Self-Lubricating Shaft Bushing Bearing Manufacturer

Request a custom shaft bushing bearing prototype!

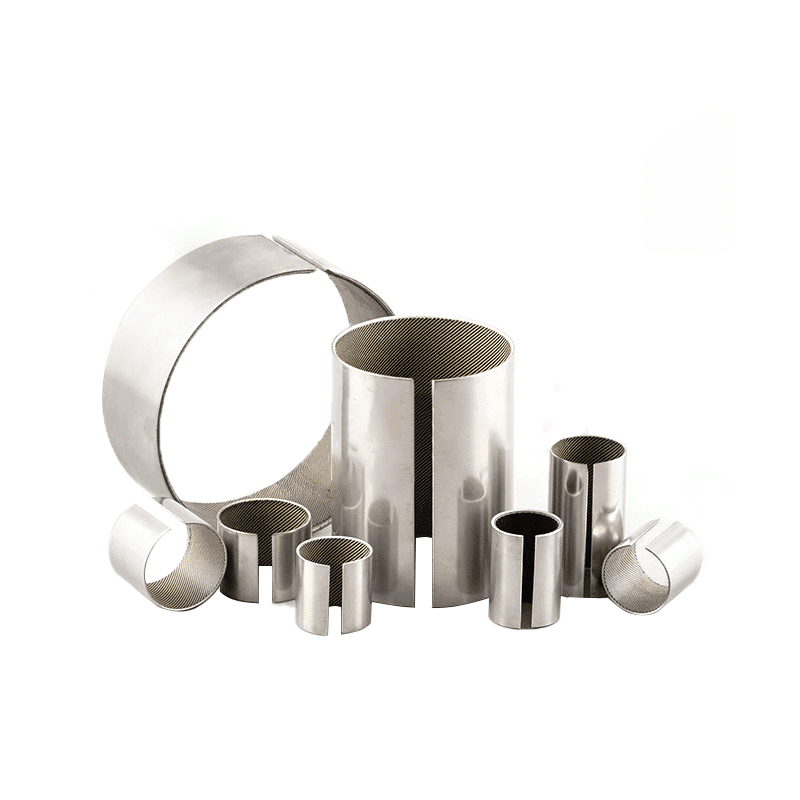

Custom Bearings Crafted from High-Strength Composite Materials for Shaft Bushings At bronzelube.com, the production process commences immediately upon receipt of your order, ensuring swift delivery of your final bearing bushing product! Self-lubricating bushings are adept at managing frequent start-ups and shut-downs, all the while delivering efficient performance with minimal wear and friction. Shop Plain & Self-Lubricating Shaft Bushings at bronzelube.com. We offers FREE CAD download, short lead times and competitive pricing.

Sliding Bushings: Shaft Materials – Bronzelube.com

Manufacturer of Self-Lubricating Shaft Bushings and Bearings

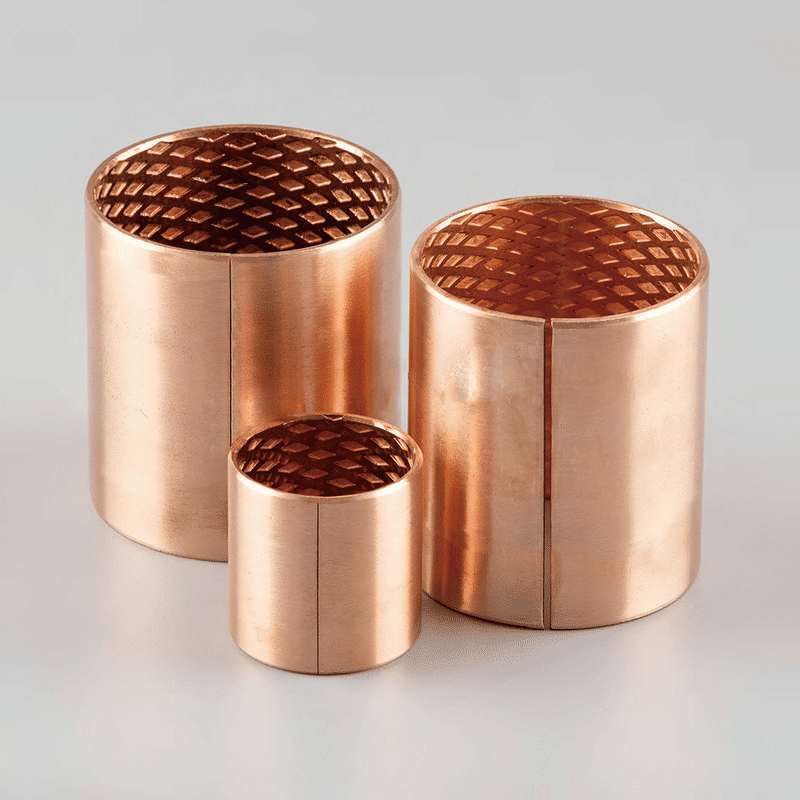

Viiplus is a recognized manufacturer specializing in self-lubricating bushings and bearings. Our extensive product line includes self-lubricating bearings crafted from a variety of materials such as plastics, metals, bronze/brass, and graphite-plugged bronze. These bearings cater to diverse industries including motion systems, aerospace, 3D printing, and hydraulic systems. We offer customizable solutions with low minimum order quantities to meet specific client requirements.

