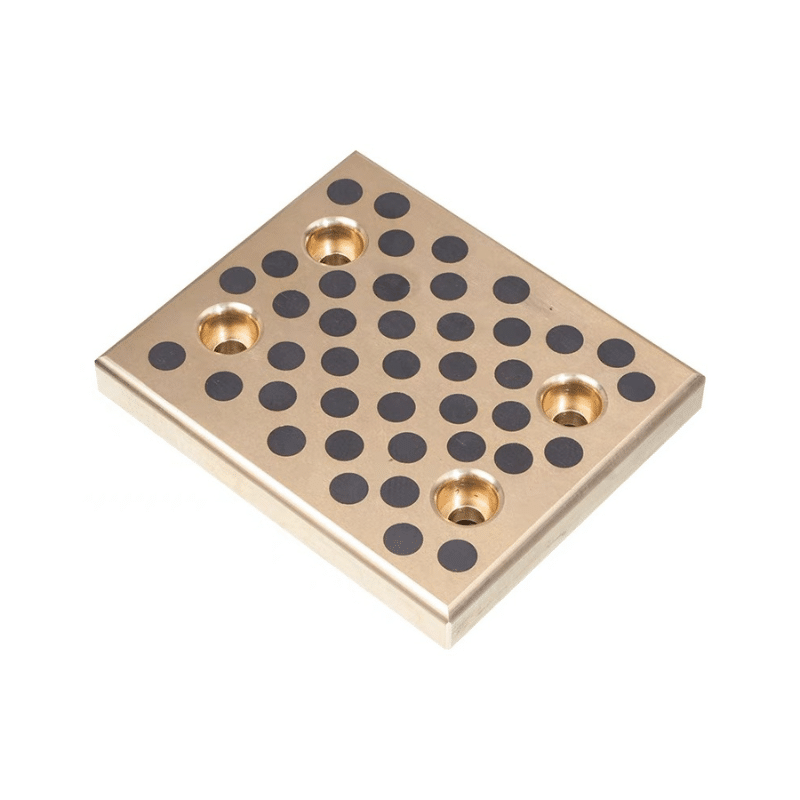

Bronze Wear Plate

Bronze Wear Plate

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Bronze Wear Plate

bronze wear plates with graphite inserts are durable, self-lubricating solutions designed to decrease wear and upkeep across a range of industrial uses. They offer customization options and are available from specialized bronze component manufacturers.

The finished machined bronze wear plates, especially those that incorporate graphite, are indispensable in industrial machinery. They bring forth benefits like durability, wear resistance, and self-lubrication, all of which are vital for the efficient and prolonged operation of the equipment.

Copper self-lubricating Plate – Plugged Graphite – Oil-free Slide Plate – Select, configure, order. We deliver punctually & offer fair prices. SLP Copper self-lubricating L-shaped rail, SWP Copper self-lubricating block.

Bronze Wear Plate self-lubricating Plate, Bronze Wear Plates – Cut To Size, Small Minimums, manufacturer wear plate and bronze bushing of Injection Machine

Bronze wear plates typically incorporate graphite as a solid lubricant, endowing them with self-lubricating properties. These plates reduce friction and wear without the need for additional lubricants, thereby enhancing machine efficiency and lifespan. Here are some key points about bronze wear plates and their graphite solid lubrication characteristics:

Self-lubricating properties: Graphite particles or plugs embedded within bronze wear plates provide continuous lubrication during operation, minimizing friction and wear.

Applications: These wear plates find extensive use across various industries including automotive, injection molding, mining, construction, chemical, marine, and energy sectors. They are particularly suitable for heavy-duty, low-speed, reciprocating or oscillating motions, and environments where lubrication is challenging.

Materials and structure: Bronze wear plates are typically crafted from high-quality copper alloys, complemented by graphite solid lubricants, forming a sturdy bronze base and self-lubricating layer.

Customization services: Manufacturers offer bronze wear plates in standard and custom sizes to meet specific application requirements.

Maintenance and operation: Due to their self-lubricating nature, bronze wear plates reduce maintenance needs and operating costs. They can operate without additional lubricants, aiding in environmental pollution reduction.

