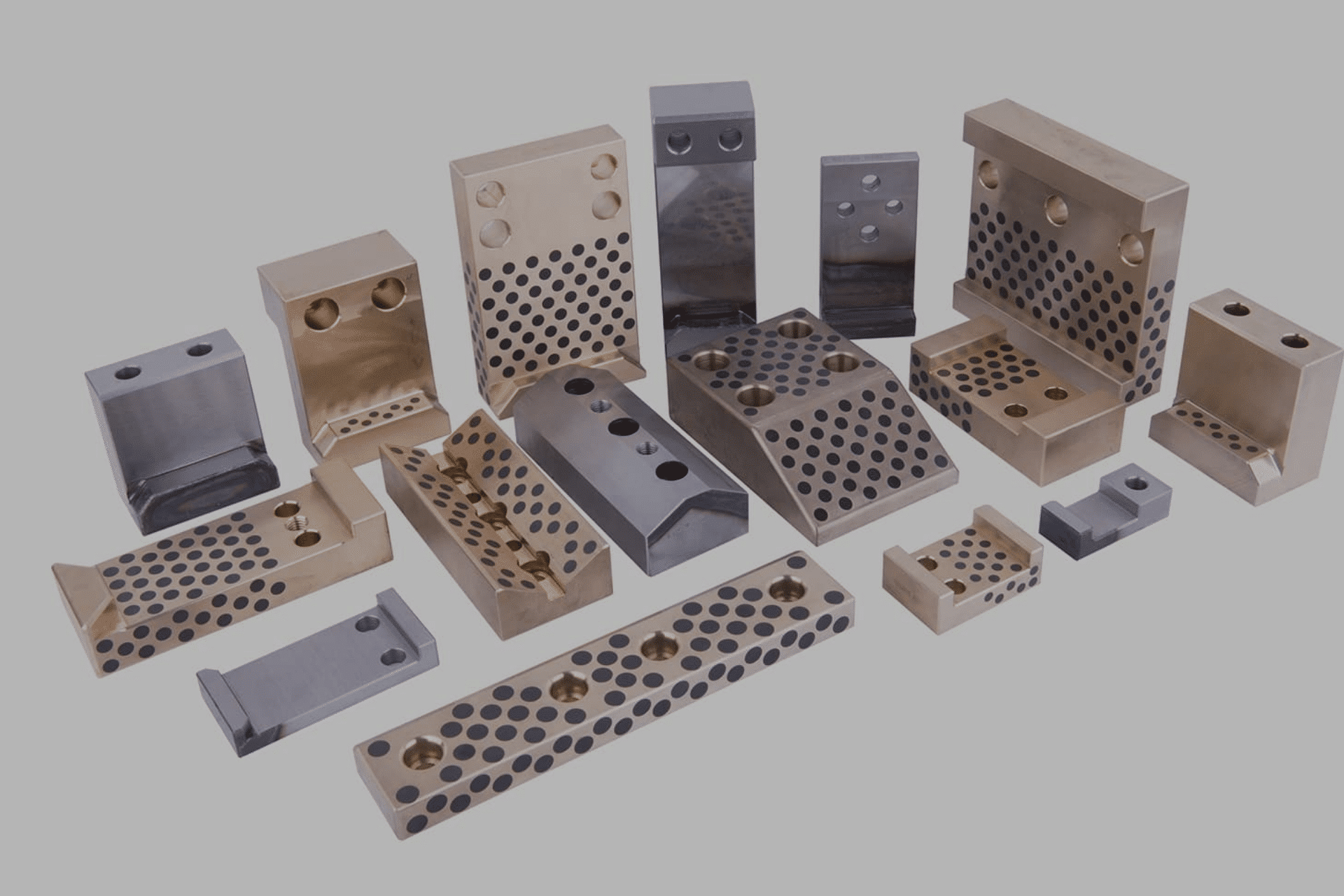

Spreader bronze bushing parts & slide plate accessories

Our Commitment to Reliability: When it comes to container handling, the durability and dependability of equipment play a vital role in maintaining smooth operations. That’s why our spreaders bronze bearing parts are engineered to deliver exceptional reliability. We use high-quality materials and employ advanced manufacturing techniques to ensure that our bronze bushings and slide plate parts can withstand the rigorous demands of port environments.

