Welcome to brass bush manufacturer: www.bronzelube.com, Brass Bushings Solutions for Your Requirements

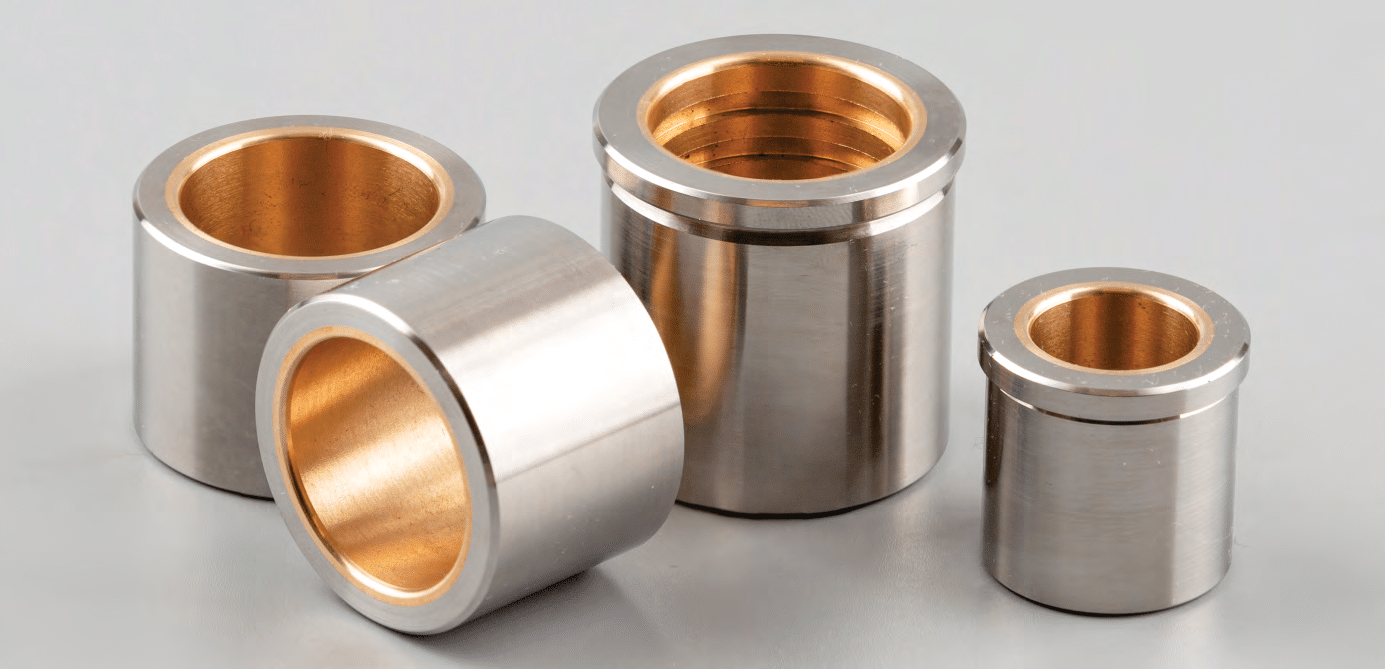

Brass Bushings Crafted by Expert Manufacturers: Your Global Source for Customized, Superior Quality Products

At the forefront of brass bushing manufacturing, we stand as a premier manufacturer, exporter, and supplier, serving clients globally. Our commitment is rooted in producing brass bushings that not only adhere to stringent industry standards but also excel in meeting the unique requirements of our diverse clientele.

We specialize in manufacturing self-lubricating bushings with variety specification & dimensions. A trusted bushing & bearing supplier in China have many years experience. Learn more about brass bush Manufacturer.

Brass Bushing manufacturers – Long-term Wear Resistance

Brass Bush Manufacturer- One-Stop Sourcing Solution, custom brass bushings

OEM Manufacturing. CNC Machining, Injection Molding, Casting, Stamping, Fabrication & More. Product component manufacturing service based on high end machining & precision.. As a manufacturer, we produce brass dimensions. Extensive Know-How. Short Periods Of Delivery. Cost-Effective Prices. Small Minimum Quantities. Highlights: Brochures Available, Offering Cost-Effective Prices. Explore the catalog brass bushings, bronze bushes and bearings of all types. Discover the wide range and fill out the form: you can also request a free quote.

Premium Brass Bushings – Custom Solutions Available, Improvisation in Brass Bushings with Changing Technology

Elevate your machinery with our high-quality brass bushings. Perfect for any application. Custom sizes & designs. Order now! Providing High Quality Self-lubricating Brass Bushings & Bearings services, experience is your right supplier for oilless bushings. Bearing, Bush, and Washers: Specializing in Graphite Filled Bronze Bushes and Flange Brass Bush Manufacturing.