Performance advantages: Compared to traditional sliding bearings, bronze wear plates not only save energy but also typically boast longer service lives.

Environmental adaptability: Bronze wear plates can operate in extreme temperatures and exhibit resistance to water and other corrosive media.

Installation and usage: Some manufacturers recommend applying light machine oil during initial use to enhance self-lubrication. Additionally, drilling holes from the backside during installation and chamfering the sliding surface ensures effective transfer of solid lubricants.

Bronze wear plates, with their self-lubricating properties and wear resistance, have become indispensable high-performance components in industrial applications. By selecting appropriate materials, sizes, and designs, significant improvements in equipment reliability and maintenance cost reduction can be achieved.

Finished machined bronze wear plates, particularly those enhanced with graphite, play a crucial role in various industrial machines. Their primary function is to mitigate wear and tear, thereby extending the equipment’s service life and boosting efficiency. These plates are tailor-made to specific requirements and are most effective in scenarios that demand high resistance to wear and durability, such as in high-friction and heavy-load environments.

Bronze wear plates featuring graphite inserts are engineered solutions crafted to ensure a robust and self-lubricating interface in diverse industrial settings. These components are constructed from robust bronze alloys and incorporate graphite inserts or plugs, serving as an effective solid lubricant. Graphite’s role is crucial in minimizing friction and wear on the plate and its interacting surfaces, offering a significant advantage in scenarios where traditional lubrication approaches are impractical or undesired.

Advantages of Using Bronze Wear Plates with Graphite Inserts:

- Self-Lubricating: Graphite inserts facilitate ongoing lubrication, diminishing the necessity for added lubricants and routine upkeep.

- Enhanced Durability: The combination of strong bronze alloys, like aluminum bronze, with the lubricating qualities of graphite, leads to superior durability and wear resistance.

- High Load Endurance: These wear plates are designed to bear substantial loads without distorting or failing, ideal for demanding conditions.

- Operational Across Wide Temperatures: Graphite’s lubrication capabilities remain stable over a vast temperature range, enabling these plates’ use in high-temperature environments.

- Corrosion Resistant: The bronze alloys used are inherently resistant to corrosion, crucial for use in aggressive or corrosive settings.

Applications: Bronze wear plates with graphite inserts find their application across:

- Industrial machinery and tools

- Mining apparatus

- Construction equipment

- Molds that necessitate slides, cams, or flat surfaces

- Situations demanding high-load support at low speeds where traditional lubrication falls short

Material Specifications and Tailoring: The selection of the bronze alloy depends on specific application demands, with options like C954 Aluminum Bronze, C932 Bearing Bronze, and C863 Manganese Bronze being popular. Customization in terms of hole layouts, graphite configurations, and dimensions is possible to cater to specific requirements.

Availability: These wear plates are accessible in standard dimensions or can be tailor-made. They are provided by manufacturers and suppliers, with some allowing online orders, such as National Bronze Manufacturing.

Their application spectrum is broad, encompassing numerous machine parts and scenarios like liner plates in mobile machinery, fixed plant liners, chutes, screens, deflector plates, high-speed conveyor chutes, fan blades, feeder bins, abrasive media pipes, and as protective elements in buckets and skid plates. In industries like earthmoving and mining, these wear plates are pivotal for safeguarding equipment, thereby reducing the frequency of part replacements, maintenance demands, and operational downtimes.

The bronze material selected for these wear plates is recognized for its high strength and wear-resistant characteristics, capable of enduring substantial loads while maintaining long-term performance. Graphite’s incorporation into the bronze adds self-lubricating properties, further diminishing the need for regular maintenance and enhancing operational efficiency. This graphite impregnation serves a dual purpose – it fills the porosities in the raw graphite, rendering it impermeable to fluids and safeguarding it against various environmental factors.

The synergy of bronze and graphite in these wear plates offers numerous advantages. It significantly lessens friction between moving components, thereby curtailing wear and tear. Additionally, it can lower the risk of overheating and control thermal expansion, which contributes to consistent performance and reduces the chances of component failure. These wear plates find diverse applications in bearings, bushings, guideways, slides, and wear pads.