Fast and Effective Bronze Bushings/Bearings & Slide Plates

At VIIPLUS, we believe that providing excellent customer service is as important as delivering superior products. We offer fast and effective after-sales support to ensure that our clients receive the assistance they need whenever they encounter any issues. Our dedicated support team is always ready to provide expert guidance, troubleshooting, and timely solutions to minimize downtime and keep operations running smoothly. Container spreaders are crucial pieces of equipment in port logistics, handling large and heavy shipping containers with precision and ease. They come in several designs, including semi-automatic, fully automatic, and manual spreaders, and can be used with cranes, reach stackers, and straddle carriers. Heavy-duty container spreaders are designed to handle particularly heavy or frequent loads and are built for durability and reliability under the tough conditions typically found at shipping ports.

Bronze Bushings/Bearings: These are critical components for ensuring smooth operation of moving parts in the spreader. As discussed before, these can be made from various types of bronze alloys, including self-lubricating varieties.

Slide Plates: These components help facilitate smooth movement of other parts of the spreader. They can be made from materials like C93200 bronze for durability and wear resistance. Each of these parts and accessories plays a critical role in the operation of a container spreader, and it’s important to ensure that they’re well-maintained and replaced as necessary to keep the spreader operating effectively and safely.

Bearing Bushing & slide plate for Container Spreader

Slide Plates, Customization for Terminal-Specific Requirements

Every port terminal has its unique needs and circumstances. Understanding this, we offer customizable spreaders bronze sleeve bushes to cater to the specific requirements of each terminal. By collaborating closely with our clients, we gather valuable insights and develop tailored solutions that address their challenges effectively. This personalized approach allows us to optimize the performance and longevity of our bronze self-lubricating bearing parts for spreaders, resulting in enhanced safety, reliability, and productivity.

container spreader self-lubricating flange bearing

Unparalleled Safety and Performance:

Safety is of utmost importance in port operations. With VIIPLUS’s customized bronze self-lubricating bearing parts, operators can significantly enhance safety measures. Our carefully engineered bronze sleeve bushes for spreaders minimize friction and wear, reducing the risk of equipment failure and accidents. By employing self-lubricating properties, our bearing parts reduce the need for constant maintenance and ensure smooth and reliable operations. These advantages translate into increased safety for personnel, cargo, and the overall port environment.

Bronze bushings or bearings are vital components in many types of machinery, including container spreaders, where they help ensure the smooth operation of moving parts. They are often chosen for their durability, resistance to wear, and ability to withstand high loads.

Headquartered in China, Global Reach:

Container spreader bronze bearing bushing

VIIPLUS is proud to have our headquarters in China, a country that has emerged as a global leader in manufacturing and international trade. From this strategic location, we cater to clients worldwide, delivering our high-quality spreaders bronze bushing and slide plate parts to ports and terminals across the globe. Our commitment to excellence, coupled with our extensive network and logistical capabilities, enables us to provide efficient and reliable solutions to our valued customers, no matter where they are located.

Improving your container handling business

Design and manufacturing of container spreaders bronze bushing and slide plate parts

VIIPLUS is a trusted name in the design and manufacturing of container spreaders bronze bushing and slide plate parts for general handling equipment in ports. Our highly reliable bearing parts, coupled with fast and effective after-sales support, ensure that operators can achieve optimal safety, reliability, and productivity. With our commitment to customization and a global presence, VIIPLUS is your ideal partner for meeting the unique challenges of the port industry.