Understanding the Distinction: Bushings vs. Bearings

While all bushings are a type of bearing, not all bearings are bushings. Bearings serve as mechanical components facilitating movement between two parts while minimizing friction. They manifest in various forms like radial bearings, thrust bearings, and linear bearings, tailored to different types of movement requirements.

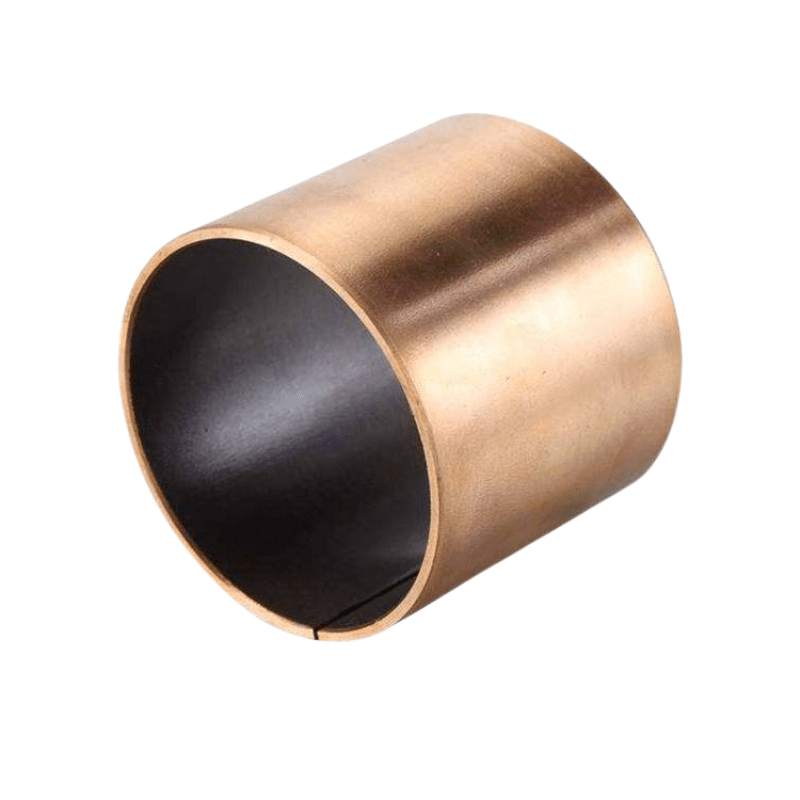

Bushings, also known as sleeve bearings or journal bearings, represent a specific bearing design primarily used in applications involving rotating or sliding parts. Simple in design, they comprise a cylindrical shape fitting around a shaft and can be fashioned from diverse materials such as metal and plastic, chosen according to the application’s demands.

Insight into Shaft Bushings

Shaft bushings are components fitting onto shafts to diminish friction between the shaft and the parts that rotate or slide along it. Available in various materials and styles like oil-embedded sleeve bearings or dry-running sleeve bearings, they play an indispensable role in myriad machinery types, spanning industrial and household applications.

Exploring Self-Lubricating Shaft Bearings

Self-lubricating bearings are engineered to function without external lubrication, housing lubricant within their structure to provide a low-friction surface. This design minimizes maintenance needs and replacement frequency, making them ideal for harsh environments where traditional lubrication methods are impractical. Crafted from solid film lubricants, fluoropolymers, or composite materials, these bearings offer resilience in challenging conditions.

At Viiplus, we specialize in manufacturing self-lubricating bearings tailored for diverse industrial applications. Bushings, a subset of bearings, are specifically designed for applications involving rotating or sliding motion. Shaft bushings play a crucial role in reducing friction on shafts across various machinery types. Self-lubricating bearings offer a maintenance-free solution, particularly suited for inaccessible or harsh environments.

Curabitur non nulla sit amet nisl tempus.