Solid Bronze Self-Lubricated Wear Plates – Plugged Graphite Plate – Select, Configure, Order. We Deliver Punctually & Offer Fair Prices. Solid bronze Self-lubricated wear plates.

C954 Graphite Impregnated Bronze Wear Plate: A High-Performance Solution for Heavy-Duty Machinery

C954 graphite impregnated bronze wear plates are a type of industrial component that is specifically designed to withstand heavy loads and harsh operating conditions. They are made of a combination of copper, tin, and aluminum, which is then impregnated with graphite to provide self-lubricating properties.

The graphite in the wear plate acts as a solid lubricant, reducing friction and wear between two moving parts without requiring external lubrication. This makes C954 wear plates an ideal solution for applications where oil lubrication is not suitable, or where frequent lubrication is not feasible.

The bronze material used in the wear plate is a high-strength and wear-resistant material that can withstand heavy loads and provide long-lasting performance. The addition of graphite to the bronze material provides self-lubrication properties, reducing maintenance requirements and improving efficiency.

C954 graphite impregnated bronze wear plates are commonly used in heavy-duty machinery, such as mining equipment, construction machinery, and industrial processing equipment. They are also used in applications where the equipment is exposed to abrasive materials or harsh environmental conditions, such as high temperatures and corrosive chemicals.

The wear plates are designed to be easy to install and replace, reducing maintenance costs and downtime for machinery. They can be easily machined or cut to size to fit specific machinery requirements, making them a customizable solution for a wide range of industrial applications.

In addition to their durability and performance, C954 graphite impregnated bronze wear plates are also an environmentally friendly solution. The elimination of external lubrication reduces the risk of oil leaks, spills, and contamination, which can harm the environment.

In conclusion, C954 graphite impregnated bronze wear plates are a high-performance and customizable solution for heavy-duty machinery lubrication. Their unique combination of bronze and graphite materials provides self-lubricating properties, reducing maintenance requirements and improving efficiency. They are easy to install and replace, making them a cost-effective solution for any industrial operation looking to improve performance and reduce maintenance costs.

Self-lubricating bearing with embedded solid lubricant.

Bronze Bushings For high load and low speed

Wear Plate, Check out the variety of configurable, Wear Plate, General Purpose Plate … Plate/Guide parts

Bronze Wear Plate – Standard Components for Press Die and Slide Components

The Bronze Wear Plate is a standard component designed for press die and slide components, offering high performance and durability in various industrial applications. The oilless wear plate design ensures smooth operation, low maintenance, and a cleaner working environment.

Outline of Oilless Wear Plate:

- Material: The wear plate is made from a high-quality bronze alloy, which provides excellent wear resistance and ensures a long service life.

- Oilless Design: The bronze wear plate features an oilless design, eliminating the need for lubrication and resulting in lower maintenance and a cleaner environment.

- L-Shape Bronze Type Slide Plate: The L-Shape design of the bronze wear plate offers greater versatility and allows for easy installation in a variety of press die and slide component configurations.

- Application: The bronze wear plate is suitable for use in press die and slide components, including stamping and forming dies, progressive dies, fine blanking dies, injection molds, and die casting molds.

- Benefits: By using a bronze wear plate, manufacturers can achieve smoother, more efficient operations, reduce maintenance costs, and improve the overall performance of their press die and slide component systems.

The Bronze Wear Plate is a high-quality, oilless component designed for press die and slide components, offering smooth operation, low maintenance, and improved performance in various industrial processes. The L-Shape Bronze Type Slide Plate allows for versatile installation and application in a wide range of systems.

Flat plates, self lubricating, manufacturer and specialize in producing finished machined bronze wear plates

Self Lube Wear Plates, Solid Bronze Wear Plate Maintenance-Free Oilless Flat Plate with Graphite Plugs, High tensile brass based / solid lubricant embedded,

General-use Type Bronze Wear Plate Thickness 20mm

SWP bronze wear plate is made with high-strength copper alloy, and the inserted solid lubricant materials are made with graphite and PTFE.