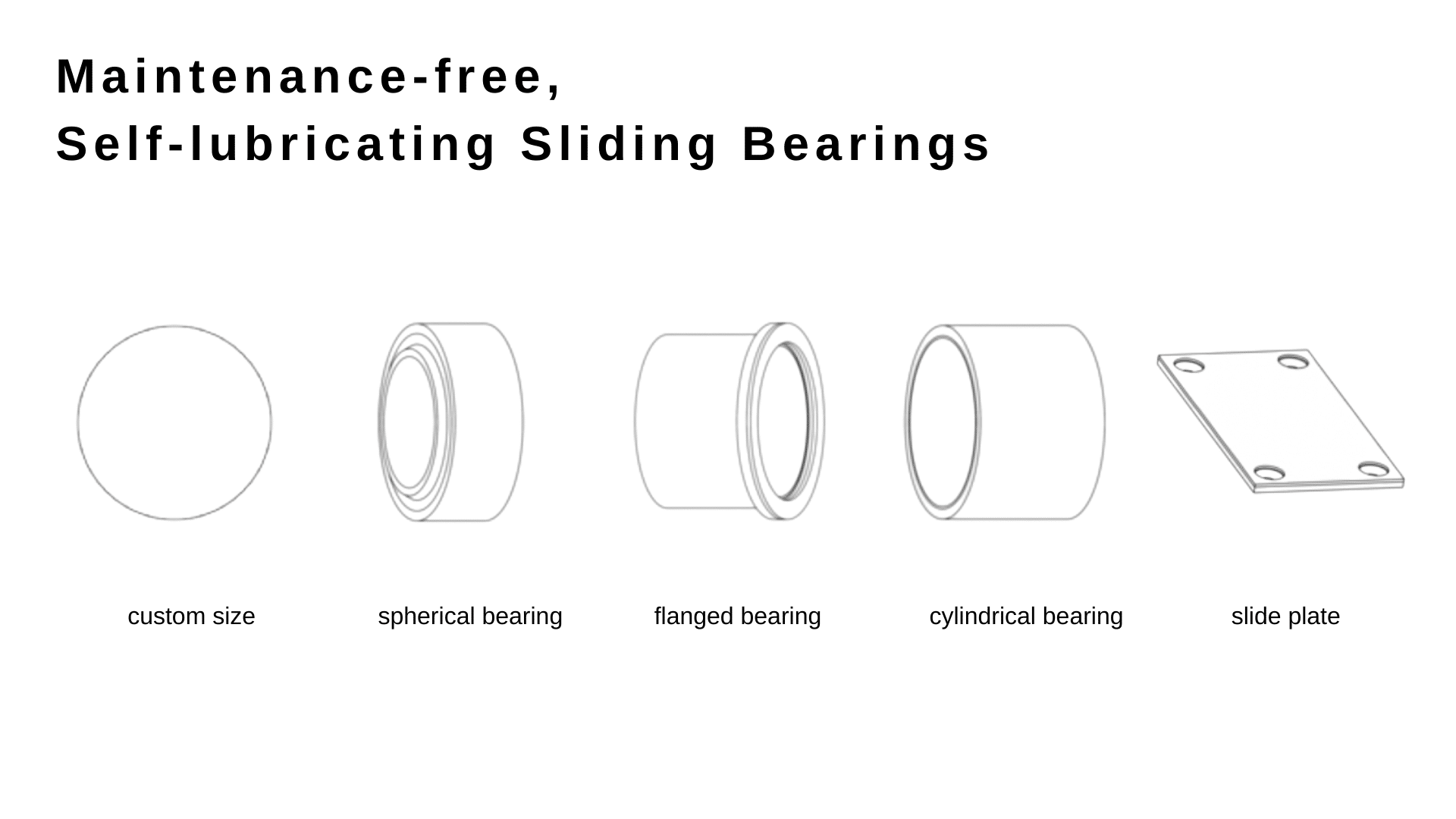

Self-lubricating bronze bearings

Container spreaders are critical pieces of equipment in the logistics and shipping industry, used for lifting and moving containers. These machines require various parts to function optimally, and one such component is the self-lubricating bronze bearing.

Self-lubricating bronze bearings, sometimes called bronze bushings, are preferred in heavy load applications such as container spreaders because they have excellent load carrying capacities. The bronze material itself is known for its good friction and wear properties. Moreover, self-lubricating bearings are designed to reduce the need for frequent lubrication, which can significantly decrease maintenance requirements and improve the durability of the machinery.

These bearings typically work by having lubricant within the bearing material itself. This can be through impregnation in a porous bronze material or through small grooves or indents in the bearing surface that contain the lubricant. When the bearing is in operation, the heat and friction cause the lubricant to seep out onto the bearing surface, reducing friction and wear.

This technology allows container spreaders and general handling equipment to operate efficiently in various conditions, including high-load and high-speed applications. It also helps reduce the operational cost since it minimizes downtime due to maintenance.

Moreover, self-lubricating bronze bearings are also resistant to corrosion, which makes them suitable for use in harsh environments often encountered in the shipping industry.

Here’s a further explanation of their purpose and composition:

Purpose: Bushings, also known as plain bearings, are used to reduce friction between rotating parts in a machine. They are placed around a rotating shaft, and the load is distributed over the bushing surface. This helps to prevent wear on the actual machine components and leads to smoother operation.

Material: Bronze is a common material choice for bushings because of its excellent wear resistance and ability to handle high loads. It also has good corrosion resistance, which is important for machines like container spreaders that may be exposed to harsh environmental conditions.