Sliding Bushings: Understanding Shaft Bushing Materials – Bronzelube.com

Sliding Bushings: Understanding Shaft Bushing Materials – Bronzelube.com, Choose from our selection of self-lubricating bushings, including sleeve shaft bushing bearings, flanged sleeve bearings, and more. In stock and ready to ship.

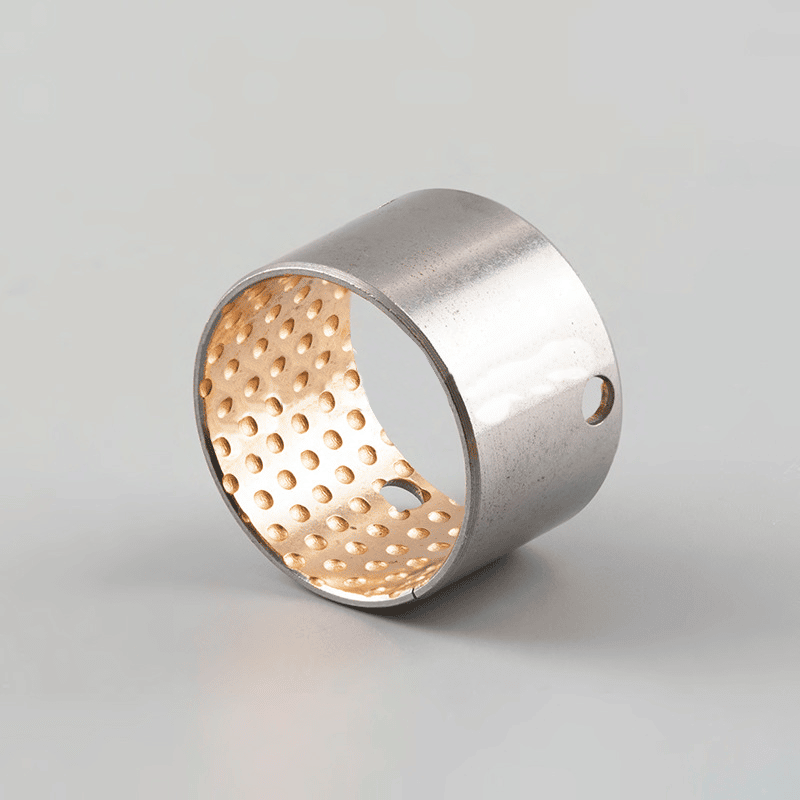

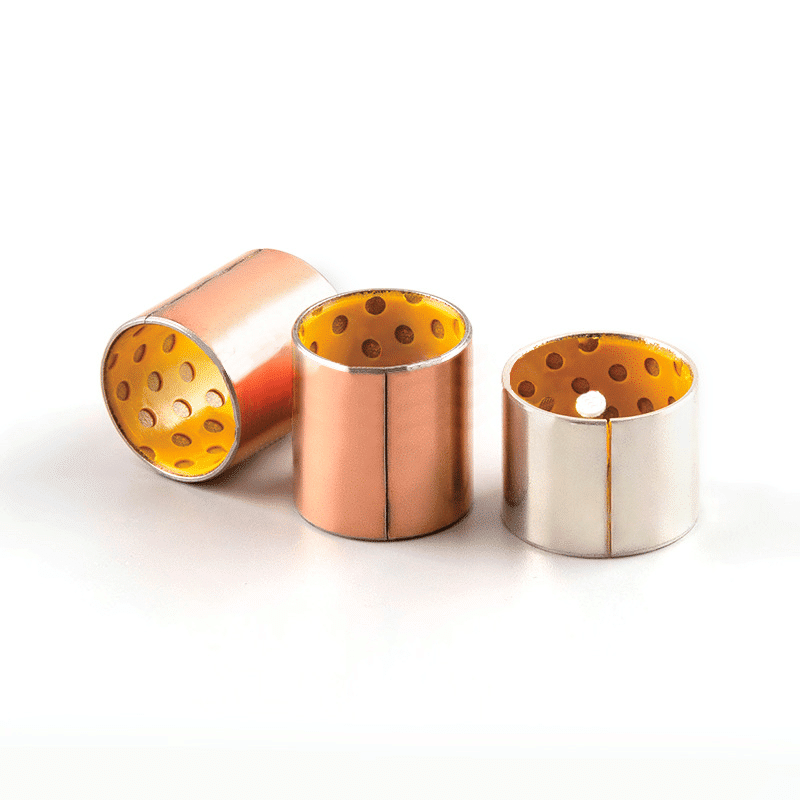

The Structure and Material of the Shaft Shank

The shaft shank stands as a pivotal element in a plain bearing, directly influencing the bearing’s performance due to its direct contact with the journal. Proper material selection and structural integrity are crucial factors. Typically, a layer of bearing alloy is cast or rolled onto the base body surface of the shaft tile, forming what is known as the bearing lining. This bearing lining directly interacts with the journal, while the shaft tile provides support. Utilizing a bearing lining on the shaft tile not only conserves precious bearing alloy but also bolsters the mechanical strength of the shaft tile. The bearing tile within the bearing body should be securely fixed, offer good lubrication, facilitate easy heat dissipation, possess adequate strength and rigidity, and be simple to install, remove, and adjust.