According to the bushings’ working conditions, the bronze combination between the different metal basements and various solid lubricants can ensure that the product can perform under various temperatures, loads, movements, and mediums as required.

Oilless bush is especially applied in oil-free high temperature, high load, low speed, contamination resistance, corruption resistance radiation resistance as well as the use under such special work conditions that cannot be lubricated, such as underwater and in vacuum space.

Product Name: BronzeWear Plate

Material: CuZn25Al5Mn3Fe3+Graphite

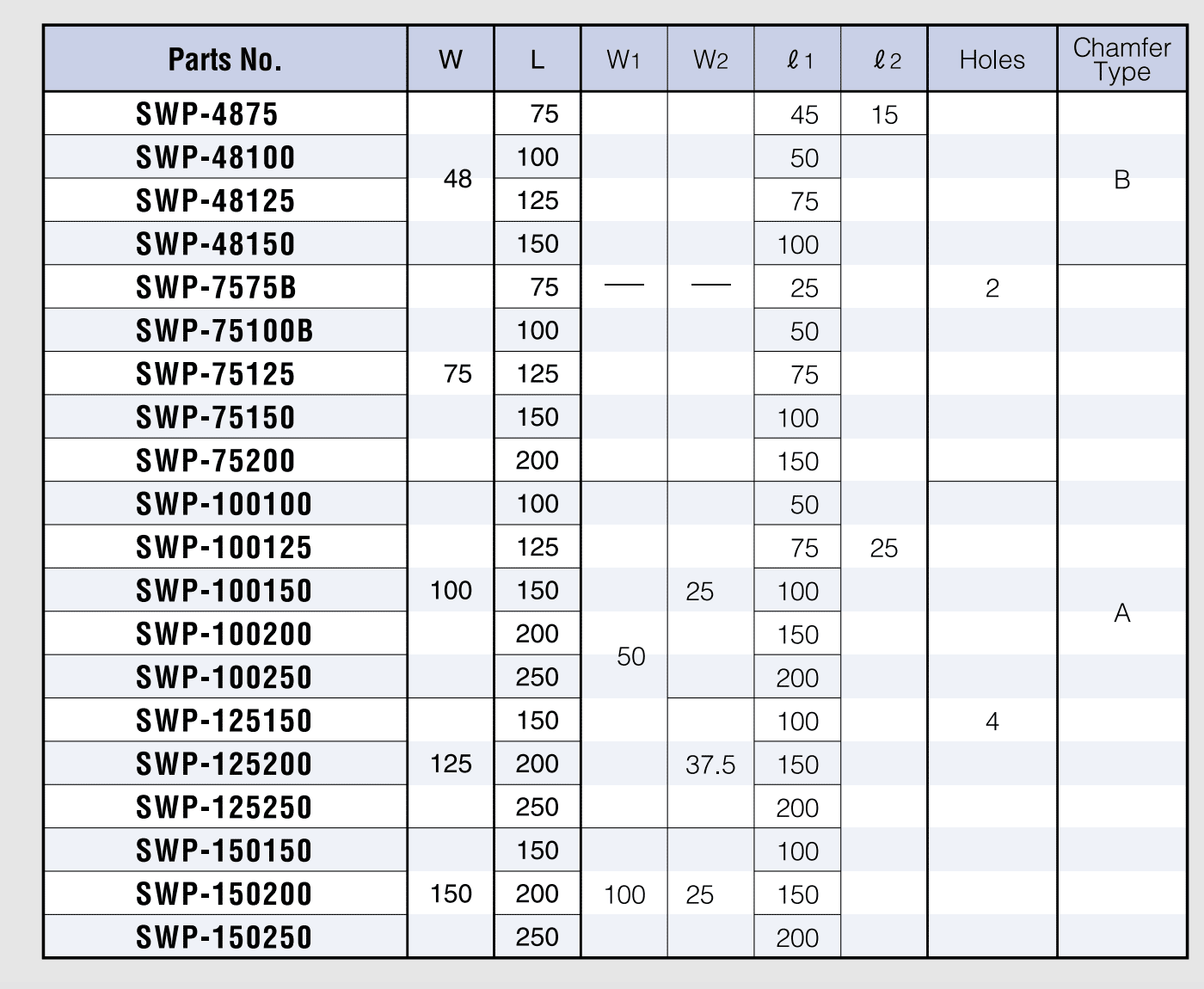

BRONZE WEAR PLATE SIZE

Greasing Can Enhance the Effectiveness of Bronze Wear Plate with Plugged Graphite

Although the bronze wear plate with plugged graphite is designed to operate without the need for additional lubrication, applying grease can further improve its effectiveness. This wear plate features a special solid lubricant embedded within the material, which ensures smooth operation and reduces friction.