Self-lubricating bearings manufacturer

Custom Bushings & Bearings – Manufacturers Of Brass Parts

Custom Bushings, Brass bush manufacturer is proud to serve a broad range of customers nationwide in some of the more exacting and demanding bushings markets. we’ve developed an extensive range of products to cater to a diverse array of applications. Our comprehensive Cast Bushings Series showcases a variety of options, including Metric and Imperial sizes, available in both plain and flanged designs, as well as washers. This versatility ensures that no matter your specific need, we have a high-quality solution ready for you. Our expertise in creating graphite filled bronze bushes and flange brass bushes sets us apart, providing exceptional performance and durability for any application.

High Performance Brass Bush Manufacturing Capabilities Get The Best In Brass Bushings. Exceptional Quality At Great Prices. Bulk Orders Welcome. Reach Out For A Bespoke Quote! High-Quality Brass Bushes – Competitive Prices. We Build Inspiring Brass Bush Products For Our Customers.

Self-lubricating bushings for longer life.

Custom Brass Components Bush Manufacturer – Brass Material

Brass bushings, cylindrical elements crafted from a blend of copper and zinc, serve the primary purpose of minimizing friction between two interacting surfaces. These components play a crucial role in supporting shafts and enhancing the durability and resistance to wear and tear of mechanical parts. Their widespread application spans across multiple industries such as machinery, automotive, aerospace, construction, and marine, highlighting their versatility and importance in various industrial contexts.

Need help choosing the right brass bushing for your application? Contact our experts for advice! brass bush manufacturer offer high performance, maintenance-free solution for many applications. Free of lubricants. Resistant to corrosion. Increased durability. Reduced costs.

Self-lubricating bushings for longer life.

Steel Brass Bushing Manufacturer & OEM Parts

Bimetal Bushes Factory, Custom Bimetal Bushes OEM/ODM… bimetal bushings are composed of two metal strips, in two different materials; the first is normally in steel, the second is normally constituted by an alloy containing copper, which when coupled with the steel strip acts as an internal covering. Furthermore, some sizes also have an external lubrication hole.

Manufacturers and Suppliers of Bi – Metal Bushes,

Brass Bushes: Metric and Inch Sizes, Oilless Bush: Choose from Wrapped, Graphite, and Bronze Bush options. Type Variants: Available in Sleeve and Flange/Cylinder types. Bush Materials: Crafted from premium Steel, Bronze, and Copper. Complete Solutions for Self-Lubricating Brass Bush Projects

Customizable Brass Bushing Supplier,

Help You Complete Self-lubricating Brass Bush Projects

Are you involved in engineering projects in sectors like automation, aerospace, defense, telecommunications, medical, or others? We offer comprehensive solutions for your needs, including expert assistance in self-lubricating brass bush projects. Contact us for a free quote and let us contribute to the success of your project with our specialized expertise and high-quality products.

Quality Brass Bush Manufacturer Diversity in Brass Bushings

Brass bushings are available in an array of sizes and types, each designed to cater to specific applications. Options range from thick-walled to thin-walled, and include flanged, sintered, or cylindrical styles. Notably, some brass bushings are engineered to be self-lubricating, featuring solid lubricants integrated during the manufacturing process to diminish the necessity for external lubrication. We have many years experienced in manufacture brass bushings, such as wrapped bronze bushings, graphite plugged bushings, bronze bushing, so on.

What Is the IATF 16949 Standard?

16949 certification is TS16949 certification, ISO/TS16949:2009 is the international automotive industry technical specifications, is based on ISO9001, added to the automotive industry technical specifications.

ISO/TS16949:2002 developed by IATF under the support of ISO/TC 176 quality management and quality assurance Technical Committee. The third edition of ISO/TS16949 canceled and replaced by the second edition, is based on the ISO9001:2008 technical revision. Because ISO/TS16949:2009 has included all the content of ISO9001:2008, so ISO/TS16949:2009 certification, also marks compliance with ISO9001:2008 standard. Requirements for the auditee:

ISO/TS16949:2009 certification registration, only applicable to the automotive plant and its direct parts manufacturers. These manufacturers must be directly related to the production of automobiles, have processing and manufacturing capabilities, and through the realization of this capability to add value to the product.

ISO/ TS16949:2009 certification registration of the company must have at least 12 consecutive months of production and quality management records, including internal review and management review of the complete record.

IATF 16949 certification emphasizes the development of a process-oriented quality management system that provides for continual improvement, defect prevention, and reduction of variation and waste in the supply chain. The goal is to meet customer requirements efficiently and effectively.

16949 certification objectives:

I. Continuous improvement in the supply chain

1. Quality improvement

2. Productivity improvement

3. Cost reduction

Second, emphasize the prevention of shortcomings

1. Application of SPC

2, error prevention measures

Third, reduce variation and waste

1. Ensure inventory turnover and minimum inventory

2. Quality cost

3. Additional cost of non-quality

Sliding Bushing Solution and Bearing Resources

The most basic structure of sliding bearing is divided into bearing bush and journal.

Learn how sliding bearings are used in high speed, high precision, heavy load, and there are low speed impact machines.

High Quality Sliding Bushing With Competitive Price

Self-lubricating, Maintenance Free

High load capacity sliding bearings

Welcome to bronzelube.com

- Simple structure, Convenient manufacturing, processing and disassembly.