Shaft Tile Types and Structures

Shaft tiles come in various types and structures, including integral, open type, and thin-walled varieties. Integral shaft tiles, also referred to as shaft sleeves, are commonly used. Open shaft tiles can be thick or thin-walled, with thick shaft tiles featuring a thicker wall, typically produced through casting methods. The thickness of the bearing lining varies depending on the diameter, with larger diameters requiring thicker linings for enhanced adhesion to the bearing housing. Thin-walled shaft tiles, on the other hand, boast thinner walls and are often made using bimetal plates or innovative continuous rolling processes. While thin-walled shaft tiles offer cost-effective solutions with stable quality, they necessitate precision machining for assembly due to their reduced rigidity.

Shaft Shim Positioning

To prevent axial movement of the shaft within the bearing seat along the circumference and axial direction, thick shaft tiles can be pinned, while thin shaft tiles may utilize lugs for positioning.

Shaft and Bearing Seat Fit

Achieving optimal stiffness and heat dissipation performance necessitates a close fit between the shaft and the bearing seat. Typically, a small amount of interference fit is employed to ensure a snug fit.

Wear Resistance of Shaft Bushings – Bronzelube.com

The wear resistance of self-lubricating shaft bushings can vary significantly depending on the material pairing, with factors such as loads and surface speeds playing crucial roles.

Bronzelube.com: Advancing Responsible Bushing Manufacturing

Bronzelube.com is a recognized manufacturer of high-performance, self-lubricating bronze bearings and pre-lubricated bushings. With production facilities in CN, the company serves global customers across diverse industries including automotive, fluid power, agriculture, construction, sports, recreation, renewable energy, primary metals, and general industrial sectors. Offering a wide range of products such as metal-polymer bushes, solid bronze bushings, bimetal and metal bearings, and plates, Bronzelube.com is committed to delivering industry-recognized R&D, testing capabilities, flexible manufacturing, and superior technical support. Stay informed and explore more about shaft bushing sleeve information at Bronzelube.com.

Custom Bearings Crafted from High-Strength Composites

Material Considerations for Shaft Bearing Bushings:

The Material of the Shaft:

Beyond the plain bearing itself, the shaft stands as a critical parameter within the bearing system, directly interfacing with the bearing and experiencing relative motion akin to the bearing. Regardless of circumstances, the shaft undergoes wear. However, contemporary bearing systems are engineered to minimize shaft wear to an extent undetectable by conventional measurement methods. Shafts can be categorized based on their hardness and surface finish.

Material Selection for Shaft Shingles:

The material requirements for shaft shingles, including bearing surfaces, are dictated by the failure modes of the bearing. Primarily, bearing failures manifest as wear and adhesion (commonly termed as “burning tile”). Adhesive damage arises from the direct metal-to-metal contact due to oil film rupture, recognized to localized welding under high temperatures and pressures followed by separation. Other forms of damage include fatigue spalling, abrasion, and corrosion.

In essence, the material properties required for shaft or bearing surface materials encompass the following aspects:

Sufficient fatigue strength to resist cracking and spalling under variable loads, along with ample compressive strength to prevent excessive plastic deformation.

Effective resistance to adhesion to avert burning tiles. Good adaptability, necessitating the bearing material to facilitate smooth running to mitigate surface irregularities and shaft deflections promptly.

Enhanced embeddability to bury contaminants within the lubricating oil, mitigating adhesion or abrasions on the journal.

Superior friction reduction and wear resistance, ensuring a low coefficient of friction for the bearing material while minimizing shaft wear.

Adequate thermal conductivity for efficient dissipation of frictional heat, preventing excessive temperature elevation and adhesion.

Additionally, corrosion resistance, manufacturing precision, compatibility between the bearing housing and the shingle material, and affinity with the lubricant are additional performance factors pertinent to bearing materials.

It’s crucial to acknowledge that some of these requirements may be conflicting, making it challenging to find a single bearing material that meets all criteria. Moreover, not all bearings necessitate every aforementioned property. Thus, it’s imperative to define reasonable requirements based on specific circumstances and operational demands.

01

Engineering Shaft Bushing

Engineers and manufactures shaft bushing bearings and sleeve bushing products that help global industries operate more efficiently.