Varieties: There are various types of bronze alloys used to make bushings. Some of the commonly used bronze alloys include C93200 bronze, CuZn25Al5Mn3Fe3, and CuAl10Fe5Ni5. The choice of bronze alloy depends on the specific requirements of the application.

Self-lubricating Bushings: One particular type of bushing that’s often used in heavy-duty applications is the self-lubricating bronze bushing. These bushings have lubricant stored within them, which is released during operation to reduce friction. Self-lubricating bushings can reduce maintenance requirements and extend the lifespan of the machinery.

By using bronze bushings in container spreaders, these machines can operate more efficiently, with less wear on their components. This ultimately leads to longer machine life and less downtime for maintenance.

Aluminum bronze slide plate

Slide plates are critical components in many types of machinery, including container spreaders, where they facilitate the smooth movement of different parts. Here’s more detail on their role and the materials used to make them:

- Function: Slide plates work as a bearing surface to support movement within a system. They are often found in applications where there are sliding or rotating movements between parts. They help reduce friction, preventing wear and tear on the machinery, and ensure a smooth operation.

- Material: Slide plates can be made from a variety of materials, depending on the requirements of the machinery. A common material for heavy-duty applications is bronze, specifically alloys such as CuAl10Fe5Ni5, an aluminum bronze.

- Aluminum Bronze: CuAl10Fe5Ni5 is a type of aluminum bronze known for its high strength, excellent wear and corrosion resistance, and good load-bearing capabilities. This makes it a suitable material for slide plates in heavy-duty machinery like container spreaders. The presence of aluminum and nickel in the alloy enhances its mechanical properties, making it more durable and resistant to wear.

By using slide plates made from aluminum bronze in container spreaders, these machines can handle heavier loads, operate more smoothly, and last longer, even under harsh operating conditions. The use of such high-quality materials can lead to lower maintenance costs and longer periods between necessary replacements.

Flange bronze bearing, self-lubricating solid lubricating for container spreaders

A flanged bearing, often known as a flange mount or flange bearing, is a type of bearing that is mounted within a cast iron flange and secured in place with bolts. These bearings are used in various machinery, including handling equipment at ports, to allow rotation between parts.

The material you mentioned, CuZn25Al5Mn3Fe3, is a type of high-strength brass (a type of bronze) alloy known for its excellent wear resistance and strength. This makes it a suitable choice for components such as flanged bearings, which need to withstand high loads, friction, and wear.

Bronze bushings in container lift spreaders are particularly important because these machines handle heavy loads and are often used in harsh environments. The bushings help to support these loads and allow for smooth and controlled movement of the spreader’s moving parts.

The bronze material used in these bushings provides excellent load-bearing properties, good resistance to impact and wear, and a high degree of corrosion resistance. All of these characteristics make bronze bushings an ideal choice for demanding applications such as container lift spreaders.

The use of self-lubricating bronze bushings can further enhance the performance and durability of these spreaders by reducing the need for regular maintenance and lubrication.

Customizing slide plates for handling equipment at ports.

Customizing bronze flanged bearings and slide plates, using specific types of bronze alloys, for use in general handling equipment at ports.

Slide plates are components used in machinery to facilitate smooth linear motion. The material you mentioned for the slide plates, CuAl10Fe5Ni5, is a type of aluminum bronze. This alloy has high strength and excellent resistance to wear, corrosion, and shock, making it ideal for slide plates in port handling equipment.

A bronze slide plate made from CuAl10Fe5Ni5 would be extremely durable and resistant to wear and corrosion, making it suitable for heavy-duty applications such as those found in port handling and shipping equipment. The slide plates would facilitate smooth linear motion in such machinery, improving their efficiency and longevity.

A C93200 Bronze Groove Slide Plate refers to a slide plate made from this specific bronze alloy. The “groove” in the name implies that the slide plate has one or more grooves on its surface, typically to accommodate lubricant or to guide motion.

Slide plates are important components in various mechanical systems where smooth and controlled motion is required. They’re typically used in heavy-duty machinery and equipment, like those found in shipping, manufacturing, and construction industries.

When made from C93200 bronze, these slide plates will have high load-bearing capabilities, excellent wear resistance, and a long service life, even under harsh working conditions. This makes them ideal for demanding applications where durability and reliability are critical.

Using these specific bronze materials for flanged bearings and slide plates could offer improved durability, less maintenance, and better overall performance for the general handling equipment used at ports.