- Good impact resistance and good vibration absorption performance, smooth operation, high rotation accuracy.

Reliable & safe sliding bushings solution

Provider of individual solutions for sliding bearings & bushings.

Rolling Bushings VS Sliding Bearings

Rolling bearings are more widely used

According to the friction properties of different bearings can be divided into rolling (friction) bearings and sliding (friction) bearings, it is obvious that rolling bearings must be smaller than sliding bearings friction resistance, fast starting, high efficiency, this is the advantages of rolling bearings.

Compared with sliding bearings, rolling bearings have larger radial size, poor vibration reduction ability, low life at high speed and larger noise.That’s the downside.

Choose your correct bearings to meet your requirements

What are the differences between rolling bearings and sliding bearings?What are the advantages and disadvantages of each?

Differences between rolling bearings and plain bearings — definitions and advantages and disadvantages

Rolling bearing, refers to the friction between the shaft and the shaft seat of mechanical operation is a rolling friction bearing, but the sliding bearing is still working under sliding friction.The structure of the rolling bearing is clear, and the uniform distribution of the rolling body can effectively reduce friction. Therefore, the mechanical starting is very fast and good, and the maintenance is also simple and convenient.In addition, it is more suitable for medium speed work, high speed work noise is relatively large, and will reduce its service life.In addition, the rolling bearing works with large vibration.Comparatively speaking, the sliding bearing runs smoothly and has no noise, but the starting resistance is relatively large.

Difference between rolling bearings and plain bearings — structure

The rolling bearing is composed of an inner ring, an outer ring, a rolling body and a cage, among which the outer ring is fixed and does not act as a support;The inner ring rotates with the shaft;The rolling body is the most important, which is related to the performance and service life of the bearing.The cage is used to assist the rolling body to make it evenly distributed.Sliding bearings do not have the above structure, in which the key role is the production material of sliding bearings.

In addition, the main role of bearings is to reduce friction, among which, the size of the friction force of rolling bearings is related to the level of manufacturing technology, that is, whether it is accurate.However, the size of the friction force of sliding bearings is related to its manufacturing materials. Usually, metal sliding bearings and non-metal sliding bearings (mostly plastic) are discussed.

Although rolling bearings and sliding bearings belong to mechanical parts, their operation is not the same.In addition, in the use of machinery, but also pay attention to the daily maintenance and repair of rolling bearings and sliding bearings.

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

brass bush manufacturer

Slide bearings facilitate precise linear motion and accommodate structural expansion.

Optimal sliding bearing solution

Custom Sliding Bearing & Part Manufacturing Service to Your Exact Specification. Quote Now! The Predictable Bearings Life Offers High Planning Reliability To Help You Save On Cost.

Full range, even for hard-to-find bearing parts.

Quality design and supply of Sliding Bearings materials

The plain bearing assembly consists of structural spacers, PTFE (or other low friction material) sliding surfaces, and plain bearing plates. Plain bearing subtypes include linear ball bearings and linear rolling bearings. Plain bearings can also be called linear bearings, pilot bearings, or linear plain bearings.

They can be used in applications such as construction (bridge expansion brackets) and precision tools.

Plain bearings, also referred to as bushes, bushings or sleeve bearings, are cylindrical shaped and have no moving parts.

Plain bearings are used for sliding, rotating, oscillating or reciprocating movements. In sliding applications, they serve as plain bearings, treads and wear plates. In these applications, the sliding surfaces are generally flat, but can also be cylindrical, and the movement is always linear rather than rotary. Plain bearing construction can be solid or with a split seal (wrapped bearings) for easier installation.

Plain bearing advantages

Plain bearings are manufactured from a variety of materials including metal-polymer, recycled plastics, fiber-reinforced composites, and metals that reduce noise, increase service life, eliminate lubricants, and improve performance. The material of the plain bearing contributes to its mechanical and tribological properties.

Sliding Bearing

Experienced bearing specialist with rich knowledge and know-how

Plain bearings are bearings in which only sliding friction is generated. The shaft is usually supported on the sliding surface and the oil and air in between facilitates the sliding. Plain bearings are lightweight and have a long life, while introducing minimal vibration or noise.

We offer a portfolio of quality sliding bearings designed to improve the reliability and efficiency of plain bearing that keep bearing in motion.

The best sliding bearing solutions come only when the problem is comprehensively understood.

Sliding bearings: a complete range for all your needs

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com

Corrosion Resistance:

Custom service

These bushings boast a high resistance to corrosion, rendering them perfect for use in marine environments and other settings where rust is a concern.

Brass Material, Cost-Effectiveness

Quality materials

We specializes in self-lubricating bearings for brass materials, such as wrapped bearings, graphite & bronze bushings. Typically, brass bushings are more affordable than their bronze counterparts, providing a cost-efficient solution for many industrial uses.

Brass Bush Manufacturer & Wear Resistance

Bushing design

Common bushing designs include solid (sleeve and flanged), split, bush material grade, and bush manufacturing process. Although brass may not be as robust as bronze, it still offers commendable wear resistance, contributing to its durability and longevity in use.