Key Features of the Bronze Wear Plate with Plugged Graphite:

- Material: The wear plate is made from a high-quality bronze alloy, providing excellent wear resistance and ensuring a long service life.

- Embedded Solid Lubricant: The special solid lubricant is embedded within the wear plate, offering a self-lubricating property that reduces friction and enhances performance.

- Plugged Graphite: The plugged graphite design helps maintain a constant supply of lubricant on the wear plate’s surface, ensuring smooth operation even under demanding conditions.

- Optional Greasing: While the wear plate is designed to function without additional lubrication, applying grease can further improve its effectiveness and prolong its service life.

- Applications: The bronze wear plate with plugged graphite is suitable for use in various industrial applications, including machinery, automotive components, and other heavy-duty systems requiring smooth, low-friction operation.

The bronze wear plate with plugged graphite is a high-quality, self-lubricating component designed for use in various industrial applications. Applying grease can further enhance its effectiveness and extend its service life, ensuring optimal performance and reduced maintenance costs.

Wear plates Advantages of Slide Elements:

※ Maintenance-free, self lube bushings

※ Wear-resistant self lube plate

※ Low frictional resistance

※ Resistant against temperatures up to approx. 300℃ (approx.572oF)

※ No impurity through discharge of lubrication ※ Environmentally friendly

※ Corrosion resistant

※ Insensitive to impact stress

※ Especially suited for oscillating slide motions ※ Stick, slip-free sliding

※ Long life

Key Characteristics:

1. May work without any oil for long period.

2. Extremely high load capacity, good anti-wear, and low friction.

3. Particularly appropriate for low speed and high load.

4. Suitable single direction axial loads

5. Free design is possible on the shape and size

6. Can be used in a wide range of temperatures, from - 40℃+ 300℃

Below wear plates size, brass wear strips

Oil-Free Slide Plates:

- Copper Alloy 20mm Type – 4 Bolt Holes

- Sintered Alloy 20mm Type – 4 Bolt Holes

- Steel 20mm Type – 2 Bolt Holes / 4 Bolt Holes

- Steel 10mm Type – 2 Bolt Holes

- Steel 20mm Type – 2 Bolt Holes / 4 Bolt Holes

Shims for Oil-Free Slide Plates:

Oil-Free Slide Plates (Copper Alloy):

- 10mm Type

- 10mm High Surface Pressure Type

- L-Shape Type

- Blank Type

- 5mm Type (Thin)

- 10mm Compact Type

Oil-Free Slide Plates (Sintered Alloy):

- Blank Type

- 10mm Type – 2 Bolt Holes

- 10mm Type – 3 Bolt Holes

- 10mm Type – 4 Bolt Holes

- 20mm Type – 2 Bolt Holes

Oil-Free Slide Plates (Copper Alloy – 10mm Type):

- 2 Bolt Holes

- 4 Bolt Holes

Oil-Free Slide Plates (Cast):

- 20mm Type – 2 Bolt Holes

- 20mm Type – 3 Bolt Holes

- 20mm Type – 4 Bolt Holes

This catalog provides an overview of various oil-free slide plates, including different types, materials, and sizes. These oil-free slide plates are designed for a range of industrial applications, offering low maintenance, high performance, and a cleaner working environment.

Bronze Plated Wear Plate is designed to minimize wear and provide additional support to moving parts within a mold. Available for purchase by the inch, it can be custom cut to lengths specified by the customer, up to 48 inches. For those needing their wear plate precisely sized, we offer a straightforward form to complete for a quick and precise quote.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.